Mode II Fatigue Delamination Growth and Healing of Bis-Maleimide Modified CFRPs by Using the Melt Electro-Writing Process Technique

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of the BMI Resin

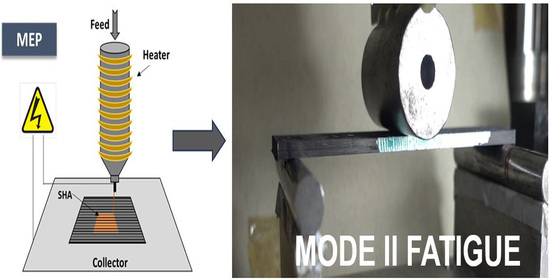

2.3. Pre-preg Modification by Melt Electro-Writing Process Technique

2.4. Composites Manufacturing and Quality Control

2.5. Mode II Quasi-Static and Mode II Fatigue Testing

2.6. Healing Process

3. Results and Discussion

3.1. Test Outline Program

3.2. Mode II Quasi-Static Tests

3.3. Delamination of CFRPs under Mode II Fatigue Loading Conditions

3.4. Repair of the Fractured CFRPS via the Healing Procedure

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- O’Brien, T.K. Towards a damage tolerance philosophy for composite materials and structures. Compos. Mater. Test. Des. ASTM Spec. Tech. Publ. 1990, 1059, 7–33. [Google Scholar]

- White, S.R.; Sottos, N.R.; Geubelle, P.H.; Moore, J.S.; Kessler, M.R.; Sriram, S.R.; Brown, E.N.; Viswanathan, S. Autonomic healing of polymer composites. Nature 2001, 409, 794–797. [Google Scholar] [CrossRef]

- Kostopoulos, V.; Kotrotsos, A.; Geitona, A.; Tsantzalis, S. Low velocity impact response and post impact assessment of carbon fibre/epoxy composites modified with Diels-Alder based healing agent. A novel approach. Compos. Part A Appl. Sci. Manuf. 2021, 140, 106151. [Google Scholar] [CrossRef]

- Kosarli, M.; Foteinidis, G.; Tsirka, K.; Bekas, D.G.; Paipetis, A.S. Concurrent recovery of mechanical and electrical properties in nanomodified capsule-based self-healing epoxies. Polymer 2021, 227, 123843. [Google Scholar]

- Kosarli, M.; Bekas, D.G.; Tsirka, K.; Baltzis, D.; Vaimakis-Tsogkas, D.T.; Orfanidis, S.; Papavassiliou, G.; Paipetis, A.S. Microcapsule-based self-healing materials: Healing efficiency and toughness reduction vs. capsule size. Compos. Part B Eng. 2019, 171, 78–86. [Google Scholar] [CrossRef]

- Pang, J.W.C.; Bond, I.P. A hollow fibre reinforced polymer composite encompassing self-healing and enhanced damage visibility. Compos. Sci. Technol. 2005, 65, 1791–1799. [Google Scholar] [CrossRef]

- Hamilton, A.R.; Sottos, N.R.; White, S.R. Pressurized vascular systems for self-healing materials. J. R. Soc. Interface 2012, 9, 1020–1028. [Google Scholar]

- Kotrotsos, A.; Rouvalis, C.; Geitona, A.; Kostopoulos, V. Toughening and healing of CFRPs by electrospun diels-alder based polymers modified with carbon nano-fillers. J. Compos. Sci. 2021, 5, 242. [Google Scholar] [CrossRef]

- Kostopoulos, V.; Kotrotsos, A. Self-healing of Structural Composites Containing Dendrimers as Healing Agent. In Dendrimers-Fundamentals and Applications; Simonescu, C.M., Ed.; Intech Open Science: London, UK, 2018; Chapter 6; pp. 101–132. [Google Scholar]

- Kotrotsos, A.; Michailidis, G.; Geitona, A.; Tourlomousis, F.; Kostopoulos, V. Toughening and healing of CFRPs by Diels-alder based nano-modified resin through melt electro-writing process technique. Int. J. Mol. Sci. 2022, 23, 3663. [Google Scholar] [CrossRef]

- Meure, S.; Wu, D.Y.; Furman, S. Polyethylene-co-methacrylic acid healing agents formendable epoxy resins. Acta Mater. 2009, 57, 4312–4320. [Google Scholar] [CrossRef]

- Pingkarawat, K.; Wang, C.H.; Varley, R.J.; Mouritz, A.P. Self-healing of delamination cracks in mendable epoxy matrix laminates using poly[ethylene-co-(methacrylic acid)]thermoplastic. Comp. Part A Appl. Sci. Manuf. 2012, 43, 1301–1307. [Google Scholar] [CrossRef]

- Kennedy, J.P.; Castner, K.F. Thermally reversible polymer systems by cyclopentadienylation. I. A model for termination by cyclopentadienylation of olefin polymerization. J. Polym. Sci. Pol. Chem. 1979, 17, 2039–2054. [Google Scholar] [CrossRef]

- Chen, X.; Dam, M.A.; Ono, K.; Mal, A.; Shen, H.; Nutt, S.R.; Sheran, K.; Wudl, F. A thermally remendable cross-linked polymeric material. Science 2002, 295, 1698–1702. [Google Scholar] [CrossRef] [PubMed]

- Park, J.S.; Darlington, T.; Starr, A.F.; Takahashi, K.; Riendeau, J.; Hahn, H.T. Multiple healing effects of thermally activated self-healing composites based on Diels–Alder reaction. Compos. Sci. Technol. 2010, 70, 2154–2159. [Google Scholar] [CrossRef]

- Kotrotsos, A. An innovative synergy between solution electrospinning process technique and self-healing of materials. A critical review. Polym. Eng. Sci. 2020, 61, 5–21. [Google Scholar] [CrossRef]

- Moon, S.C.; Choi, J.K.; Farris, R.J. Preparation of Aligned Polyetherimide Fiber by Electrospinning. J. Appl. Polym. Sci. 2008, 109, 691–694. [Google Scholar] [CrossRef]

- Sung-Seen, C.; Seung Goo, L.; Chang Whan, J.; Seung Soon, I.; Seong Hun, K. Formation of interfiber bondingin electrospun poly(etherimide) nanofiber web. J. Mater. Sci. 2004, 39, 1511–1513. [Google Scholar]

- Yan, X.Z.; Zhou, M.; Chen, J.Z.; Chi, X.D.; Dong, S.Y.; Zhang, M.M.; Ding, X.; Yu, Y.H.; Shao, S.; Huang, F.H. Supramolecular polymer nanofibers via electrospinning of a heteroditopic monomer. Chem. Commun. 2011, 47, 7086–7088. [Google Scholar] [CrossRef]

- Hermida-Merino, D.; Belal, M.; Greenland, B.W.; Woodward, P.; Slark, A.T.; Davis, F.J.; Mitchell, G.R.; Hamley, I.W.; Hayes, W. Electrospun supramolecular polymer fibres. Eur. Polym. J. 2012, 48, 1249–1255. [Google Scholar] [CrossRef]

- Tourlomousis, F.; Ding, H.; Kalyon, D.M.; Chang, R.C. Melt Electrospinning Writing Process Guided by a “Printability Number”. J. Manuf. Sci. Eng. 2017, 139, 081004. [Google Scholar] [CrossRef]

- AITM 1.0006; Airbus Industry Test Method, Carbon Fiber Reinforced Plastics. Determination of Interlaminar Fracture Toughness Energy. Mode II. Cedex: Blagnac, France, 1994.

- AITM 1.0005; Airbus Industry Test Method, Carbon Fiber Reinforced Plastics. Determination of Interlaminar Fracture Toughness Energy, Mode I. Cedex: Blagnac, France, 1994; Issue 2.

- Wang, C.H.; Sidhu, K.; Yang, T.; Zhang, J.; Shanks, R. Interlayer self-healing and toughening of carbon fibre/epoxy composites using copolymer films. Comp. Part A 2012, 43, 512–518. [Google Scholar] [CrossRef]

- de Moura, M.F.S.F. Interlaminar Mode II Fracture Characterization, Delamination Behaviour of Composites. In Book Delamination Behaviour of Composites; Sridharan, S., Ed.; Woodhead Publishing: Sawston, UK, 2008; pp. 310–326. [Google Scholar]

- Davies, P.; Blackman, B.R.K.; Brunner, A.J. Mode II delamination. In Fracture Mechanics Testing Methods for Polymers Adhesives and Composites; Moore, D.R., Pavan, A., Williams, J.G., Eds.; E-Publishing Inc.: Amsterdam, The Netherlands; New York, NY, USA; London, UK, 2001; pp. 307–334. [Google Scholar]

- Kanninen, M.F.; Popelar, C.H. Advanced Fracture Mechanics, 1st ed.; Oxford University Press: Oxford, UK, 1985. [Google Scholar]

- Arrese, A.; Carbajal, N.; Vargas, G.; Mujika, F. A new method for determining mode II R-curve by the End-Notched Flexure test. Eng. Fract. Mech. 2010, 77, 51–70. [Google Scholar] [CrossRef]

- Kotrotsos, A.; Geitona, A.; Kostopoulos, V. On the mode I and mode II fatigue delamination growth of CFRPs modified by electrospun Bis-maleimide resin. Compos. Sci. Technol. 2023, 237, 110000. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kotrotsos, A.; Kostopoulos, V. Mode II Fatigue Delamination Growth and Healing of Bis-Maleimide Modified CFRPs by Using the Melt Electro-Writing Process Technique. J. Compos. Sci. 2023, 7, 350. https://doi.org/10.3390/jcs7090350

Kotrotsos A, Kostopoulos V. Mode II Fatigue Delamination Growth and Healing of Bis-Maleimide Modified CFRPs by Using the Melt Electro-Writing Process Technique. Journal of Composites Science. 2023; 7(9):350. https://doi.org/10.3390/jcs7090350

Chicago/Turabian StyleKotrotsos, Athanasios, and Vassilis Kostopoulos. 2023. "Mode II Fatigue Delamination Growth and Healing of Bis-Maleimide Modified CFRPs by Using the Melt Electro-Writing Process Technique" Journal of Composites Science 7, no. 9: 350. https://doi.org/10.3390/jcs7090350

APA StyleKotrotsos, A., & Kostopoulos, V. (2023). Mode II Fatigue Delamination Growth and Healing of Bis-Maleimide Modified CFRPs by Using the Melt Electro-Writing Process Technique. Journal of Composites Science, 7(9), 350. https://doi.org/10.3390/jcs7090350