Temperature-Dependent Shape-Memory Textiles: Physical Principles and Applications

Abstract

:1. Introduction

2. Brief History

3. Physical Principles

4. Manufacturing Processes and Treatments

5. Shape-Memory Textiles

- (i)

- Functional properties: It is well-known that some physical properties are significantly altered when a polymer passes through Tg. The volume expansivity, for example, has a constant slope below Tg and another constant (and higher) slope above Tg. This occurs due to the fast increase in the main backbone in a short time interval, increasing the free volume among the chains and, consequently, expanding this volume. Water vapor permeability is a more specific application for textiles where moisture is required at higher temperatures and avoided at lower temperatures. This characteristic is excellent for sportswear, where the clothing detects a higher body temperature and the coating responds accordingly, enabling the clothing to become more comfortable. If the temperature drops, the heat is maintained inside by “closing” the pores or approximating the fibers. The polymer must have the characteristics required for such a purpose. For example, if the humidity level is the triggering element, its potential use in hygiene products such as diapers, training pants, and incontinence products is visualized.

- (ii)

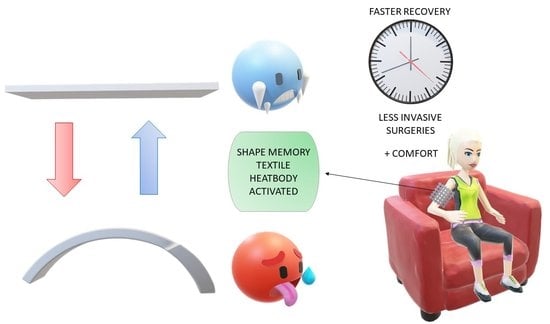

- Property changes due to phase transformation: Significant changes in some properties, such as elastic modulus and hardness, are directly related to crystal structure changes at specific temperatures. Sutures are one application that exploits these changes in temporary and permanent shapes. It is known that keyhole surgery is complicated, and if a smart shape-memory suture that ties itself into a perfect knot is applied, many drawbacks are eliminated. MenemoScience developed a self-knotting suture where a slight body temperature increase was able to be detected. Moreover, the suture could seal complex wounds where access was limited. Following this principle, other applications are expected, such as its use in army uniforms, camping materials, artificial leathers, temperature sensors, and artificial blood vessels, among others.

- (iii)

- Outdoor, casual, and sportswear: The change in physical properties when a material goes through a transition temperature makes SMPs’ potential use in garments a valid application, mainly for when such a textile creases. The original state would be recovered by washing the textile at higher temperatures. In contrast, the original wrinkles would be retrieved by immersing the fabric in water. Following this principle, multilayer fabrics for adaptable protective clothing or leisurewear features could be developed. This would guarantee protection from wind and weather, dissipate perspiration, and enable excellent stretch and recovery properties. In addition, the fibers could respond to external stimuli in a predetermined manner, making them valuable for sportswear.

6. Today’s Applications for Different Uses

- General and regenerative medicine: A medical stent is the flagship for SMPs’ biomedical use, with enormous material use per year—more than 600,000 coronary stents are implanted annually in the United States [74]. New developments in biomedical textiles for cardiovascular and endovascular applications are extremely innovative, with complex and fully customizable geometries. These biomedical textiles are already being used for heart valve replacements, aortic arch reinforcement, stent graft covering, carotid artery repair fabrics, tissue grafts, PAD (peripheral artery disease) treatments, hypertension treatments, angioplasty balloon/reinforcement, distal/embolic protection, coronary bypass grafts, cardiovascular patches, vascular prostheses, branch vessel filtration, and sewing rings for heart valves. Its main advantages include lower invasiveness, a lower profile, controlled density and porosity, flexibility, shape transformations, high tensile strength, biocompatibility, its inherent capabilities for promoting the healing of cardiovascular tissue, radial reinforcement, and expansion. These textiles can be formed via knitting, braiding, or weaving medical-grade fibers [75]. Regarding regenerative medicine, SMPs are used for wound healing and tissue regeneration [76]. Polyurethanes are an excellent choice due to their thermomechanical, chemical, and shape-memory properties after implantation, and they provide a reliable platform for controlled responses [77,78].

- Drug delivery: Incorporating microcapsules into textiles has been studied over the years. Studies have shown that textiles that incorporate microcapsules containing active principles with antimicrobial, cosmetic, or even drug characteristics, will enable them to be released from the microcapsules and penetrate the skin upon contact, unraveling many exciting applications. The main advantages include protection from weather conditions, breathability, flexibility, comfort, and the expression of our personality [79,80]. The main issue is how to design vernacularizing systems for precise incorporation into the fabrics. For example, chemical affinity significantly affects release behavior. Therefore, using textiles with two functionalities broadens the range of applications, including diseases via skin-textile contact, which creates advantages over the administration of the active substance.

7. Future Research

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- El Feninat, F.; Laroche, G.; Fiset, M.; Mantovani, D. Shape memory materials for biomedical applications. Adv. Eng. Mat. 2002, 4, 91–104. [Google Scholar] [CrossRef]

- Lendlein, A.; Kelch, S. Shape-memory polymers. Angew. Chem. 2002, 41, 2034–2057. [Google Scholar] [CrossRef]

- Alteheld, A.; Feng, Y.; Kelch, S.; Lendlein, A. Biodegradable, amorphous copolyester-urethane networks having shape-memory properties. Angw. Chem. 2005, 44, 1188–1192. [Google Scholar] [CrossRef] [PubMed]

- Behl, M.; Zotzmann, J.; Schroeter, M.; Lendlein, A. Biodegradable Shape-Memory Polymers. In Handbook of Biodegradable Polymers: Isolation, Synthesis, Characterization and Applications; Wiley, Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2011. [Google Scholar] [CrossRef]

- Du, Z.; Zeng, X.; Liu, Q.; Schuh, C.; Gan, C. Superelasticity in micro-scale shape memory ceramic particles. Acta Mater. 2017, 123, 255–263. [Google Scholar] [CrossRef]

- Yu, H.; Hassani-Gangaraj, M.; Du, Z.; Gan, C.; Schuh, C. Granular shape memory ceramic packings. Acta Mater. 2017, 132, 455–466. [Google Scholar] [CrossRef]

- Zhao, X.; Lai, A.; Schuh, C. Shape memory zirconia foams through ice templating. Scr. Mater. 2017, 135, 50–53. [Google Scholar] [CrossRef]

- Kabir, H.; Gong, J.; Watanabe, Y.; Makino, M.; Furukawa, H. The Applications of Shape Memory gel as a Smart Material. In Proceedings of the 12th Asia Pacific Physics Conference (APPC12), Nakuhari, Japan, March 2014; Volume 1. [Google Scholar] [CrossRef]

- Schartz, M. Smart Materials Handbook, 1st ed.; CRC Presss: Boca Raton, FL, USA, 2008; p. 504. [Google Scholar] [CrossRef]

- Yu, X.; Cheng, H.; Zhang, M.; Zhao, Y.; Qu, L.; Shi, G. Graphene-based smart materials. Nat. Rev. Mater. 2017, 2, 17046. [Google Scholar] [CrossRef]

- Jani, J.; Leary, M.; Subic, A.; Gibson, M. A review of shape memory alloy research, applications and opportunities. Mat. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Huang, W.; Ding, Z.; Wang, C.; Wei, J.; Zhao, P. Shape memory materials. Mater. Today Commun. 2010, 13, 54–61. [Google Scholar] [CrossRef]

- Smart Shirt Rolls up its Sleeves. Available online: http://news.bbc.co.uk/2/hi/europe/1458231.stm (accessed on 17 March 2023).

- Amaterrace. Available online: http://www.amaterrace.com/product/dl_2.html (accessed on 16 March 2023).

- 4D Printing a Shape Memory Polymer. Available online: https://www.sculpteo.com/blog/2018/01/09/4d-printing-a-shape-memory-polymer/ (accessed on 15 March 2023).

- Kaneko, D.; Gong, J.; Osada, Y. Polymer gels as soft and wet thermomechanical systems–an approach to artificial muscles. J. Mat. Chem. 2002, 12, 2169–2177. [Google Scholar] [CrossRef]

- Lai, A.; Du, Z.; Gan, C.; Schuh, C. Shape memory and superelastic ceramics at small scales. Science 2013, 341, 1505–1508. [Google Scholar] [CrossRef] [Green Version]

- Ornaghi, H.L., Jr.; Neves, R.M.; Monticeli, F.M.; Dall Agnol, L. Smart fabric textiles: Recent advances and challenges. Textiles 2022, 2, 582–605. [Google Scholar] [CrossRef]

- Uddin, F. Textile Manufacturing Processes, 1st ed.; BoD–Books on Demand: Norderstedt, Germany, 2019; p. 98. [Google Scholar] [CrossRef]

- Ölander, A. An electrochemical investigation of solid cadmium-gold alloys. J. Am. Chem. Soc. 1932, 54, 3819–3833. [Google Scholar] [CrossRef]

- Bowles, J.; Barrett, C.; Guttman, L. Crystallography of cubic0tetragonal transformation in the indium-thallium system. JOM 1950, 2, 1478–1485. [Google Scholar] [CrossRef]

- Chang, L.; Read, T. Plastic deformation and diffusionless phase changes in metals–the gold-cadmium beta phase. JOM 1951, 3, 47–52. [Google Scholar] [CrossRef]

- Fu, C.; Sealy, M.; Guo, Y.; Wei, X. Austenite-martensite phase transformation of biomedical Nitinol by ball burnishing. J. Mater. Process. Technol. 2014, 214, 3122–3130. [Google Scholar] [CrossRef]

- Wayman, C.; Harrison, J. The origins of the shape memory effect. JOM 1989, 41, 26–28. [Google Scholar] [CrossRef]

- Genevray, A. Martensitic Transformation in Muntz Metal. MIT Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, May 1953. [Google Scholar]

- Chen, C. Some characteristics of the martensite transformation. JOM 1957, 9, 1202–1203. [Google Scholar] [CrossRef]

- Hornbogen, E.; Wassermann, G. Über den Einfluß von Spannungen und das Auftreten von Umwandlungsplastizität bei der Beta1-Beta”-Umwandlung des Messings. Int. J. Mater. Res. 1956, 47, 470614. [Google Scholar] [CrossRef]

- Dayyoub, T.; Maksimkin, A.; Filippova, O.; Tcherdyntsev, V.; Telyshev, D. Shape memory polymers as smart materials: A review. Polymers 2022, 14, 3511. [Google Scholar] [CrossRef]

- Mu, T.; Liu, L.; Lan, X.; Liu, Y.; Leng, J. Shape memory polymers for composites. Compos. Sci. Technol. 2018, 160, 169–198. [Google Scholar] [CrossRef]

- Pujolle-Robic, C.; Noirez, L. Observation of shear-induced nematic-isotropic transition in side-chain liquid crystal polymers. Nature 2001, 409, 167–171. [Google Scholar] [CrossRef] [PubMed]

- Hu, J. Shape Memory Polymers and Textiles; Elsevier: Amsterdam, The Netherlands, 2007; p. 306. ISBN 978-1-84569-306-0. [Google Scholar]

- Ferry, J.; Myers, H. Viscoelastic properties of polymers. J. Electrochem. Soc. 1961, 108, 142C. [Google Scholar] [CrossRef]

- Thermal Properties of Polymers. Available online: https://textilestudycenter.com/thermal-properties-of-polymers (accessed on 1 March 2023).

- Elder, R.; Andzelm, J.; Sirk, T. A molecular simulation study of the glass-transition of crosslinked poly(dicyclopentadiene) networks. Chem. Phys. Lett. 2015, 637, 103–109. [Google Scholar] [CrossRef] [Green Version]

- Reyes, L.; Zhang, J.; Dao, B.; Nguyen, D.; Varley, R. Subtle variations in the structure of crosslinked epoxy networks and the impact upon mechanical and thermal properties. J. Appl. Polym. Sci. 2020, 137, 48874. [Google Scholar] [CrossRef]

- Ito, S.; Oki, S.; Sato, N.; Yamamoto, M. Micro-Brownian motion of polymer segments in a monolayer at the air-water interface: A time-resolved study of intralayer energy transfer. Macromolecules 1996, 29, 724–729. [Google Scholar] [CrossRef]

- Roland, C.; Santangelo, P.; Ngai, K. The application of the energy landscape model to polymers. J. Chem. Phys. 1999, 111, 5593. [Google Scholar] [CrossRef]

- Sunthar, P. Rheology of complex liquids. In Polymer Rheology; Springer: New York, NY, USA, 2010; pp. 171–191. [Google Scholar] [CrossRef]

- Salaris, V.; Leonés, A.; Lopez, D.; Kenny, J.M.; Peponi, L. Shape-memory materials via electrospinning: A review. Polymers 2022, 15, 995. [Google Scholar] [CrossRef]

- Zhu, Y.; Hu, J.L.; Yeung, L.-Y.; Liu, Y.; Ji, F.L.; Yeung, K.W. Development of shape memory polyurethane fiber with complete shape recoverability. Smart Mater. Struct. 2006, 15, 1385. [Google Scholar] [CrossRef]

- Singhal, P.; Small, W.; Cosgriff-Hernandez, E.; Maitland, D.J.; Wilson, T.S. Low density biodegradable shape memory polyurethane foams for embolic biomedical applications. Acta Biomater. 2014, 10, 67–76. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, T.T.; Yu, R.; Li, X.P.; Cheng, B.; Zhang, Y.; Yang, X.; Zhao, X.J.; Zhao, Y.L.; Huang, W. 4D printing of shape memory polyurethane via stereolithography. Eur. Polym. J. 2018, 101, 120–126. [Google Scholar] [CrossRef]

- Hufenus, R.; Yan, Y.; Dauner, M.; Kikutani, T. Melt-spun fibers for textile applications. Materials 2020, 13, 4298. [Google Scholar] [CrossRef]

- Meng, Y.H.; Hu, J.L.; Zhu, Y.; Lu, J.; Liu, Y. Polycaprolactone-based shape memory segmented polyurethane fiber. J. Appl. Polym. Sci. 2007, 106, 2515–2523. [Google Scholar] [CrossRef]

- Meng, Y.H.; Hu, J.L.; Zhu, Y.; Lu, J.; Liu, Y. Morphology, phase separation, thermal and mechanical property differences of shape memory fibres prepared by different spinning methods. Smart Mater. Struct. 2007, 16, 1192. [Google Scholar] [CrossRef]

- Meng, Q.H.; Hu, J.L.; Yeung, L.Y.; Hu, Y. The influence of heat treatment on the properties of shape memory fibers. II. Tensile properties, dimensional stability, recovery force relaxation, and thermomechanical cyclic properties. J. Appl. Polym. Sci. 2009, 111, 1156–1164. [Google Scholar] [CrossRef]

- Kumar, B.; Hu, J.L.; Pan, N. Smart medical stocking using memory polymer for chronic venous disorders. Biomaterials 2016, 75, 174–181. [Google Scholar] [CrossRef] [Green Version]

- Kumar, B.; Hu, J.L.; Pan, N. Memory bandage for functional compression management for venous ulcers. Fibers 2016, 4, 10. [Google Scholar] [CrossRef]

- Kumar, B. Shape memory textiles for functional compression management. Veins Lymphat. 2017, 6, 162–172. [Google Scholar] [CrossRef] [Green Version]

- Jing, L.; Hu, J.L. Study on the properties of core spun yarn and fabrics of shape memory polyurethane. Fibres Text. East. Eur. 2010, 18, 39–42. [Google Scholar]

- Dyer, P. Integration of small diameter wire form SMA for the creation of dynamic shape memory textiles. Adv. Sci. Technol. 2012, 80, 53–58. [Google Scholar] [CrossRef]

- Vili, Y.Y.F.C. Investigating smart textiles based on shape memory materials. Text. Res. J. 2007, 77, 290–300. [Google Scholar] [CrossRef]

- Wang, L.; Lu, Y.; He, J. On the effectiveness of temperature-responsive protective fabric incorporated with shape memory alloy (SMA) under radiant heat exposure. Cloth. Text. Res. J. 2019, 38, 212–224. [Google Scholar] [CrossRef]

- Winchester, R.C.C.; Stylios, G.K. Designing knitted apparel by engineering the attributes of shape memory alloy. Int. J. Choth. Sci. Technol. 2003, 15, 359–366. [Google Scholar] [CrossRef]

- Hu, J. Shape memory finishing treatments for smart textiles. Book Adv. Shape Mem. Polym. 2013, 146, 259–280. [Google Scholar] [CrossRef]

- Smith, W.C. Smart Textile Coatings and Laminates; Woodhead Publishing Series in Textiles: Cambridge, UK, 2010; ISBN 978-1-84569-379-4. [Google Scholar]

- Stylios, G.K.; Wan, T. Shape memory training for smart fabrics. Trans. Inst. Meas. Control 2007, 29, 321–336. [Google Scholar] [CrossRef]

- Patadiya, J.; Gawande, A.; Joshi, G.; Kandasubramanian, B. Additive manufacturing of shape memory polymer composites for futuristic technology. Ind. Eng. Chem. Res. 2021, 60, 15885–15912. [Google Scholar] [CrossRef]

- Pieri, K. 4D Printing Shape Memory Polymers for Biomedical Applications. Ph.D. Thesis, Syracuse University, Syracuse, NY, USA, 2020. Available online: https://surface.syr.edu/etd/1256 (accessed on 1 May 2023).

- Nadgorny, M.; Ameli, A. Functional polymers and nanocomposites for 3D printing of smart structures and devices. ACS Appl. Mater. Interfaces 2018, 10, 17489–17507. [Google Scholar] [CrossRef]

- Azam, A.; Laflin, K.E.; Jamal, M.; Fernandes, R.; Gracias, D.H. Self-folding micropatterned polymeric matrices. Biomed Microdevices 2011, 13, 51–58. [Google Scholar] [CrossRef]

- Malachowski, K.; Breger, J.; Kwag, H.R.; Wang, M.O.; Fisher, J.P.; Selaru, F.M.; Gracias, D.H. Stimuli-responsive theragrippers for chemomechanical controlled release. Angew. Chem. Int. Ed. 2014, 28, 8045–8049. [Google Scholar] [CrossRef]

- Bodaghi, M.; Damanpack, A.R.; Liao, W.H. Self-expanding/shrinking structures by 4D printing. Smart Mater. Struct. 2016, 25, 105034. [Google Scholar] [CrossRef]

- Ge, Q.; Sakhaei, A.H.; Lee, H.; Dunn, C.K.; Fang, N.X.; Dunn, M.L. Multimaterial 4D printing with tailorable shape memory polymers. Sci. Rep. 2016, 6, 31110. [Google Scholar] [CrossRef] [Green Version]

- Senatov, F.S.; Zadorozhnyy, M.Y.; Niaza, K.; Medvedev, V.V.; Kaloshkin, S.D.; Anisimova, N.Y.; Kiselevsky, M.V.; Tang, K.-C. Shape memory effect in 3D-printed scaffolds for self-fitting implants. Eur. Polym. J. 2017, 93, 222–231. [Google Scholar] [CrossRef]

- Hendrikson, W.J.; Rouwkema, J.; Clementi, F.; van Blitterswijk, C.A.; Farè, S.; Moroni, L. Towards 4D printed scaffolds for tissue engineering: Exploiting 3D shape memory polymers to deliver time-controlled stimulus on cultured cells. Biofabrication 2017, 9, 031001. [Google Scholar] [CrossRef]

- Pearson, A.; Naguib, H.E. Novel polyurethane elastomeric composites reinforced with alumina, aramid, and poly(p-phenylene-2,6-benzobisoxazole) short fibers, development, and characterization of the thermal and dynamic mechanical properties. Compos. B Eng. 2017, 122, 192–201. [Google Scholar] [CrossRef]

- Niu, R.; Han, K.; Walsh, R.P.; Buchholz, K.; Goddard, R.E.; Besara, T.; Siegrist, T.M. Aging effect of Zylon. IEEE Trans. Appl. SuperConductivity 2018, 28, 1–4. [Google Scholar] [CrossRef]

- Peng, T.; Wang, S.; Huang, Y.D.; Jiang, F.; Sun, Q.Q.; Li, L.; Xiao, H. Study of the fatigue behaviour of unidirectional zylon/epoxy composite used in pulsed magnets. IEEE Trans. Appl. SuperConductivity 2020, 99, 1. [Google Scholar] [CrossRef]

- Xia, Y.; He, Y.; Zhang, F.; Liu, Y.; Leng, J. A review of shape memory polymers and composites: Mechanisms, materials, and applications. Adv. Mater. 2020, 33, 2000713. [Google Scholar] [CrossRef]

- Phan, P.; Hoang, T.; Thai, M.; Low, H.; Davies, J.; Lovell, N.; Do, T. Smart surgical sutures using soft artificial muscles. Sci. Rep. 2021, 11, 22420. [Google Scholar] [CrossRef] [PubMed]

- Cera, L.; Gonzalez, G.; Liu, Q.; Choi, S.; Chantre, C.; Lee, J.; Gabardi, R.; Choi, M.; Shin, K.; Parker, K. A bioinspired and hierarchically structured shape-memory material. Nat. Mat. 2021, 20, 242–249. [Google Scholar] [CrossRef]

- Wool-like Material Can Remember and Change Shape. Available online: https://www.youtube.com/watch?v=ngmQwnR79Fs (accessed on 1 March 2023).

- Drhuva, S.S.; Parzynski, C.S.; Gamble, G.M.; Curtis, J.P.; Desai, N.R.; Yeh, R.W.; Masoudi, F.A.; Kuntz, R.; Shaw, R.E.; Marinac-Dabic, D.; et al. Attribution of adverse events following coronary stent placement identified using administrative claims data. J. Am. Hear. Assoc. 2020, 9, e013606. [Google Scholar] [CrossRef]

- Biomedical Textiles for Cardiovascular and Endovascular Applications. Available online: https://www.cortlandbiomedical.com/textile-solutions-cardiovascular-applications/ (accessed on 1 May 2023).

- Tatu, R.; Oria, M.; Pulliam, S.; Signey, L.; Rao, M.B.; Peiro, J.L.; Lin, C.-Y. Using poly(l-lactic acid) and poly(ɛ-caprolactone) blends to fabricate self-expanding, watertight and biodegradable surgical patches for potential fetoscopic myelomeningocele repair. J. Biomed. Mater. Res. Part B Appl. Biomater. 2019, 107, 295–305. [Google Scholar] [CrossRef]

- Ramezani, M.; Monroe, M.B.B. Biostable segmented thermoplastic polyurethane shape memory polymers for smart biomedical applications. ACS Appl. Polym. Mater. 2022, 4, 1956–1965. [Google Scholar] [CrossRef]

- Calvo-Correas, T.; Shirole, A.; Crippa, F.; Fink, A.; Weder, C.; Corcuera, M.A.; Eceiza, A. Biocompatible thermo- and magneto-responsive shape-memory polyurethane bionanocomposites. Mater. Sci. Eng. C 2019, 97, 658–668. [Google Scholar] [CrossRef]

- Textile-Embedded Microcapsules: The Future of Drug Delivery. Available online: https://researchoutreach.org/articles/textile-embedded-microcapsules-future-drug-delivery/ (accessed on 1 May 2023).

- Arias, M.K.L.; Coderch, L.; Marti, M.; Alonso, C.; Carmona, O.G.; Carmona, C.G.; Maesta, F. Vehiculation of active principles as a way to create smart and biofunctional textiles. Materials 2018, 11, 2152. [Google Scholar] [CrossRef] [Green Version]

- van Langenhove, L. Advances in Smart Medical Textiles, Treatments, and Health Monitoring; Woodhead Publishing Series in Textiles: Cambridge, UK, 2016; ISBN 978-1-78242-4000-0. [Google Scholar]

- Narayana, H.; Hu, J.; Kumar, B.; Shang, S.; Han, J.; Liu, P.; Lin, T.; Ji, F.; Zhu, Y. Stress-memory polymeric filaments for advanced compression therapy. J. Mater. Chem. B 2017, 5, 1905. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Hu, J.; Yuen, C.-W.; Chan, L. Novel moisture-sensitive shape memory polyurethanes containing pyridine moieties. Polymer 2009, 50, 4424. [Google Scholar] [CrossRef]

- Chen, J.; Hu, J.; Leung, A.K.L.; Chen, C.; Zhang, J.; Zhang, Y.; Zhu, Y.; Han, J. Shape memory ankle-foot orthoses. ACS Appl. Mater. Interfaces 2018, 10, 32941–32965. [Google Scholar] [CrossRef]

- Rousseau, I.A. Challenges of shape memory polymers: A review of the progress toward overcoming SMP’s limitations. Polym. Eng. Sci. 2008, 48, 2075–2089. [Google Scholar] [CrossRef]

- Shape Memory Textiles. Available online: https://www.textileengineers.org/shape-memory-textile/ (accessed on 1 May 2023).

| Polymers | Physical Interactions | |

|---|---|---|

| Transient Shape | Original Shape | |

| Polynonbornene entanglement | Glassy state | Chain |

| Polyurethane | Glassy state | Microcrystal |

| Polyethylene/nylon-6 graft copolymer | Microcrystal | Crosslinking |

| Styrene-1,4-butadiene block copolymer | Microcrystal/glassy state of poly(1,4-butadiene) | Microcrystal/glassy state of polystyrene |

| Ethylene oxide-ethylene terephthalate block copolymer | Microcrystal of PEO | Microcrystal of PET |

| Poly (methylene-1,3-cyclopentane) polyethylene block copolymer | Glassy state/microcrystal of PMCP | Microcrystal of PE |

| Thermally Responsive Textiles | Strategies and Functions |

|---|---|

| Shape-memory finishing | Dynamic aesthetic textiles |

| Finishing for wrinkle-free properties Finishing for crease retention Finishing for anti-shrinkage properties | |

| Shape-memory fiber | Wet-spinning methods |

| Melt-spinning methods Profiled fibers Electroactive SMP fibers | |

| Shape-memory fabrics | Spun SMP fibers Low-pressure apparel Biological safety textiles Dynamic aesthetic fabrics Temperature and moisture management fabrics |

| Two-way fabrics | Two-way SMP textiles |

| Breathable fabrics | Traditional breathable fabrics Breathable fabrics with improved WVP |

| Damping fabrics | Damping properties of SMPs Damping properties of SMP fibers |

| Phase-change materials | Solid–solid PCMs Chemical crosslinking PCMs Thermoplastic PCMs SMP fibers with phase-change effects |

| SMP nanofibers | SMP nanofiber coated fabric SMP nonwoven nanofiber |

| Shape-memory foams | SMP foam pillows SMP foam mattresses SMP insoles |

| Thermochromic textiles | Liquid crystal type Molecular rearrangement type |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ornaghi, H.L., Jr.; Bianchi, O. Temperature-Dependent Shape-Memory Textiles: Physical Principles and Applications. Textiles 2023, 3, 257-274. https://doi.org/10.3390/textiles3020017

Ornaghi HL Jr., Bianchi O. Temperature-Dependent Shape-Memory Textiles: Physical Principles and Applications. Textiles. 2023; 3(2):257-274. https://doi.org/10.3390/textiles3020017

Chicago/Turabian StyleOrnaghi, Heitor Luiz, Jr., and Otávio Bianchi. 2023. "Temperature-Dependent Shape-Memory Textiles: Physical Principles and Applications" Textiles 3, no. 2: 257-274. https://doi.org/10.3390/textiles3020017

APA StyleOrnaghi, H. L., Jr., & Bianchi, O. (2023). Temperature-Dependent Shape-Memory Textiles: Physical Principles and Applications. Textiles, 3(2), 257-274. https://doi.org/10.3390/textiles3020017