Effects of Silica Fume and Micro Silica on the Properties of Mortars Containing Waste PVC Plastic Fibers

Abstract

:1. Introduction

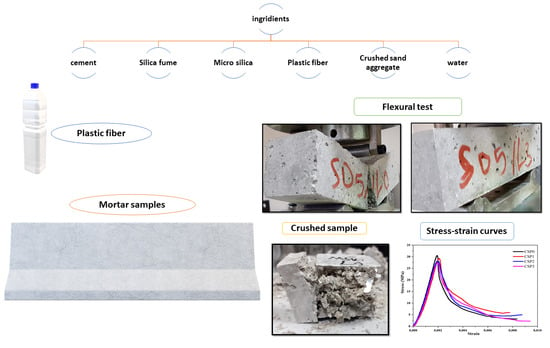

2. Materials and Methods

2.1. Materials

2.2. Preparation of Samples

2.3. Experimental Procedure

3. Results and Discussion

3.1. Fresh State Properties

3.2. Physical Properties

3.2.1. Dry Bulk Density Values

3.2.2. SSD Bulk Density Values

3.2.3. Apparent Porosity Values

3.2.4. Water Absorption

3.3. Mechanical Properties

3.3.1. Flexural Strength

3.3.2. Compressive Strength

3.3.3. Stress–Strain Behavior

3.3.4. Modulus of Elasticity

3.3.5. Toughness

3.4. Durability Properties

Capillary Water Absorption

3.5. Microstructure

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gu, L.; Ozbakkaloglu, T. Use of Recycled Plastics in Concrete: A Critical Review. Waste Manag. 2016, 51, 19–42. [Google Scholar] [CrossRef] [PubMed]

- Plastics Europe Plastics Europe Association of Plastics Manufacturers Plastics—The Facts 2021 an Analysis of European Plastics Production, Demand and Waste Data. Available online: https://plasticseurope.org/knowledge-hub/plastics-the-facts-2021/ (accessed on 17 July 2022).

- Madhavan Nampoothiri, K.; Nair, N.R.; John, R.P. An Overview of the Recent Developments in Polylactide (PLA) Research. Bioresour. Technol. 2010, 101, 8493–8501. [Google Scholar] [CrossRef]

- Yang, S.; Yue, X.; Liu, X.; Tong, Y. Properties of Self-Compacting Lightweight Concrete Containing Recycled Plastic Particles. Constr. Build. Mater. 2015, 84, 444–453. [Google Scholar] [CrossRef]

- Ghernouti, Y.; Rabehi, B.; Bouziani, T.; Ghezraoui, H.; Makhloufi, A. Fresh and Hardened Properties of Self-Compacting Concrete Containing Plastic Bag Waste Fibers (WFSCC); Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Borg, R.P.; Baldacchino, O.; Ferrara, L. Early Age Performance and Mechanical Characteristics of Recycled PET Fibre Reinforced Concrete. Constr. Build. Mater. 2016, 108, 29–47. [Google Scholar] [CrossRef] [Green Version]

- Mahmood, R.A.; Kockal, N.U. Cementitious Materials Incorporating Waste Plastics: A Review. SN Appl. Sci. 2020, 2, 13. [Google Scholar] [CrossRef]

- Kurup, A.R.; Kumar, K.S. Novel Fibrous Concrete Mixture Made from Recycled PVC Fibers from Electronic Waste. J. Hazard. Toxic Radioact. Waste 2017, 21, 04016020. [Google Scholar] [CrossRef]

- Foti, D. Preliminary Analysis of Concrete Reinforced with Waste Bottles PET Fibers. Constr. Build. Mater. 2011, 25, 1906–1915. [Google Scholar] [CrossRef]

- Anandan, S.; Alsubih, M. Mechanical Strength Characterization of Plastic Fiber Reinforced Cement Concrete Composites. Appl. Sci. 2021, 11, 852. [Google Scholar] [CrossRef]

- Suksiripattanapong, C.; Phetprapai, T.; Singsang, W.; Phetchuay, C.; Thumrongvut, J.; Tabyang, W. Utilization of Recycled Plastic Waste in Fiber Reinforced Concrete for Eco-Friendly Footpath and Pavement Applications. Sustainability 2022, 14, 6839. [Google Scholar] [CrossRef]

- Suksiripattanapong, C.; Uraikhot, K.; Tiyasangthong, S.; Wonglakorn, N.; Tabyang, W.; Jomnonkwao, S.; Phetchuay, C. Performance of Asphalt Concrete Pavement Reinforced with High-Density Polyethylene Plastic Waste. Infrastructures 2022, 7, 72. [Google Scholar] [CrossRef]

- Amin, M.; Zeyad, A.M.; Tayeh, B.A.; Saad Agwa, I. Effect of Ferrosilicon and Silica Fume on Mechanical, Durability, and Microstructure Characteristics of Ultra High-Performance Concrete. Constr. Build. Mater. 2022, 320, 126233. [Google Scholar] [CrossRef]

- Yang, J.; Lu, J.; Wu, Q.; Xia, M.F.; Li, X. Influence of Steel Slag Powders on the Properties of MKPC Paste. Constr. Build. Mater. 2018, 159, 137–146. [Google Scholar] [CrossRef]

- Kamali, M.; Ghahremaninezhad, A. Effect of Glass Powders on the Mechanical and Durability Properties of Cementitious Materials. Constr. Build. Mater. 2015, 98, 407–416. [Google Scholar] [CrossRef]

- Mehta, A.; Ashish, D.K. Silica Fume and Waste Glass in Cement Concrete Production: A Review. J. Build. Eng. 2020, 29, 100888. [Google Scholar] [CrossRef]

- Fallah, S.; Nematzadeh, M. Mechanical Properties and Durability of High-Strength Concrete Containing Macro-Polymeric and Polypropylene Fibers with Nano-Silica and Silica Fume. Constr. Build. Mater. 2017, 132, 170–187. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A. The impact resistance and mechanical properties of fiber reinforced self-compacting concrete (SCC) containing nano-SiO2 and silica fume. Eur. J. Environ. Civ. Eng. 2016, 22, 1–27. [Google Scholar] [CrossRef]

- Tests for Geometrical Properties of Aggregates Part 1: Determination of Particle Size Distribution—Sieving Method. Available online: https://knowledge.bsigroup.com/products/tests-for-geometrical-properties-of-aggregates-determination-of-particle-size-distribution-sieving-method-1/standard (accessed on 17 July 2022).

- Admixtures for Concrete—Definitions and Requirements. Turk. Stand. Insti. Ankara, Turkey | Engineering360. Available online: https://standards.globalspec.com/std/1056936/TSEN1015-3 (accessed on 17 July 2022).

- TSE-TS EN 1015-3—Methods of Test for Mortar for Masonry—Part 3: Determination of Consistence of Fresh Mortar (by Flow Table)|Engineering360. Available online: https://standards.globalspec.com/std/1056936/TSEN1015-3 (accessed on 17 July 2022).

- TSE-TS EN 1015-6/A1—Methods of Test for Mortar for Masonry—Part 6: Determination of Bulk Density of Fresh Mortar | Engineering360. Available online: https://standards.globalspec.com/std/14259534/TSEN1015-6/A1 (accessed on 17 July 2022).

- ASTM C642: Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. Available online: https://global.ihs.com/doc_detail.cfm?document_name=ASTMC642&item_s_key=00014902 (accessed on 17 July 2022).

- Kockal, N.U. Investigation about the Effect of Different Fine Aggregates on Physical, Mechanical and Thermal Properties of Mortars. Constr. Build. Mater. 2016, 124, 816–825. [Google Scholar] [CrossRef]

- TSE-TS EN 1015-11—Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar | Engineering360. Available online: https://standards.globalspec.com/std/1057272/ts-en-1015-11 (accessed on 17 July 2022).

- Kockal, N.U.; Kocaer, T.Z. Effects of Using Metal Granules on Strength and Stiffness. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Kiev, Ukraine, 1 September 2019; IOP Publishing: Bristol, UK, 2019; Volume 629, p. 012032. [Google Scholar]

- ASTM C109 / C109M Standard Test Method for Comprehensive Strength of Hydraulic Cement Mortars—ELearning Course. Available online: https://www.astm.org/astm-tpt-182.html (accessed on 17 July 2022).

- Al-Hadithi, A.I.; Hilal, N.N. The Possibility of Enhancing Some Properties of Self-Compacting Concrete by Adding Waste Plastic Fibers. J. Build. Eng. 2016, 8, 20–28. [Google Scholar] [CrossRef]

- Karahan, O.; Atiş, C.D. The Durability Properties of Polypropylene Fiber Reinforced Fly Ash Concrete. Mater. Des. 2011, 32, 1044–1049. [Google Scholar] [CrossRef]

- Faraj, R.H.; Sherwani, A.F.H.; Daraei, A. Mechanical, Fracture and Durability Properties of Self-Compacting High Strength Concrete Containing Recycled Polypropylene Plastic Particles. J. Build. Eng. 2019, 25, 100808. [Google Scholar] [CrossRef]

- Gupta, T.; Chaudhary, S.; Sharma, R.K. Mechanical and Durability Properties of Waste Rubber Fiber Concrete with and without Silica Fume. J. Clean. Prod. 2016, 112, 702–711. [Google Scholar] [CrossRef]

- Senhadji, Y.; Siad, H.; Escadeillas, G.; Benosman, A.S.; Chihaoui, R.; Mouli, M.; Lachemi, M. Physical, Mechanical and Thermal Properties of Lightweight Composite Mortars Containing Recycled Polyvinyl Chloride. Constr. Build. Mater. 2019, 195, 198–207. [Google Scholar] [CrossRef]

- Kockal, N.U.; Camurlu, H.E. Lightweight Pumice Mortars with Polypropylene Fiber Reinforcement. Arab. J. Sci. Eng. 2020, 45, 8087–8097. [Google Scholar] [CrossRef]

- Wang, W.; Shen, A.; Lyu, Z.; He, Z.; Nguyen, K.T.Q. Fresh and Rheological Characteristics of Fiber Reinforced Concrete—A Review. Constr. Build. Mater. 2021, 296, 123734. [Google Scholar] [CrossRef]

- Meddah, M.S.; Bencheikh, M. Properties of Concrete Reinforced with Different Kinds of Industrial Waste Fibre Materials. Constr. Build. Mater. 2009, 23, 3196–3205. [Google Scholar] [CrossRef]

- Bagherzadeh, R.; Sadeghi, A.H.; Latifi, M. Utilizing Polypropylene Fibers to Improve Physical and Mechanical Properties of Concrete. Text. Res. J. 2012, 82, 88–96. [Google Scholar] [CrossRef]

- López-Buendía, A.M.; Romero-Sánchez, M.D.; Climent, V.; Guillem, C. Surface Treated Polypropylene (PP) Fibres for Reinforced Concrete. Cem. Concr. Res. 2013, 54, 29–35. [Google Scholar] [CrossRef]

- Mazaheripour, H.; Ghanbarpour, S.; Mirmoradi, S.H.; Hosseinpour, I. The Effect of Polypropylene Fibers on the Properties of Fresh and Hardened Lightweight Self-Compacting Concrete. Constr. Build. Mater. 2011, 25, 351–358. [Google Scholar] [CrossRef]

- Nili, M.; Afroughsabet, V. The Effects of Silica Fume and Polypropylene Fibers on the Impact Resistance and Mechanical Properties of Concrete. Constr. Build. Mater. 2010, 24, 927–933. [Google Scholar] [CrossRef]

- Fraternali, F.; Spadea, S.; Berardi, V.P. Effects of Recycled PET Fibres on the Mechanical Properties and Seawater Curing of Portland Cement-Based Concretes. Constr. Build. Mater. 2014, 61, 293–302. [Google Scholar] [CrossRef]

- Liu, K.; Wang, S.; Quan, X.; Duan, W.; Nan, Z.; Wei, T.; Xu, F.; Li, B. Study on the Mechanical Properties and Microstructure of Fiber Reinforced Metakaolin-Based Recycled Aggregate Concrete. Constr. Build. Mater. 2021, 294, 123554. [Google Scholar] [CrossRef]

| Specific Gravity (g/cm3) | 1.40 |

| Diameter (mm) | 2–3 |

| Length (mm) | 8–12 |

| Bulk modulus (GPa) | 4.70 |

| Tensile strength (MPa) | 52 |

| Softening point (°C) | 82 |

| Poisson’s ratio | 0.40 |

| Constituents | Cement | Silica Fume | Micro Silica |

|---|---|---|---|

| NA2O | - | 2.150 | 0.09 |

| MgO | 1.91 | 14.320 | 0.08 |

| Al2O3 | 4.06 | 1.684 | 0.12 |

| SiO2 | 18.3 | 78.020 | 97.52 |

| P2O5 | 0.0845 | 0.02396 | - |

| SO3 | 3.74 | 0.2984 | 0 |

| CI | - | 0.02678 | - |

| K2O | 0.788 | 1.097 | 0.01 |

| CaO | 67.7 | 0.1931 | 0.06 |

| TiO2 | 0.369 | - | 1.07 |

| Cr2O3 | 0.0753 | 1.405 | - |

| MnO | 0.0371 | 0.0560 | - |

| Fe2O3 | 2.77 | 0.3170 | 0.16 |

| CuO | 0.0047 | - | - |

| ZnO | 0.0059 | 0.1950 | - |

| SrO | 0.0878 | - | - |

| ZrO2 | - | <0.068 | - |

| Mix ID | Cement (kg/m3) | Silica Fume (kg/m3) | Micro Silica (kg/m3) | Crushed Sand Aggregate (kg/m3) | PVC Fiber (%) | PVC Fiber (kg/m3) | Water (kg/m3) | Plasticizer (kg/m3) |

|---|---|---|---|---|---|---|---|---|

| CSP0 | 340 | - | - | 1712.29 | 0 | 0 | 274.38 | 0 |

| CSP1 | 340 | - | - | 1712.29 | 1 | 14 | 274.38 | 3.4 |

| CSP2 | 340 | - | - | 1712.29 | 2 | 28 | 274.38 | 6.8 |

| CSP3 | 340 | - | - | 1712.29 | 3 | 42 | 274.38 | 6.8 |

| MS15P0 | 289 | - | 51 | 1688.90 | 0 | 0 | 273.88 | 0 |

| MS15P1 | 289 | - | 51 | 1688.90 | 1 | 14 | 273.88 | 3.4 |

| MS15P2 | 289 | - | 51 | 1688.90 | 2 | 28 | 273.88 | 6.8 |

| MS15P3 | 289 | - | 51 | 1688.90 | 3 | 42 | 273.88 | 6.8 |

| MS10P0 | 306 | - | 34 | 1696.86 | 0 | 0 | 274.04 | 0 |

| MS10P1 | 306 | - | 34 | 1696.86 | 1 | 14 | 274.04 | 3.4 |

| MS10P2 | 306 | - | 34 | 1696.86 | 2 | 28 | 274.04 | 6.8 |

| MS10P3 | 306 | - | 34 | 1696.86 | 3 | 42 | 274.04 | 6.8 |

| MS5P0 | 323 | - | 17 | 1704.83 | 0 | 0 | 274.21 | 0 |

| MS5P1 | 323 | - | 17 | 1704.83 | 1 | 14 | 274.21 | 3.4 |

| MS5P2 | 323 | - | 17 | 1704.83 | 2 | 28 | 274.21 | 6.8 |

| MS5P3 | 323 | - | 17 | 1704.83 | 3 | 42 | 274.21 | 6.8 |

| SF15P0 | 289 | 51 | - | 1696.60 | 0 | 0 | 274.04 | 0 |

| SF15P1 | 289 | 51 | - | 1696.60 | 1 | 14 | 274.04 | 3.4 |

| SF15P2 | 289 | 51 | - | 1696.60 | 2 | 28 | 274.04 | 6.8 |

| SF15P3 | 289 | 51 | - | 1696.60 | 3 | 42 | 274.04 | 6.8 |

| SF10P0 | 306 | 34 | - | 1702 | 0 | 0 | 274.15 | 0 |

| SF101 | 306 | 34 | - | 1702 | 1 | 14 | 274.15 | 3.4 |

| SF10P2 | 306 | 34 | - | 1702 | 2 | 28 | 274.15 | 6.8 |

| SF10P3 | 306 | 34 | - | 1702 | 3 | 42 | 274.15 | 6.8 |

| SF5P0 | 323 | 17 | - | 1707.39 | 0 | 0 | 274.27 | 0 |

| SF5P1 | 323 | 17 | - | 1707.39 | 1 | 14 | 274.27 | 3.4 |

| SF5P2 | 323 | 17 | - | 1707.39 | 2 | 28 | 274.27 | 6.8 |

| SF5P3 | 323 | 17 | - | 1707.39 | 3 | 42 | 274.27 | 6.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahmood, R.A.; Kockal, N.U. Effects of Silica Fume and Micro Silica on the Properties of Mortars Containing Waste PVC Plastic Fibers. Microplastics 2022, 1, 587-609. https://doi.org/10.3390/microplastics1040041

Mahmood RA, Kockal NU. Effects of Silica Fume and Micro Silica on the Properties of Mortars Containing Waste PVC Plastic Fibers. Microplastics. 2022; 1(4):587-609. https://doi.org/10.3390/microplastics1040041

Chicago/Turabian StyleMahmood, Rawa Ahmed, and Niyazi Ugur Kockal. 2022. "Effects of Silica Fume and Micro Silica on the Properties of Mortars Containing Waste PVC Plastic Fibers" Microplastics 1, no. 4: 587-609. https://doi.org/10.3390/microplastics1040041

APA StyleMahmood, R. A., & Kockal, N. U. (2022). Effects of Silica Fume and Micro Silica on the Properties of Mortars Containing Waste PVC Plastic Fibers. Microplastics, 1(4), 587-609. https://doi.org/10.3390/microplastics1040041