Stab-Resistant Performance of the Well-Engineered Soft Body Armor Materials Using Shear Thickening Fluid

Abstract

:1. Introduction

2. Results and Discussion

2.1. Rheological Behavior of STF

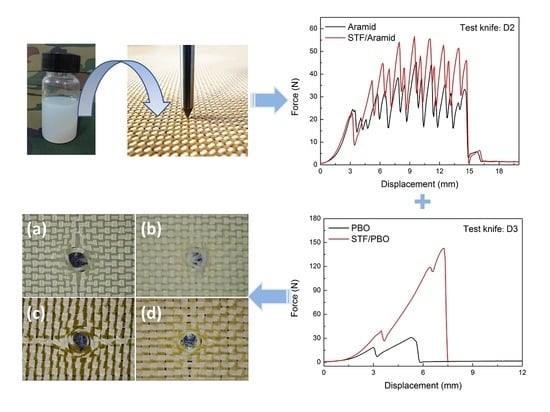

2.2. Quasi-Static Behaviors of the STF/Fabrics

2.3. Dynamic Impact Behaviors of the STF/Fabrics

2.4. Microstructures of the Neat and STF-Treated Fabrics

3. Materials and Methods

3.1. Materials

3.2. Preparation and Rheological Characterization of STF

3.3. Treatment of Fabrics with STF

3.4. Quasi-Static Impact Tests

3.5. Dynamic Impact Tests

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Crouch, I.G. Body armour—New materials, new systems. Def. Technol. 2019, 15, 241–253. [Google Scholar] [CrossRef]

- Mawkhlieng, U.; Majumdar, A. Soft body armour. Text Prog. 2019, 51, 139–224. [Google Scholar] [CrossRef]

- Horsfall, I. Key issues in body armour: Threats, materials and design. In Advances in Military Textiles & Personal Equipment; Sparks, E., Ed.; Woodhead Publishing: London, UK, 2002; pp. 3–20. [Google Scholar]

- Mawkhlieng, U.; Majumdar, A.; Laha, A. A review of fibrous materials for soft body armour applications. RSC Adv. 2020, 10, 1066–1086. [Google Scholar] [CrossRef]

- Gopinath, G.; Zheng, J.Q.; Batra, R.C. Effect of matrix on ballistic performance of soft body armor. Compos. Struct. 2012, 94, 2690–2696. [Google Scholar] [CrossRef]

- Kim, H.; Nam, I. Stab resisting behavior of polymeric resin reinforced p-aramid fabrics. J. Appl. Polym. Sci. 2012, 123, 2733–2742. [Google Scholar] [CrossRef]

- Hosur, M.V.; Mayo Jr, J.B.; Wetzel, E.; Jeelani, S. Studies on the Fabrication and Stab Resistance Characterization of Novel Thermoplastic-Kevlar Composites. Solid State Phenom. 2008, 136, 83–92. [Google Scholar] [CrossRef]

- Li, C.S.; Huang, X.C.; Li, Y.; Yang, N.; Shen, Z.; Fan, X.H. Stab resistance of UHMWPE fiber composites impregnated with thermoplastics. Polym. Adv. Technol. 2014, 25, 1014–1019. [Google Scholar] [CrossRef]

- Wagner, N.J.; Brady, J.F. Shear thickening in colloidal dispersions. Phys. Today 2009, 62, 27–32. [Google Scholar] [CrossRef] [Green Version]

- Barnes, H.A. Shear-Thickening (Dilatancy) in suspensions of non-aggregating solid particles dispersed in newtonian liquids. J. Rheol. 1999, 33, 329–366. [Google Scholar] [CrossRef]

- Gurgen, S.; Kushan, M.C.; Li, W. Shear thickening fluids in protective applications: A review. Prog. Polym. Sci. 2017, 75, 48–72. [Google Scholar] [CrossRef]

- Brown, E.; Jaeger, H.M. Shear thickening in concentrated suspensions: Phenomenology, mechanisms, and relations to jamming. Rep. Prog. Phys. 2014, 77, 046602. [Google Scholar]

- Lee, Y.S.; Wagner, N.J. Rheological properties and small-angle neutron scattering of a shear thickening, nanoparticle dispersion at high shear rates. Ind. Eng. Chem. Res. 2006, 45, 7015–7024. [Google Scholar] [CrossRef]

- Hassan, T.A.; Rangari, V.K.; Jeelani, S. Synthesis, processing and characterization of shear thickening fluid (STF) impregnated fabric composites. Mat. Sci. Eng. A 2010, 527, 2892–2899. [Google Scholar] [CrossRef]

- Hasanzadeh, M.; Mottaghitalab, V.; Sharma, P. Puncture resistance enhancement of woven fabrics using concentrated nanosilica suspension. Procedia Eng. 2017, 173, 1494–1498. [Google Scholar] [CrossRef]

- Kang, T.J.; Hong, K.H.; Yoo, M.R. Preparation and properties of fumed silica/Kevlar composite fabrics for application of stab resistant material. Fiber Polym. 2010, 11, 719–724. [Google Scholar] [CrossRef]

- Yeh, S.K.; Lin, J.J.; Zhuang, H.Y.; Chen, Y.C.; Chang, H.C.; Zheng, J.Y.; Yang, L.Y.; Lee, K.C.; Chen, Y.L.; Rwei, S.P. Light shear thickening fluid (STF)/Kevlar composites with improved ballistic impact strength. J. Polym. Res. 2019, 26, 155. [Google Scholar] [CrossRef]

- Joselin, R.; Wilson, W.J. Investigation on impact strength properties of kevlar fabric using different shear thickening fluid composition. Def. Sci. J. 2014, 64, 236–243. [Google Scholar] [CrossRef] [Green Version]

- Santos, T.F.; Santos, C.M.S.; Aquino, M.S.; Ionesi, D.; Medeiros, J.I. Influence of silane coupling agent on shear thickening fluids (STF) for personal protection. J. Mater. Res. Technol. 2019, 8, 4032–4039. [Google Scholar] [CrossRef]

- Gürgen, S.; Kuşhan, M.C. The stab resistance of fabrics impregnated with shear thickening fluids including various particle size of additives. Compos. Part A-Appl. S 2017, 94, 50–60. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, X.; Wang, Y.; Yuan, Z. Stabbing resistance of body armour panels impregnated with shear thickening fluid. Compos. Struct. 2017, 163, 465–473. [Google Scholar] [CrossRef] [Green Version]

- Li, T.T.; Dai, W.; Wu, L.; Peng, H.K.; Zhang, X.; Shiu, B.C.; Lin, J.H.; Lou, C.W. Effects of STF and fiber characteristics on quasi-static stab resistant properties of shear thickening fluid (STF)-impregnated UHMWPE/Kevlar composite fabrics. Fibers Polym. 2019, 20, 328–336. [Google Scholar] [CrossRef]

- Gong, X.; Xu, Y.; Zhu, W.; Xuan, S.; Jiang, W.F.; Jiang, W.Q. Study of the knife stab and puncture-resistant performance for shear thickening fluid enhanced fabric. J. Compos. Mater. 2014, 48, 641–657. [Google Scholar] [CrossRef]

- Baharvandi, H.R.; Khaksari, P.; Alebouyeh, M.; Alizadeh, M.; Khojasteh, J.; Kordani, N. Investigating the quasi-static puncture resistance of p-aramid nanocomposite impregnated with the shear thickening fluid. J. Reinf. Plast. Comp. 2014, 33, 2064–2072. [Google Scholar] [CrossRef]

- Li, W.; Xiong, D.; Zhao, X.; Sun, L.; Liu, J. Dynamic stab resistance of ultra-high molecular weight polyethylene fabric impregnated with shear thickening fluid. Mater. Des. 2016, 102, 162–167. [Google Scholar] [CrossRef]

- Wei, R.; Dong, B.; Wang, F.; Yang, J.; Jiang, Y.; Zhai, W.; Li, H. Effects of silica morphology on the shear-thickening behavior of shear thickening fluids and stabbing resistance of fabric composites. J. Appl. Polym. Sci. 2020, 137, 48809. [Google Scholar] [CrossRef]

- Stöber, W.; Fink, A.; Bohn, E. Controlled growth of monodisperse silica spheres in the micron size range. J. Colloid Interf. Sci. 1968, 26, 62–69. [Google Scholar] [CrossRef]

| Samples | Tool | Peak Piercing Force (N) | Average (N) | Standard Deviation |

|---|---|---|---|---|

| P-aramid fabric | D2 | 45.1; 47.0; 40.5 | 44.2 | 3.3 |

| STF/P-aramid fabric | D2 | 56.6; 46.2; 47.4 | 50.1 | 5.7 |

| PBO fabric | D2 | 55.9; 63.2; 48.4 | 55.8 | 7.4 |

| STF/PBO fabric | D2 | 81.1; 65.8; 71.7 | 72.9 | 7.7 |

| Carbon fabric | D2 | 13.8; 14.3; 9.9 | 12.7 | 2.4 |

| STF/Carbon fabric | D2 | 13.9; 11.5; 12.5 | 12.6 | 1.2 |

| Samples | Tool | Peak Piercing Force (N) | Average (N) | Standard Deviation |

|---|---|---|---|---|

| P-aramid fabric | D3 | 129.9; 142.1; 114.6 | 128.9 | 13.8 |

| STF/P-aramid fabric | D3 | 275.6; 254.4; 234.1 | 254.7 | 20.8 |

| PBO fabric | D3 | 30.9; 20.1; 26.8 | 25.9 | 5.5 |

| STF/PBO fabric | D3 | 142.7; 110.1; 153.4 | 135.4 | 22.6 |

| Carbon fabric | D3 | 16.6; 9.6; 10.5 | 12.2 | 3.8 |

| STF/Carbon fabric | D3 | 20.3; 18.5; 20.0 | 19.6 | 1.0 |

| Samples | Areal Density (g/m2) | Fibre Specification | Fiber Tensile Strength (GPa) |

|---|---|---|---|

| P-aramid fabric | 200 | 840 D | 3.4 |

| PBO fabric | 206 | 1000 D | 5.8 |

| Carbon fabric | 200 | 3 K | 2.3 |

| Samples | STF Content (wt.%) | Areal Density (g/m2) |

|---|---|---|

| STF/P-aramid fabric | 24.8 | 266 |

| STF/PBO fabric | 24.5 | 273 |

| STF/Carbon fabric | 27.0 | 274 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, R.; Dong, B.; Zhai, W.; Li, H. Stab-Resistant Performance of the Well-Engineered Soft Body Armor Materials Using Shear Thickening Fluid. Molecules 2022, 27, 6799. https://doi.org/10.3390/molecules27206799

Wei R, Dong B, Zhai W, Li H. Stab-Resistant Performance of the Well-Engineered Soft Body Armor Materials Using Shear Thickening Fluid. Molecules. 2022; 27(20):6799. https://doi.org/10.3390/molecules27206799

Chicago/Turabian StyleWei, Rubin, Bin Dong, Wen Zhai, and Hui Li. 2022. "Stab-Resistant Performance of the Well-Engineered Soft Body Armor Materials Using Shear Thickening Fluid" Molecules 27, no. 20: 6799. https://doi.org/10.3390/molecules27206799

APA StyleWei, R., Dong, B., Zhai, W., & Li, H. (2022). Stab-Resistant Performance of the Well-Engineered Soft Body Armor Materials Using Shear Thickening Fluid. Molecules, 27(20), 6799. https://doi.org/10.3390/molecules27206799