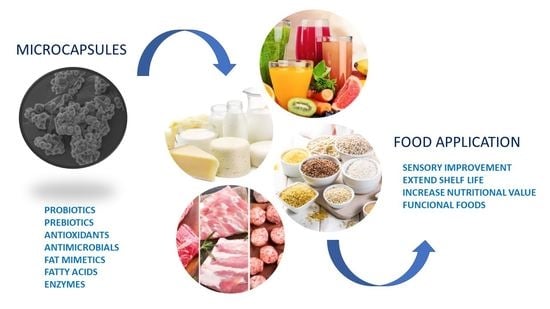

The Role of Microencapsulation in Food Application

Abstract

:1. Introduction

2. Microcapsules in Food Preservation

2.1. Microcapsules Containing Antimicrobials

2.1.1. Meat

2.1.2. Milk and Derivates

2.2. Microcapsules Containing Antioxidants

Meat

3. Microcapsules in Functional Foods

3.1. Incorporation of Fatty Acids

3.1.1. Meat

3.1.2. Milk and Derivates

3.1.3. Cereals and Derivates

3.1.4. Fruit and Juices

3.2. Microcapsules Containg Prebiotics and Probiotics

3.2.1. Meat

3.2.2. Milk and Derivates

3.2.3. Cereals and Derivates

3.2.4. Fruits and Juices

3.2.5. Other Products

3.3. Microcapsules with Antioxidants in Functional Products

3.3.1. Milk and Derivates

3.3.2. Cereals and Derivates

3.4. Other Functional Benefits of Microcapsules

3.4.1. Milk and Derivates

3.4.2. Cereals and Derivates

4. Microcapsules for Fat Replacement

Fat Replacement in Meat

5. Application of Microcapsules for Sensory Improvement

5.1. Meat

5.2. Milk and Derivates

5.3. Cereals and Derivates

5.4. Fruits and Juices

6. Perspectives of Microencapsulation in Foods

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dias, M.I.; Ferreira, I.C.F.R.; Barreiro, M.F. Microencapsulation of bioactives for food applications. Food Funct. 2015, 6, 1035–1052. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Đorđević, V.; Balanč, B.; Belščak-Cvitanović, A.; Lević, S.; Trifković, K.; Kalušević, A.; Kostić, I.; Komes, D.; Bugarski, B.; Nedović, V. Trends in Encapsulation Technologies for Delivery of Food Bioactive Compounds. Food Eng. Rev. 2015, 7, 452–490. [Google Scholar] [CrossRef]

- Oxley, J. Chapter 4—Overview of Microencapsulation Process Technologies. In Microencapsulation in the Food Industry; Gaonkar, A.G., Vasisht, N., Khare, A.R., Sobel, R., Eds.; Academic Press: San Diego, CA, USA, 2014; pp. 35–46. [Google Scholar]

- Gul, O. Microencapsulation of Lactobacillus casei Shirota by spray drying using different combinations of wall materials and application for probiotic dairy dessert. J. Food Process. Preserv. 2017, 41, e13198. [Google Scholar] [CrossRef]

- Rutz, J.K.; Borges, C.D.; Zambiazi, R.C.; Da Rosa, C.G.; Da Silva, M.M. Elaboration of microparticles of carotenoids from natural and synthetic sources for applications in food. Food Chem. 2016, 202, 324–333. [Google Scholar] [CrossRef]

- Papillo, V.A.; Locatelli, M.; Travaglia, F.; Bordiga, M.; Garino, C.; Arlorio, M.; Coïsson, J.D. Spray-dried polyphenolic extract from Italian black rice (Oryza sativa L., var. Artemide) as new ingredient for bakery products. Food Chem. 2018, 269, 603–609. [Google Scholar] [CrossRef]

- Ezhilarasi, P.N.; Indrani, D.; Jena, B.S.; Anandharamakrishnan, C. Microencapsulation of Garcinia fruit extract by spray drying and its effect on bread quality. J. Sci. Food Agric. 2014, 94, 1116–1123. [Google Scholar] [CrossRef]

- Habibi, A.; Keramat, J.; Hojjatoleslamy, M.; Tamjidi, F. Preparation of Fish Oil Microcapsules by Complex Coacervation of Gelatin-Gum Arabic and their Utilization for Fortification of Pomegranate Juice. J. Food Process Eng. 2017, 40, e12385. [Google Scholar] [CrossRef]

- Chen, K.; Zhang, M.; Mujumdar, A.S.; Wang, H. Quinoa protein-gum Arabic complex coacervates as a novel carrier for eugenol: Preparation, characterization and application for minced pork preservation. Food Hydrocoll. 2021, 120, 106915. [Google Scholar] [CrossRef]

- Najjaa, H.; Chekki, R.; Elfalleh, W.; Tlili, H.; Jaballah, S.; Bouzouita, N. Freeze-dried, oven-dried, and microencapsulation of essential oil from Allium sativum as potential preservative agents of minced meat. Food Sci. Nutr. 2020, 8, 1995–2003. [Google Scholar] [CrossRef] [Green Version]

- Ramírez-Santiago, C.; Lobato-Calleros, C.; Espinosa-Andrews, H.; Vernon-Carter, E.J. Viscoelastic properties and overall sensory acceptability of reduced-fat Petit-Suisse cheese made by replacing milk fat with complex coacervate. Dairy Sci. Technol. 2012, 92, 383–398. [Google Scholar] [CrossRef] [Green Version]

- Ng, S.L.; Lai, K.W.; Nyam, K.L.; Pui, L.P. Microencapsulation of Lactobacillus plantarum 299v incorporated with oli-gofructose in chitosan coated-alginate beads and its storage stability in ambarella juice. Malays. J. Microbiol. 2019, 15, 408–418. [Google Scholar]

- Shehata, M.; Abd-Rabou, H.S.; El Sohaimy, S. Plant Extracts in Probiotic Encapsulation: Evaluation of their Effects on Strains Survivability in Juice and Drinkable Yogurt During Storage and an in-vitro Gastrointestinal Model. J. Pure Appl. Microbiol. 2019, 13, 609–617. [Google Scholar] [CrossRef] [Green Version]

- Nami, Y.; Lornezhad, G.; Kiani, A.; Abdullah, N.; Haghshenas, B. Alginate-Persian Gum-Prebiotics microencapsulation impacts on the survival rate of Lactococcus lactis ABRIINW-N19 in orange juice. LWT 2020, 124, 109190. [Google Scholar] [CrossRef]

- Arslan-Tontul, S.; Erbas, M.; Gorgulu, A. The Use of Probiotic-Loaded Single- and Double-Layered Microcapsules in Cake Production. Probiotics Antimicrob. Proteins 2019, 11, 840–849. [Google Scholar] [CrossRef] [PubMed]

- Heck, R.T.; Fagundes, M.B.; Cichoski, A.J.; de Menezes, C.R.; Barin, J.S.; Lorenzo, J.M.; Wagner, R.; Campagnol, P.C.B. Volatile compounds and sensory profile of burgers with 50% fat replacement by microparticles of chia oil enriched with rosemary. Meat Sci. 2019, 148, 164–170. [Google Scholar] [CrossRef]

- Turhan, E.U.; Erginkaya, Z.; Selli, S. The effect of microencapsulated Lactobacillus rhamnosus and storage period on aroma properties of Turkish dry-fermented sausage (sucuk). J. Food Meas. Charact. 2017, 11, 2131–2141. [Google Scholar] [CrossRef]

- Juvi, D.; Sthefanie, S.; Sugata, M.; Jap, L.; Andrian, D.; Rizkinata, D.; Michelle, M.; Jan, T.J. Evaluation of microencapsulated local isolates Lactobacillus casei 97/l3 and Lactobacillus delbrueckii 94/L4 for improved probiotic and yogurt starter culture application. Microbiol. Biotechnol. Lett. 2019, 47, 211–219. [Google Scholar] [CrossRef]

- Haffner, F.B.; Pasc, A. Freeze-dried alginate-silica microparticles as carriers of probiotic bacteria in apple juice and beer. LWT Food Sci. Technol. 2018, 91, 175–179. [Google Scholar] [CrossRef]

- Gupta, C.; Chawla, P.; Arora, S.; Tomar, S.; Singh, A. Iron microencapsulation with blend of gum arabic, maltodextrin and modified starch using modified solvent evaporation method—Milk fortification. Food Hydrocoll. 2015, 43, 622–628. [Google Scholar] [CrossRef]

- Akgün, D.; Gültekin-Özgüven, M.; Yücetepe, A.; Altin, G.; Gibis, M.; Weiss, J.; Özçelik, B. Stirred-type yoghurt incorporated with sour cherry extract in chitosan-coated liposomes. Food Hydrocoll. 2020, 101, 105532. [Google Scholar] [CrossRef]

- MacDonald, R.; Reitmeier, C. Chapter 6—Food Processing. In Understanding Food Systems; MacDonald, R., Reitmeier, C., Eds.; Academic Press: Cambridge, MA, USA, 2017; pp. 179–225. [Google Scholar]

- Lima, M.; de Sousa, C.P.; Fernandez-Prada, C.; Harel, J.; Dubreuil, J.; de Souza, E. A review of the current evidence of fruit phenolic compounds as potential antimicrobials against pathogenic bacteria. Microb. Pathog. 2019, 130, 259–270. [Google Scholar] [CrossRef]

- Xu, L.; Cheng, J.-R.; Liu, X.-M.; Zhu, M.-J. Effect of microencapsulated process on stability of mulberry polyphenol and oxidation property of dried minced pork slices during heat processing and storage. LWT 2019, 100, 62–68. [Google Scholar] [CrossRef]

- Wang, Y.-F.; Jia, J.-X.; Tian, Y.-Q.; Shu, X.; Ren, X.-J.; Guan, Y.; Yan, Z.-Y. Antifungal effects of clove oil microcapsule on meat products. LWT Food Sci. Technol. 2018, 89, 604–609. [Google Scholar] [CrossRef]

- Tao, F.; Hill, L.E.; Peng, Y.; Gomes, C.L. Synthesis and characterization of β-cyclodextrin inclusion complexes of thymol and thyme oil for antimicrobial delivery applications. LWT 2014, 59, 247–255. [Google Scholar] [CrossRef]

- Huq, T.; Riedl, B.; Bouchard, J.; Salmieri, S.; Lacroix, M. Microencapsulation of nisin in alginate-cellulose nanocrystal (CNC) microbeads for prolonged efficacy against Listeria monocytogenes. Cellulose 2014, 21, 4309–4321. [Google Scholar] [CrossRef]

- Petsong, K.; Benjakul, S.; Vongkamjan, K. Evaluation of storage conditions and efficiency of a novel microencapsulated Salmonella phage cocktail for controlling S. enteritidis and S. typhimurium in-vitro and in fresh foods. Food Microbiol. 2019, 83, 167–174. [Google Scholar] [CrossRef]

- Huq, T.; Vu, K.D.; Riedl, B.; Bouchard, J.; Lacroix, M. Synergistic effect of gamma (γ)-irradiation and microencapsulated antimicrobials against Listeria monocytogenes on ready-to-eat (RTE) meat. Food Microbiol. 2015, 46, 507–514. [Google Scholar] [CrossRef] [Green Version]

- Moghanjougi, Z.M.; Bari, M.R.; Khaledabad, M.A.; Almasi, H.; Amiri, S. Bio-preservation of white brined cheese (Feta) by using probiotic bacteria immobilized in bacterial cellulose: Optimization by response surface method and characterization. LWT 2020, 117, 108603. [Google Scholar] [CrossRef]

- dos Reis, A.S.; Diedrich, D.; de Moura, C.; Pereira, D.; Almeida, J.d.F.; da Silva, L.D.; Plata-Oviedo, M.S.V.; Tavares, T.A.W.; Carpes, S.T. Physico-chemical characteristics of microencapsulated propolis co-product extract and its effect on storage stability of burger meat during storage at −15 °C. LWT Food Sci. Technol. 2017, 76, 306–313. [Google Scholar] [CrossRef]

- Song, J.; Jiang, L.; Peng, H.; Qi, M.; Zhang, M.; Qi, J.; Ma, C.; Li, H.; Zhang, D. Microcapsule prepared by extruding starch and procyanidins inhibited protein oxidation and improved quality of chicken sausages. LWT 2022, 154, 112617. [Google Scholar] [CrossRef]

- Cunha, L.; Monteiro, M.L.G.; Costa-Lima, B.R.; Guedes-Oliveira, J.M.; Alves, V.H.; Almeida, A.L.; Tonon, R.V.; Rosenthal, A.; Conte-Junior, C.A. Effect of microencapsulated extract of pitaya (Hylocereus costaricensis) peel on color, texture and oxidative stability of refrigerated ground pork patties submitted to high pressure processing. Innov. Food Sci. Emerg. Technol. 2018, 49, 136–145. [Google Scholar] [CrossRef]

- Cunha, L.C.M.; Monteiro, M.L.G.; Costa-Lima, B.R.C.; Guedes-Oliveira, J.M.; Alves, V.H.M.; Almeida, A.L.; Tonon, R.V.; Rosenthal, A.; Conte-Junior, C.A. Effect of microencapsulated extract of pitaya (Hylocereus costaricensis) peel on oxidative quality parameters of refrigerated ground pork patties subjected to UV-C radiation. J. Food Process. Preserv. 2021, 45, 136–145. [Google Scholar] [CrossRef]

- Nicoletti, M. Nutraceuticals and botanicals: Overview and perspectives. Int. J. Food Sci. Nutr. 2012, 63, 2–6. [Google Scholar] [CrossRef] [PubMed]

- Moghadasian, M.H.; Shahidi, F. Fatty Acids. In International Encyclopedia of Public Health, 2nd ed.; Second, E., Quah, S.R., Eds.; Academic Press: Oxford, UK, 2017; pp. 114–122. [Google Scholar]

- Vargas-Ramella, M.; Pateiro, M.; Barba, F.J.; Franco, D.; Campagnol, P.C.B.; Munekata, P.E.S.; Tomasevic, I.; Domínguez, R.; Lorenzo, J.M. Microencapsulation of healthier oils to enhance the physicochemical and nutritional properties of deer pâté. LWT 2020, 125, 109223. [Google Scholar] [CrossRef]

- Pérez-Palacios, T.; Ruiz-Carrascal, J.; Jiménez-Martín, E.; Solomando, J.C.; Antequera, T. Improving the lipid profile of ready-to-cook meat products by addition of omega-3 microcapsules: Effect on oxidation and sensory analysis. J. Sci. Food Agric. 2018, 98, 5302–5312. [Google Scholar] [CrossRef]

- Jiménez-Martín, E.; Pérez-Palacios, T.; Carrascal, J.R.; Rojas, T.A. Enrichment of Chicken Nuggets with Microencapsulated Omega-3 Fish Oil: Effect of Frozen Storage Time on Oxidative Stability and Sensory Quality. Food Bioprocess Technol. 2016, 9, 285–297. [Google Scholar] [CrossRef]

- Domínguez, R.; Pateiro, M.; Agregán, R.; Lorenzo, J.M. Effect of the partial replacement of pork backfat by microencapsulated fish oil or mixed fish and olive oil on the quality of frankfurter type sausage. J. Food Sci. Technol. 2017, 54, 26–37. [Google Scholar] [CrossRef] [Green Version]

- Novaes, S.S.C.; Dantas, F.B.H.; Alvim, I.D.; de Oliveira Miguel, A.M.R.; Dantas, S.T.; Alves, R.M.V. Stability of omega-3 enriched milk powder in different commercial packages stored under accelerated conditions of temperature and relative humidity. Int. Dairy J. 2019, 88, 1–9. [Google Scholar] [CrossRef]

- Mora, H.B.; Piñeros, M.; Moreno, D.E.; Restrepo, S.R.; Jaramillo, J.C.; Solano, Ó.A.; Fernandez-Niño, M.; Barrios, A.G. Multiscale design of a dairy beverage model composed of Candida utilis single cell protein supplemented with oleic acid. J. Dairy Sci. 2019, 102, 9749–9762. [Google Scholar] [CrossRef]

- Gomez-Betancur, A.M.; Carmona-Tamayo, R.; Martínez-Álvarez, O.L.; Casanova-Yepes, H.; Torres-Oquendo, J.D. Effect of fat substitution using long-chain inulin and fortification with microencapsulated calcium in the rheological and sensory properties of yogurt mousse. J. Food Process Eng. 2020, e13433. [Google Scholar] [CrossRef]

- Hasani, S.; Ojagh, S.M.; Hasani, M.; Ghorbani, M. Sensory and technological properties of developed functional bread enriched by microencapsulated fish oil. Prog. Nutr. 2019, 21, 406–415. [Google Scholar]

- González, A.; Martínez, M.L.; León, A.E.; Ribotta, P.D. Effects on bread and oil quality after functionalization with microencapsulated chia oil. J. Sci. Food Agric. 2018, 98, 4903–4910. [Google Scholar] [CrossRef]

- Jeyakumari, A.; Janarthanan, G.; Chouksey, M.K.; Venkateshwarlu, G. Effect of fish oil encapsulates incorporation on the physico-chemical and sensory properties of cookies. J. Food Sci. Technol. 2016, 53, 856–863. [Google Scholar] [CrossRef] [Green Version]

- Beikzadeh, S.; Shojaee-Aliabadi, S.; Dadkhodazade, E.; Sheidaei, Z.; Abedi, A.-S.; Mirmoghtadaie, L.; Hosseini, S.M. Comparison of Properties of Breads Enriched with Omega-3 Oil Encapsulated in β-Glucan and Saccharomyces cerevisiae Yeast Cells. Appl. Food Biotechnol 2020, 7, 11–20. [Google Scholar]

- Bowles, M. Chapter 51—Probiotic Agents. In Canine and Feline Gastroenterology; Washabau, R.J., Day, M.J., Eds.; W.B. Saunders: Saint Louis, MO, USA, 2013; pp. 526–529. [Google Scholar]

- Barragán-Martínez, L.P.; Totosaus, A.; Pérez-Chabela, M.D.L. Probiotication of cooked sausages employing agroindustrial coproducts as prebiotic co-encapsulant in ionotropic alginate–pectin gels. Int. J. Food Sci. Technol. 2020, 55, 1088–1096. [Google Scholar] [CrossRef]

- Machado Vasconcelos, L.I.; da Silva-Buzanello, R.A.; Kalschne, D.L.; Scremin, F.R.; Bittencourt, P.R.S.; Dias, J.T.G.; Canan, C.; Corso, M.P. Functional fermented sausages incorporated with microencapsulated Lactobacillus plan-tarum BG 112 in Acrycoat S100. LWT 2021, 148, 111596. [Google Scholar] [CrossRef]

- Bosnea, L.A.; Moschakis, T.; Biliaderis, C.G. Microencapsulated cells of Lactobacillus paracasei subsp. paracasei in biopolymer complex coacervates and their function in a yogurt matrix. Food Funct. 2017, 8, 554–562. [Google Scholar] [CrossRef]

- Gómez-Mascaraque, L.G.; Miralles, B.; Recio, I.; López-Rubio, A. Microencapsulation of a whey protein hydrolysate within micro-hydrogels: Impact on gastrointestinal stability and potential for functional yoghurt development. J. Funct. Foods 2016, 26, 290–300. [Google Scholar] [CrossRef] [Green Version]

- Moghaddas Kia, E.M.; Ghasempour, Z.; Ghanbari, S.; Pirmohammadi, R.; Ehsani, A. Development of probiotic yogurt by incorporation of milk protein concentrate (MPC) and microencapsulated Lactobacillus paracasei in gellan-caseinate mixture. Br. Food J. 2018, 120, 1516–1528. [Google Scholar] [CrossRef]

- Wang, M.; Wang, C.; Gao, F.; Guo, M. Effects of polymerised whey protein-based microencapsulation on survivability of Lactobacillus acidophilus LA-5 and physiochemical properties of yoghurt. J. Microencapsul. 2018, 35, 504–512. [Google Scholar] [CrossRef]

- Verruck, S.; Barretta, C.; Miotto, M.; Canella, M.H.M.; de Liz, G.R.; Maran, B.M.; Garcia, S.G.; da Silveira, S.M.; Vieira, C.R.W.; da Cruz, A.G.; et al. Evaluation of the interaction between microencapsulated Bifidobacterium BB-12 added in goat’s milk Frozen Yogurt and Escherichia coli in the large intestine. Food Res. Int. 2020, 127, 108690. [Google Scholar] [CrossRef]

- Dokoohaki, Z.N.; Sekhavatizadeh, S.S.; Hosseinzadeh, S. Dairy dessert containing microencapsulated Lactobacillus rhamnosus (ATCC 53103) with quince seed mucilage as a coating material. LWT 2019, 115, 108429. [Google Scholar] [CrossRef]

- Sengsaengthong, S.; Oonsivilai, R. Effect of microencapsulation of Lactobacillus sp. 21C2-10 isolated from cassava pulp on physicochemical, sensorial and microbiological characteristics of ice cream. Int. Food Res. J. 2019, 26, 585–594. [Google Scholar]

- Nambiar, R.B.; Sellamuthu, P.S.; Perumal, A.B. Development of milk chocolate supplemented with microencapsulated Lactobacillus plantarum HM47 and to determine the safety in a Swiss albino mice model. Food Control 2018, 94, 300–306. [Google Scholar] [CrossRef]

- Shu, G.; He, Y.; Chen, L.; Song, Y.; Meng, J.; Chen, H. Microencapsulation of Bifidobacterium bifidum BB01 by xanthan–chitosan: Preparation and its stability in pure milk. Artif. Cells Nanomed. Biotechnol. 2018, 46, 588–596. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Borrás-Enríquez, A.J.; de la Cruz-Martínez, A.; Delgado-Portales, R.E.; González-Chávez, M.M.; Abud-Archila, M.; Moscosa-Santillán, M. Microbiological-physicochemical assessment and gastrointestinal simulation of functional (Probiotic and symbiotic) gouda-type cheeses during ripening. Evaluación microbiológica, fisicoquímica y simulación gastrointestinal de quesos funcionales Probiótico. Rev. Mex. Ing. Quim. 2018, 17, 791–803. [Google Scholar] [CrossRef]

- Seyedain-Ardabili, M.; Sharifan, A.; Tarzi, B.G. The production of synbiotic bread by microencapsulation. Food Technol. Biotechnol. 2016, 54, 52–59. [Google Scholar] [CrossRef]

- Olivares, A.; Soto, C.; Caballero, E.; Altamirano, C. Survival of microencapsulated Lactobacillus casei (prepared by vibration technology) in fruit juice during cold storage. Electron. J. Biotechnol. 2019, 42, 42–48. [Google Scholar] [CrossRef]

- Phoem, A.N.; Chanthachum, S.; Voravuthikunchai, S.P. Applications of Microencapsulated Bifidobacterium Longum with Eleutherine Americana in Fresh Milk Tofu and Pineapple Juice. Nutrients 2015, 7, 2469–2484. [Google Scholar] [CrossRef] [Green Version]

- Dias, C.O.; dos Santos Opuski de Almeida, J.; Pinto, S.S.; de Oliveira Santana, F.C.; Verruck, S.; Müller, C.M.O.; Prudêncio, E.S.; de Mello Castanho Amboni, R.D. Development and physico-chemical characterization of microencapsulated bifidobacteria in passion fruit juice: A functional non-dairy product for probiotic delivery. Food Biosci. 2018, 24, 26–36. [Google Scholar] [CrossRef]

- Azarkhavarani, P.R.; Ziaee, E.; Hosseini, S.M.H. Effect of encapsulation on the stability and survivability of Enterococcus faecium in a non-dairy probiotic beverage. Food Sci. Technol. Int. 2019, 25, 233–242. [Google Scholar] [CrossRef] [PubMed]

- Burns, P.G.; Patrignani, F.; Tabanelli, G.; Vinderola, G.C.; Siroli, L.; Reinheimer, J.A.; Gardini, F.; Lanciotti, R. Potential of high pressure homogenisation on probiotic Caciotta cheese quality and functionality. J. Funct. Foods 2015, 13, 126–136. [Google Scholar] [CrossRef]

- Calabuig-Jiménez, L.; Betoret, E.; Betoret Valls, N.; Patrignani, F.; Barrera Puigdollers, C.; Seguí Gil, L.; Lanciotti, R. High pressures homogenization (HPH) to microencapsulate L. salivarius spp. salivarius in mandarin juice. Probiotic survival and in vitro digestion. J. Food Eng. 2019, 240, 43–48. [Google Scholar] [CrossRef]

- Lieu, M.D.; Le, T.K.N.; Nguyen, T.L.; Dang, T.K.T.; Do, D.G. Effect of calcium-alginate bead and Anoectochilus formosanus hayata extract fluid on the viability of lactobacillus plantarum ATCC 8014 and bioactive compounds in fermented apple juice. Food Res. 2020, 4, 652–658. [Google Scholar] [CrossRef]

- Davì, G.; Santilli, F.; Patrono, C. Nutraceuticals in Diabetes and Metabolic Syndrome. Cardiovasc. Ther. 2010, 28, 216–226. [Google Scholar] [CrossRef]

- Ho, S.; Thoo, Y.Y.; Young, D.J.; Siow, L.F. Stability and recovery of cyclodextrin encapsulated catechin in various food matrices. Food Chem. 2019, 275, 594–599. [Google Scholar] [CrossRef]

- Petrović, J.; Pajin, B.; Lončarević, I.; Šaponjac, V.T.; Nikolić, I.; Ačkar, Đurđica; Zarić, D. Encapsulated sour cherry pomace extract: Effect on the colour and rheology of cookie dough. Food Sci. Technol. Int. 2019, 25, 130–140. [Google Scholar] [CrossRef]

- Tumbas Šaponjac, V.; Ćetković, G.; Čanadanović-Brunet, J.; Pajin, B.; Djilas, S.; Petrović, J.; Lončarević, I.; Stajčić, S.; Vulić, J. Sour cherry pomace extract encapsulated in whey and soy proteins: Incorporation in cookies. Food Chem. 2016, 207, 27–33. [Google Scholar] [CrossRef]

- Hidalgo, A.; Brandolini, A.; Čanadanović-Brunet, J.; Ćetković, G.; Tumbas Šaponjac, V.T. Microencapsulates and extracts from red beetroot pomace modify antioxidant capacity, heat damage and colour of pseudocereals-enriched einkorn water biscuits. Food Chem. 2018, 268, 40–48. [Google Scholar] [CrossRef]

- Pasrija, D.; Ezhilarasi, P.; Indrani, D.; Anandharamakrishnan, C. Microencapsulation of green tea polyphenols and its effect on incorporated bread quality. LWT Food Sci. Technol. 2015, 64, 289–296. [Google Scholar] [CrossRef]

- Ahn, S.-I.; Lee, Y.-K.; Kwak, H.-S. Physicochemical and sensory properties of milk supplemented with lactase microcapsules coated with enteric coating materials. J. Dairy Sci. 2019, 102, 6959–6970. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zhong, Q. Freeze-dried capsules prepared from emulsions with encapsulated lactase as a potential delivery system to control lactose hydrolysis in milk. Food Chem. 2018, 241, 397–402. [Google Scholar] [CrossRef] [PubMed]

- Moslemi, M.; Hosseini, H.; Neyestani, T.R.; Akramzadeh, N.; Fard, R.M.N. Effects of non-digestive polymers used in iron encapsulation on calcium and iron apparent absorption in rats fed by infant formula. J. Trace Elem. Med. Biol. 2018, 50, 393–398. [Google Scholar] [CrossRef] [PubMed]

- Jalili, M. Chemical composition and sensory characteristics of Feta cheese fortified with iron and ascorbic acid. Dairy Sci. Technol. 2016, 96, 579–589. [Google Scholar] [CrossRef] [Green Version]

- Bryszewska, M.A.; Tomás-Cobos, L.; Gallego, E.; Villalba, M.; Rivera, D.; Saa, D.L.T.; Gianotti, A. In vitro bioaccessibility and bioavailability of iron from breads fortified with microencapsulated iron. LWT 2019, 99, 431–437. [Google Scholar] [CrossRef]

- Heck, R.T.; Vendruscolo, R.G.; de Araújo Etchepare, M.; Cichoski, A.J.; de Menezes, C.R.; Barin, J.S.; Lorenzo, J.M.; Wagner, R.; Campagnol, P.C.B. Is it possible to produce a low-fat burger with a healthy n−6/n−3 PUFA ratio without affecting the techno-logical and sensory properties? Meat Sci. 2017, 130, 16–25. [Google Scholar] [CrossRef]

- Lorenzo, J.M.; Munekata, P.E.S.; Pateiro, M.; Campagnol, P.C.B.; Domínguez, R. Healthy Spanish salchichón enriched with encapsulated n − 3 long chain fatty acids in konjac glucomannan matrix. Food Res. Int. 2016, 89, 289–295. [Google Scholar] [CrossRef]

- Krishna, A. An integrative review of sensory marketing: Engaging the senses to affect perception, judgment and behavior. J. Consum. Psychol. 2012, 22, 332–351. [Google Scholar] [CrossRef] [Green Version]

- Bilenler, T.; Karabulut, I.; Candogan, K. Effects of encapsulated starter cultures on microbial and physicochemical properties of traditionally produced and heat treated sausages (sucuks). LWT 2017, 75, 425–433. [Google Scholar] [CrossRef]

- Baldin, J.C.; Michelin, E.C.; Polizer, Y.J.; Rodrigues, I.; de Godoy, S.H.S.; Fregonesi, R.P.; Pires, M.A.; Carvalho, L.T.; Fávaro-Trindade, C.S.; de Lima, C.G.; et al. Microencapsulated jabuticaba (Myrciaria cauliflora) extract added to fresh sausage as natural dye with antioxidant and antimicrobial activity. Meat Sci. 2016, 118, 15–21. [Google Scholar] [CrossRef]

- Arab, M.; Razavi, S.H.; Hosseini, S.M.; Nayebzadeh, K.; Meybodi, N.M.; Khanniri, E.; Mortazavian, A.M. Production and characterization of functional flavored milk and flavored fermented milk using microencap-sulated canthaxanthin. LWT 2019, 114, 108373. [Google Scholar] [CrossRef]

- Kim, G.-Y.; Lee, J.; Lim, S.; Kang, H.; Ahn, S.-I.; Jhoo, J.-W.; Ra, C.-S. Microencapsulation of Caramel Flavor and Properties of Ready-to-drink Milk Beverages Supplemented with Coffee Containing These Microcapsules. Korean J. Food Sci. Anim. Resour. 2019, 39, 780–791. [Google Scholar] [CrossRef] [Green Version]

- Haghighat-Kharazi, S.; Milani, J.M.; Kasaai, M.R.; Khajeh, K. Microencapsulation of α-amylase in beeswax and its application in gluten-free bread as an anti-staling agent. LWT 2018, 92, 73–79. [Google Scholar] [CrossRef]

- Silva, E.K.; Toledo Hijo, A.A.C.; da Costa, J.M.G.; Marques, G.R.; Pereira, J.; Borges, S.V. Influence of the addition of microencapsulated Swiss cheese bioaroma on the technical and sensory qualities of cheese bread. Int. J. Dairy Technol. 2017, 70, 372–379. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, X.; Zhang, J.; Kilmartin, P.A.; Quek, S.Y. Exploring the effects of microencapsulation on odour retention of fermented noni juice. J. Food Eng. 2020, 273, 109892. [Google Scholar] [CrossRef]

| Microencapsulation Technique | Process | Advantages | Disadvantages | Representative References |

|---|---|---|---|---|

| Spray drying | Drying of particles in suspension or in emulsion using hot air. The solution, emulsion or suspension is atomized in the equipment. | High production rates and efficiency Easy handling product powders Reproducibility Low operation cost It is used in a wide variety of compounds, with diverse polarities and compositions. Short time process | Not recommended for thermolabile compounds Nonuniform particles Can form aggregates | [4,6,7] |

| Complex coacervation | Combination of 2 polymers, such as protein and carbohydrate at specific pH value and proportion | Heat-resistant Different core compounds can be used Stable products | Different forms depending on materials Expensive Variable encapsulation efficiency Use of organic solvents | [8,9,10,11] |

| Encapsulation in cyclodextrins | Inclusion molecular complex in a cyclic oligosaccharide | Controlled release of actives Solubility and stability of hydrophobic actives Reduce loss and volatility of compounds | Expensive material Restricted to low-molecular-weight compounds Can form aggregates | [12,13,14] |

| Spray chilling | Microcapsule made up of lipids and the compound of interest, which are atomized in a cold chamber, leaving a solid particle | Low operation cost Suitable for heat-sensitive actives | Scaling parameters (melting, atomizer air temperature and pressure, cooling temperature, feed flow) Rapid release of actives Specific for hydrophobic compounds Nonuniform particles Variable encapsulation efficiency | [15,16] |

| Extrusion | Physical–mechanical process that involves the extrusion of the material through a nozzle | Cost-effective method No need for high temperatures, nor the use organic solvents or any specific pH condition for its elaboration. | Different sized and shaped products Difficulties with viscous solutions | [12,17,18] |

| Freeze drying | Freezing, sublimation (lyophilization) and desorption | Good option for temperature-sensitive compounds | Slow process Styrofoam texture Product cost | [4,7,19] |

| Microencapsulation Technique and Conditions | Wall Material | Core Material | Food System Application | Reference |

|---|---|---|---|---|

| Spray drying (150 °C inlet temperature; feed flow 7 mL/min and airflow 40 m3/h) | Maltodextrin and gum Arabic (50:50, w/w) | Artemide black rice extract (polyphenols 122 ± 4.6 mg/g extract) | Biscuit (0.32% microcapsules in formulation, total polyphenols 975 ± 13 µg/g biscuit) | [6] |

| Complex coacervation (Oil/water emulsion, 50 °C, pH 4, and lyophilized) | Gelatin and gum Arabic (1:3) | Omega-3 fish rich oil | Pomegranate juice (0.04, 0.07, 0.1% powder microcapsules, i.e., 50, 100 and 150 mg DHA + EPA/L) | [8] |

| Modified solvent evaporation (mix solution of core and coat material, sonication at 5 °C with 5-s pulse rate for 15 min, spray in chilled alcohol, and later evaporation) | Gum Arabic, maltodextrin, modified starch (4:1:1) | Ferrous sulphate hepta hydrate | Fresh cow and buffalo milk (1:1), iron salt 25 ppm | [20] |

| Coextrusion (coextrusion equipment with inner (150 µm) and outer nozzles (300 µm), vibration frequency of 300 Hz, pressure 600 mbar, and voltage of 1.5 kV) | Sodium alginate (1.5% w/w) with chitosan (0.1%) and CaCl2 (different concentrations | Lactobacullis plantarum 299v and oligofructose | Ambarella juice (more than 107 CFU/mL) and oligofructose (4%) | [12] |

| Electrospray + mineralization + freeze drying (equipment with stainless steel sterile needle and aluminium plate with collector dish, voltage 7.5 kV, flow 15 mL/h, followed by the addition of (3-aminopropyl)trimethoxysilane and tetramethyl orthosilicate) and freeze drying at −85 °C for 20 h. | Sodium alginate (1.0% w/w) and CaCl2 (1.5 wt%) | Lactobacillus rhamnosus GG | 5.2 × 106 CFU/mL in apple juice (pH 3.6) and 5.2 × 106 CFU/mL in beer (5 vt% alcohol content) | [19] |

| Liposomes + spray drying. Lecithin solution at high-pressure homogenization (25,000 psi) followed by deposition of chitosan layers. Spray dryer conditions: 90 °C outlet temperature, 160 °C inlet temperature, 2.5 cm3/min feed rate and 0.67 m3/min air flow | Lecithin (2% w/w) and Chitosan (0.2%) + maltodextrin (20%) + lecithin (0.05%) | Sour cherry extract | Stirred-type yogurt (pH 4.5; 4 mg GAE/100 g) | [21] |

| Spray chilling + spray drying or spray drying + spray chilling (Spray dryer: 120 °C inlet air temperature and 50 °C outlet air temperature, feed rate 16.5 mL/min. For spray chilling: molten hydrogenated palm oil, homogenized, and spray chilled with nozzle fixed at 38 °C, compressed air at 0.3 bar, aspiration rate of 20 m3/h | Gum arabic and β-cyclodextrin (9:1 w/w) and hydrogenated palm oil | Saccharomyces boulardii, Lactobacillus acidophilus, Bifidobacterium bifidum | Cakes (cream-filled, marmalade-filled, and chocolate-coated; around 1 and 4.3 Log CFU/g after baking) | [15] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Calderón-Oliver, M.; Ponce-Alquicira, E. The Role of Microencapsulation in Food Application. Molecules 2022, 27, 1499. https://doi.org/10.3390/molecules27051499

Calderón-Oliver M, Ponce-Alquicira E. The Role of Microencapsulation in Food Application. Molecules. 2022; 27(5):1499. https://doi.org/10.3390/molecules27051499

Chicago/Turabian StyleCalderón-Oliver, Mariel, and Edith Ponce-Alquicira. 2022. "The Role of Microencapsulation in Food Application" Molecules 27, no. 5: 1499. https://doi.org/10.3390/molecules27051499

APA StyleCalderón-Oliver, M., & Ponce-Alquicira, E. (2022). The Role of Microencapsulation in Food Application. Molecules, 27(5), 1499. https://doi.org/10.3390/molecules27051499