Effect of the Addition of Naringenin Derived from Citrus on the Properties of Epoxy Resin Compositions

Abstract

:1. Introduction

2. Results and Discussion

2.1. Microscopic Characteristics of Samples

2.2. Determination of the Physicochemical Properties of Epoxy Resin Compositions

2.3. Determination of Microbiological Properties of Samples

3. Materials and Methods

3.1. Preparation of Composites Based on Epoxy Resin and Naringenin

3.2. Microstructure Observations

3.3. Solar Aging

3.4. Determination of Sample Density

3.5. Determination of Contact Angles and Surface Free Energy

3.6. Fourier Transform Infrared (FTIR) Spectroscopy

3.7. Determination of the Hardness of Polymer Compositions

3.8. Color Change Analysis

3.9. One-Directional Tensile Test

3.10. Microbiological Assay

4. Conclusions

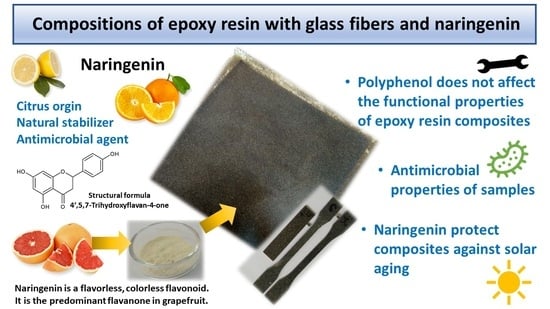

- Innovative solutions such as replacing synthetic stabilizers with compounds of natural origin are expected in current polymer technologies. An important industry in which epoxy materials are used is the railway industry, where seats made of epoxy resins and glass fibers are used. The solutions proposed in this work increased the environmental aspect of epoxy materials because of the application of a natural stabilizer from the group of polyphenols naringenin. Naringenin provided compositions with adequate resistance to solar aging associated with the use of railway wagons. Replacing commercial stabilizers with naringenin obtained from citrus waste may have a positive impact on the economic properties of epoxy compositions by reducing its price. Furthermore, the prototypes of seat elements obtained showed antimicrobial properties, which is an important and beneficial feature in public transport by potentially reducing microbiological threats to passengers.

- The addition of naringenin did not significantly affect the functional properties (hardness) and surface properties (surface energy and its parameters) of the epoxy materials. In addition, no effect of increasing the concentration of naringenin on the investigated properties of the samples before aging was found.

- Solar aging lasting 800 h did not cause significant changes in the hardness (82.9–88.6 Shore C and 76.1–81 Shore D) of the samples, which meant that they retained their resistance to local plastic deformation. Furthermore, the mechanical parameters also remained stable after the aging process.

- The surface energy of the materials also did not decrease after controlled aging, but the polar component corresponding to the change in polarity of the samples increased (about three to eight times), thus indicating the beginning of the degradation process of the resin composition. The carbonyl indexes of naringenin-containing materials, calculated from FTIR spectra, were about four times lower than those for the reference sample, which meant that naringenin stabilized the polymer composites. Materials containing naringenin were characterized by a greater color change (about 1.5–2 times) than the reference sample, which was associated with a change in the color of the polyphenol during its oxidation.

- Naringenin can be used as a potential antimicrobial agent in epoxy resin composites. In the test of microbial cell viability in contact with composite surfaces, a decrease in the number of viable bacterial and yeast cells was found compared with the reference sample.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Szatkowski, P.; Szatkowska, M.; Gralewski, J.; Czechowski, L.; Kedziora, S. Biocomposites with Epoxy Resin Matrix Modified with Ingredients of Natural Origin. Materials 2022, 15, 7167. [Google Scholar] [CrossRef] [PubMed]

- Sienkiewicz, N.; Dominic, M.; Parameswaranpillai, J. Natural Fillers as Potential Modifying Agents for Epoxy Composition: A Review. Polymers 2022, 14, 265. [Google Scholar] [CrossRef] [PubMed]

- Sarikaya, E.; Çallioğlu, H.; Demirel, H. Production of Epoxy Composites Reinforced by Different Natural Fibers and Their Mechanical Properties. Compos. B Eng. 2019, 167, 461–466. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites Reinforced with Natural Fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Salasinska, K.; Barczewski, M.; Górny, R.; Kloziński, A. Evaluation of Highly Filled Epoxy Composites Modified with Walnut Shell Waste Filler. Polym. Bull. 2018, 75, 2511–2528. [Google Scholar] [CrossRef]

- Barczewski, M.; Sałasińska, K.; Szulc, J. Application of Sunflower Husk, Hazelnut Shell and Walnut Shell as Waste Agricultural Fillers for Epoxy-Based Composites: A Study into Mechanical Behavior Related to Structural and Rheological Properties. Polym. Test 2019, 75, 1–11. [Google Scholar] [CrossRef]

- Masiewicz, J.; Roszowska-Jarosz, M.; Kostrzewa, M.; Jasik, A.; Krawczyk, P. The Modification of an Epoxy Resin by Natural Plant Materials. Environ. Prot. Nat. Resour. 2020, 31, 14–20. [Google Scholar] [CrossRef]

- Kirschweng, B.; Tátraaljai, D.; Földes, E.; Pukánszky, B. Natural Antioxidants as Stabilizers for Polymers. Polym. Degrad. Stab. 2017, 145, 25–40. [Google Scholar] [CrossRef]

- Galleano, M.; Verstraeten, S.V.; Oteiza, P.I.; Fraga, C.G. Antioxidant Actions of Flavonoids: Thermodynamic and Kinetic Analysis. Arch. Biochem. Biophys. 2010, 501, 23–30. [Google Scholar] [CrossRef]

- Jacob, V.; Hagai, T.; Soliman, K. Structure-Activity Relationships of Flavonoids. Curr. Org. Chem. 2011, 15, 2641–2657. [Google Scholar] [CrossRef]

- Kumar, S.; Pandey, A.K. Chemistry and Biological Activities of Flavonoids: An Overview. Sci. World J. 2013, 2013, 162750. [Google Scholar] [CrossRef] [PubMed]

- Kirschweng, B.; Tátraaljai, D.; Földes, E.; Pukánszky, B. Efficiency of Curcumin, a Natural Antioxidant, in the Processing Stabilization of PE: Concentration Effects. Polym. Degrad. Stab. 2015, 118, 17–23. [Google Scholar] [CrossRef]

- Kirschweng, B.; Bencze, K.; Sárközi, M.; Hégely, B.; Samu, G.; Hári, J.; Tátraaljai, D.; Földes, E.; Kállay, M.; Pukánszky, B. Melt Stabilization of Polyethylene with Dihydromyricetin, a Natural Antioxidant. Polym. Degrad. Stab. 2016, 133, 192–200. [Google Scholar] [CrossRef]

- Tátraaljai, D.; Földes, E.; Pukánszky, B. Efficient Melt Stabilization of Polyethylene with Quercetin, a Flavonoid Type Natural Antioxidant. Polym. Degrad. Stab. 2014, 102, 41–48. [Google Scholar] [CrossRef]

- Tátraaljai, D.; Kirschweng, B.; Kovács, J.; Földes, E.; Pukánszky, B. Processing Stabilisation of PE with a Natural Antioxidant, Curcumin. Eur. Polym. J. 2013, 49, 1196–1203. [Google Scholar] [CrossRef]

- Samper, M.D.; Fages, E.; Fenollar, O.; Boronat, T.; Balart, R. The Potential of Flavonoids as Natural Antioxidants and UV Light Stabilizers for Polypropylene. J. Appl. Polym. Sci. 2013, 129, 1707–1716. [Google Scholar] [CrossRef]

- Masek, A. Flavonoids as Natural Stabilizers and Color Indicators of Ageing for Polymeric Materials. Polymers 2015, 7, 1125–1144. [Google Scholar] [CrossRef]

- Masek, A.; Latos-Brozio, M. The Effect of Substances of Plant Origin on the Thermal and Thermo-Oxidative Ageing of Aliphatic Polyesters (PLA, PHA). Polymers 2018, 10, 1252. [Google Scholar] [CrossRef]

- Latos-Brozio, M.; Masek, A. The Application of (+)-Catechin and Polydatin as Functional Additives for Biodegradable Polyesters. Int. J. Mol. Sci. 2020, 21, 414. [Google Scholar] [CrossRef]

- Kharouf, N.; Sauro, S.; Hardan, L.; Fawzi, A.; Suhanda, I.E.; Zghal, J.; Addiego, F.; Affolter-Zbaraszczuk, C.; Arntz, Y.; Ball, V.; et al. Impacts of Resveratrol and Pyrogallol on Physicochemical, Mechanical and Biological Properties of Epoxy-Resin Sealers. Bioengineering 2022, 9, 85. [Google Scholar] [CrossRef]

- Bao, Y.; Guo, S.; Jia, Z.; Guan, H. Effects of MOFs-Derived Ni@NC/CNT Nanocomposites on Impermeability and Microwave Absorption of Modified Epoxy Resin Coatings on Cement-Based Materials. Constr. Build. Mater. 2023, 383, 131337. [Google Scholar] [CrossRef]

- Li, Y.; Guan, H.; Bao, Y.; Guo, S.; Lei, D.; Zhao, T.; Zhong, B.; Li, Z. Ni0.6Zn0.4Fe2O4/Ti3C2Tx Nanocomposite Modified Epoxy Resin Coating for Improved Microwave Absorption and Impermeability on Cement Mortar. Constr. Build. Mater. 2021, 310, 125213. [Google Scholar] [CrossRef]

- Busiak, R.; Masek, A.; Węgier, A.; Rylski, A. Accelerated Aging of Epoxy Biocomposites Filled with Cellulose. Materials 2022, 15, 3256. [Google Scholar] [CrossRef] [PubMed]

- Capricho, J.C.; Fox, B.; Hameed, N. Multifunctionality in Epoxy Resins. Polym. Rev. 2020, 60, 1–41. [Google Scholar] [CrossRef]

- Masek, A.; Olejnik, O.; Czechowski, L.; Kaźmierczyk, F.; Miszczak, S.; Węgier, A.; Krauze, S. Epoxy Resin-Based Materials Containing Natural Additives of Plant Origin Dedicated to Rail Transport. Materials 2023, 16, 7080. [Google Scholar] [CrossRef]

- Cavia-Saiz, M.; Busto, M.D.; Pilar-Izquierdo, M.C.; Ortega, N.; Perez-Mateos, M.; Muñiz, P. Antioxidant Properties, Radical Scavenging Activity and Biomolecule Protection Capacity of Flavonoid Naringenin and Its Glycoside Naringin: A Comparative Study. J. Sci. Food Agric. 2010, 90, 1238–1244. [Google Scholar] [CrossRef]

- Plota, A.; Masek, A. Analysis of the Aging and Stabilization Processes in Cyclic Polyolefins Containing Various Natural or Synthetic Stabilizers. Polymer 2023, 273, 125879. [Google Scholar] [CrossRef]

- UNE-EN ISO 527-1:2020; Plastics—Determination of Mechanical Properties under Static Stretching—Part 1: General Principles. UNE Asociación Española de Normalización: Madrid, Spain, 2020.

| Sample | Before Aging | After Aging | ||||

|---|---|---|---|---|---|---|

| PD | MD | 45 | PD | MD | 45 | |

| Epoxy resin | 14.36 ± 0.40 | 17.31 ± 0.20 | 9.34 ± 0.65 | 14.78 ± 0.45 | 18.43 ± 0.24 | 10.39 ± 0.18 |

| Epoxy resin/naringenin 2 phr | 15.53 ± 0.52 | 16.58 ± 0.30 | 8.72 ± 0.49 | 16.23 ± 0.06 | 17.83 ± 0.44 | 9.24 ± 0.07 |

| Epoxy resin/naringenin 4 phr | 15.05 ± 1.46 | 18.97 ± 0.38 | 8.19 ± 0.31 | 15.49 ± 0.66 | 18.55 ± 0.08 | 9.22 ± 0.27 |

| Epoxy resin/naringenin 8 phr | 14.34 ± 0.08 | 16.28 ± 1.09 | 9.20 ± 0.41 | 15.43 ± 0.13 | 18.13 ± 0.01 | 9.63 ± 0.41 |

| Sample | Before Aging | After Aging | ||||

|---|---|---|---|---|---|---|

| PD | MD | 45 | PD | MD | 45 | |

| Epoxy resin | 223.6 ± 6.7 | 277.7 ± 4.6 | 116.9 ± 8.9 | 223.8 ± 14.2 | 284.9 ± 4.7 | 114.9 ± 4.0 |

| Epoxy resin/naringenin 2 phr | 212.9 ± 8.5 | 277.9 ± 7.6 | 79.5 ± 16.8 | 219.9 ± 8.6 | 258.1 ± 18.8 | 80.3 ± 11.2 |

| Epoxy resin/naringenin 4 phr | 171.1 ± 8.9 | 311.4 ± 4.8 | 69.2 ± 4.1 | 167.8 ± 3.4 | 313.6 ± 3.7 | 85.6 ± 4.5 |

| Epoxy resin/naringenin 8 phr | 176.06 ± 6.9 | 239.5 ± 3.4 | 98.8 ± 12.7 | 171.8 ± 11.4 | 274.8 ± 1.3 | 101.0 ± 9.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Latos-Brozio, M.; Masek, A.; Czechowski, L.; Jastrzębska, A.; Miszczak, S. Effect of the Addition of Naringenin Derived from Citrus on the Properties of Epoxy Resin Compositions. Molecules 2024, 29, 512. https://doi.org/10.3390/molecules29020512

Latos-Brozio M, Masek A, Czechowski L, Jastrzębska A, Miszczak S. Effect of the Addition of Naringenin Derived from Citrus on the Properties of Epoxy Resin Compositions. Molecules. 2024; 29(2):512. https://doi.org/10.3390/molecules29020512

Chicago/Turabian StyleLatos-Brozio, Malgorzata, Anna Masek, Leszek Czechowski, Aleksandra Jastrzębska, and Sebastian Miszczak. 2024. "Effect of the Addition of Naringenin Derived from Citrus on the Properties of Epoxy Resin Compositions" Molecules 29, no. 2: 512. https://doi.org/10.3390/molecules29020512

APA StyleLatos-Brozio, M., Masek, A., Czechowski, L., Jastrzębska, A., & Miszczak, S. (2024). Effect of the Addition of Naringenin Derived from Citrus on the Properties of Epoxy Resin Compositions. Molecules, 29(2), 512. https://doi.org/10.3390/molecules29020512