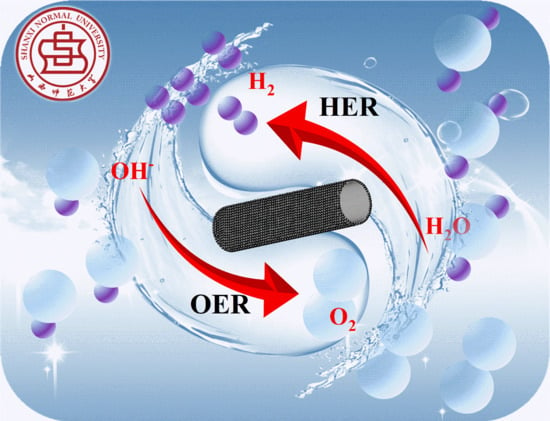

Controllable La Deficiency Engineering within Perovskite Oxides for Enhanced Overall Water Splitting

Abstract

:1. Introduction

2. Results and Discussion

2.1. Structural and Surface Morphology Characterization of Catalysts

2.2. Characterization of Surface Valence States of Catalysts

2.3. Electrocatalytic Performance for HER in Alkaline

2.4. Electrocatalytic Performance for OER and OWS in Alkaline

3. Experimental Section

3.1. Materials

3.2. Preparation of LaxCoFe/NFF Catalyst

3.3. Characterization

3.4. Electrochemical Measurements

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ji, D.; Liu, C.; Yao, Y.; Luo, L.; Wang, W.; Chen, Z. Cerium substitution in LaCoO3 perovskite oxide as bifunctional electrocatalysts for hydrogen and oxygen evolution reactions. Nanoscale 2021, 13, 9952–9959. [Google Scholar] [CrossRef]

- Zhang, Y.-Q.; Tao, H.-B.; Chen, Z.; Li, M.; Sun, Y.-F.; Hua, B.; Luo, J.-L. In situ grown cobalt phosphide (CoP) on perovskite nanofibers as an optimized trifunctional electrocatalyst for Zn–air batteries and overall water splitting. J. Mater. Chem. A 2019, 7, 26607–26617. [Google Scholar] [CrossRef]

- Ashraf, S.; Liu, Y.; Wei, H.; Shen, R.; Zhang, H.; Wu, X.; Mehdi, S.; Liu, T.; Li, B. Bimetallic Nanoalloy Catalysts for Green Energy Production: Advances in Synthesis Routes and Characterization Techniques. Small 2023, 19, e2303031. [Google Scholar] [CrossRef]

- Bu, Y.; Kim, S.; Kwon, O.; Zhong, Q.; Kim, G. A Composite Catalyst Based on Perovskites for Overall Water Splitting in Alkaline Conditions. ChemElectroChem 2019, 6, 1520–1524. [Google Scholar] [CrossRef]

- Wang, W.; Xu, X.; Zhou, W.; Shao, Z. Recent Progress in Metal–Organic Frameworks for Applications in Electrocatalytic and Photocatalytic Water Splitting. Adv. Sci. 2017, 4, 1600371. [Google Scholar] [CrossRef] [PubMed]

- Sun, H.; Xu, X.; Kim, H.; Shao, Z.; Jung, W. Advanced electrocatalysts with unusual active sites for electrochemical water splitting. InfoMat 2024, 6, e12494. [Google Scholar] [CrossRef]

- Ledendecker, M.; Krick Calderon, S.; Papp, C.; Steinruck, H.P.; Antonietti, M.; Shalom, M. The synthesis of nanostructured Ni5P4 films and their use as a non–noble bifunctional electrocatalyst for full water splitting. Angew. Chem. Int. Ed. 2015, 54, 12361–12365. [Google Scholar] [CrossRef] [PubMed]

- Li, M.-X.; Ma, Y.; Xiao, B.; Zhou, Y.-N.; Yu, W.-L.; Zhai, X.-J.; Lv, R.-Q.; Chai, Y.-M.; Dong, B. S, Fe dual doped and precisely regulated CoP porous nanoneedle arrays for efficient hydrogen evolution at 3 A cm−2. Chem. Eng. J. 2023, 470, 144081–144092. [Google Scholar] [CrossRef]

- Guo, X.; Li, M.; Qiu, L.; Tian, F.; He, L.; Geng, S.; Liu, Y.; Song, Y.; Yang, W.; Yu, Y. Engineering electron redistribution of bimetallic phosphates with CeO2 enables high–performance overall water splitting. Chem. Eng. J. 2023, 453, 139796–139805. [Google Scholar] [CrossRef]

- Iffelsberger, C.; Pumera, M. High resolution electrochemical additive manufacturing of microstructured active materials: Case study of MoSx as a catalyst for the hydrogen evolution reaction. J. Mater. Chem. A 2021, 9, 22072–22081. [Google Scholar] [CrossRef]

- Huang, Z.; Xu, B.; Li, Z.; Ren, J.; Mei, H.; Liu, Z.; Xie, D.; Zhang, H.; Dai, F.; Wang, R.; et al. Accurately Regulating the Electronic Structure of NixSey@NC Core–Shell Nanohybrids through Controllable Selenization of a Ni–MOF for pH–Universal Hydrogen Evolution Reaction. Small 2020, 16, e2004231. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Wang, Z.; Zhang, H.; Zhang, Z.; Zhou, J.; Hou, Y.; Liu, P.; Xu, B.; Zhang, H.; Guo, J. Interface engineering of porous Co(OH)2/La(OH)3@Cu nanowire heterostructures for high efficiency hydrogen evolution and overall water splitting. J. Mater. Chem. A 2023, 11, 4355–4364. [Google Scholar] [CrossRef]

- Xiong, G.; Chen, Y.; Zhou, Z.; Liu, F.; Liu, X.; Yang, L.; Liu, Q.; Sang, Y.; Liu, H.; Zhang, X.; et al. Rapid Synthesis of Various Electrocatalysts on Ni Foam Using a Universal and Facile Induction Heating Method for Efficient Water Splitting. Adv. Funct. Mater. 2021, 31, 2009580. [Google Scholar] [CrossRef]

- Wang, J.; Hu, J.; Liang, C.; Chang, L.; Du, Y.; Han, X.; Sun, J.; Xu, P. Surface reconstruction of phosphorus–doped cobalt molybdate microarrays in electrochemical water splitting. Chem. Eng. J. 2022, 446, 137094. [Google Scholar] [CrossRef]

- Qi, J.; Liu, H.; Feng, M.; Xu, H.; Liu, H.; Wang, C.; Wang, A.; Lü, W. Enhanced hydrogen evolution reaction in Sr doped BiFeO3 by achieving the coexistence of ferroelectricity and ferromagnetism at room temperature. J. Energy Chem. 2021, 53, 93–98. [Google Scholar] [CrossRef]

- Xu, X.; Wang, W.; Zhou, W.; Shao, Z. Recent Advances in Novel Nanostructuring Methods of Perovskite Electrocatalysts for Energy–Related Applications. Small Methods 2018, 2, 1800071. [Google Scholar] [CrossRef]

- Karki, S.B.; Hona, R.K.; Yu, M.; Ramezanipour, F. Enhancement of Electrocatalytic Activity as a Function of Structural Order in Perovskite Oxides. ACS Catal. 2022, 12, 10333–10337. [Google Scholar] [CrossRef]

- Xu, X.; Pan, Y.; Zhong, Y.; Shi, C.; Guan, D.; Ge, L.; Hu, Z.; Chin, Y.; Lin, H.; Chen, C.; et al. New Undisputed Evidence and Strategy for Enhanced Lattice–Oxygen Participation of Perovskite Electrocatalyst through Cation Deficiency Manipulation. Adv. Sci. 2022, 9, 2200530. [Google Scholar] [CrossRef]

- Chen, J.; Wang, F.; Qi, X.; Yang, H.; Peng, B.; Xu, L.; Xiao, Z.; Hou, X.; Liang, T. A simple strategy to construct cobalt oxide-based high–efficiency electrocatalysts with oxygen vacancies and heterojunctions. Electrochim. Acta 2019, 326, 134979. [Google Scholar] [CrossRef]

- Sun, J.; Guo, N.; Shao, Z.; Huang, K.; Li, Y.; He, F.; Wang, Q. A Facile Strategy to Construct Amorphous Spinel-Based Electrocatalysts with Massive Oxygen Vacancies Using Ionic Liquid Dopant. Adv. Energy Mater. 2018, 8, 1800980. [Google Scholar] [CrossRef]

- Liu, H.; Ding, X.; Wang, L.; Ding, D.; Zhang, S.; Yuan, G. Cation deficiency design: A simple and efficient strategy for promoting oxygen evolution reaction activity of perovskite electrocatalyst. Electrochim. Acta 2018, 259, 1004–1010. [Google Scholar] [CrossRef]

- Suntivich, J.; May, K.J.; Gasteiger, H.A.; Goodenough, J.B.; Horn, Y.S. A Perovskite Oxide Optimized for Oxygen Evolution Catalysis from Molecular Orbital Principles. Science 2011, 9, 1381–1385. [Google Scholar] [CrossRef] [PubMed]

- Yao, H.; Zheng, Y.; Yue, S.; Hu, S.; Yuan, W.; Guo, X. B–site substitution in NaCo1−2xFexNixF3 perovskites for efficient oxygen evolution. Inorg. Chem. Front. 2023, 10, 804–814. [Google Scholar] [CrossRef]

- Duan, Y.; Sun, S.; Xi, S.; Ren, X.; Zhou, Y.; Zhang, G.; Yang, H.; Du, Y.; Xu, Z.J. Tailoring the Co 3d–O 2p Covalency in LaCoO3 by Fe Substitution to Promote Oxygen Evolution Reaction. Chem. Mater. 2017, 29, 10534–10541. [Google Scholar] [CrossRef]

- Ashok, A.; Kumar, A.; Bhosale, R.R.; Almomani, F.; Malik, S.S.; Suslov, S.; Tarlochan, F. Combustion synthesis of bifunctional LaMO3 (M = Cr, Mn, Fe, Co, Ni) perovskites for oxygen reduction and oxygen evolution reaction in alkaline Media. J. Electroanal. Chem. 2018, 809, 22–30. [Google Scholar] [CrossRef]

- Qiu, C.; Wang, L.; Chen, R.; Zhang, J.; Ding, J.; Zhang, J.; Wan, H.; Guan, G. Insight of the State for Deliberately Introduced A-Site Defect in Nanofibrous LaFeO3 for Boosting Artificial Photosynthesis of CH3OH. ACS Appl. Mater. Interfaces 2023, 15, 56945–56956. [Google Scholar] [CrossRef]

- She, S.; Yu, J.; Tang, W.; Zhu, Y.; Chen, Y.; Sunarso, J.; Zhou, W.; Shao, Z. Systematic Study of Oxygen Evolution Activity and Stability on La1–xSrxFeO3−δ Perovskite Electrocatalysts in Alkaline Media. ACS Appl. Mater. Interfaces 2018, 10, 11715–11721. [Google Scholar] [CrossRef] [PubMed]

- Yuan, R.-H.; He, Y.; He, W.; Ni, M.; Leung, M.K.H. Bifunctional electrocatalytic activity of La0.8Sr0.2MnO3–based perovskite with the A–site deficiency for oxygen reduction and evolution reactions in alkaline media. Appl. Energy 2019, 251, 113406. [Google Scholar] [CrossRef]

- Chen, C.-F.; King, G.; Dickerson, R.M.; Papin, P.A.; Gupta, S.; Kellogg, W.R.; Wu, G. Oxygen-deficient BaTiO3−x perovskite as an efficient bifunctional oxygen electrocatalyst. Nano. Energy 2015, 13, 423–432. [Google Scholar] [CrossRef]

- Zhao, T.; Wang, Y.; Chen, X.; Li, Y.; Su, Z.; Zhao, C. Vertical Growth of Porous Perovskite Nanoarrays on Nickel Foam for Efficient Oxygen Evolution Reaction. ACS Sustain. Chem. Eng. 2020, 8, 4863–4870. [Google Scholar] [CrossRef]

- Huang, Y.; Cui, F.; Zhao, Y.; Lian, J.; Bao, J.; Liu, T.; Li, H. 3D hierarchical CMF/MoSe2 composite foam as highly efficient electrocatalyst for hydrogen evolution. Electrochim. Acta 2018, 263, 94–101. [Google Scholar] [CrossRef]

- Li, X.; Liu, X.; Zhang, C.; Wang, R.; Wei, G.; Yang, T.; Zhang, J.; Chen, Y.; Gao, S. A corrosion–etching strategy for fabricating RuO2 coupled with defective NiFeZn(OH)x for a highly efficient hydrogen evolution reaction. J. Mater. Chem. A 2022, 10, 20453–20463. [Google Scholar] [CrossRef]

- Zhang, R.-L.; Feng, J.-J.; Yao, Y.-Q.; Fang, K.-M.; Zhang, L.; Yin, Z.-Z.; Wang, A.-J. Straw–like phosphorus–doped Co2MnO4 nanoneedle arrays supported on nickel foam for high-efficiency hydrogen evolution reaction in wide pH range of electrolytes. Appl. Surf. Sci. 2021, 548, 149280. [Google Scholar] [CrossRef]

- Chen, J.; Wu, J.; Liu, Y.; Hu, X.; Geng, D. Assemblage of Perovskite LaNiO3 Connected with In Situ Grown Nitrogen-Doped Carbon Nanotubes as High-Performance Electrocatalyst for Oxygen Evolution Reaction. Phys. Status Solidi A 2018, 215, 1800380. [Google Scholar] [CrossRef]

- Wang, W.; Yang, Y.; Huan, D.; Wang, L.; Shi, N.; Xie, Y.; Xia, C.; Peng, R.; Lu, Y. An excellent OER electrocatalyst of cubic SrCoO3−δ prepared by a simple F–doping strategy. J. Mater. Chem. A 2019, 7, 12538–12546. [Google Scholar] [CrossRef]

- Zhou, Q.; Xu, C.; Hou, J.; Ma, W.; Jian, T.; Yan, S.; Liu, H. Duplex Interpenetrating-Phase FeNiZn and FeNi3 Heterostructure with Low-Gibbs Free Energy Interface Coupling for Highly Efficient Overall Water Splitting. Nano-Micro Lett. 2023, 15, 95. [Google Scholar] [CrossRef]

- Bindu, G.H.; Kammara, V.; Srilekha, P.; Swetha, K.; Laxmi, Y.K.; Veerasomaiah, P.; Vithal, M. Preparation, characterization and photocatalytic studies of LaAl0.5Fe0.5O3, LaAl0.5Cr0.5O3 and LaCr0.5Fe0.5O3. J. Mol. Struct. 2023, 1273, 134220. [Google Scholar] [CrossRef]

- Natile, M.M.; Poletto, F.; Galenda, A.; Glisenti, A.; Montini, T.; De Rogatis, L.; Fornasiero, P. La0.6Sr0.4Co1−yFeyO3−δ Perovskites: Influence of the Co/Fe Atomic Ratio on Properties and Catalytic Activity toward Alcohol Steam–Reforming. Chem. Mater. 2008, 20, 2314–2327. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, Z.; Wang, X.; Yu, T.; Guan, J.; Yu, Z.; Li, Z.; Zou, Z. Increasing the Oxygen Vacancy Density on the TiO2 Surface by La–Doping for Dye–Sensitized Solar Cells. J. Phys. Chem. C 2010, 114, 18396–18400. [Google Scholar] [CrossRef]

- Ramana, C.V.; Bandi, M.; N Nair, A.; Manciu, F.S.; Sreenivasan, S.; Shutthanandan, V. Electronic Structure, Chemical Bonding, and Electrocatalytic Activity of Ba(Fe0.7Ta0.3)O3−δ Compounds. ACS Appl. Energy Mater. 2021, 4, 1313–1322. [Google Scholar] [CrossRef]

- Liu, R.; Zhang, Y.; Duan, L.; Zhao, X. Effect of Fe2+/Fe3+ ratio on photocatalytic activities of Zn1−xFexO nanoparticles fabricated by the auto combustion method. Ceram. Int. 2020, 46, 1–7. [Google Scholar] [CrossRef]

- Wang, Z.; Tan, S.; Xiong, Y.; Wei, J. Effect of B sites on the catalytic activities for perovskite oxides La.6Sr.4CoxFe1−xO3−δ as metal-air batteries catalysts. Prog. Nat. Sci. Mater. Int. 2018, 28, 399–407. [Google Scholar] [CrossRef]

- Gao, J.; Zhang, Y.; Wang, X.; Jia, L.; Jiang, H.; Huang, M.; Toghan, A. Nitrogen–doped Sr2Fe1.5Mo0.5O6−δ perovskite as an efficient and stable catalyst for hydrogen evolution reaction. Mater. Today Energy 2021, 20, 100695. [Google Scholar] [CrossRef]

- Yi, Y.; Wu, Q.; Li, J.; Yao, W.; Cui, C. Phase–Segregated SrCo0.8Fe0.5−xO3−δ/FexOy Heterostructured Catalyst Promotes Alkaline Oxygen Evolution Reaction. ACS Appl. Mater. Interfaces 2021, 13, 17439–17449. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Dai, J.; Zhou, C.; Guan, D.; Wu, X.; Zhou, W.; Shao, Z. Engineering Charge Redistribution within Perovskite Oxides for Synergistically Enhanced Overall Water Splitting. ACS Mater. Lett. 2021, 3, 1258–1265. [Google Scholar] [CrossRef]

- Hui, J.; Yan, C.; Shi, Y.; Yang, Z. Rare-earth metal multicomponent perovskite as a electrocatalyst for water splitting. Mater. Lett. 2023, 332, 133532. [Google Scholar] [CrossRef]

- Junita, J.; Jayalakshmi, D.; Rodney, J.D. Combustion–derived BaNiO3 nanoparticles as a potential bifunctional electrocatalyst for overall water splitting. Int. J. Hydrogen Energy 2023, 48, 14287–14298. [Google Scholar] [CrossRef]

- Karki, S.B.; Andriotis, A.N.; Menon, M.; Ramezanipour, F. Enhancement of Electrocatalytic Activity for both Hydrogen and Oxygen Evolution Reactions of a Perovskite Oxide. J. Phys. Chem. C 2022, 126, 20011–20019. [Google Scholar] [CrossRef]

- Junita, J.; Jayalakshmi, D.; Rodney, J.D. Effect of annealing temperature on the bifunctional electrocatalytic properties of strontium nickelate (SrNiO3) nanoparticles for efficient overall water splitting. Int. J. Hydrogen Energy 2022, 47, 30602–30612. [Google Scholar] [CrossRef]

- Zhou, Y.-N.; Wang, F.-G.; Zhen, Y.-N.; Nan, J.; Dong, B.; Chai, Y.-M. Crystal facet engineering of perovskite cobaltite with optimized electronic regulation for water splitting. Sci. China Mater. 2022, 65, 2665–2674. [Google Scholar] [CrossRef]

- Rana, A.K.; Jeong, M.H.; Noh, Y.I.; Park, H.; Baik, J.M.; Choi, K.J. Phase–Tuned MoS2 and Its Hybridization with Perovskite Oxide as Bifunctional Catalyst: A Rationale for Highly Stable and Efficient Water Splitting. ACS Appl. Mater. Interfaces 2022, 14, 18248–18260. [Google Scholar] [CrossRef] [PubMed]

- Sarmad, Q.; Khan, U.M.; Baig, M.M.; Hassan, M.; Butt, F.A.; Khoja, A.H.; Liaquat, R.; Khan, Z.S.; Anwar, M.; Muhammed Ali, S.A. Praseodymium–doped Sr2TiFeO6−δ double perovskite as a bi-functional electrocatalyst for hydrogen production through water splitting. J. Environ. Chem. Eng. 2022, 10, 107609. [Google Scholar] [CrossRef]

- Wu, X.; Yu, J.; Yang, G.; Liu, H.; Zhou, W.; Shao, Z. Perovskite oxide/carbon nanotube hybrid bifunctional electrocatalysts for overall water splitting. Electrochim. Acta 2018, 286, 47–54. [Google Scholar] [CrossRef]

- Yu, J.; Wu, X.; Guan, D.; Hu, Z.; Weng, S.-C.; Sun, H.; Song, Y.; Ran, R.; Zhou, W.; Ni, M.; et al. Monoclinic SrIrO3: An Easily Synthesized Conductive Perovskite Oxide with Outstanding Performance for Overall Water Splitting in Alkaline Solution. Chem. Mater. 2020, 32, 4509–4517. [Google Scholar] [CrossRef]

- He, B.; Tan, K.; Gong, Y.; Wang, R.; Wang, H.; Zhao, L. Coupling amorphous cobalt hydroxide nanoflakes on Sr2Fe1.5Mo0.5O5+δ perovskite nanofibers to induce bifunctionality for water splitting. Nanoscale 2020, 12, 9048–9057. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Z.; Jin, C.; Li, C.; Li, X.; Li, Y.; Yang, R.; Liu, M. Enhanced overall water electrolysis on a bifunctional perovskite oxide through interfacial engineering. Electrochim. Acta 2019, 318, 120–129. [Google Scholar] [CrossRef]

- Tang, L.; Chen, Z.; Zuo, F.; Hua, B.; Zhou, H.; Li, M.; Li, J.; Sun, Y. Enhancing perovskite electrocatalysis through synergistic functionalization of B–site cation for efficient water splitting. Chem. Eng. J. 2020, 401, 126082. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, X.; Guo, K.; Yu, X. Controllable La Deficiency Engineering within Perovskite Oxides for Enhanced Overall Water Splitting. Molecules 2024, 29, 1342. https://doi.org/10.3390/molecules29061342

Xu X, Guo K, Yu X. Controllable La Deficiency Engineering within Perovskite Oxides for Enhanced Overall Water Splitting. Molecules. 2024; 29(6):1342. https://doi.org/10.3390/molecules29061342

Chicago/Turabian StyleXu, Xiaohu, Kaiwei Guo, and Xinyue Yu. 2024. "Controllable La Deficiency Engineering within Perovskite Oxides for Enhanced Overall Water Splitting" Molecules 29, no. 6: 1342. https://doi.org/10.3390/molecules29061342

APA StyleXu, X., Guo, K., & Yu, X. (2024). Controllable La Deficiency Engineering within Perovskite Oxides for Enhanced Overall Water Splitting. Molecules, 29(6), 1342. https://doi.org/10.3390/molecules29061342