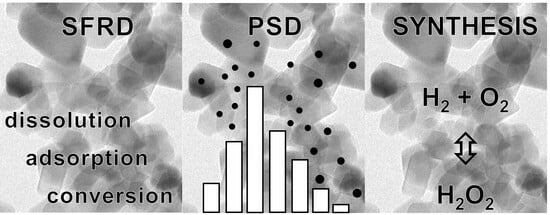

Deposition of Pd, Pt, and PdPt Nanoparticles on TiO2 Powder Using Supercritical Fluid Reactive Deposition: Application in the Direct Synthesis of H2O2

Abstract

:1. Introduction

2. Results and Discussion

2.1. Size and Metal Loading of the Catalysts

2.2. Productivity of the Different Catalysts

3. Experimental Section

3.1. Materials

3.2. Apparatus and Procedure

3.3. Characterization Methods

3.4. Determination of the H2O2 Productivity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Türk, M.; Erkey, C. Synthesis of supported nanoparticles in supercritical fluids by supercritical fluid reactive deposition: Current state, further perspectives and needs. J. Supercrit. Fluids 2018, 134, 176–183. [Google Scholar] [CrossRef]

- Zhou, Q.-L. Transition-metal catalysis and organocatalysis: Where can progress be expected? Angew. Chem. Int. Ed. 2016, 55, 5352–5353. [Google Scholar] [CrossRef] [PubMed]

- Ludwig, J.R.; Schindler, C.S. Catalyst: Sustainable catalysis. Chem 2017, 2, 313–316. [Google Scholar] [CrossRef]

- Rössler, A.; Skillas, G.; Pratsinis, S.E. Nanopartikel—Materialien der Zukunft. Chem. Unserer Zeit 2001, 35, 32–41. [Google Scholar] [CrossRef]

- Guisbiers, G.; Abudukelimu, G.; Hourlier, D. Size-dependent catalytic and melting properties of platinum-palladium nanoparticles. Nanoscale Res. Lett. 2011, 6, 396. [Google Scholar] [CrossRef] [PubMed]

- NIST Standard Reference Database 69, NIST Chemistry WebBook. Available online: https://webbook.nist.gov/chemistry/fluid/ (accessed on 19 April 2024).

- Pascu, O.; Moisan, S.; Marty, J.-D.; Aymonier, C. Highly reactive Pd NCs by versatile continuous supercritical fluids synthesis for the preparation of metal–nonmetal Pd-based NCs. Phys. Chem. C 2014, 118, 14017–14025. [Google Scholar] [CrossRef]

- Pascu, O.; Cacciuttolo, B.; Marre, S.; Pucheault, M.; Aymonier, C. ScCO2 assisted preparation of supported metal NPs. Application to catalyst design. J. Supercrit. Fluids 2015, 105, 84–91. [Google Scholar] [CrossRef]

- Aymonier, C.; Philippot, G.; Erriguible, A.; Marre, S. Playing with chemistry in supercritical solvents and the associated technologies for advanced materials by design. J. Supercrit. Fluids 2018, 134, 184–196. [Google Scholar] [CrossRef]

- Siril, P.F.; Türk, M. Synthesis of metal nanostructures using supercritical carbon dioxide: A green and upscalable process. Small 2020, 16, 2001972. [Google Scholar] [CrossRef]

- Yousefzadeh, H.; Akgün, I.S.; Barim, S.B.; Sari, T.B.; Eris, G.; Uzunlar, E.; Bozbag, S.E.; Erkey, C. Supercritical fluid reactive deposition: A process intensification technique for synthesis of nanostructured materials. Chem. Eng. Process 2022, 176, 108934. [Google Scholar] [CrossRef]

- Erkey, C.; Türk, M. Synthesis of Nanostructured Materials in Near and/or Supercritical Fluids, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2021; ISBN 978-0-444-64089-5. [Google Scholar]

- Crone, M.; Türk, M. Adsorption of precursors on substrates in the presence of scCO2 for the synthesis of supported metallic nanoparticles: Experiments and modeling. Fluids 2023, 8, 121. [Google Scholar] [CrossRef]

- Centi, G.; Perathoner, S. Encyclopedia of Catalysis; Horvath, I.T., Ed.; John Wiley & Sons, Inc.: New York, NY, USA, 2003; Volume 6, pp. 239–299. [Google Scholar]

- Goor, G.; Glenneberg, J.; Jacobi, S.; Dadabhoy, J.; Candido, E. Ullmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2019. [Google Scholar] [CrossRef]

- Fu, L.; Liu, S.; Deng, Y.; He, H.; Yuan, S.; Ouyang, L. Fabrication of the PdAu surface alloy on an ordered intermetallic Au3Cu core for direct H2O2 synthesis at ambient pressure. Ind. Eng. Chem. Res. 2022, 61, 11655–11665. [Google Scholar] [CrossRef]

- Rodriguez-Martinez, C.E.; Sossa-Briceño, M.P.; Cortés, J.A. Decontamination and reuse of N95 filtering facemask respirators: A systematic review of the literature. Am. J. Infect. Control 2020, 48, 1520–1532. [Google Scholar] [CrossRef] [PubMed]

- Sickbert-Bennett, E.E.; Samet, J.M.; Clapp, P.W.; Chen, H.; Berntsen, J.; Zeman, K.L.; Tong, H.; Weber, D.J.; Bennett, W.D. Filtration efficiency of hospital face mask alternatives available for use during the COVID-19 pandemic. JAMA Intern. Med. 2020, 180, 1607–1612. [Google Scholar] [CrossRef] [PubMed]

- Campos-Martin, J.M.; Blanco-Brieva, G.; Fierro, J.L.G. Hydrogen peroxide synthesis: An outlook beyond the anthraquinone process. Angew. Chem. Ind. Ed. 2006, 45, 6962–6984. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Verdaguer-Casadevall, A.; Arnarson, L.; Silvioli, L.; Colic, V.; Frydendal, R.; Rossmeisl, J.; Chorkendorff, I.; Stephens, I.E.L. Toward the decentralized electrochemical production of H2O2: A focus on the catalysis. ACS Catal. 2018, 8, 4064–4081. [Google Scholar] [CrossRef]

- Flaherty, D.W. Direct synthesis of H2O2 from H2 and O2 on Pd catalysts: Current understanding, outstanding questions, and research needs. ACS Catal. 2018, 8, 1520–1527. [Google Scholar] [CrossRef]

- Samanta, C. Direct synthesis of hydrogen peroxide from hydrogen and oxygen: An overview of recent developments in the process. Appl. Catal. A Gen. 2008, 350, 133–149. [Google Scholar] [CrossRef]

- Trinkies, L.L.; Ng, D.; Xie, Z.; Hornung, C.H.; Kraut, M.; Dittmeyer, R. Direct synthesis of hydrogen peroxide at additively manufactured fluid guiding elements as structured catalysts. Chem. Eng. Process 2023, 188, 109353. [Google Scholar] [CrossRef]

- Kant, P.; Trinkies, L.L.; Gensior, N.; Fischer, D.; Rubin, M.; Ozin, G.A.; Dittmeyer, R. Isophotonic reactor for the precise determination of quantum yields in gas, liquid, and multi-phase photoreactions. Chem. Eng. J. 2023, 452, 139204. [Google Scholar] [CrossRef]

- Yen, C.H.; Shimizu, K.; Lin, Y.-Y.; Bailey, F.; Cheng, I.F.; Wai, C.M. Chemical fluid deposition of Pt-based bimetallic nanoparticles on multiwalled carbon nanotubes for direct methanol fuel cell application. Energy Fuels 2007, 21, 2268–2271. [Google Scholar] [CrossRef]

- Qiao, Y.; Said, N.; Rauser, M.; Yan, K.; Qin, F.; Theyssen, N.; Leitner, W. Preparation of SBA-15 supported Pt/Pd bimetallic catalysts using supercritical fluid reactive deposition: How do solvent effects during material synthesis affect catalytic properties? Green Chem. 2017, 19, 977–986. [Google Scholar] [CrossRef]

- Cangül, B.; Zhang, L.C.; Aindow, M.; Erkey, C. Preparation of carbon black supported Pd, Pt and Pd–Pt nanoparticles using supercritical CO2 deposition. J. Supercrit. Fluids 2009, 50, 82–90. [Google Scholar] [CrossRef]

- Bayrakceken, A.; Cangül, B.; Zhang, L.C.; Aindow, M.; Erkey, C. PtPd/BP2000 electrocatalysts prepared by sequential supercritical carbon dioxide deposition. Int. J. Hydrogen Energy 2010, 35, 11669–11680. [Google Scholar] [CrossRef]

- Hu, D.; Xu, H.; Yi, Z.; Chen, Z.; Ye, C.; Wu, Z.; Garces, H.F.; Yan, K. Green CO2-assisted synthesis of mono- and bimetallic Pd/Pt nanoparticles on porous carbon fabricated from sorghum for highly selective hydrogenation of furfural. ACS Sustain. Chem. Eng. 2019, 7, 15339–15345. [Google Scholar] [CrossRef]

- Barim, S.B.; Bozbag, S.E.; Deljoo, B.; Aindow, M.; Erkey, C. Highly active carbon supported PtCu electrocatalysts for PEMFCs by in situ supercritical deposition coupled with electrochemical dealloying. Fuel Cells 2020, 20, 285–299. [Google Scholar] [CrossRef]

- Lin, Y.; Cui, X.; Yen, C.H.; Wai, C.M. PtRu/carbon nanotube nanocomposite synthesized in supercritical fluid: A novel electrocatalyst for direct methanol fuel cells. Langmuir 2005, 21, 11474–11479. [Google Scholar] [CrossRef] [PubMed]

- Sánchez-Miguel, E.; Tenorio, M.J.; Morère, J.; Cabañas, A. Green preparation of PtRu and PtCu/SBA-15 catalysts using supercritical CO2. J. CO2 Util. 2017, 22, 382–391. [Google Scholar] [CrossRef]

- Casapu, M.; Fischer, A.; Gänzler, A.M.; Popescu, R.; Crone, M.; Gerthsen, D.; Türk, M.; Grunwaldt, J.-D. Origin of the normal and inverse hysteresis behavior during CO oxidation over Pt/Al2O3. ACS Catal. 2017, 7, 343–355. [Google Scholar] [CrossRef]

- Trinkies, L.L.; Crone, M.; Türk, M.; Kraut, M.; Dittmeyer, R. Supercritical deposition of mono- and bimetallic Pd and Pt on TiO2 coated additively manufactured substrates for the application in the direct synthesis of hydrogen peroxide. Chem. Eng. Process 2024, 195, 109618. [Google Scholar] [CrossRef]

- Lagalante, A.F.; Hansen, B.N.; Bruno, T.J.; Sievers, R.E. Solubilities of copper (II) and chromium (III) β-diketonates in supercritical carbon dioxide. Inorg. Chem. 1995, 34, 5781–5785. [Google Scholar] [CrossRef]

- Ashraf-Khorassani, M.; Combs, M.T.; Taylor, L.T. Solubility of metal chelates and their extraction from an aqueous environment via supercritical CO2. Talanta 1997, 44, 755–763. [Google Scholar] [CrossRef] [PubMed]

- Incera Garrido, G.; Patcas, F.C.; Upper, G.; Türk, M.; Yilmaz, S.; Kraushaar-Czarnetzki, B. Supercritical deposition of Pt on SnO2-coated Al2O3 foams: Phase behaviour and catalytic performance. Appl. Catal. A Gen. 2008, 338, 58–65. [Google Scholar] [CrossRef]

- Wolf, A. Bestimmung der Löslichkeit von Metallchelaten in Überkritischem Kohlendioxid. Ph.D. Thesis, Fachbereich 8, Universität-Gesamthochschule Siegen, Siegen, Germany, 1999. [Google Scholar]

- Skerget, M.; Knez, Z.; Knez-Hrncic, M. Solubility of solids in sub- and supercritical fluids: A Review. J. Chem. Eng. Data 2011, 56, 694–719. [Google Scholar] [CrossRef]

- Deschner, B.J.; Doronkin, D.E.; Sheppard, T.L.; Rabsch, G.; Grunwaldt, J.-D.; Dittmeyer, R. Continuous-flow reactor setup for operando X-ray absorption spectroscopy of high pressure heterogeneous liquid-solid catalytic processes. Rev. Sci. Instrum. 2021, 92, 124101. [Google Scholar] [CrossRef] [PubMed]

- Pashkova, A.; Svajda, K.; Black, G.; Dittmeyer, R. Automated system for spectrophotometric detection of liquid phase hydrogen peroxide for concentrations up to 5% w/w. Rev. Sci. Instrum. 2009, 80, 055104. [Google Scholar] [CrossRef]

- Liebertseder, M.; Maliakkal, C.B.; Crone, M.; Nails, G.; Casapu, M.; Grunwaldt, J.-D.; Türk, M.; Kübel, C.; Feldmann, C. TiO2-CeOx-Pt hollow nanosphere catalyst for low-temperature CO oxidation. ChemCatChem 2023, 16, e202301358. [Google Scholar] [CrossRef]

| CAT | x10 nm | x50 nm | x90 nm | Δ – | Loading wt% | Mean Productivity mmol · gmetal−1 · h−1 |

|---|---|---|---|---|---|---|

| -Pd1 | 1.7 | 2.5 | 3.8 | 0.43 | 0.84 | 458 |

| -Pd2 | 1.0 | 2.0 | 5.7 | 1.16 | 0.77 | 325 |

| -Pt | 1.4 | 2.0 | 4.4 | 0.74 | 1.00 | 179 |

| -Pd1Pt | 0.9 | 2.8 | 4.5 | 0.64 | 0.51/0.49 | 292 |

| -Pd3-IWI | 2.1 | 7.2 | 13.1 | 0.76 | 0.99 | 78 |

| M g · mol−1 | Mmetal g · mol−1 | Metal Content % | Purity % | |

|---|---|---|---|---|

| Pd(acac)2 | 304.64 | 106.42 | 34.9 | 99 |

| Pd(tmhd)2 | 472.95 | 106.42 | 22.5 | 98 |

| Pt(cod)me2 | 333.34 | 195.08 | 58.5 | 99 |

| Pd(NO3)2 · H2O | 266.46 | 106.42 | 39.9 | 95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Crone, M.; Trinkies, L.L.; Dittmeyer, R.; Türk, M. Deposition of Pd, Pt, and PdPt Nanoparticles on TiO2 Powder Using Supercritical Fluid Reactive Deposition: Application in the Direct Synthesis of H2O2. Molecules 2024, 29, 2142. https://doi.org/10.3390/molecules29092142

Crone M, Trinkies LL, Dittmeyer R, Türk M. Deposition of Pd, Pt, and PdPt Nanoparticles on TiO2 Powder Using Supercritical Fluid Reactive Deposition: Application in the Direct Synthesis of H2O2. Molecules. 2024; 29(9):2142. https://doi.org/10.3390/molecules29092142

Chicago/Turabian StyleCrone, Marlene, Laura L. Trinkies, Roland Dittmeyer, and Michael Türk. 2024. "Deposition of Pd, Pt, and PdPt Nanoparticles on TiO2 Powder Using Supercritical Fluid Reactive Deposition: Application in the Direct Synthesis of H2O2" Molecules 29, no. 9: 2142. https://doi.org/10.3390/molecules29092142

APA StyleCrone, M., Trinkies, L. L., Dittmeyer, R., & Türk, M. (2024). Deposition of Pd, Pt, and PdPt Nanoparticles on TiO2 Powder Using Supercritical Fluid Reactive Deposition: Application in the Direct Synthesis of H2O2. Molecules, 29(9), 2142. https://doi.org/10.3390/molecules29092142