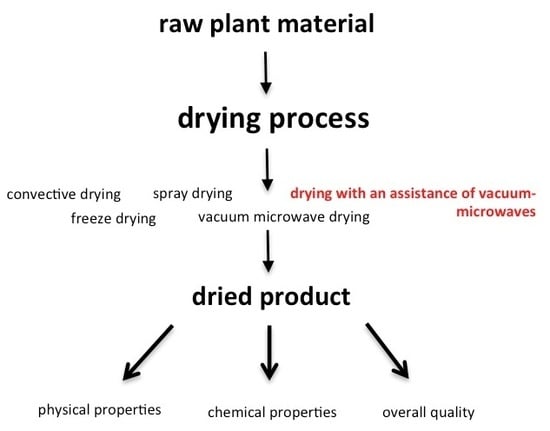

Overall Quality of Fruits and Vegetables Products Affected by the Drying Processes with the Assistance of Vacuum-Microwaves

Abstract

:1. Introduction

2. Drying Processes and Their Combinations Used for Fruit and Vegetable Preservation

3. The Effect of Microwave Vacuum Drying on the Overall Properties of the Dried Products

4. Convective Pre-Drying Followed by Vacuum-Microwave Finish Drying (CPD-VMFD)

5. Heat Pumps for Better Quality and Energy Efficiency in Combined Drying with VMFD

6. Osmotic Dehydration as a Pre-Treatment before VMFD

7. New Perspectives for Combined Drying as a Method of Preservation and Fortification of Dried Products

8. Conclusions

Acknowledgments

Conflicts of Interest

References

- Brandt, K. Chapter 50—Vegetables and fruits in the prevention of chronic age-related diseases. In Molecular Basis of Nutrition and Aging; Malavolta, M., Mocchegiani, E., Eds.; Academic Press: San Diego, CA, USA, 2016; pp. 707–722. [Google Scholar]

- David, B.; Wolfender, J.-L.; Dias, D.A. The pharmaceutical industry and natural products: Historical status and new trends. Phytochem. Rev. 2015, 14, 299–315. [Google Scholar] [CrossRef]

- Jain Manu, S.; Lohare Ganesh, B.; Chavan Randhir, B.; Barhate Shashikant, D.; Shah Chirag, B. Spray drying in pharmaceutical industry: A review. Res. J. Pharm. Dos. Forms Technol. 2012, 4, 74–79. [Google Scholar]

- Johnston, J.L.; Fanzo, J.C.; Cogill, B. Understanding sustainable diets: A descriptive analysis of the determinants and processes that influence diets and their impact on health, food security, and environmental sustainability. Adv. Nutr. Int. Rev. J. 2014, 5, 418–429. [Google Scholar] [CrossRef] [PubMed]

- Van der Goot, A.J.; Pelgrom, P.J.M.; Berghout, J.A.M.; Geerts, M.E.J.; Jankowiak, L.; Hardt, N.A.; Keijer, J.; Schutyser, M.A.I.; Nikiforidis, C.V.; Boom, R.M. Concepts for further sustainable production of foods. J. Food Eng. 2016, 168, 42–51. [Google Scholar] [CrossRef]

- Augustin, M.A.; Riley, M.; Stockmann, R.; Bennett, L.; Kahl, A.; Lockett, T.; Osmond, M.; Sanguansri, P.; Stonehouse, W.; Zajac, I.; et al. Role of food processing in food and nutrition security. Trends Food Sci. Technol. 2016, 56, 115–125. [Google Scholar] [CrossRef]

- Nicoli, M.C.; Anese, M.; Parpinel, M.T.; Franceschi, S.; Lerici, C.R. Loss and/or formation of antioxidants during food processing and storage. Cancer Lett. 1997, 114, 71–74. [Google Scholar] [CrossRef]

- Weaver, C.M.; Dwyer, J.; Fulgoni, V.L.; King, J.C.; Leveille, G.A.; MacDonald, R.S.; Ordovas, J.; Schnakenberg, D. Processed foods: Contributions to nutrition. Am. J. Clin. Nutr. 2014, 99, 1525–1542. [Google Scholar] [CrossRef] [PubMed]

- Grabowski, S.; Marcotte, M. Pre-treatment efficiency in osmotic dehydration of cranberries. In Transport Phenomena in Food Processing; Welti-Chanes, W., Velez-Ruiz, F., Barbosa-Canovas, G.V., Eds.; CRC Press: New York, NY, USA, 2003; pp. 83–94. [Google Scholar]

- Sagar, V.R.; Suresh Kumar, P. Recent advances in drying and dehydration of fruits and vegetables: A review. J. Food Sci. Technol. 2010, 47, 15–26. [Google Scholar] [CrossRef] [PubMed]

- Ratti, C. Hot air and freeze-drying of high-value foods: A review. J. Food Eng. 2001, 49, 311–319. [Google Scholar] [CrossRef]

- Sanchez, V.; Baeza, R.; Chirife, J. Comparison of monomeric anthocyanins and colour stability of fresh, concentrate and freeze-dried encapsulated cherry juice stored at 38 °C. J. Berry Res. 2015, 5, 243–251. [Google Scholar] [CrossRef]

- Tang, X.; Pikal, M.J. Design of freeze-drying processes for pharmaceuticals: Practical advice. Pharm. Res. 2004, 21, 191–200. [Google Scholar] [CrossRef] [PubMed]

- Nail, S.L.; Jiang, S.; Chongprasert, S.; Knopp, S.A. Fundamentals of freeze-drying. Pharm. Biotechnol. 2002, 14, 281–360. [Google Scholar] [PubMed]

- Huang, L.; Zhang, M.; Yan, W.; Mujumdar, A.S.; Sun, D. Effect of coating on post-drying of freeze-dried strawberry pieces. J. Food Eng. 2009, 92, 107–111. [Google Scholar] [CrossRef]

- Chiou, D.; Langrish, T.A.G. Development and characterisation of novel nutraceuticals with spray drying technology. J. Food Eng. 2007, 82, 84–91. [Google Scholar] [CrossRef]

- Alamilla-Beltrán, L.; Chanona-Pérez, J.J.; Jiménez-Aparicio, A.R.; Gutiérrez-López, G.F. Description of morphological changes of particles along spray drying. J. Food Eng. 2005, 67, 179–184. [Google Scholar] [CrossRef]

- Hammami, C.; René, F. Determination of freeze-drying process variables for strawberries. J. Food Eng. 1997, 32, 133–154. [Google Scholar] [CrossRef]

- Horszwald, A.; Andlauer, W.; Heritier, J. Characterisation of Aronia powders obtained by different drying processes. Food Chem. 2013, 5, 2858–2863. [Google Scholar] [CrossRef] [PubMed]

- Soysal, Y.; Ayhan, Z.; Eştürk, O.; Arıkan, M.F. Intermittent microwave–convective drying of red pepper: Drying kinetics, physical (colour and texture) and sensory quality. Biosyst. Eng. 2009, 103, 455–463. [Google Scholar] [CrossRef]

- Mayor, L.; Sereno, A.M. Modelling shrinkage during convective drying of food materials: A review. J. Food Eng. 2004, 61, 373–386. [Google Scholar] [CrossRef]

- Figiel, A. Drying kinetics and quality of beetroots dehydrated by combination of convective and vacuum-microwave methods. J. Food Eng. 2010, 98, 461–470. [Google Scholar] [CrossRef]

- Marfil, P.H.M.; Santos, E.M.; Telis, V.R.N. Ascorbic acid degradation kinetics in tomatoes at different drying conditions. LWT Food Sci. Technol. 2008, 41, 1642–1647. [Google Scholar] [CrossRef]

- Maskan, M. Kinetics of colour change of kiwifruits during hot air and microwave drying. J. Food Eng. 2001, 48, 169–175. [Google Scholar] [CrossRef]

- Melgar-Almanza, A.; Horacio Guzmán-Maldonado, S.; Núñez-Colín, C.; Herrera-Hernández, M.G.; Medina-Ramos, G. Effect of drying on antioxidant capacity, physicochemical and functional characteristics of Mexican serviceberry fruit. J. Berry Res. 2015, 5, 97–105. [Google Scholar] [CrossRef]

- Kudra, D.T. Energy aspects in drying. Dry. Technol. 2004, 22, 917–932. [Google Scholar] [CrossRef]

- Zotarelli, M.F.; Porciuncula, B.D.A.; Laurindo, J.B. A convective multi-flash drying process for producing dehydrated crispy fruits. J. Food Eng. 2012, 108, 523–531. [Google Scholar] [CrossRef]

- Nimmol, C.; Devahastin, S. Evaluation of performance and energy consumption of an impinging stream dryer for paddy. Appl. Therm. Eng. 2010, 30, 2204–2212. [Google Scholar] [CrossRef]

- Musielak, G.; Mierzwa, D.; Kroehnke, J. Food drying enhancement by ultrasound—A review. Trends Food Sci. Technol. 2016, 56, 126–141. [Google Scholar] [CrossRef]

- Reyes, A.; Campos, C.; Vega, R. Drying of turnip seeds with microwaves in fixed and pulsed fluidized beds. Dry. Technol. 2006, 24, 1469–1480. [Google Scholar] [CrossRef]

- Gunasekaran, S. Pulsed microwave-vacuum drying of food materials. Dry. Technol. 1999, 17, 395–412. [Google Scholar] [CrossRef]

- Vadivambal, R.; Jayas, D.S. Changes in quality of microwave-treated agricultural products—A review. Biosyst. Eng. 2007, 98, 1–16. [Google Scholar] [CrossRef]

- Hu, Q.; Zhang, M.; Mujumdar, A.S.; Xiao, G.; Jin-Cai, S. Drying of edamames by hot air and vacuum microwave combination. J. Food Eng. 2006, 77, 977–982. [Google Scholar] [CrossRef]

- Calín-Sánchez, Á.; Figiel, A.; Wojdyło, A.; Szarycz, M.; Carbonell-Barrachina, Á.A. Drying of garlic slices using convective pre-drying and vacuum-microwave finishing drying: Kinetics, energy consumption, and quality studies. Food Bioprocess Technol. 2013, 7, 398–408. [Google Scholar] [CrossRef]

- Wojdyło, A.; Figiel, A.; Oszmiański, J. Effect of drying methods with the application of vacuum microwaves on the bioactive compounds, color, and antioxidant activity of strawberry fruits. J. Agric. Food Chem. 2009, 57, 1337–1343. [Google Scholar] [CrossRef] [PubMed]

- Sham, P.W.Y.; Scaman, C.H.; Durance, T.D. Texture of vacuum microwave dehydrated apple chips as affected by calcium pretreatment, vacuum level, and apple variety. J. Food Sci. 2001, 66, 1341–1347. [Google Scholar] [CrossRef]

- Alves-Filho, O. Heat pump dryers: Theory, design and industrial applications. Available online: https://www.crcpress.com/Heat-Pump-Dryers-Theory-Design-and-Industrial-Applications/Alves-Filho/p/book/9781498711333 (accessed on 11 November 2016).

- Chong, C.H.; Law, C.L.; Figiel, A.; Wojdyło, A.; Oziembłowski, M. Colour, phenolic content and antioxidant capacity of some fruits dehydrated by a combination of different methods. Food Chem. 2013, 141, 3889–3896. [Google Scholar] [CrossRef] [PubMed]

- Devahastin, S.; Suvarnakuta, P.; Soponronnarit, S.; Mujumdar, A.S. A comparative study of low-pressure superheated steam and vacuum drying of a heat-sensitive material. Dry. Technol. 2004, 22, 1845–1867. [Google Scholar] [CrossRef]

- Lazarides, H.N.; Katsanidis, E.; Nickolaidis, A. Mass transfer kinetics during osmotic preconcentration aiming at minimal solid uptake. J. Food Eng. 1995, 25, 151–166. [Google Scholar] [CrossRef]

- Fito, P. Modelling of vacuum osmotic dehydration of food. J. Food Eng. 1994, 22, 313–328. [Google Scholar] [CrossRef]

- Garcia-Noguera, J.; Oliveira, F.I.P.; Gallão, M.I.; Weller, C.L.; Rodrigues, S.; Fernandes, F.A.N. Ultrasound-assisted osmotic dehydration of strawberries: effect of pretreatment time and ultrasonic frequency. Dry. Technol. 2010, 28, 294–303. [Google Scholar] [CrossRef]

- Lech, K.; Figiel, A.; Wojdyło, A.; Korzeniowska, M.; Serowik, M.; Szarycz, M. Drying kinetics and bioactivity of beetroot slices pretreated in concentrated chokeberry juice and dried with vacuum microwaves. Dry. Technol. 2015, 33, 1644–1653. [Google Scholar] [CrossRef]

- Zielinska, M.; Michalska, A. Microwave-assisted drying of blueberry (Vaccinium corymbosum L.) fruits: Drying kinetics, polyphenols, anthocyanins, antioxidant capacity, colour and texture. Food Chem. 2016, 212, 671–680. [Google Scholar] [CrossRef] [PubMed]

- Sunjka, P.S.; Rennie, T.J.; Beaudry, C.; Raghavan, G.S.V. Microwave-convective and microwave-vacuum drying of cranberries: A comparative study. Dry. Technol. 2004, 22, 1217–1231. [Google Scholar] [CrossRef]

- Krulis, M.; Kühnert, S.; Leiker, M.; Rohm, H. Influence of energy input and initial moisture on physical properties of microwave-vacuum dried strawberries. Eur. Food Res. Technol. 2005, 221, 803–808. [Google Scholar] [CrossRef]

- Mousa, N.; Farid, M. Microwave vacuum drying of banana slices. Dry. Technol. 2002, 20, 2055–2066. [Google Scholar] [CrossRef]

- Nawirska, A.; Figiel, A.; Kucharska, A.Z.; Sokół-Łętowska, A.; Biesiada, A. Drying kinetics and quality parameters of pumpkin slices dehydrated using different methods. J. Food Eng. 2009, 94, 14–20. [Google Scholar] [CrossRef]

- Cui, Z.-W.; Xu, S.-Y.; Sun, D.-W. Microwave–vacuum drying kinetics of carrot slices. J. Food Eng. 2004, 65, 157–164. [Google Scholar] [CrossRef]

- Cui, Z.-W.; Xu, S.-Y.; Sun, D.-W. Dehydration of garlic slices by combined microwave-vacuum and air drying. Dry. Technol. 2003, 21, 1173–1184. [Google Scholar] [CrossRef]

- Delwiche, S.R.; Shupe, W.L.; Pearson, J.L.; Sanders, T.H.; Wilson, D.M. Microwave vacuum drying effect on peanut quality. Peanut Sci. 1986, 13, 21–27. [Google Scholar] [CrossRef]

- Chan, E.W.C.; Lim, Y.Y.; Wong, S.K.; Lim, K.K.; Tan, S.P.; Lianto, F.S.; Yong, M.Y. Effects of different drying methods on the antioxidant properties of leaves and tea of ginger species. Food Chem. 2009, 113, 166–172. [Google Scholar] [CrossRef]

- Calín-Sánchez, Á.; Figiel, A.; Lech, K.; Szumny, A.; Martínez-Tomé, J.; Carbonell-Barrachina, Á.A. Dying methods affect the aroma of Origanum majorana L. analyzed by GC–MS and descriptive sensory analysis. Ind. Crops Prod. 2015, 74, 218–227. [Google Scholar] [CrossRef]

- Tang, J. Dielectric properties of foods. In The Microwave Processing of Foods; Schubert, H., Regier, M., Eds.; CRC Press LLC: Boca Raton, FL, USA; Boston, MA, USA; New York, NY, USA; Washington, DC, USA, 2005; pp. 22–40. [Google Scholar]

- Lin, T.M.; Durance, T.D.; Scaman, C.H. Characterization of vacuum microwave, air and freeze dried carrot slices. Food Res. Int. 1998, 31, 111–117. [Google Scholar] [CrossRef]

- Lewicki, P.P. Some remarks on rehydration of dried foods. J. Food Eng. 1998, 36, 81–87. [Google Scholar] [CrossRef]

- Figiel, A. Dehydration of apple by a combination of convective and vacuum-microwave drying. Pol. J. Food Nutr. Sci. 2007, 57, 131–135. [Google Scholar]

- Figiel, A. Drying kinetics and quality of vacuum-microwave dehydrated garlic cloves and slices. J. Food Eng. 2009, 94, 98–104. [Google Scholar] [CrossRef]

- Manzocco, L.; Calligaris, S.; Mastrocola, D.; Nicoli, M.C.; Lerici, C.R. Review of non-enzymatic browning and antioxidant capacity in processed foods. Trends Food Sci. Technol. 2000, 11, 340–346. [Google Scholar] [CrossRef]

- Morales, F.J.; Jiménez-Pérez, S. Free radical scavenging capacity of Maillard reaction products as related to colour and fluorescence. Food Chem. 2001, 72, 119–125. [Google Scholar] [CrossRef]

- Yilmaz, Y.; Toledo, R. Antioxidant activity of water-soluble Maillard reaction products. Food Chem. 2005, 93, 273–278. [Google Scholar] [CrossRef]

- Michalska, A.; Wojdyło, A.; Lech, K.; Łysiak, G.P.; Figiel, A. Physicochemical properties of whole fruit plum powders obtained using different drying technologies. Food Chem. 2016, 207, 223–232. [Google Scholar] [CrossRef] [PubMed]

- Wojdyło, A.; Figiel, A.; Lech, K.; Nowicka, P.; Oszmiański, J. Effect of convective and vacuum–microwave drying on the bioactive compounds, color, and antioxidant capacity of sour cherries. Food Bioprocess Technol. 2014, 7, 829–841. [Google Scholar] [CrossRef]

- Wojdyło, A.; Figiel, A.; Legua, P.; Lech, K.; Carbonell-Barrachina, Á.A.; Hernández, F. Chemical composition, antioxidant capacity, and sensory quality of dried jujube fruits as affected by cultivar and drying method. Food Chem. 2016, 207, 170–179. [Google Scholar] [CrossRef] [PubMed]

- Hamrouni-Sellami, I.; Rahali, F.Z.; Rebey, I.B.; Bourgou, S.; Limam, F.; Marzouk, B. Total phenolics, flavonoids, and antioxidant activity of sage (Salvia officinalis L.) plants as affected by different drying methods. Food Bioprocess Technol. 2013, 6, 806–817. [Google Scholar] [CrossRef]

- Vvedenskaya, I.O.; Rosen, R.T.; Guido, J.E.; Russell, D.J.; Mills, K.A.; Vorsa, N. Characterization of flavonols in cranberry (Vaccinium macrocarpon) powder. J. Agric. Food Chem. 2004, 52, 188–195. [Google Scholar] [CrossRef] [PubMed]

- Mejia-Meza, E.; Yanez, J.A.; Davies, N.M.; Rasco, B.; Younce, F.; Remsberg, C.; Clary, C. Improving nutritional value of dried blueberries (Vaccinium corymbosum L.) combining microwave-vacuum, hot-air drying and freeze drying technologies. Int. J. Food Eng. 2008, 4. [Google Scholar] [CrossRef]

- Leusink, G.J.; Kitts, D.D.; Yaghmaee, P.; Durance, T. Retention of antioxidant capacity of vacuum microwave dried cranberry. J. Food Sci. 2010, 75, C311–C316. [Google Scholar] [CrossRef] [PubMed]

- Durance, T.D.; Wang, J.H. Energy consumption, density, and rehydration rate of vacuum microwave- and hot-air convection-dehydrated tomatoes. J. Food Sci. 2002, 67, 2212–2216. [Google Scholar] [CrossRef]

- Böhm, V.; Kühnert, S.; Rohm, H.; Scholze, G. Improving the nutritional quality of microwave-vacuum dried strawberries: A preliminary study. Food Sci. Technol. Int. 2006, 12, 67–75. [Google Scholar] [CrossRef]

- Henderson, S.; Pabis, S. Grain drying theory I. Temperature effect on drying coefficient. J. Agric. Eng. Res. 1961, 6, 169–174. [Google Scholar]

- Andrés, A.; Bilbao, C.; Fito, P. Drying kinetics of apple cylinders under combined hot air–microwave dehydration. J. Food Eng. 2004, 63, 71–78. [Google Scholar] [CrossRef]

- Szumny, A.; Figiel, A.; Gutiérrez-Ortíz, A.; Carbonell-Barrachina, Á.A. Composition of rosemary essential oil (Rosmarinus officinalis) as affected by drying method. J. Food Eng. 2010, 97, 253–260. [Google Scholar] [CrossRef]

- Figiel, A.; Szumny, A.; Gutiérrez-Ortíz, A.; Carbonell-Barrachina, Á.A. Composition of oregano essential oil (Origanum vulgare) as affected by drying method. J. Food Eng. 2010, 98, 240–247. [Google Scholar] [CrossRef]

- Cui, Z.-W.; Xu, S.-Y.; Sun, D.-W.; Chen, W. Temperature changes during microwave-vacuum drying of sliced carrots. Dry. Technol. 2005, 23, 1057–1074. [Google Scholar] [CrossRef]

- Calín-Sánchez, Á.; Lech, K.; Szumny, A.; Figiel, A.; Carbonell-Barrachina, Á.A. Volatile composition of sweet basil essential oil (Ocimum basilicum L.) as affected by drying method. Food Res. Int. 2012, 48, 217–225. [Google Scholar] [CrossRef]

- Calín-Sánchez, Á.; Figiel, A.; Lech, K.; Szumny, A.; Carbonell-Barrachina, Á.A. Effects of drying methods on the composition of thyme (Thymus vulgaris L.) essential oil. Dry. Technol. 2013, 31, 224–235. [Google Scholar] [CrossRef]

- Calín-Sanchez, Á.; Figiel, A.; Szarycz, M.; Lech, K.; Nuncio-Jáuregui, N.; Carbonell-Barrachina, Á.A. Drying kinetics and energy consumption in the dehydration of pomegranate (Punica granatum L.) arils and rind. Food Bioprocess Technol. 2013, 7, 2071–2083. [Google Scholar] [CrossRef]

- Fatouh, M.; Metwally, M.N.; Helali, A.B.; Shedid, M.H. Herbs drying using a heat pump dryer. Energy Convers. Manag. 2006, 47, 2629–2643. [Google Scholar] [CrossRef]

- Alves-Filho, O.; Eikevik, T.M.; Goncharova-Alves, S.V. Single- and multistage heat pump drying of protein. Dry. Technol. 2008, 26, 470–475. [Google Scholar] [CrossRef]

- Horszwald, A.; Alves-Filho, O. Innovative blueberry heat pump drying technology: Evaluation of anthocyanins, antioxidant capacity and kinetics. In Proceedings of the 6th Nordic Drying Conference, Copenhagen, Denmark, 5–7 June 2013.

- Patel, K.K.; Kar, A. Heat pump assisted drying of agricultural produce—An overview. J. Food Sci. Technol. 2012, 49, 142–160. [Google Scholar] [CrossRef] [PubMed]

- Chong, C.H.; Figiel, A.; Law, C.L.; Wojdyło, A. Combined drying of apple cubes by using of heat pump, vacuum-microwave, and intermittent techniques. Food Bioprocess Technol. 2013, 7, 975–989. [Google Scholar] [CrossRef]

- Lim, Y.Y.; Murtijaya, J. Antioxidant properties of Phyllanthus amarus extracts as affected by different drying methods. LWT Food Sci. Technol. 2007, 40, 1664–1669. [Google Scholar] [CrossRef]

- Dueñas, M.; Hernández, T.; Estrella, I. Influence of the action of exogenous enzymes on the polyphenolic composition of pea: Effect on the antioxidant activity. Eur. Food Res. Technol. 2007, 225, 493–500. [Google Scholar] [CrossRef]

- Donovan, J.L.; Meyer, A.S.; Waterhouse, A.L. Phenolic composition and antioxidant activity of prunes and prune juice (Prunus domestica). J. Agric. Food Chem. 1998, 46, 1247–1252. [Google Scholar] [CrossRef]

- Ferreira, D.; Guyot, S.; Marnet, N.; Delgadillo, I.; Renard, C.M.G.C.; Coimbra, M.A. Composition of phenolic compounds in a Portuguese pear (Pyrus communis L. var. S. Bartolomeu) and changes after sun-drying. J. Agric. Food Chem. 2002, 50, 4537–4544. [Google Scholar] [PubMed]

- Piga, A.; del Caro, A.; Corda, G. From plums to prunes: Influence of drying parameters on polyphenols and antioxidant activity. J. Agric. Food Chem. 2003, 51, 3675–3681. [Google Scholar] [CrossRef] [PubMed]

- Chong, C.H.; Law, C.L.; Cloke, M.; Abdullah, L.C.; Daud, W.R.W. Drying models and quality analysis of sun-dried ciku. Dry. Technol. 2009, 27, 985–992. [Google Scholar] [CrossRef]

- Chong, C.; Figiel, A.; Wojdyło, A.; Law, C.L. Drying kinetics, biochemical, physical appearance and rheology properties of combined hybrid heat pump vacuum-microwave drying of ciku. In Proceeding of the 4th World Engineering Congress, Kuching, Malaysia, 2–5 August 2010.

- Raoult-Wack, A.L. Recent advances in the osmotic dehydration of foods. Trends Food Sci. Technol. 1994, 5, 255–260. [Google Scholar] [CrossRef]

- Pereira, L.M.; Ferrari, C.C.; Mastrantonio, S.D.S.; Rodrigues, A.C.C.; Hubinger, M.D. Kinetic aspects, texture, and color evaluation of some tropical fruits during osmotic dehydration. Dry. Technol. 2006, 24, 475–484. [Google Scholar] [CrossRef]

- Mayor, L.; Moreira, R.; Chenlo, F.; Sereno, A.M. Osmotic dehydration kinetics of pumpkin fruits using ternary solutions of sodium chloride and sucrose. Dry. Technol. 2007, 25, 1749–1758. [Google Scholar] [CrossRef]

- Emam-Djomeh, Z.; Dehghannya, J.; Gharabagh, R.S. Assessment of osmotic process in combination with coating on effective diffusivities during drying of apple slices. Dry. Technol. 2006, 24, 1159–1164. [Google Scholar] [CrossRef]

- Korzeniowska, M.; Figiel, A.; Lech, K.; Oziembłowski, M.; Szarycz, M. Sensory properties of pumpkin treated with sucrose osmotic solutions followed by vacuum-microwave drying. In Product Development and Quality Assurance; Jarmouk, A., Oziembłowski, M., Zimoch, A., Eds.; Wrocław University of Environmental and Life Sciences Publishing House: Wroclaw, Poland, 2011; pp. 157–170. [Google Scholar]

- Piotrowski, D.; Lenart, A.; Wardzyński, A. Influence of osmotic dehydration on microwave-convective drying of frozen strawberries. J. Food Eng. 2004, 65, 519–525. [Google Scholar] [CrossRef]

- Falade, K.O.; Akinwale, T.O.; Adedokun, O.O. Effect of drying methods on osmotically dehydrated cashew apples. Eur. Food Res. Technol. 2003, 216, 500–504. [Google Scholar] [CrossRef]

- Shafafi Zenoozian, M.; Devahastin, S. Application of wavelet transform coupled with artificial neural network for predicting physicochemical properties of osmotically dehydrated pumpkin. J. Food Eng. 2009, 90, 219–227. [Google Scholar] [CrossRef]

- Falade, K.O.; Oyedele, O.O. Effect of osmotic pretreatment on air drying characteristics and colour of pepper (Capsicum spp) cultivars. J. Food Sci. Technol. 2010, 47, 488–495. [Google Scholar] [CrossRef] [PubMed]

- Al-Harahsheh, M.; Al-Muhtaseb, A.H.; Magee, T.R.A. Microwave drying kinetics of tomato pomace: Effect of osmotic dehydration. Chem. Eng. Process. Process Intensif. 2009, 48, 524–531. [Google Scholar] [CrossRef]

- Chua, K.J.; Chou, S.K.; Mujumdar, A.S.; Ho, J.C.; Hon, C.K. Radiant-convective drying of osmotic treated agro-products: effect on drying kinetics and product quality. Food Control 2004, 15, 145–158. [Google Scholar] [CrossRef]

- Torringa, E.; Esveld, E.; Scheewe, I.; van den Berg, R.; Bartels, P. Osmotic dehydration as a pre-treatment before combined microwave-hot-air drying of mushrooms. J. Food Eng. 2001, 49, 185–191. [Google Scholar] [CrossRef]

- Nowicka, P.; Wojdyło, A.; Lech, K.; Figiel, A. Influence of osmodehydration pretreatment and combined drying method on the bioactive potential of sour cherry fruits. Food Bioprocess Technol. 2014, 8, 824–836. [Google Scholar] [CrossRef]

- Corrêa, J.L.G.; Dev, S.R.S.; Gariepy, Y.; Raghavan, G.S.V. Drying of pineapple by microwave-vacuum with osmotic pretreatment. Dry. Technol. 2011, 29, 1556–1561. [Google Scholar] [CrossRef]

- Lech, K.; Figiel, A.; Oziembłowski, M. Application of sodium chloride osmotic solutions and vacuum-microwaves as drying methods for beetroot slices. In Novel Operations and Materials in Food Processing; Kopeć, W., Korzeniowska, M., Eds.; Publishing House of Wroclaw University of Environmental and Life Sciences: Wroclaw, Poland, 2011; pp. 41–53. [Google Scholar]

- Figiel, A.; Oziembłowski, M.; Korzeniowska, M.; Szarycz, M. The effect of a vacuum-microwave drying after osmotic pre-treatment in sodium chloride solutions on the quality of pumpkin slices. In Novel Operations and Materials in Food Processing; Kopeć, W., Korzeniowska, M., Eds.; Publishing House of Wroclaw University of Environmental and Life Sciences: Wroclaw, Poland, 2011; pp. 27–40. [Google Scholar]

- Figiel, A.; Wojdyło, A.; Nowicka, P. Vacuum-microwave drying of pumpkin slices pre-treated in concentrated raspberry juice. In Proceedings of the XIII Polish Drying Symposium, Kołobrzeg, Poland, 5–6 September 2013.

- Figiel, A.; Lech, K.; Nawirska-Olszanska, A.; Wojdyło, A. Method for Obtaining Chips from Fruits or Vegetables. Patent 400135, 3 November 2014. [Google Scholar]

- Figiel, A.; Wojdyło, A.; Nowicka, P. Vacuum-microwave drying of pumpkin slices pre-treated in concentrated chokeberry juice. In Proceedings of the 6th Nordic Drying Conference, Kopenhagen, Denmark, 5–7 June 2013; p. 34.

- Calín-Sánchez, Á.; Kharaghani, A.; Lech, K.; Figiel, A.; Carbonell-Barrachina, Á.A.; Tsotsas, E. Drying kinetics and microstructural and sensory properties of black chokeberry (Aronia melanocarpa) as affected by drying method. Food Bioprocess Technol. 2015, 8, 63–74. [Google Scholar] [CrossRef]

- Azuara, E.; Garcia, H.S.; Beristain, C.I. Effect of the centrifugal force on osmotic dehydration of potatoes and apples. Food Res. Int. 1996, 29, 195–199. [Google Scholar] [CrossRef]

- Beker, C. Energy efficiency in drying. Stewart Post-Harvest Rev. 2005, 4, 8–12. [Google Scholar] [CrossRef]

- Nicoli, M.C.; Anese, M.; Parpinel, M. Influence of processing on the antioxidant properties of fruit and vegetables. Trends Food Sci. Technol. 1999, 10, 94–100. [Google Scholar] [CrossRef]

- Chan, J.W.R.; Chong, C.; Abdul Malek, N.F.; Khek, C.H.; Figiel, A.; Wojdyło, A. Trends in drying and extracting bioactive components from herbs. In Processing of Foods, Vegetables and Fruits: Recent Advances; Hii, C.L., Jangam, S.V., Ong, S.Z., Show, P.L., Mujumbar, A.S., Eds.; National University of Singapore: Singapore, 2015; pp. 85–104. [Google Scholar]

- Drouzas, A.E.; Schubert, H. Microwave application in vacuum drying of fruits. J. Food Eng. 1996, 28, 203–209. [Google Scholar] [CrossRef]

- Hosseinpour, S.; Rafiee, S.; Aghbashlo, M.; Mohtasebi, S.S. A novel image processing approach for in-line monitoring of visual texture during shrimp drying. J. Food Eng. 2014, 143, 154–166. [Google Scholar] [CrossRef]

- Benalia, S.; Cubero, S.; Prats-Montalban, J.M.; Bernardi, B.; Zimbalatti, G.; Blasco, J. Computer vision for automatic quality inspection of dried figs (Ficus carica L.) in real-time. Comput. Electron. Agric. 2016, 120, 17–25. [Google Scholar] [CrossRef]

- Udomkun, P.; Nagle, M.; Argyropoulos, D.; Mahayothee, B.; Muller, J. Multi-sensor approach to improve optical monitoring of papaya shrinkage during drying. J. Food Eng. 2016, 189, 82–89. [Google Scholar] [CrossRef]

- Brosnan, T.; Sun, D.-W. Improving quality inspection of food products by computer vision—A review. J. Food Eng. 2004, 61, 3–16. [Google Scholar] [CrossRef]

- Sampson, D.J.; Chang, Y.K.; Rupasinghe, H.P.V.; Zaman, Q.U.Z. A dual-view computer-vision system for volume and image texture analysis in a multiple apple slices drying. J. Food Eng. 2014, 127, 49–57. [Google Scholar] [CrossRef]

- Coskun, A.L.; Turkyilmaz, M.; Aksu, O.T.; Koc, B.E.; Yemis, O.; Ozkan, M. Effects of various sulphuring methods and storage temperatures on the physical and chemical quality of dried apricots. Food Chem. 2013, 141, 3670–3680. [Google Scholar] [CrossRef] [PubMed]

- Acevedo, N.C.; Briones, V.; Buera, P.; Aguilera, J.M. Microstructure affects the rate of chemical, physical and color changes during storage of dried apple discs. J. Food Eng. 2008, 85, 222–231. [Google Scholar] [CrossRef]

- Agudelo-Laverde, L.M.; Schebor, C.; del Pilar Buera, M. Water content effect on the chromatic attributes of dehydrated strawberries during storage, as evaluated by image analysis. LWT Food Sci. Technol. 2013, 52, 157–162. [Google Scholar] [CrossRef]

| Plant Material | Parameter | t (min) | T (°C) | TPC (mg 100 g−1) | FRAP (mmol Trolox 100 g−1 dm) | TV (mg 100 g−1 dm) | References | |

|---|---|---|---|---|---|---|---|---|

| Strawberries “Elsanta” | Fresh | 2405.9 | 18.1 | [35] | ||||

| FD | 30 | 2411.5 | 16.8 | |||||

| CD | 70 °C | 550 | 70 | 1541.5 | 13.6 | |||

| VMD | 240 W | 33 | 2302.4 | 14.4 | ||||

| 360 W | 21 | 2277.8 | 12.5 | |||||

| 480 W | 16 | 2253.2 | 16.2 | |||||

| Cherries | Fresh | 790.6 | 24.49 | [63] | ||||

| FD | 26 | 653.8 | 24.06 | |||||

| CD | 50 °C | 2400 | 50 | 518.2 | 16.62 | |||

| 60 °C | 1450 | 60 | 488.6 | 13.26 | ||||

| 70 °C | 840 | 70 | 479.2 | 12.71 | ||||

| VMD | 240 W | 28 | 87.5 | 641.0 | 14.73 | |||

| 240/120 W | 48 | 62.3 | 751.0 | 16.45 | ||||

| 360/240 W | 24 | 77.1 | 619.5 | 15.76 | ||||

| 360/120 W | 44 | 64.5 | 732.0 | 18.24 | ||||

| 480/240 W | 23 | 81.2 | 652.6 | 16.93 | ||||

| 480/120 W | 40 | 61.3 | 758.7 | 18.96 | ||||

| Marjoram | Fresh | 825 | [53] | |||||

| CD | 40 °C | 2100 | 40 | 677 | ||||

| 50 °C | 500 | 50 | 637 | |||||

| 60 °C | 250 | 60 | 573 | |||||

| VMD | 240 W | 28 | 53 | 965 | ||||

| 360 W | 21 | 51 | 896 | |||||

| 480 W | 14 | 48 | 820 | |||||

| Jujube “MSI” | FD | 26 | 981 | 48.2 | [64] | |||

| CD | 50 °C | 660 | 50 | 430 | 31.7 | |||

| 60 °C | 420 | 60 | 637 | 17.7 | ||||

| 70 °C | 330 | 70 | 367 | 15.9 | ||||

| VMD | 120 W | 96 | 74 | 813 | 27.1 | |||

| 480 W | 28 | 142 | 567 | 26.2 | ||||

| 480/120 W | 64 | 79 | 982 | 47.8 | ||||

| Plum halves | FD | 20 | 1352.3 | 8.72 | [62] | |||

| CD | 70 °C | 3250 | 70 | 1135.9 | 6.73 | |||

| VMD | 120 W | 120 | 75.8 | 1593.9 | 10.08 | |||

| 480 W | 32 | 128.5 | 872.8 | 11.58 | ||||

| 480/120 W | 100 | 61.9 | 1064.5 | 10.31 | ||||

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Figiel, A.; Michalska, A. Overall Quality of Fruits and Vegetables Products Affected by the Drying Processes with the Assistance of Vacuum-Microwaves. Int. J. Mol. Sci. 2017, 18, 71. https://doi.org/10.3390/ijms18010071

Figiel A, Michalska A. Overall Quality of Fruits and Vegetables Products Affected by the Drying Processes with the Assistance of Vacuum-Microwaves. International Journal of Molecular Sciences. 2017; 18(1):71. https://doi.org/10.3390/ijms18010071

Chicago/Turabian StyleFigiel, Adam, and Anna Michalska. 2017. "Overall Quality of Fruits and Vegetables Products Affected by the Drying Processes with the Assistance of Vacuum-Microwaves" International Journal of Molecular Sciences 18, no. 1: 71. https://doi.org/10.3390/ijms18010071

APA StyleFigiel, A., & Michalska, A. (2017). Overall Quality of Fruits and Vegetables Products Affected by the Drying Processes with the Assistance of Vacuum-Microwaves. International Journal of Molecular Sciences, 18(1), 71. https://doi.org/10.3390/ijms18010071