The Potential Application of Starch and Walnut Shells as Biofillers for Natural Rubber (NR) Composites

Abstract

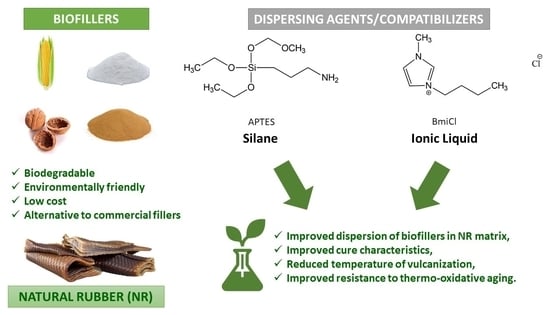

:1. Introduction

2. Results and Discussion

2.1. Cure Characteristics and Crosslink Density of NR Composites

2.2. Dispersion of Biofillers and Curatives in NR Composites

2.3. Tensile Properties and Hardness of NR Composites Filled with Biofillers

2.4. Dynamic Mechanical Properties of NR Composites Filled with Biofillers

2.5. Thermo-Oxidative Aging Resistance of NR Composites Filled with Biofillers

2.6. Thermal Stability of NR Composites Filled with Biofillers

3. Materials and Methods

3.1. Materials

3.2. Preparation and Characterization of NR Compounds

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wypych, G. Handbook of Fillers, 4th ed.; ChemTec Publishing: Toronto, ON, Canada, 2016. [Google Scholar]

- Gonzales-Fernandes, M.; Andrade, C.G.B.; Esper, F.J.; Valenzuela-Diaz, F.R.; Wiebeck, H. Improvement of Mechanical Properties in Natural Rubber with Organic Fillers. In Characterization of Minerals, Metals, and Materials 2016; Ikhmayies, S.J., Li, B., Carpenter, J.S., Hwang, J.-Y., Monteiro, S.N., Li, J., Firrao, D., Zhang, M., Peng, Z., Escobedo-Diaz, J.P., et al., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2016; pp. 623–627. [Google Scholar] [CrossRef]

- Li, M.-C.; Cho, U.R. Effectiveness of Coupling Agents in the Poly(methylmethacrylate)-Modified Starch/Styrene-Butadiene Rubber Interfaces. Mater. Lett. 2013, 92, 132–135. [Google Scholar] [CrossRef]

- Jethoo, A.S. Effect of Fiber Reinforcement on Tensile Strength and Flexibility of Corn Starch-Based Bioplastic. IOP Conf. Ser. Mater. Sci. Eng. 2019, 652, 012035. [Google Scholar] [CrossRef]

- Kopcilova, M.; Hubackova, J.; Ruzicka, J.; Dvorackova, M.; Julinova, M.; Koutny, M.; Tomalova, M.; Alexy, P.; Bugaj, P.; Filip, J. Biodegradability and Mechanical Properties of Poly(vinyl alcohol)-Based Blend Plastics Trough Extrusion Method. J. Polym. Environ. 2013, 21, 88–94. [Google Scholar] [CrossRef]

- Roy, K.; Debnath, S.C.; Pongwisuthiruchte, A.; Potiyaraj, P. Recent Advances of Natural Fibers Based Green Rubber Composites: Properties, Current Status, and Future Perspectives. J. Appl. Polym. Sci. 2021, 138, e50866. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A Review of the Recent Developments in Biocomposites Based on Natural Fibres and Their Application Perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Morreale, M. Green Composites: A Brief Review. Compos. Part A Appl. Sci. Manuf. 2011, 42, 579–588. [Google Scholar] [CrossRef]

- Masek, A.; Cichosz, S.; Piotrowska, M. Biocomposites of Epoxidized Natural Rubber/Poly(lactic acid) Modified with Natural Fillers (Part I). Int. J. Mol. Sci. 2021, 22, 3150. [Google Scholar] [CrossRef]

- Clotildes, S.; Rodrigues, S.; da Silva, A.S.; de Carvalho, L.H.; Alves, T.S.; Barbosa, R. Morphological, Structural, Thermal Properties of a Native Starch Obtained from Babassu Mesocarp for Food Packaging Application. J. Mater. Res. Technol. 2020, 9, 15670–15678. [Google Scholar] [CrossRef]

- Ye, J.; Luo, S.; Huang, A.; Chen, J.; Liu, C.; McClements, D.J. Synthesis and Characterization of Citric Acid Esterified Rice Starch by Reactive Extrusion: A New Method of Producing Resistant Starch. Food Hydrocoll. 2019, 92, 135–142. [Google Scholar] [CrossRef]

- Misman, M.A.; Rashid, A.; Yahya, S.R. Modification and Application of Starch in Natural Rubber Latex Composites. Rubber Chem. Technol. 2018, 91, 184–204. [Google Scholar] [CrossRef]

- Amin, M.R.; Mahmud, M.A.; Anannya, F.R. Natural Fiber Reinforced Starch Based Biocomposites. Polym. Sci. Ser. A 2019, 61, 533–543. [Google Scholar] [CrossRef]

- Yin, P.; Dong, X.; Zhou, W.; Zha, D.; Xu, J.; Guo, B.; Li, P. A Novel Method to Produce Sustainable Biocomposites Based on Thermoplastic Corn-Starch Reinforced by Polyvinyl Alcohol Fibers. RSC Adv. 2020, 10, 23632–23643. [Google Scholar] [CrossRef] [PubMed]

- Rouilly, A.; Rigal, L.; Gilbert, R.G. Synthesis and Properties of Composites of Starch and Chemically Modified Natural Rubber. Polymer 2004, 45, 7813–7820. [Google Scholar] [CrossRef] [Green Version]

- Gunawardene, O.H.P.; Gunathilake, C.; Amaraweera, S.; Fernando, N.M.L.; Wanninayaka, D.; Manamperi, A.; Kulatungam, A.; Rajapaksha, S.; Dassanayake, R.; Fernando, C.A.N.; et al. Compatibilization of Starch/Synthetic Biodegradable Polymer Blends for Packaging Applications: A Review. J. Compos. Sci. 2021, 5, 300. [Google Scholar] [CrossRef]

- Ojogbo, E.; Ogunsona, E.O.; Mekonnen, T.H. Chemical and Physical Modifications of Starch for Renewable Polymeric Materials. Mater. Today Sustain. 2020, 7–8, 100028–100106. [Google Scholar] [CrossRef]

- Ptak, S.; Zarski, A.; Kapusniak, J. The Importance of Ionic Liquids in the Modification of Starch and Processing of Starch-Based Materials. Materials 2020, 13, 4479. [Google Scholar] [CrossRef]

- Gericke, M.; Fardim, P.; Heinze, T. Ionic Liquids—Promising but Challenging Solvents for Homogeneous Derivatization of Cellulose. Molecules 2012, 17, 7458–7502. [Google Scholar] [CrossRef] [Green Version]

- Lehmann, A.; Volkert, B. Investigations on Esterification Reactions of Starches in 1-N-butyl-3-methylimidazolium chloride and Resulting Substituent Distribution. J. Appl. Polym. Sci. 2009, 114, 369–376. [Google Scholar] [CrossRef]

- Xu, Q.; Kennedy, J.F.; Liu, L.J. An Ionic Liquid as Reaction Media in the Ring Opening Graft Polymerization of ε-caprolactone Onto Starch Granules. Carbohydr. Polym. 2008, 72, 113–121. [Google Scholar] [CrossRef]

- Stevenson, D.G.; Biswas, A.; Jane, J.L.; Inglett, G.E. Changes in Structure and Properties of Starch of Four Botanical Sources Dispersed in the Ionic Liquid, 1-butyl-3-methylimidazolium chloride. Carbohydr. Polym. 2007, 67, 21–31. [Google Scholar] [CrossRef]

- Anderson, E.B.; Long, T.E. Imidazole- and Imidazolium-containing Polymers for Biology and Material Science Applications. Polymer 2010, 51, 2447–2454. [Google Scholar] [CrossRef] [Green Version]

- El-Hamshary, H.; Fouda, M.M.G.; Mohideen, M.; El-Newehy, M.H.; Al-Deyab, S.S.; Abdel-Megeed, A. Synthesis and Antibacterial of Carboxymethyl Starch-grafted Poly(vinyl imidazole) Against Some Plant Pathogens. Int. J. Biol. Macromol. 2015, 72, 1466–1472. [Google Scholar] [CrossRef] [PubMed]

- Jordan, T.; Schmidt, S.; Liebert, T.; Heinze, T. Molten Imidazole—A Starch Solvent. Green Chem. 2014, 16, 1967–1973. [Google Scholar] [CrossRef]

- Shah, M.A.; Khan, M.N.S.; Kumar, V. Biomass Residue Characterization for Their Potential Application as Biofuels. J. Therm. Anal. Calorim. 2018, 134, 2137–2145. [Google Scholar] [CrossRef]

- Wang, X.; Chen, H.; Li, S.; Zhou, J.; Xu, J. Physicochemical Properties Antioxidant Activities and Antihypertensive Effects of Walnut Protein and Its Hydrolysates. J. Sci. Food Agric. 2016, 96, 2579–2587. [Google Scholar] [CrossRef]

- Li, S.; Xu, S.; Liu, S.; Yang, C.; Lu, Q. Fast Pyrolysis of Biomass in Freefall Reactor for Hydrogen-rich Gas. Fuel Process. Technol. 2004, 85, 1201–1211. [Google Scholar] [CrossRef]

- Gungor, A.; Akbay, I.K.; Ozdemir, T. Waste Walnut Shell as an Alternative Bio-based Filler for the EPDM: Mechanical, Thermal, and Kinetic Studies. J. Mater. Cycles Waste Manag. 2019, 21, 145–154. [Google Scholar] [CrossRef]

- Karaagac, B. Use of Ground Pistachio Shell as Alternative Filler in Natural Rubber/Styrene-butadiene Rubber-Based Rubber Compounds. Polym. Compos. 2014, 35, 245–252. [Google Scholar] [CrossRef]

- Patil, A.G.; Poornachandra, S.; Gumageri, R.; Rajkumar, K.; Anandhan, S. Chitosan Composites Reinforced with Nanostructured Waste Fly Ash. J. Mater. Cycles Waste Manag. 2017, 19, 870–883. [Google Scholar] [CrossRef]

- Menona, R.R.; Pillai, C.K.S.; Nando, G.B. Physicomechanical Properties of Filled Natural Rubber Vulcanizates Modified with Phosphorylated Cashew Nut Shell Liquid. J. Appl. Polym. Sci. 1998, 68, 1303–1311. [Google Scholar] [CrossRef]

- Barczewski, M.; Matykiewicz, D.; Krygier, A.; Andrzejewski, J.; Skorczewska, K. Characterization of Poly(lactic acid) Biocomposites Filled with Chestnut Shell Waste. J. Mater. Cycles Waste Manag. 2017, 20, 914–924. [Google Scholar] [CrossRef]

- Miedzianowska, J.; Maslowski, M.; Rybinski, P.; Strzelec, K. Properties of Chemically Modified (Selected Silanes) Lignocellulosic Filler and Its Application in Natural Rubber Biocomposites. Materials 2020, 13, 4163. [Google Scholar] [CrossRef] [PubMed]

- Ansarifar, A.; Wang, L.; Ellis, R.J.; Kirtley, S.P.; Riyazuddin, N. Enhancing the Mechanical Properties of Styrene–butadiene Rubber by Optimizing the Chemical Bonding between Silanized Silica Nanofiller and the Rubber. J. Appl. Polym. Sci. 2007, 105, 322–332. [Google Scholar] [CrossRef]

- Szadkowski, B.; Marzec, A.; Rybinski, P. Silane Treatment as an Effective Way of Improving the Reinforcing Activity of Carbon Nanofibers in Nitrile. Materials 2020, 13, 3481. [Google Scholar] [CrossRef] [PubMed]

- Roy, K.; Debnath, S.C.; Tzounis, L.; Pongwisuthiruchte, A.; Potiyaraj, P.E. Effect of Various Surface Treatments on the Performance of Jute Fibers Filled Natural Rubber (NR) Composites. Polymers 2020, 12, 369. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Srisuwan, L.; Jarukumjorn, K.; Suppakarn, N. Effect of Silane Treatment Methods on Physical Properties of Rice Husk Flour/Natural Rubber Composites. Adv. Mater. Sci. Eng. 2018, 2018, 4583974. [Google Scholar] [CrossRef] [Green Version]

- Sahu, P.; Gupta, M.K. A Review on the Properties of Natural Fibres and its Bio-composites: Effect of Alkali Treatment. Proc. Inst. Mech. Eng. Part L 2020, 234, 198–217. [Google Scholar] [CrossRef]

- Ming, P.T.S.; Bao, C.A.; Kamaruddin, S.; Ying, C.S. The Potential of Oil Palm Ash and Eggshell Powder as Hybrid Biofillers in Natural Rubber Biocomposites. IOP Conf. Ser. Mater. Sci. Eng. 2020, 859, 012013. [Google Scholar] [CrossRef]

- Miedzianowska, J.; Maslowski, M.; Rybinski, P.; Strzelec, K. Straw/Nano-Additive Hybrids as Functional Fillers for Natural Rubber Biocomposites. Materials 2021, 14, 321. [Google Scholar] [CrossRef]

- Maciejewska, M.; Sowinska-Baranowska, A. Bromide and Chloride Ionic Liquids Applied to Enhance the Vulcanization and Performance of Natural Rubber Biocomposites Filled with Nanosized Silica. Nanomaterials 2022, 12, 1209. [Google Scholar] [CrossRef]

- Riyajan, S.A.; Sasithornsonti, Y.; Phinyocheep, P. Green Natural Rubber-g-Modified Starch for Controlling Urea Release. Carbohyd. Polym. 2012, 89, 251–258. [Google Scholar] [CrossRef] [PubMed]

- Alwaan, I.M. Rheological Characterization and Modeling of Vulcanization Kinetics of Natural Rubber/Starch Blends. J. Appl. Polym. Sci. 2018, 135, 46347. [Google Scholar] [CrossRef]

- Chundawat, N.S.; Parmar, B.S.; Deuri, A.S.; Vaidya, D.; Sepehr, K.S.; Chauchan, N.P.S. Walnut Shell as a Sustainable Material for Compounding with Bromobutyl Rubber for Tire Inner Liner Applications. Polym. Compos. 2020, 41, 5317–5330. [Google Scholar] [CrossRef]

- Yan, H.; Sun, K.; Zhang, Y.; Zhang, Y.; Fan, Y. Effects of Silane Coupling Agents on the Vulcanization Characteristics of Natural Rubber. J. Appl. Polym. Sci. 2004, 94, 1511–1518. [Google Scholar] [CrossRef]

- Maciejewska, M.; Zaborski, M. Ionic Liquids as Coagents for Sulfur Vulcanization of Butadiene–Styrene Elastomer Filled with Carbon Black. Polym. Bull. 2018, 75, 4499–4514. [Google Scholar] [CrossRef] [Green Version]

- Yasin, S.; Hussain, M.; Zheng, Q.; Song, Y. Effects of Ionic Liquid on Cellulosic Nanofiller Filled Natural Rubber Bionanocomposites. J. Colloid Interface Sci. 2021, 591, 409–417. [Google Scholar] [CrossRef]

- Hussain, M.; Yasin, S.; Akram, M.A.; Xu, H.; Song, Y.; Zheng, Q. Influence of Ionic Liquids on Structure and Rheological Behaviors of Silica-Filled Butadiene Rubber. Ind. Eng. Chem. Res. 2019, 58, 18205–18212. [Google Scholar] [CrossRef]

- Steinrück, H.P.; Wasserscheid, P. Ionic Liquids in Catalysis. Catal. Lett. 2015, 145, 380–397. [Google Scholar] [CrossRef]

- Sowinska, A.; Maciejewska, M.; Grajewska, A. Bis(trifluoromethylsulfonyl)imide Ionic Liquids Applied for Fine-Tuning the Cure Characteristics and Performance of Natural Rubber Composites. Int. J. Mol. Sci. 2021, 22, 3678. [Google Scholar] [CrossRef]

- Masłowski, M.; Miedzianowska, J.; Strzelec, K. Natural Rubber Composites Filled with Crop Residues as an Alternative to Vulcanizates with Common Fillers. Polymers 2019, 11, 972. [Google Scholar] [CrossRef] [Green Version]

- Lappalainen, K.; Karkkainen, J.; Lajunen, M. Dissolution and Depolymerization of Barley Starch in Selected Ionic Liquids. Carbohydr. Polym. 2013, 93, 89–94. [Google Scholar] [CrossRef] [PubMed]

- Karkkainen, J.; Lappalainen, K.; Joensuu, P.; Lajunen, M. HPLC-ELSD Analysis of Six Starch Species Heat-dispersed in [BMIM] Cl Ionic Liquid. Carbohydr. Polym. 2011, 84, 509–516. [Google Scholar] [CrossRef]

- Heo, G.; Park, S. Effect of Coupling Agents on Thermal, Flow and Adhesion Properties of Epoxy/Silica Compounds for Capillary under Fill Applications. Powder Technol. 2012, 230, 145–150. [Google Scholar] [CrossRef]

- Gadhave, R.V.; Sheety, P.; Mahanwar, P.A.; Gadekar, P.T.; Desai, B.J. Silane Modification of Starch-Based Wood Adhesive: Review. Open J. Polym. Chem. 2019, 9, 53–62. [Google Scholar] [CrossRef] [Green Version]

- Maciejewska, M.; Zaborski, M. Ionic Liquids Applied to Improve the Dispersion of Coagent Particles in an Elastomer. J. Compos. 2013, 2013, 286534. [Google Scholar] [CrossRef] [Green Version]

- Sowinska, A.; Maciejewska, M.; Guo, L.; Delebecq, E. Task-Specific Ionic Liquids with Lactate Anion Applied to Improve ZnO Dispersibility in the Ethylene-Propylene-Diene Elastomer. Polymers 2021, 13, 774. [Google Scholar] [CrossRef]

- Shamsuri, A.A.; Daik, R. Applications of Ionic Liquids and Their Mixtures for Preparation of Advanced Polymer Blends and Composites: A Short Review. Rev. Adv. Mater. Sci. 2015, 40, 45–59. [Google Scholar]

- Das, A.; Stöckelhuber, K.W.; Jurk, R.; Fritzsche, J.; Klüppel, M.; Heinrich, G. Coupling Activity of Ionic Liquids between Diene Elastomers and Multi-Walled Carbon Nanotubes. Carbon 2009, 47, 3313–3321. [Google Scholar] [CrossRef]

- Ding, Y.; Wang, P.; Wang, Z.; Chen, L.; Xu, H.; Chen, S. Magnesium Hydroxide Modified by 1-N-Tetradecyl-3-Carboxymethyl Imidazolium Chloride and its Effects on the Properties of LLDPE. Polym. Eng. Sci. 2011, 51, 1519–1524. [Google Scholar] [CrossRef]

- Akiba, M.; Hashim, A.S. Vulcanization and Crosslinking in Elastomers. Prog. Polym. Sci. 1997, 22, 475–521. [Google Scholar] [CrossRef]

- Menard, K.P.; Menard, N.R. Dynamic Mechanical Analysis in the Analysis of Polymers and Rubbers. In Encyclopedia of Polymer Science and Technology, 4th ed.; Matyjaszewski, K., Ed.; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar] [CrossRef]

- Maciejewska, M.; Sowinska-Baranowska, A. The Synergistic Effect of Dibenzyldithiocarbamate Based Accelerator on the Vulcanization and Performance of the Silica-Filled Styrene–Butadiene Elastomer. Materials 2022, 15, 1450. [Google Scholar] [CrossRef] [PubMed]

- Joy, J.; George, E.; Thomas, S.; Anas, S. Effect of Filler Loading on Polymer Chain Confinement and Thermomechanical Properties of Epoxy/Boron Nitride (h-BN) Nanocomposites. New J. Chem. 2020, 44, 4494–4503. [Google Scholar] [CrossRef]

- Yoon, B.; Kim, J.Y.; Hong, U.; Oh, M.K.; Kim, M.; Han, S.B.; Nam, J.-D.; Suhr, J. Dynamic Viscoelasticity of Silica-filled Styrene-Butadiene Rubber/Polybutadiene Rubber (SBR/BR) Elastomer Composites. Compos. Part B Eng. 2020, 187, 107865–107871. [Google Scholar] [CrossRef]

- Moreno, R.M.B.; Ferreira, M.; Goncalves, P.; Capparelli, M.L.H. Technological Properties of Latex and Natural Rubber of Hevea Brasiliensis Clones. Sci. Agric. 2005, 62, 112–126. [Google Scholar] [CrossRef] [Green Version]

- Maslowski, M.; Miedzianowska, J.; Strzelec, K. Silanized Cereal Straw as a Novel, Functional Filler of Natural Rubber Biocomposites. Cellulose 2019, 26, 1025–1040. [Google Scholar] [CrossRef] [Green Version]

- Sowinska-Baranowska, A.; Maciejewska, M. Influence of the Silica Specific Surface Area and Ionic Liquids on the Curing Characteristics and Performance of Styrene-Butadiene Rubber Composites. Nanomaterials 2022, 14, 5302. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.H.; Cho, M.; Nam, J.-D.; Lee, Y. Effect of ZnO Particle Sizes on Thermal Aging Behavior of Natural Rubber Vulcanizates. Polym. Degrad. Stab. 2018, 148, 50–55. [Google Scholar] [CrossRef]

- Choi, S.S.; Kim, J.C.; Lee, S.G.; Joo, Y.L. Influence of the Cure Systems on Long Time Thermal Aging Behaviors of NR Composites. Macromol. Res. 2008, 16, 561–566. [Google Scholar] [CrossRef]

- Choi, S.S. Influence of Thermal Aging in Change of Crosslink Density and Deformation of Natural Rubber Vulcanizates. Bull. Korean Chem. Soc. 2000, 21, 628–634. [Google Scholar] [CrossRef]

- Coran, A.Y. Chemistry of the Vulcanization and Protection of Elastomers: A Review of the Achievements. J. Appl. Polym. Sci. 2003, 87, 24–30. [Google Scholar] [CrossRef]

- Gregorova, A.; Kosikova, B.; Moravcik, R. Stabilization Effect of Lignin in Natural Rubber. Polym. Degrad. Stab. 2006, 91, 229–233. [Google Scholar] [CrossRef]

- Shah, M.A.; Kumar, N.S.K. Kinetics of Walnut Shells through Pyrolysis Assessed as an Alternative Bio-fuel. Int. J. Eng. Adv. Technol. 2020, 9, 593–601. [Google Scholar] [CrossRef]

- Maciejewska, M.; Zaborski, M. Thermal Analysis and Mechanical Methods Applied to Studying Properties of SBR Compounds Containing Ionic Liquids. Polym. Test. 2017, 61, 349–363. [Google Scholar] [CrossRef]

- Patnaik, S.; Panda, A.K.; Kumar, S. Thermal Degradation of Corn Starch Based Biodegradable Plastic Plates and Determination of Kinetic Parameters by Isoconversional Methods Using Thermogravimetric Analyzer. J. Energy Inst. 2020, 93, 1449–1459. [Google Scholar] [CrossRef]

- Liu, X.; Yu, L.; Xie, F.; Li, M.; Chen, L.; Li, X. Kinetics and Mechanism of Thermal Decomposition of Cornstarches with Different Amylose/amylopectin Ratios. Starch 2010, 62, 139–146. [Google Scholar] [CrossRef]

- Liu, X.X.; Yu, L.; Liu, H.S.; Chen, L.; Li, L. In Situ Thermal Decomposition of Starch with Constant Moisture in a Sealed System. Polym. Degrad. Stabil. 2008, 93, 260–262. [Google Scholar] [CrossRef]

- Fan, F.; Li, H.; Xu, Y.; Liu, Y.; Zheng, Z.; Kan, H. Thermal Behaviour of Walnut Shells by Thermogravimetry with Gas Chromatography–mass Spectrometry Analysis. R. Soc. Open Sci. 2018, 5, 180331–180340. [Google Scholar] [CrossRef] [Green Version]

- Tripathi, M.; Sahu, J.; Ganesan, P. Effect of Process Parameters on Production of Biochar from Biomass Waste through Pyrolysis: A Review. Renew. Sustain. Energy Rev. 2016, 55, 467–481. [Google Scholar] [CrossRef]

- Shen, Y.; Jarboe, L.; Brown, R.; Wen, Z. A Thermochemical-biochemical Hybrid Processing of Lignocellulosic Biomass for Producing Fuels and Chemicals. Biotechnol. Adv. 2015, 33, 1799–1813. [Google Scholar] [CrossRef]

- Uzun, B.B.; Yaman, E. Thermogravimetric Characteristics and Kinetics of Scrap Tyre and Juglans Regia Shell Co-pyrolysis. Waste Manag. Res. 2014, 32, 961–970. [Google Scholar] [CrossRef]

- Gu, X.; Xu, M.; Li, L.; Liu, C.; Cheng, K.; Li, Z. Pyrolysis of Poplar Wood Sawdust by TG-FTIR and Py-GC/MS. J. Anal. Appl. Pyrol. 2013, 102, 16–23. [Google Scholar] [CrossRef]

- Xu, S.; Ou, C.; Chen, Y.; Xiao, H.; Fu, C.; Lu, W.; Wu, Z. Study on the Pyrolysis Characteristics of Walnut Processing by-Products. IOP Conf. Ser. Earth Environ. Sci. 2020, 508, 012126. [Google Scholar] [CrossRef]

- ISO 6502-3:2018; Rubber—Measurement of Vulcanization Characteristics Using Curemeters—Part 3: Rotorless Rheometer. International Organization for Standardization: Geneva, Switzerland, 2018.

- ISO 11357-1:2016; Plastics—Differential Scanning Calorimetry (DSC)—Part 1: General Principles. International Organization for Standardization: Geneva, Switzerland, 2016.

- ISO 11357-2:2020; Plastics—Differential Scanning Calorimetry (DSC)—Part 2: Determination of Glass Transition Temperature and Ttep Teight. International Organization for Standardization: Geneva, Switzerland, 2020.

- ISO 1817:2015; Rubber, Vulcanized or Thermoplastic—Determination of Effect of Liquids. International Organization for Standardization: Geneva, Switzerland, 2017.

- Flory, P.J.; Rehner, J. Statistical Mechanics of Cross-linked Polymer Networks. II. Swelling. J. Chem. Phys. 1943, 11, 521–526. [Google Scholar] [CrossRef]

- ISO 37:2017; Rubber, Vulcanized or Thermoplastic—Determination of Tensile Stress-Strain Properties. International Organization for Standardization: Geneva, Switzerland, 2017.

- ISO 868:2003; Plastics and Ebonite—Determination of Indentation Hardness by Means of a Durometer (Shore Hardness). International Organization for Standardization: Geneva, Switzerland, 2003.

- ISO 188:2011; Rubber, Vulcanized or Thermoplastic—Accelerated Ageing and Heat Resistance Tests. International Organization for Standardization: Geneva, Switzerland, 2011.

- Maciejewska, M.; Siwek, M. The Influence of Curing Systems on the Cure Characteristics and Physical Properties of Styrene–Butadiene Elastomer. Materials 2020, 13, 5329. [Google Scholar] [CrossRef] [PubMed]

| Compounds | Smin (dNm) | Smax (dNm) | ∆S (dNm) | t02 (min) | t90 (min) | |

|---|---|---|---|---|---|---|

| Unfilled sample | 0.5 | 5.4 | 4.9 | 2 | 7 | 1.2 |

| NR compounds filled with starch | ||||||

| 10 St | 0.4 | 6.2 | 5.9 | 3 | 5 | 2.8 |

| 20 St | 0.4 | 7.2 | 6.8 | 3 | 5 | 2.9 |

| 20 St/APTES | 0.6 | 7.8 | 7.2 | 1 | 3 | 3.3 |

| 20 St/BmiCl | 0.2 | 8.5 | 8.3 | 1 | 3 | 3.4 |

| NR compounds filled with walnut shells | ||||||

| 10 WS | 0.4 | 6.1 | 5.6 | 3 | 5 | 2.6 |

| 20 WS | 0.3 | 6.2 | 5.9 | 3 | 4 | 2.1 |

| 20 WS/APTES | 0.4 | 6.8 | 6.4 | 1 | 3 | 2.6 |

| 20 WS/BmiCl | 0.2 | 7.5 | 7.3 | 1 | 3 | 2.8 |

| Compounds | Tg (°C) | ∆Cp (J/g × K) | Temperature of Crosslinking (°C) | ∆H (J/g) |

|---|---|---|---|---|

| Unfilled sample | −62 | 0.43 | 167–227 | 15.6 |

| NR compounds filled with starch | ||||

| 10 St | −62 | 0.42 | 165–220 | 12.5 |

| 20 St | −62 | 0.49 | 164–220 | 11.7 |

| 20 St/APTES | −62 | 0.43 | 133–221 | 17.6 |

| 20 St/BmiCl | −62 | 0.43 | 130–224 | 18.4 |

| NR compounds filled with walnut shells | ||||

| 10 WS | −62 | 0.41 | 168–220 | 9.9 |

| 20 WS | −62 | 0.41 | 165–220 | 10.5 |

| 20 WS/APTES | −62 | 0.43 | 131–208 | 11.5 |

| 20 WS/BmiCl | −62 | 0.43 | 131–209 | 12.7 |

| Biofiller | Wt. (%) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C K | O K | Al K | Na K | Mg K | Si K | P K | S K | Cl K | K K | Ca K | Fe K | Cu K | Total | |

| Starch | 49.55 | 50.00 | 0.45 | - | - | - | - | - | - | - | - | - | - | 100 |

| Walnut shells | 46.24 | 42.72 | - | 0.01 | 0.15 | 0.22 | 0.15 | 0.27 | 0.22 | 8.13 | 1.41 | 0.17 | 0.31 | 100 |

| NR Vulcanizates | SE300 (MPa) | TS (MPa) | EB (%) | H (Shore A) |

|---|---|---|---|---|

| Unfilled sample | 1.2 ± 0.1 | 10.4 ± 0.1 | 820 ± 20 | 31 ± 1 |

| NR vulcanizates filled with starch | ||||

| 10 St | 1.6 ± 0.1 | 12.1 ± 0.2 | 607 ± 22 | 33 ± 1 |

| 20 St | 1.6 ± 0.1 | 11.7 ± 0.3 | 673 ± 16 | 33 ± 1 |

| 20 St/APTES | 2.2 ± 0.1 | 11.0 ± 0.5 | 570 ± 26 | 35 ± 1 |

| 20 St/BmiCl | 2.2 ± 0.1 | 11.5 ± 0.4 | 507 ± 9 | 38 ± 1 |

| NR vulcanizates filled with walnut shells | ||||

| 10 WS | 1.4 ± 0.1 | 11.3 ± 0.3 | 668 ± 21 | 34 ± 1 |

| 20 WS | 1.3 ± 0.1 | 10.8 ± 0.5 | 686 ± 21 | 32 ± 1 |

| 20 WS/APTES | 1.7 ± 0.1 | 9.9 ± 0.6 | 645 ± 8 | 32 ± 1 |

| 20 WS/BmiCl | 1.8 ± 0.1 | 11.1 ± 0.5 | 588 ± 28 | 34 ± 1 |

| NR Vulcanizates | Tg (°C) | Tan δTg (-) | Tan δ25 °C (-) | Tan δ50 °C (-) |

|---|---|---|---|---|

| Unfilled sample | −68 ± 1 | 2.6 ± 0.1 | 0.06 ± 0.02 | 0.05 ± 0.02 |

| NR vulcanizates filled with starch | ||||

| NR/10 St | −68 ± 1 | 2.5 ± 0.1 | 0.05 ± 0.02 | 0.05 ± 0.02 |

| NR/20 St | −68 ± 1 | 2.4 ± 0.1 | 0.06 ± 0.02 | 0.05 ± 0.02 |

| NR/20 St/APTES | −68 ± 1 | 2.4 ± 0.1 | 0.07 ± 0.02 | 0.05 ± 0.02 |

| NR/20 St/BmiCl | −69 ± 1 | 2.5 ± 0.1 | 0.05 ± 0.02 | 0.04 ± 0.02 |

| NR vulcanizates filled with walnut shells | ||||

| NR/10 WS | −68 ± 1 | 2.4 ± 0.1 | 0.07 ± 0.02 | 0.05 ± 0.02 |

| NR/20 WS | −69 ± 1 | 2.3 ± 0.1 | 0.07 ± 0.02 | 0.07 ± 0.02 |

| NR/20 WS/APTES | −69 ± 1 | 2.5 ± 0.1 | 0.08 ± 0.02 | 0.05 ± 0.02 |

| NR/20 WS/BmiCl | −70 ± 1 | 2.4 ± 0.1 | 0.08 ± 0.02 | 0.06 ± 0.02 |

| NR Vulcanizates | Af (-) |

|---|---|

| Unfilled sample | 0.6 ± 0.1 |

| NR vulcanizates filled with starch | |

| 10 St | 0.6 ± 0.1 |

| 20 St | 0.6 ± 0.1 |

| 20 St/APTES | 0.7 ± 0.1 |

| 20 St/BmiCl | 0.8 ± 0.1 |

| NR vulcanizates filled with walnut shells | |

| 10 WS | 0.8 ± 0.1 |

| 20 WS | 0.8 ± 0.1 |

| 20 WS/APTES | 0.7 ± 0.1 |

| 20 WS/BmiCl | 0.8 ± 0.1 |

| Biofiller | T5% (°C) | TDTG (°C) | ∆m25–150 °C (%) | ∆m150–700 °C (%) | ∆m700–800 °C (%) | Residue at 800 °C (%) |

|---|---|---|---|---|---|---|

| Starch | 75 | 318 | 7.2 | 77.4 | 10.4 | 5.0 |

| Walnut shells | 78 | 305 | 3.0 | 48.2 | 16.8 | 32.0 |

| NR Vulcanizates | T5% (°C) | TDTG (°C) | ∆m25–600 °C (%) | ∆m600–800 °C (%) | Residue at 800 °C (%) |

|---|---|---|---|---|---|

| Unfilled sample | 322 | 401 | 97.1 | 0.9 | 1.9 |

| NR vulcanizates filled with starch | |||||

| 10 St | 298 | 400 | 97.1 | 1.6 | 1.3 |

| 20 St | 290 | 399 | 96.2 | 2.3 | 1.5 |

| 20 St/APTES | 285 | 399 | 91.2 | 2.9 | 6.9 |

| 20 St/BmiCl | 280 | 401 | 91.4 | 3.2 | 5.4 |

| NR vulcanizates filled with walnut shells | |||||

| 10 WS | 289 | 401 | 91.7 | 2.4 | 5.9 |

| 20 WS | 274 | 400 | 89.0 | 3.7 | 7.3 |

| 20 WS/APTES | 271 | 399 | 87.9 | 4.0 | 8.1 |

| 20 WS/BmiCl | 268 | 400 | 88.0 | 4.3 | 7.7 |

| Ingredient, Phr | Unfilled Sample (0) | NR/St (1–2) | NR/St/BmiCl (3) | NR/St/APTES (4) | NR/WS (5–6) | NR/WS/BmiCl (7) | NR/WS/APTES (8) |

|---|---|---|---|---|---|---|---|

| NR | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Sulfur | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| ZnO | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| MBT | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| St.A. | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| St | - | 10; 20 | 20 | 20 | - | - | - |

| WS | - | - | - | - | 10; 20 | 20 | 20 |

| BmiCl | - | - | 2 | - | - | 2 | - |

| APTES | - | - | - | 2 | - | - | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sowińska-Baranowska, A.; Maciejewska, M.; Duda, P. The Potential Application of Starch and Walnut Shells as Biofillers for Natural Rubber (NR) Composites. Int. J. Mol. Sci. 2022, 23, 7968. https://doi.org/10.3390/ijms23147968

Sowińska-Baranowska A, Maciejewska M, Duda P. The Potential Application of Starch and Walnut Shells as Biofillers for Natural Rubber (NR) Composites. International Journal of Molecular Sciences. 2022; 23(14):7968. https://doi.org/10.3390/ijms23147968

Chicago/Turabian StyleSowińska-Baranowska, Anna, Magdalena Maciejewska, and Paulina Duda. 2022. "The Potential Application of Starch and Walnut Shells as Biofillers for Natural Rubber (NR) Composites" International Journal of Molecular Sciences 23, no. 14: 7968. https://doi.org/10.3390/ijms23147968

APA StyleSowińska-Baranowska, A., Maciejewska, M., & Duda, P. (2022). The Potential Application of Starch and Walnut Shells as Biofillers for Natural Rubber (NR) Composites. International Journal of Molecular Sciences, 23(14), 7968. https://doi.org/10.3390/ijms23147968