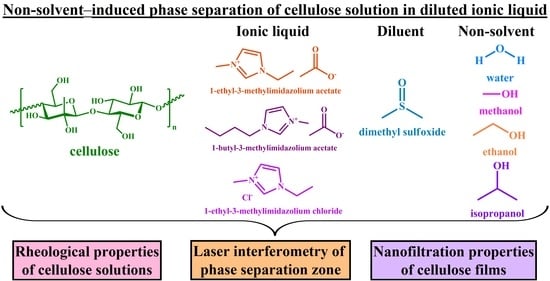

The Effect of Non-Solvent Nature on the Rheological Properties of Cellulose Solution in Diluted Ionic Liquid and Performance of Nanofiltration Membranes

Abstract

:1. Introduction

2. Results and Discussion

2.1. Rheology of Cellulose Solutions in Diluted Ionic Liquids

2.2. Effect of Non-Solvent Addition on the Rheological Properties of Cellulose Solutions

2.3. Phase Separation and Diffusion in Contact of Cellulose Solution with Non-Solvents

2.4. Morphology and Transport Properties of Cellulose Membranes

3. Materials and Methods

3.1. Materials

3.2. Preparation of Cellulose Solutions

3.3. Formation of Membranes

3.4. Rheometry of Cellulose Solutions

3.5. Laser Interferometry

3.6. Morphology and Nanofiltration Characteristics of Membranes

4. Conclusions

- Any low-viscosity liquids that are not solvents of cellulose nevertheless can be its nominal co-solvents at low doses, reducing the viscosity of the forming solution up to 50 times (the case of [BMIM]Ac/DMSO = 25/75) by lowering the viscosity of the used ionic liquid and deteriorating its thermodynamic affinity for cellulose macromolecules. This effect is observed for ionic liquids that are amorphous at the test temperature ([EMIM]Ac and [BMIM]Ac) but is inverse for the crystallizing ionic liquid ([EMIM]Cl), whose dilution increases the cellulose solution viscosity.

- Moderate dilution of the amorphous ionic liquid with a non-solvent causes strong (in the case of water) or weak (alcohols) structuring of the cellulose solution, manifesting as gel formation or an anomaly of low-frequency storage modulus, respectively. In the row of water, methanol, ethanol, isopropanol, and DMSO, the characteristic mass fraction of the non-solvent that causes the structuring increases, and DMSO can cause both strong and weak structuring, depending on its concentration and type of ionic liquid.

- The transition from water and methanol to ethanol and then isopropanol reduces the rate of interdiffusion of substances during the phase separation of the cellulose solution up to four times and thus slows it down. Moreover, a change in the used non-solvent can shift the mass transfer direction relative to the forming cellulose membrane, contributing to its contraction (ethanol) or swelling (water).

- The transition to diluted ionic liquid ([EMIM]Ac/DMSO equimixture in our case) enhances the rejection properties of cellulose nanofiltration membrane without changing its permeability performance. This effect is possibly due to the accelerated formation of the membrane skin layer because of the decreased viscosity of the cellulose solution (and consequently accelerated diffusion of the non-solvent) and reduced thermodynamic quality of the solvent, resulting in phase separation under the action of less quantity of the non-solvent. As a result, the membrane skin becomes denser and finely porous, improving rejection without changing the porosity of the support layer, i.e., maintaining high permeability. In turn, the replacement of water by alcohols allows for increasing permeability of the cellulose membrane while maintaining (ethanol and isopropanol) or slightly decreasing (methanol) its rejection properties. This change occurs probably due to better pore growth in the membrane support layer thanks to the absence of the gelation stage during phase separation and its slowdown. The resulting support layer becomes less dense and more porous, raising permeability, while the skin’s density decreases only slightly or remains unchanged, maintaining good rejection.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Stanley, T.H. A tribute to Dr Willem J. Kolff: Innovative inventor, physician, scientist, bioengineer, mentor, and significant contributor to modern cardiovascular surgical and anesthetic practice. J. Cardiothorac. Vasc. Anesth. 2013, 27, 600–613. [Google Scholar] [CrossRef]

- Cheryan, M. Ultrafiltration and Microfiltration Handbook; A Technomic Publishing Company: Lancaster, PA, USA, 1998. [Google Scholar]

- Turbak, A.F.; Hammer, R.B.; Davies, R.E.; Portnoy, N.A. A Critical Review of Cellulose Solvent Systems. In Solvent Spun Rayon, Modified Cellulose Fibers and Derivatives; Turbak, A.F., Ed.; American Chemical Society: Washington, DC, USA, 1977; Chapter 2; pp. 12–24. [Google Scholar]

- Hudson, S.M.; Cuculo, J.A. The Solubility of Unmodified Cellulose: A Critique of the Literature. J. Macromol. Sci. Polym. Rev. 1980, 18, 1–82. [Google Scholar] [CrossRef]

- Heinze, T.; Liebert, T. Unconventional methods in cellulose functionalization. Prog. Polym. Sci. 2001, 26, 1689–1762. [Google Scholar] [CrossRef]

- Heinze, T.; Koschella, A. Solvents Applied in the Field of Cellulose Chemistry—A Mini Review. Polímeros 2005, 15, 84–90. [Google Scholar] [CrossRef]

- Williamson, S.L.; Armentrout, R.S.; Porter, R.S.; McCormick, C.L. Microstructural examination of semi-interpenetrating networks of poly (N,N-dimethylacrylamide) with cellulose or chitin synthesized in lithium chloride/N,N-dimethylacetamide. Macromolecules 1998, 31, 8134. [Google Scholar] [CrossRef]

- Nishino, T.; Matsuda, I.; Hirao, K. All-cellulose composite. Macromolecules 2004, 37, 7683–7687. [Google Scholar] [CrossRef]

- Edgar, K.J.; Arnold, K.M.; Blount, W.W.; Lawniczak, J.E.; Lowman, D.W. Synthesis and Properties of Cellulose Acetoacetates. Macromolecules 1995, 28, 4122–4128. [Google Scholar] [CrossRef]

- Masson, J.F.; Manley, R.S.J. Cellulose/Poly(4-Vinylpyridine) Blends. Macromolecules 1991, 24, 5914–5921. [Google Scholar] [CrossRef]

- Masson, J.F.; Manley, R.S.J. Miscible Blends of Cellulose and Poly(Vinylpyrrolidone). Macromolecules 1991, 24, 6670–6679. [Google Scholar] [CrossRef]

- Vinogradov, V.V.; Mizerovskii, L.N.; Akaev, O.P. Reaction of Cellulose with Aqueous Solutions of Orthophosphoric Acid. Fibre Chem. 2002, 34, 167–171. [Google Scholar] [CrossRef]

- Graenacher, C.; Sallmann, R. Cellulose Solutions and Process of Making Same. U.S. Patent 2,179,181, 7 November 1939. [Google Scholar]

- Graenacher, C.; Sallmann, R. Gesellschaft für Chemische Industrie. DE Patent 713,486, 8 November 1941. [Google Scholar]

- Johnson, D.L. Improvements in solutions. GB Patent 1,144,048, 1 September 1967. [Google Scholar]

- Johnson, D.L. Polymer composition. GB Patent 1,144,759, 1 September 1967. [Google Scholar]

- Taeger, E.; Michels, C.; Nechwatal, A. Untersuchungen zur Auflösung und Verformung von Cellulose in N-Methylmorpholin-N-oxid. Das. Papier. 1991, 45, 784–788. [Google Scholar]

- Bang, Y.; Lee, S.; Park, J.; Cho, H. Effect of coagulation conditions on fine structure of regenerated cellulosic films made from cellulose/N-methylmorpholine-N-oxide/H2O systems. J. Appl. Polym. Sci. 1999, 73, 2681–2690. [Google Scholar] [CrossRef]

- Kulichikhin, V.G.; Golova, L.K.; Makarov, I.S.; Bondarenko, G.N.; Berkovich, A.K.; Ilyin, S.O. Cellulose–Co-Polyacrylonitrile Blends: Properties of Combined Solutions in N-Metylmorpholine-N-Oxide and the Formation and Thermolysis of Composite Fibers. Polym. Sci. Ser. C 2016, 58, 74–84. [Google Scholar] [CrossRef]

- Wu, J.; Yuan, Q. Gas Permeability of a Novel Cellulose Membrane. J. Membr. Sci. 2002, 204, 185–194. [Google Scholar] [CrossRef]

- Jie, X.; Cao, Y.; Lin, B.; Yuan, Q. Gas Permeation Performance of Cellulose Hollow Fiber Membranes Made from the Cellulose/N-Methylmorpholine-N-Oxide/H2O System. J. Appl. Polym. Sci. 2004, 91, 1873–1880. [Google Scholar] [CrossRef]

- Mao, Z.; Cao, Y.; Jie, X.; Kang, G.; Zhou, M.; Yuan, Q. Dehydration of Isopropanol–Water Mixtures Using a Novel Cellulose Membrane Prepared from Cellulose/N-Methylmorpholine-N-Oxide/H2O Solution. Sep. Purif. Technol. 2010, 72, 28–33. [Google Scholar] [CrossRef]

- Abe, Y.; Mochizuki, A. Hemodialysis Membrane Prepared from Cellulose/N-Methylmorpholine-N-Oxide Solution. I. Effect of Membrane Preparation Conditions on Its Permeation Characteristics. J. Appl. Polym. Sci. 2002, 84, 2302–2307. [Google Scholar] [CrossRef]

- Li, H.-J.; Cao, Y.-M.; Qin, J.-J.; Jie, X.-M.; Wang, T.-H.; Liu, J.-H.; Yuan, Q. Development and Characterization of Anti-Fouling Cellulose Hollow Fiber UF Membranes for Oil–Water Separation. J. Membr. Sci. 2006, 279, 328–335. [Google Scholar] [CrossRef]

- Zhang, Y.; Shao, H.; Wu, C.; Hu, X. Formation and Characterization of Cellulose Membranes FromN-Methylmorpholine-N-Oxide Solution. Macromol. Biosci. 2001, 1, 141–148. [Google Scholar] [CrossRef]

- Ichwan, M.; Son, T.-W. Preparation and Characterization of Dense Cellulose Film for Membrane Application. J. Appl. Polym. Sci. 2012, 124, 1409–1418. [Google Scholar] [CrossRef]

- Ilyin, S.O.; Makarova, V.V.; Anokhina, T.S.; Ignatenko, V.Y.; Brantseva, T.V.; Volkov, A.V.; Antonov, S.V. Diffusion and Phase Separation at the Morphology Formation of Cellulose Membranes by Regeneration from N-Methylmorpholine N-Oxide Solutions. Cellulose 2018, 25, 2515–2530. [Google Scholar] [CrossRef]

- Lu, Y.; Wu, Y. Influence of Coagulation Bath on Morphology of Cellulose Membranes Prepared by NMMO Method. Front. Chem. Eng. China 2008, 2, 204–208. [Google Scholar] [CrossRef]

- Mao, Z.; Jie, X.; Cao, Y.; Wang, L.; Li, M.; Yuan, Q. Preparation of Dual-Layer Cellulose/Polysulfone Hollow Fiber Membrane and Its Performance for Isopropanol Dehydration and CO2 Separation. Sep. Purif. Technol. 2011, 77, 179–184. [Google Scholar] [CrossRef]

- Kulichikhin, V.; Golova, L.; Makarov, I.; Bondarenko, G.; Makarova, V.; Ilyin, S.; Skvortsov, I.; Berkovich, A. Solutions of Acrylonitrile Copolymers in N -Methylmorpholine- N -Oxide: Structure, Properties, Fiber Spinning. Eur. Polym. J. 2017, 92, 326–337. [Google Scholar] [CrossRef]

- Pan, M.L.; Li, W.J.; Wang, M.R.; You, C. Preparation of the Reed Cellulose Membrane by Using NMMO Method. AMR 2012, 538–541, 128–131. [Google Scholar] [CrossRef]

- Khare, V.P.; Greenberg, A.R.; Kelley, S.S.; Pilath, H.; Juhn Roh, I.; Tyber, J. Synthesis and Characterization of Dense and Porous Cellulose Films. J. Appl. Polym. Sci. 2007, 105, 1228–1236. [Google Scholar] [CrossRef]

- Gorbacheva, S.N.; Yadykova, A.Y.; Ilyin, S.O. A Novel Method for Producing Cellulose Nanoparticles and Their Possible Application as Thickeners for Biodegradable Low-Temperature Greases. Cellulose 2021, 28, 10203–10219. [Google Scholar] [CrossRef]

- Marsh, K.N.; Boxall, J.A.; Lichtenthaler, R. Room Temperature Ionic Liquids and Their Mixtures—A Review. Fluid Phase Equilibria 2004, 219, 93–98. [Google Scholar] [CrossRef]

- Graenacher, C. Cellulose solution. U.S. Patent 1,943,176, 1 September 1934. [Google Scholar]

- Xu, A.; Wang, J.; Wang, H. Effects of Anionic Structure and Lithium Salts Addition on the Dissolution of Cellulose in 1-Butyl-3-Methylimidazolium-Based Ionic Liquid Solvent Systems. Green Chem. 2010, 12, 268–275. [Google Scholar] [CrossRef]

- Rogers, R.D.; Seddon, K.R. ACS Symposium Series 818; American Chemical Society: Washington, DC, USA, 2002. [Google Scholar]

- Azimi, B.; Maleki, H.; Gigante, V.; Bagherzadeh, R.; Mezzetta, A.; Milazzo, M.; Guazzelli, L.; Cinelli, P.; Lazzeri, A.; Danti, S. Cellulose-Based Fiber Spinning Processes Using Ionic Liquids. Cellulose 2022, 29, 3079–3129. [Google Scholar] [CrossRef]

- Heinze, T.; Schwikal, K.; Barthel, S. Ionic Liquids as Reaction Medium in Cellulose Functionalization. Macromol. Biosci. 2005, 5, 520–525. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, J.; Zhang, J.; He, J. 1-Allyl-3-Methylimidazolium Chloride Room Temperature Ionic Liquid: A New and Powerful Nonderivatizing Solvent for Cellulose. Macromolecules 2005, 38, 8272–8277. [Google Scholar] [CrossRef]

- Freemantle, M. Designer solvents-Ionic liquids may boost clean technology development. Chem. Eng. News 1998, 76, 32–37. [Google Scholar] [CrossRef]

- Matsumoto, H.; Yanagida, M.; Tanimoto, K.; Nomura, M.; Kitagawa, Y.; Miyazaki, Y. Highly Conductive Room Temperature Molten Salts Based on Small Trimethylalkylammonium Cations and Bis(Trifluoromethylsulfonyl)Imide. Chem. Lett. 2000, 29, 922–923. [Google Scholar] [CrossRef]

- Swatloski, R.P.; Spear, S.K.; Holbrey, J.D.; Rogers, R.D. Dissolution of Cellose with Ionic Liquids. J. Am. Chem. Soc. 2002, 124, 4974–4975. [Google Scholar] [CrossRef]

- Parviainen, H.; Parviainen, A.; Virtanen, T.; Kilpeläinen, I.; Ahvenainen, P.; Serimaa, R.; Grönqvist, S.; Maloney, T.; Maunu, S.L. Dissolution Enthalpies of Cellulose in Ionic Liquids. Carbohydr. Polym. 2014, 113, 67–76. [Google Scholar] [CrossRef]

- Chowdhury, Z.Z.; Zain, S.M.; Abd Hamid, S.B.; Khalid, K. Catalytic Role of Ionic Liquids for Dissolution and Degradation of Biomacromolecules. BioResources 2014, 9, 1787–1823. [Google Scholar] [CrossRef]

- Chen, H.-Z.; Wang, N.; Liu, L.-Y. Regenerated Cellulose Membrane Prepared with Ionic Liquid 1-Butyl-3-Methylimidazolium Chloride as Solvent Using Wheat Straw. J. Chem. Technol. Biotechnol. 2012, 87, 1634–1640. [Google Scholar] [CrossRef]

- Li, X.-L.; Zhu, L.-P.; Zhu, B.-K.; Xu, Y.-Y. High-Flux and Anti-Fouling Cellulose Nanofiltration Membranes Prepared via Phase Inversion with Ionic Liquid as Solvent. Sep. Purif. Technol. 2011, 83, 66–73. [Google Scholar] [CrossRef]

- Sukma, F.M.; Çulfaz-Emecen, P.Z. Cellulose Membranes for Organic Solvent Nanofiltration. J. Membr. Sci. 2018, 545, 329–336. [Google Scholar] [CrossRef]

- Anokhina, T.S.; Ignatenko, V.Y.; Kostyuk, A.V.; Ilyin, S.O.; Volkov, A.V.; Antonov, S.V. The Effect of the Nature of a Coagulant on the Nanofiltration Properties of Cellulose Membranes Formed from Solutions in Ionic Media. Membr. Membr. Technol. 2020, 2, 149–158. [Google Scholar] [CrossRef]

- Durmaz, E.N.; Zeynep Çulfaz-Emecen, P. Cellulose-Based Membranes via Phase Inversion Using [EMIM]OAc-DMSO Mixtures as Solvent. Chem. Eng. Sci. 2018, 178, 93–103. [Google Scholar] [CrossRef]

- Alammar, A.; Hardian, R.; Szekely, G. Upcycling Agricultural Waste into Membranes: From Date Seed Biomass to Oil and Solvent-Resistant Nanofiltration. Green Chem. 2022, 24, 365–374. [Google Scholar] [CrossRef]

- Hardian, R.; Alammar, A.; Holtzl, T.; Szekely, G. Fabrication of Sustainable Organic Solvent Nanofiltration Membranes Using Cellulose–Chitosan Biopolymer Blends. J. Membr. Sci. 2022, 658, 120743. [Google Scholar] [CrossRef]

- Vandezande, P.; Gevers, L.E.M.; Vankelecom, I.F.J. Solvent Resistant Nanofiltration: Separating on a Molecular Level. Chem. Soc. Rev. 2008, 37, 365–405. [Google Scholar] [CrossRef] [PubMed]

- Marchetti, P.; Jimenez Solomon, M.F.; Szekely, G.; Livingston, A.G. Molecular Separation with Organic Solvent Nanofiltration: A Critical Review. Chem. Rev. 2014, 114, 10735–10806. [Google Scholar] [CrossRef]

- Paul, M.; Jons, S.D. Chemistry and Fabrication of Polymeric Nanofiltration Membranes: A Review. Polymer 2016, 103, 417–456. [Google Scholar] [CrossRef]

- Strathmann, H.; Kock, K. The Formation Mechanism of Phase Inversion Membranes. Desalination 1977, 21, 241–255. [Google Scholar] [CrossRef]

- Mulder, M.H.V. Membrane preparation. In Encyclopedia of Separation Science: Phase Inversion Membranes; Academic Press: Cambridge, MA, USA, 2000; pp. 3331–3346. [Google Scholar]

- Ilyina, S.O.; Anokhina, T.S.; Ilyin, S.O. Non-Solvent- and Temperature-Induced Phase Separations of Polylaurolactam Solutions in Benzyl Alcohol as Methods for Producing Microfiltration Membranes. Colloids Interfaces 2023, 7, 10. [Google Scholar] [CrossRef]

- Lalia, B.S.; Kochkodan, V.; Hashaikeh, R.; Hilal, N. A Review on Membrane Fabrication: Structure, Properties and Performance Relationship. Desalination 2013, 326, 77–95. [Google Scholar] [CrossRef]

- Guillen, G.R.; Pan, Y.; Li, M.; Hoek, E.M.V. Preparation and Characterization of Membranes Formed by Nonsolvent Induced Phase Separation: A Review. Ind. Eng. Chem. Res. 2011, 50, 3798–3817. [Google Scholar] [CrossRef]

- Perepechkin, L.P. Methods for Obtaining Polymeric Membranes. Russ. Chem. Rev. 1988, 57, 539–548. [Google Scholar] [CrossRef]

- Guillen, G.R.; Ramon, G.Z.; Kavehpour, H.P.; Kaner, R.B.; Hoek, E.M.V. Direct Microscopic Observation of Membrane Formation by Nonsolvent Induced Phase Separation. J. Membr. Sci. 2013, 431, 212–220. [Google Scholar] [CrossRef]

- Sadrzadeh, M.; Bhattacharjee, S. Rational Design of Phase Inversion Membranes by Tailoring Thermodynamics and Kinetics of Casting Solution Using Polymer Additives. J. Membr. Sci. 2013, 441, 31–44. [Google Scholar] [CrossRef]

- Gavillon, R.; Budtova, T. Kinetics of Cellulose Regeneration from Cellulose−NaOH−Water Gels and Comparison with Cellulose− N -Methylmorpholine-N-Oxide−Water Solutions. Biomacromolecules 2007, 8, 424–432. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Shao, H.; Hu, X. Atomic Force Microscopy of Cellulose Membranes Prepared from TheN-Methylmorpholine-N-Oxide/Water Solvent System. J. Appl. Polym. Sci. 2002, 86, 3389–3395. [Google Scholar] [CrossRef]

- Ilyin, S.O.; Makarova, V.V.; Anokhina, T.S.; Volkov, A.V.; Antonov, S.V. Effect of Coagulating Agent Viscosity on the Kinetics of Formation, Morphology, and Transport Properties of Cellulose Nanofiltration Membranes. Polym. Sci. Ser. A 2017, 59, 676–684. [Google Scholar] [CrossRef]

- Dang, N.; Phi Huang, N.; Van Hoang, C.; Van der Bruggen, B. Preparation of an Asymmetric Membrane from Sugarcane Bagasse Using DMSO as Green Solvent. Appl. Sci. 2019, 9, 3347. [Google Scholar] [CrossRef]

- Lee, W.J.; Goh, P.S.; Lau, W.J.; Ismail, A.F.; Hilal, N. Green Approaches for Sustainable Development of Liquid Separation Membrane. Membranes 2021, 11, 235. [Google Scholar] [CrossRef]

- Venault, A.; Aini, H.N.; Galeta, T.A.; Chang, Y. Using the Dimethyl Sulfoxide Green Solvent for the Making of Antifouling PEGylated Membranes by the Vapor-Induced Phase Separation Process. J. Membr. Sci. Lett. 2022, 2, 100025. [Google Scholar] [CrossRef]

- Russo, F.; Ursino, C.; Avruscio, E.; Desiderio, G.; Perrone, A.; Santoro, S.; Galiano, F.; Figoli, A. Innovative Poly (Vinylidene Fluoride) (PVDF) Electrospun Nanofiber Membrane Preparation Using DMSO as a Low Toxicity Solvent. Membranes 2020, 10, 36. [Google Scholar] [CrossRef]

- Ilyin, S.O.; Malkin, A.Y.; Kulichikhin, V.G.; Denisova, Y.I.; Krentsel, L.B.; Shandryuk, G.A.; Litmanovich, A.D.; Litmanovich, E.A.; Bondarenko, G.N.; Kudryavtsev, Y.V. Effect of Chain Structure on the Rheological Properties of Vinyl Acetate–Vinyl Alcohol Copolymers in Solution and Bulk. Macromolecules 2014, 47, 4790–4804. [Google Scholar] [CrossRef]

- Ilyin, S.O.; Kulichikhin, V.G.; Malkin, A.Y. Unusual Rheological Effects Observed in Polyacrylonitrile Solutions. Polym. Sci. Ser. A 2013, 55, 503–509. [Google Scholar] [CrossRef]

- Gericke, M.; Schlufter, K.; Liebert, T.; Heinze, T.; Budtova, T. Rheological Properties of Cellulose/Ionic Liquid Solutions: From Dilute to Concentrated States. Biomacromolecules 2009, 10, 1188–1194. [Google Scholar] [CrossRef]

- Haward, S.J.; Sharma, V.; Butts, C.P.; McKinley, G.H.; Rahatekar, S.S. Shear and Extensional Rheology of Cellulose/Ionic Liquid Solutions. Biomacromolecules 2012, 13, 1688–1699. [Google Scholar] [CrossRef] [PubMed]

- Ilyin, S.O.; Makarova, V.V.; Polyakova, M.Y.; Kulichikhin, V.G. Phase State and Rheology of Polyisobutylene Blends with Silicone Resin. Rheol. Acta 2020, 59, 375–386. [Google Scholar] [CrossRef]

- Lv, Y.; Wu, J.; Zhang, J.; Niu, Y.; Liu, C.-Y.; He, J.; Zhang, J. Rheological Properties of Cellulose/Ionic Liquid/Dimethylsulfoxide (DMSO) Solutions. Polymer 2012, 53, 2524–2531. [Google Scholar] [CrossRef]

- Gorbacheva, S.N.; Yadykova, A.Y.; Ilyin, S.O. Rheological and Tribological Properties of Low-Temperature Greases Based on Cellulose Acetate Butyrate Gel. Carbohydr. Polym. 2021, 272, 118509. [Google Scholar] [CrossRef] [PubMed]

- Ilyin, S.O.; Makarova, V.V.; Polyakova, M.Y.; Kulichikhin, V.G. Phase Behavior and Rheology of Miscible and Immiscible Blends of Linear and Hyperbranched Siloxane Macromolecules. Mater. Today Commun. 2020, 22, 100833. [Google Scholar] [CrossRef]

- Melekhina, V.Y.; Kostyuk, A.V.; Smirnova, N.M.; Ilyin, S.O. Asphaltene-Stabilized Polyisobutylene Pressure-Sensitive Adhesives for Ultraviolet Protection and Surface Bonding. Materials 2023, 16, 1209. [Google Scholar] [CrossRef] [PubMed]

- Kulichikhin, V.G.; Ilyin, S.O.; Mironova, M.V.; Berkovich, A.K.; Nifant’ev, I.E.; Malkin, A.Y. From Polyacrylonitrile, Its Solutions, and Filaments to Carbon Fibers: I. Phase State and Rheology of Basic Polymers and Their Solutions. Adv. Polym. Technol. 2018, 37, 1076–1084. [Google Scholar] [CrossRef]

- Malkin, A.; Ilyin, S.; Roumyantseva, T.; Kulichikhin, V. Rheological Evidence of Gel Formation in Dilute Poly(Acrylonitrile) Solutions. Macromolecules 2013, 46, 257–266. [Google Scholar] [CrossRef]

- Ilyin, S.O.; Kulichikhin, V.G.; Malkin, A.Y. The Rheological Characterisation of Typical Injection Implants Based on Hyaluronic Acid for Contour Correction. Rheol. Acta 2016, 55, 223–233. [Google Scholar] [CrossRef]

- Ilyin, S.O.; Baskakov, A.A.; Chernikova, E.V.; Kulichikhin, V.G. Rheological Properties of Acrylonitrile—Acrylamide—Styrene Copolymer Solutions Synthesized by Classical and Controlled Radical Polymerizations. Russ. Chem. Bull. 2017, 66, 711–716. [Google Scholar] [CrossRef]

- Marcus, Y. The Properties of Organic Liquids That Are Relevant to Their Use as Solvating Solvents. Chem. Soc. Rev. 1993, 22, 409. [Google Scholar] [CrossRef]

- Fan, Z.; Chen, J.; Guo, W.; Ma, F.; Sun, S.; Zhou, Q. Anti-Solvents Tuning Cellulose Nanoparticles through Two Competitive Regeneration Routes. Cellulose 2018, 25, 4513–4523. [Google Scholar] [CrossRef]

- Gorbacheva, S.N.; Ilyin, S.O. Structure, Rheology and Possible Application of Water-in-Oil Emulsions Stabilized by Asphaltenes. Colloids Surf. A Physicochem. Eng. Asp. 2021, 618, 126442. [Google Scholar] [CrossRef]

- Vshivkov, S.A.; Kulichikhin, S.G.; Rusinova, E.V. Phase Transitions in Polymer Solutions Induced by Mechanical Fields. Russ. Chem. Rev. 1998, 67, 233–243. [Google Scholar] [CrossRef]

- Karpukhina, E.A.; Il’in, S.O.; Makarova, V.V.; Meshkov, I.B.; Kulichikhin, V.G. Phase State and Rheology of Polyisobutylene Mixtures with Decyl Surface Modified Silica Nanoparticles. Polym. Sci. Ser. A 2014, 56, 798–811. [Google Scholar] [CrossRef]

- Ilyin, S.O.; Kotomin, S.V. Mesophase State and Shear-Affected Phase Separation of Poly(p-Phenylene-Benzimidazole-Terephthalamide) Solutions in N,N-Dimethylacetamide. J. Polym. Res. 2022, 29, 326. [Google Scholar] [CrossRef]

- Anokhina, T.; Ignatenko, V.; Ilyin, S.; Antonov, S.; Volkov, A. Fabrication of Cellulose-Based Composite Membranes for Organic Solvent Nanofiltration. J. Phys. Conf. Ser. 2018, 1099, 012039. [Google Scholar] [CrossRef]

- Yadykova, A.Y.; Ilyin, S.O. Rheological and Adhesive Properties of Nanocomposite Bitumen Binders Based on Hydrophilic or Hydrophobic Silica and Modified with Bio-Oil. Constr. Build. Mater. 2022, 342, 127946. [Google Scholar] [CrossRef]

- Ilyin, S.O.; Yadykova, A.Y.; Makarova, V.V.; Yashchenko, V.S.; Matveenko, Y.V. Sulfonated Polyoxadiazole Synthesis and Processing into Ion-conducting Films. Polym. Int. 2020, 69, 1243–1255. [Google Scholar] [CrossRef]

- Tsar’kov, S.E.; Malakhov, A.O.; Litvinova, E.G.; Volkov, A.V. Nanofiltration of Dye Solutions through Membranes Based on Poly(Trimethylsilylpropyne). Pet. Chem. 2013, 53, 537–545. [Google Scholar] [CrossRef]

| Solvent | Non-Solvent | PDMF, kg·m−2·h−1·atm−1 | R350, % | R626, % |

|---|---|---|---|---|

| [EMIM]Ac | water | 0.27 ± 0.05 | 24 ± 4 | 31 ± 5 |

| [EMIM]Ac/DMSO | water | 0.23 ± 0.05 | 55 ± 7 | 75 ± 5 |

| [EMIM]Ac/DMSO | MeOH | 1.20 ± 0.20 | 35 ± 4 | 47 ± 9 |

| [EMIM]Ac/DMSO | EtOH | 0.28 ± 0.09 | 56 ± 7 | 71 ± 9 |

| [EMIM]Ac/DMSO | iPrOH | 0.42 ± 0.24 | 55 ± 9 | 68 ± 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ilyin, S.O.; Kostyuk, A.V.; Anokhina, T.S.; Melekhina, V.Y.; Bakhtin, D.S.; Antonov, S.V.; Volkov, A.V. The Effect of Non-Solvent Nature on the Rheological Properties of Cellulose Solution in Diluted Ionic Liquid and Performance of Nanofiltration Membranes. Int. J. Mol. Sci. 2023, 24, 8057. https://doi.org/10.3390/ijms24098057

Ilyin SO, Kostyuk AV, Anokhina TS, Melekhina VY, Bakhtin DS, Antonov SV, Volkov AV. The Effect of Non-Solvent Nature on the Rheological Properties of Cellulose Solution in Diluted Ionic Liquid and Performance of Nanofiltration Membranes. International Journal of Molecular Sciences. 2023; 24(9):8057. https://doi.org/10.3390/ijms24098057

Chicago/Turabian StyleIlyin, Sergey O., Anna V. Kostyuk, Tatyana S. Anokhina, Viktoria Y. Melekhina, Danila S. Bakhtin, Sergey V. Antonov, and Alexey V. Volkov. 2023. "The Effect of Non-Solvent Nature on the Rheological Properties of Cellulose Solution in Diluted Ionic Liquid and Performance of Nanofiltration Membranes" International Journal of Molecular Sciences 24, no. 9: 8057. https://doi.org/10.3390/ijms24098057

APA StyleIlyin, S. O., Kostyuk, A. V., Anokhina, T. S., Melekhina, V. Y., Bakhtin, D. S., Antonov, S. V., & Volkov, A. V. (2023). The Effect of Non-Solvent Nature on the Rheological Properties of Cellulose Solution in Diluted Ionic Liquid and Performance of Nanofiltration Membranes. International Journal of Molecular Sciences, 24(9), 8057. https://doi.org/10.3390/ijms24098057

.png)