Measuring Three-Dimensional Temperature Distributions in Steel–Concrete Composite Slabs Subjected to Fire Using Distributed Fiber Optic Sensors

Abstract

:1. Introduction

2. Experimental Program

2.1. Specimens and Material Properties

- Each end of the two parallel steel beams was connected by a perpendicular, welded rectangular steel tube so that the beams maintained their position during fabrication.

- A 1219 mm × 914 mm rectangular wood formwork was prepared.

- The trapezoidal metal decking was laid on top of the beams inside the formwork.

- The headed studs were welded through the metal decking to the steel beams (Figure 1).

- The welded wire mesh was supported by plastic chairs 8 mm above the metal decking.

- Optical fibers and thermocouples were deployed as detailed in Section 2.

- Concrete was poured into the formwork. Concrete placement using a hand trowel as well as placement directly from the chute on the concrete truck was used.

- The sides of the formwork were tapped using a rubber mallet to consolidate concrete at the edges; no mechanical vibrators were used.

- The cast specimen was covered under wet burlap and a plastic sheet, demolded after 1 day, and cured at room temperature (22 °C ± 3 °C).

2.2. Instrumentation

2.3. Test Setup

2.4. Fire Testing Protocol

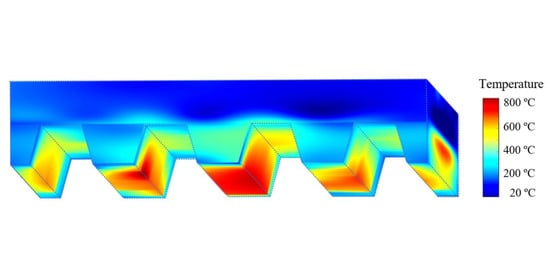

3. Results and Discussion

3.1. Observations

3.2. DFOS Temperature Measurements

3.3. Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Moroşan, P.D.; Bourdais, R.; Dumur, D.; Buisson, J. Building temperature regulation using a distributed model predictive control. Energy Build. 2010, 42, 1445–1452. [Google Scholar] [CrossRef]

- Li, X.; Bao, Y.; Wu, L.; Yan, Q.; Ma, H.; Chen, G.; Zhang, H. Thermal and mechanical properties of high-performance fiber-reinforced cementitious composites after exposure to high temperatures. Constr. Build. Mater. 2017, 157, 829–838. [Google Scholar] [CrossRef]

- Meng, W.; Khayat, K.H. Effect of graphite nanoplatelets and carbon nanofibers on rheology, hydration, shrinkage, mechanical properties, and microstructure of UHPC. Cem. Concr. Res. 2018, 105, 64–71. [Google Scholar] [CrossRef]

- Kodur, V.; Dwaikat, M.; Fike, R. High-temperature properties of steel for fire resistance modeling of structures. J. Mater. Civ. Eng. 2010, 22, 423–434. [Google Scholar] [CrossRef]

- Lamont, S.; Gillie, M.; Usmani, A.S. Composite steel-framed structures in fire with protected and unprotected edge beams. J. Constr. Steel Res. 2007, 63, 1138–1150. [Google Scholar] [CrossRef]

- Bundy, M.F.; Hamins, A.P.; Johnsson, E.L.; Kim, S.C.; Ko, G.; Lenhert, D.B. Measurements of Heat and Combustion Products in Reduced-Scale Ventilation-Limited Compartment Fires; NIST Technical Note; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2007; Volume 1483. [CrossRef]

- McGrattan, K.; McDermott, R.; Mell, W.; Forney, G.; Floyd, J.; Hostikka, S.; Matala, A. Modeling the Burning of Complicated Objects Using Lagrangian Particles. In Proceedings of the Twelfth International Interflam Conference, Nottingham, UK, 5–7 July 2010; Interscience Communications: London, UK, 2010; pp. 743–753. Available online: https://tsapps.nist.gov/publication/get_pdf.cfm?pub_id=905798 (accessed on 1 March 2020).

- Bertola, V.; Cafaro, E. Deterministic–Stochastic approach to compartment fire modelling. Proc. R. Soc. A Math. Phys. Eng. Sci. 2009, 465, 1029–1041. [Google Scholar] [CrossRef]

- Ramesh, S.; Ramesh, S.; Choe, L.; Seif, M.; Hoehler, M.; Grosshandler, W.; Sauca, A.; Bundy, M.; Luecke, W.; Bao, Y.; et al. Compartment Fire Experiments on Long-Span Composite-Beams with Simple Shear Connections Part 1: Experimental Design and Beam Behavior at Ambient Temperature. US Department of Commerce, National Institute of Standards and Technology, 2019. Available online: https://nvlpubs.nist.gov/nistpubs/TechnicalNotes/NIST.TN.2054.pdf (accessed on 1 March 2020).

- Hoehler, M.S.; Smith, C.M. Influence of Fire on the Lateral Load Capacity of Steel-Sheathed Cold-Formed Steel Shear Walls-Report of Test. US Department of Commerce, National Institute of Standards and Technology, 2016. Available online: https://nvlpubs.nist.gov/nistpubs/ir/2016/NIST.IR.8160.pdf (accessed on 1 March 2020).

- Li, X.; Bao, Y.; Xue, N.; Chen, G. Bond strength of steel bars embedded in high-performance fiber-reinforced cementitious composite before and after exposure to elevated temperatures. Fire Saf. J. 2017, 92, 98–106. [Google Scholar] [CrossRef]

- Li, X.; Xu, Z.; Bao, Y.; Cong, Z. Post-fire seismic behavior of two-bay two-story frames with high-performance fiber-reinforced cementitious composite joints. Eng. Struct. 2019, 183, 150–159. [Google Scholar] [CrossRef]

- Bao, Y.; Huang, Y.; Hoehler, M.S.; Chen, G. Review of fiber optic sensors for structural fire engineering. Sensors 2019, 19, 877. [Google Scholar] [CrossRef] [Green Version]

- Lonnermark, A.; Hedekvist, P.O.; Ingason, H. Gas temperature measurements using fibre Bragg grating during fire experiments in a tunnel. Fire Saf. J. 2008, 43, 119–126. [Google Scholar] [CrossRef]

- Rinaudo, P.; Torres, B.; Paya-Zaforteza, I.; Calderon, P.A.; Sales, S. Evaluation of new regenerated fiber Bragg grating high-temperature sensors in an ISO834 fire test. Fire Saf. J. 2015, 71, 332–339. [Google Scholar] [CrossRef]

- Huang, Y.; Fang, X.; Bevans, W.J.; Zhou, Z.; Xiao, H.; Chen, G. Large-strain optical fiber sensing and real-time FEM updating of steel structures under the high temperature effect. Smart Mater. Struct. 2013, 22, 015016. [Google Scholar] [CrossRef]

- Bao, Y.; Chen, Y.; Hoehler, M.S.; Smith, C.M.; Bundy, M.; Chen, G. Temperature and Strain Measurements with Fiber Optic Sensors for Steel Beams Subjected to Fire. In Proceedings of the 9th International Conference on Structures in Fire, Princeton, NJ, USA, 8–10 June 2016; Available online: https://scholarsmine.mst.edu/cgi/viewcontent.cgi?article=1983&context=civarc_enveng_facwork (accessed on 1 March 2020).

- Bao, Y.; Meng, W.; Chen, Y.; Chen, G.; Khayat, K.H. Measuring mortar shrinkage and cracking by pulse pre-pump Brillouin optical time domain analysis with a single optical fiber. Mater. Lett. 2015, 145, 344–346. [Google Scholar] [CrossRef]

- Bao, Y.; Chen, G. Temperature-dependent strain and temperature sensitivities of fused silica single mode fiber sensors with pulse pre-pump Brillouin optical time domain analysis. Meas. Sci. Technol. 2016, 27, 065101. [Google Scholar] [CrossRef]

- Bao, Y.; Chen, G. High-temperature measurement with Brillouin optical time domain analysis of an annealed fused-silica single-mode fiber. Opt. Lett. 2016, 41, 3177–3180. [Google Scholar] [CrossRef]

- Bao, Y.; Chen, Y.; Hoehler, M.S.; Smith, C.M.; Bundy, M.; Chen, G. Experimental analysis of steel beams subjected to fire enhanced by Brillouin scattering-based fiber optic sensor data. J. Struct. Eng. 2017, 143, 04016143. [Google Scholar] [CrossRef] [Green Version]

- Bao, Y.; Hoehler, M.S.; Smith, C.M.; Bundy, M.; Chen, G. Temperature measurement and damage detection in concrete beams exposed to fire using PPP-BOTDA based fiber optic sensors. Smart Mater. Struct. 2017, 26, 105034. [Google Scholar] [CrossRef]

- Pour-Ghaz, M.; Castro, J.; Kladivko, E.J.; Weiss, J. Characterizing lightweight aggregate desorption at high relative humidities using a pressure plate apparatus. J. Mater. Civil Eng. 2012, 24, 961–969. [Google Scholar] [CrossRef]

- Meng, W.; Khayat, K. Effects of saturated lightweight sand content on key characteristics of ultra-high-performance concrete. Cem. Concr. Res. 2017, 101, 46–54. [Google Scholar] [CrossRef]

- Meng, W.; Samaranayake, V.A.; Khayat, K.H. Factorial design and optimization of ultra-high-performance concrete with lightweight sand. ACI Mater. J. 2018, 115, 129–138. [Google Scholar] [CrossRef]

- Maluk, C.; Bisby, L.; Terrasi, G.P. Effects of polypropylene fibre type and dose on the propensity for heat-induced concrete spalling. Eng. Struct. 2017, 141, 584–595. [Google Scholar] [CrossRef] [Green Version]

- ASTM International. C39 /C39M–Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; American Society for Testing Material: West Conshohocken, PA, USA, 2020. [Google Scholar] [CrossRef]

- ASTM International. A992–Standard Specification for Structural Steel Shapes; American Society for Testing Material: West Conshohocken, PA, USA, 2015. [Google Scholar] [CrossRef]

- ASTM International. A108–Standard Specification for Steel Bar, Carbon and Alloy, Cold-Finished; American Society for Testing Material: West Conshohocken, PA, USA, 2013. [Google Scholar] [CrossRef]

- ASTM International. A185–Standard Specification for Steel Welded Wire Reinforcement, Plain, for Concrete; American Society for Testing Material: West Conshohocken, PA, USA, 2007. [Google Scholar] [CrossRef]

- ASTM International. A611–Standard Specification for Structural Steel (SS), Sheet, Carbon, Cold-Rolled; American Society for Testing Material: West Conshohocken, PA, USA, 1997. [Google Scholar] [CrossRef]

- Bao, Y.; Chen, G. Fully-distributed fiber optic sensor for strain measurement at high temperature. In Proceedings of the Tenth International Workshop on Structural Health Monitoring, Stanford, CA, USA, 1–3 September 2015; Chang, F.K., Kopsaftopoulos, F., Eds.; DEStech Publications Inc.: Lancaster, PA, USA, 2015. [Google Scholar] [CrossRef]

- Bao, Y. Novel Applications of Pulse Pre-Pump Brillouin Optical Time Domain Analysis for Behavior Evaluation of Structures under Thermal and Mechanical Loading. Ph.D. Thesis, Missouri University of Science and Technology, Rolla, MO, USA, 2017. Available online: https://scholarsmine.mst.edu/doctoral_dissertations/2580 (accessed on 1 March 2020).

- Bryant, R.; Bundy, M. The NIST 20 MW Calorimetry Measurement System for Large-Fire Research; Technical Note; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2019; Volume 2077. [CrossRef]

- Li, X.; Xu, H.; Meng, W.; Bao, Y. Tri-axial compressive properties of high-performance fiber-reinforced cementitious composites after exposure to high temperatures. Constr. Build. Mater. 2018, 190, 939–947. [Google Scholar] [CrossRef]

| Designation | Age at Testing (days) | Internal Relative Humidity before Test | Number of Studs | Distributed Sensors | Thermocouples |

|---|---|---|---|---|---|

| CS-1 | 33 | 94.3% | 6 | DFOS-1 to DFOS-3 | TC1 to TC6 |

| CS-2 | 34 | 93.5% | 6 | DFOS-1 to DFOS-3 | TC1 to TC6 |

| CS-3 | 35 | 95.0% | 4 | DFOS-1 to DFOS-3 | TC1 to TC6 |

| CS-4 | 36 | 95.2% | 4 | DFOS-1 to DFOS-3 | TC1 to TC6 |

| CS-5 | 350 | 77.7% | 4 | DFOS-1 to DFOS-4 | TC1 to TC6; ST1 * to ST9 |

| CS-6 | 351 | 78.6% | 6 | DFOS-1 to DFOS-4 | TC1 to TC6; ST1 to ST9 |

| Steel Used in the Specimens | ASTM Material Standards | Tensile Yield Strength (MPa) | Ultimate Strength (MPa) | Modulus of Elasticity (GPa) | Testing Standard |

|---|---|---|---|---|---|

| Beams | A992 (structural steel) | 345 | 450 | 200 | [28] |

| Headed studs | A108 (cold drawn) | 414 | 496 | 205 | [29] |

| Welded wire mesh | A185 Grade 65 | 448 | 517 | 200 | [30] |

| Galvanized metal decking | A611 Grade D (cold rolled) | 276 | 359 | 203 | [31] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bao, Y.; Hoehler, M.S.; Smith, C.M.; Bundy, M.; Chen, G. Measuring Three-Dimensional Temperature Distributions in Steel–Concrete Composite Slabs Subjected to Fire Using Distributed Fiber Optic Sensors. Sensors 2020, 20, 5518. https://doi.org/10.3390/s20195518

Bao Y, Hoehler MS, Smith CM, Bundy M, Chen G. Measuring Three-Dimensional Temperature Distributions in Steel–Concrete Composite Slabs Subjected to Fire Using Distributed Fiber Optic Sensors. Sensors. 2020; 20(19):5518. https://doi.org/10.3390/s20195518

Chicago/Turabian StyleBao, Yi, Matthew S. Hoehler, Christopher M. Smith, Matthew Bundy, and Genda Chen. 2020. "Measuring Three-Dimensional Temperature Distributions in Steel–Concrete Composite Slabs Subjected to Fire Using Distributed Fiber Optic Sensors" Sensors 20, no. 19: 5518. https://doi.org/10.3390/s20195518

APA StyleBao, Y., Hoehler, M. S., Smith, C. M., Bundy, M., & Chen, G. (2020). Measuring Three-Dimensional Temperature Distributions in Steel–Concrete Composite Slabs Subjected to Fire Using Distributed Fiber Optic Sensors. Sensors, 20(19), 5518. https://doi.org/10.3390/s20195518