Assessment of Grain Harvest Moisture Content Using Machine Learning on Smartphone Images for Optimal Harvest Timing

Abstract

:1. Introduction

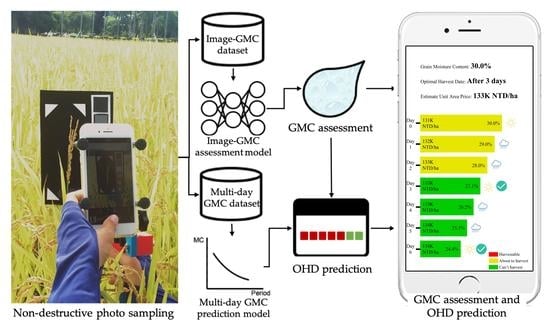

- Designing a wide range GMC measurement process applicable for the duration of grain maturity based on machine learning technology.

- Practicing the non-destructive GMC measurement process on smartphones to collect real-time, low-cost, and large-area GMC data in the field.

- Establishing a multi-day GMC prediction model to predict the future GMC variation for scheduling a suitable harvest time.

2. Materials and Methods

2.1. Field Survey

2.1.1. Field Sampling

2.1.2. Image Devices

2.1.3. GMC Measurement

2.2. Image Processing

2.2.1. Contrast Correction

2.2.2. Gamma Correction

2.2.3. Halation Removal

2.2.4. ROI Cropping

2.2.5. Background Removal

2.2.6. CI Extraction

2.3. Image-Based GMC Assessment Model

2.3.1. Principal Component Analysis

2.3.2. Random Forest

2.3.3. Multiple Layer Perceptron

2.3.4. Support Vector Regression

2.3.5. Multiple Linear Regression

2.4. Multiday GMC Prediction Model

2.5. Performance Evaluation

3. Results

3.1. Image-Based GMC Dataset

3.2. Image-Based GMC Assessment Model

3.3. Image-Based GMC Prediction Model

3.4. Model Performance

4. Discussion

4.1. Performance of the Image-Based GMC Assessment Model

4.2. Performance of the Moltiday GMC Prediction Model

4.3. Futrue Work

5. Conclusions

- The GMC assessment model applying the SVR algorithm has a great performance with a MAE of 1.23% for a GMC of below 40% and a MAE of 1.08% for a GMC of below 32%, so as to perceive the GMC variation in the field at a very early stage.

- The proposed non-destructive GMC assessment model executed through smartphones is low-cost and handy so as to efficiently collect the field GMC over a broad area in time.

- The proposed multi-day GMC prediction model provides the prediction of daily GMC variation for the coming week, which helps to evaluate the best harvest timing and optimize the scheduling of agricultural machinery.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CIs | color indices |

| ExG | Excess Green Index |

| GD | growth days |

| GI | Green Index |

| GIGR | green immature grains rate |

| GMC | grain moisture content |

| HLS | hue, luminance, saturation |

| HMC | harvest moisture content |

| HSV | hue, saturation, value |

| MAE | mean absolute error |

| MAPE | mean absolute percentage error |

| MLR | multivariate linear regression |

| MLP | multilayer perceptron |

| NDI | Normalized Difference Index |

| OHD | optimal harvest date |

| PCA | principal component analysis |

| QR | quick-response |

| RBF | radial basis function |

| RF | random forest |

| RGB | red, green, and blue |

| RGRI | Red–green Ratio Index |

| RMSE | root mean square error |

| RMSProp | root mean square propagation |

| ROI | region of interest |

| SSCB | simple spectral–geometric correction board |

| SVM | support vector machine |

| SVR | support vector regression |

| TNG67 | Tainung no. 67 |

| TNG71 | Tainung no. 71 |

| w.b. | wet basis |

| YOLOv4 | You Only Look Once v4 |

References

- Sarkar, T.K.; Kang, Y.S. Artificial neural network-based model for predicting moisture content in rice using UAV remote sensing data. Korean J. Remote Sens. 2018, 34, 611–624. [Google Scholar]

- Hong, M.C.; Song, S. Studies on the quality of embroyed rice. I. Effect of grain characters, harvesting time and moisture content on the quality of embryoed rice. Symp. Rice Grain Qual. 1988, 13, 249–258. [Google Scholar]

- Song, S.; Hong, M.C. Studies on the identification of wet rice quality. Denki Kagaku Oyobi Kogyo Butsuri Kagaku 1995, 63, 694–698. [Google Scholar]

- Chau, N.N.; Kunze, O.R. Moisture content variation among harvested rice grains. Trans. ASAE 1982, 25, 1037–1040. [Google Scholar] [CrossRef]

- Desikachar, H.S.R.; Bhashyam, M.K.; Ranganath, K.A.; Mahadevappa, M. Effect of differential maturity of paddy grains in a panicle on their milling quality. J. Sci. Food Agric. 1973, 24, 893–896. [Google Scholar] [CrossRef]

- Ban, T. Rice Cracking in high rate drying. JARQ Jpn. Agric. Res. Q. 1971, 6, 113–116. [Google Scholar]

- Kunze, O.R. Effect of drying on grain quality—Moisture readsorption causes fissured rice grains. Cereal Foods World 2001, 46, 16–19. [Google Scholar]

- Kuehner, E.C.; Alvarez, R.; Paulsen, P.J.; Murphy, T.J. Production and analysis of special high-purity acids purified by subboiling distillation. Anal. Chem. 1972, 44, 2050–2056. [Google Scholar] [CrossRef]

- Rajanna, B.; Andrews, C.H. Trends in seed maturation of rice (Oryza sativa L.). In Proceedings of the Association of Official Seed Analysts, Jefferson City, MO, USA, 21–26 June 1970; 60, pp. 188–196. [Google Scholar]

- Lin, T.C.; Liu, W.T.; Haung, K.T.; Sung, J.M.; Li, C.P.; Wu, D.H.; Lia, M.H. Study on changes of grain shape of rice cultivar ‘TNG67’ during filling stage by image analysis. J. Taiwan Agric. Res. 2014, 63, 122–128. [Google Scholar]

- Kocher, M.F.; Siebenmorgen, T.J.; Norman, R.J.; Wells, B.R. Rice kernel moisture content variation at harvest. Trans. ASABE 1990, 33, 541–548. [Google Scholar] [CrossRef]

- Moldenhauer, K.; Counce, P.; Hardke, J. Rice growth and development. In Rice Production Handbook; Slaton, N.A., Ed.; University of Arkansas Division of Agriculture Cooperative Extension Service: Little Rock, AR, USA, 2001; Volume 192, pp. 7–14. [Google Scholar]

- Bowden, P.J. Comparison of three routine oven methods for grain moisture content determination. J. Stored Prod. Res. 1984, 20, 97–106. [Google Scholar] [CrossRef]

- Noomhorm, A.; Verma, L.R. A comparison of microwave, air oven and moisture meters with the standard method for rough rice moisture determination. Trans. ASABE 1982, 25, 1464–1470. [Google Scholar] [CrossRef]

- Baryeh, E.A. A simple grain impact damage assessment device for developing countries. J. Stored Prod. Res. 2003, 56, 37–42. [Google Scholar] [CrossRef]

- Singh, K.K.; Goswami, T.K. Physical properties of cumin seed. J. Agric. Eng. Res. 1996, 64, 93–98. [Google Scholar] [CrossRef]

- Abdullah, N.; Nawawi, A.; Othman, I. Fungal spoilage of starch-based foods in relation to its water activity (aw). J. Stored Prod. Res. 2000, 36, 47–54. [Google Scholar] [CrossRef]

- Hurburgh, C.R.; Hazen, T.E.; Bern, C.J. Corn moisture measurement accuracy. Trans. ASABE 1985, 28, 634–640. [Google Scholar] [CrossRef]

- Chen, C.C.; Tsao, C.T. Performance of the resistance moisture meters for rough rice. J. Agric. Res. China 1995, 44, 313–334. [Google Scholar]

- Lei, P.K.; Chen, C.C. Study of the performance of the capacitance moisture meters for rough rice. J. Agric. For. 1996, 45, 35–45. [Google Scholar]

- Yang, M.D.; Su, T.C.; Lin, H.Y. Fusion of infrared thermal image and visible image for 3D thermal model reconstruction using smartphone sensors. Sensors 2018, 18, 2003. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Okamoto, K.; Yanai, K. An automatic calorie estimation system of food images on a smartphone. In Proceedings of the 2nd International Workshop on Multimedia Assisted Dietary Management, New York, NY, USA, 16 October 2016; pp. 63–70. [Google Scholar]

- Chakma, A.; Vizena, B.; Cao, T.; Lin, J.; Zhang, J. Image-based air quality analysis using deep convolutional neural network. In Proceedings of the 2017 IEEE International Conference on Image Processing (ICIP), Beijing, China, 17–20 September 2017; pp. 3949–3952. [Google Scholar]

- Laamrani, A.; Pardo Lara, R.; Berg, A.A.; Branson, D.; Joosse, P. Using a mobile device “App” and proximal remote sensing technologies to assess soil cover fractions on agricultural fields. Sensors 2018, 18, 708. [Google Scholar] [CrossRef] [Green Version]

- Intaravanne, Y.; Sumriddetchkajorn, S. BaiKhao (rice leaf) app: A mobile device-based applicaion in analyzing the color level of the rice leaf for nitrogen estimation. Proc. SPIE 2012, 8558. [Google Scholar] [CrossRef]

- Li, Z.R.; Ho, D.J. Research on identify technologies of apple’s disease based on mobile photograph image analysis. Comput. Eng. Des. 2010, 13, 3051–3053. [Google Scholar]

- Mohan, P.J.; Gupta, S.D. Intelligent image analysis for retrieval of leaf chlorophyll content of rice from digital images of smartphone under natural light. Photosynthetica 2019, 57, 388–398. [Google Scholar] [CrossRef] [Green Version]

- Qi, J.; Xie, D.; Li, L.; Zhang, W.; Mu, X.; Yan, G. Estimating leaf angle distribution from smartphone photographs. IEEE Geosci. Remote Sens. Lett. 2019, 16, 1190–1194. [Google Scholar] [CrossRef]

- Wang, Z.; Koirala, A.; Walsh, K.; Anderson, N.; Verma, B. In field fruit sizing using a smart phone application. Sensors 2018, 18, 3331. [Google Scholar] [CrossRef] [Green Version]

- Qian, J.; Xing, B.; Wu, X.; Chen, M.; Wang, Y.A. A smartphone-based apple yield estimation application using imaging features and the ANN method in mature period. Sci. Agric. 2018, 75, 273–280. [Google Scholar] [CrossRef]

- Fang, H.; Ye, Y.; Liu, W.; Wei, S.; Ma, L. Continuous estimation of canopy leaf area index (LAI) and clumping index over broadleaf crop fields: An investigation of the PASTIS-57 instrument and smartphone applications. Agric. For. Meteorol. 2018, 253, 48–61. [Google Scholar] [CrossRef]

- Gupta, V.K.; Aulakh, R.; Tomar, S. Novel method for the determination of preservative (formaldehyde) in bovine milk through smart phone-based colorimetric technology. Indian J. Vet. Sci. Biot. 2019, 15, 30–33. [Google Scholar] [CrossRef]

- De Souza, E.G.; Scharf, P.C.; Sudduth, K.A. Sun position and cloud effects on reflectance and vegetation indices of corn. Agron. J. 2010, 102, 734–744. [Google Scholar] [CrossRef] [Green Version]

- Aquino, A.; Barrio, I.; Diago, M.P.; Millan, B.; Tardaguila, J. vitisBerry: An Android-smartphone application to early evaluate the number of grapevine berries by means of image analysis. Comput. Electron. Agric. 2018, 148, 19–28. [Google Scholar] [CrossRef]

- Giraldo, P.J.R.; Aguirre, Á.G.; Muñoz, C.M.; Prieto, F.A.; Oliveros, C.E. Sensor fusion of a mobile device to control and acquire videos or images of coffee branches and for georeferencing trees. Sensors 2017, 17, 786. [Google Scholar] [CrossRef] [Green Version]

- Busemeyer, L.; Mentrup, D.; Möller, K.; Wunder, E.; Alheit, K.; Hahn, V.; Maurer, H.P.; Reif, J.C.; Würschum, T.; Müller, J.; et al. BreedVision—A multi-sensor platform for non-destructive field-based phenotyping in plant breeding. Sensors 2013, 13, 2830–2847. [Google Scholar] [CrossRef]

- Van, L.D.; Lin, Y.B.; Wu, T.H.; Lin, Y.W.; Peng, S.R.; Kao, L.H.; Chang, C.H. PlantTalk: A smartphone-based intelligent hydroponic plant box. Sensors 2019, 19, 1763. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chaugule, A.; Mali, S. Seed technological development—A survey. In Proceedings of the International Conference on Information Technology in Signal and Image Processing, Kunming, China, 21–23 September 2013; pp. 71–78. [Google Scholar]

- Yang, C.Y.; Yang, M.D.; Tseng, W.C.; Hsu, Y.C.; Li, G.S.; Lai, M.H.; Wu, D.H.; Lu, H.Y. Assessment of rice developmental stage using time series UAV imagery for variable irrigation management. Sensors 2020, 20, 5354. [Google Scholar] [CrossRef] [PubMed]

- Yang, M.D.; Huang, K.S.; Kuo, Y.H.; Tsai, H.P.; Lin, L.M. Spatial and spectral hybrid image classification for rice lodging assessment through UAV imagery. Remote Sens. 2017, 9, 583. [Google Scholar] [CrossRef] [Green Version]

- Chaugule, A.; Mali, S. Evaluation of shape and color features for classification of four paddy varieties. Int. J. Image Graph. Signal Process. 2014, 6, 32–38. [Google Scholar] [CrossRef] [Green Version]

- Magalhães, S.A.; Castro, L.; Moreira, G.; dos Santos, F.N.; Cunha, M.; Dias, J.; Moreira, A.P. Evaluating the single-shot multibox detector and YOLO deep learning models for the detection of tomatoes in a greenhouse. Sensors 2021, 21, 3569. [Google Scholar] [CrossRef] [PubMed]

- Sanaeifar, A.; Bakhshipour, A.; de la Guardia, M. Prediction of banana quality indices from color features using support vector regression. Talanta 2016, 148, 54–61. [Google Scholar] [CrossRef] [PubMed]

- Jimenez-Sierra, D.A.; Correa, E.S.; Benítez-Restrepo, H.D.; Calderon, F.C.; Mondragon, I.F.; Colorado, J.D. Novel feature-extraction methods for the estimation of above-ground biomass in rice crops. Sensors 2021, 21, 4369. [Google Scholar] [CrossRef] [PubMed]

- Mithun, B.S.; Shinde, S.; Bhavsar, K.; Chowdhury, A.; Mukhopadhyay, S.; Gupta, K.; Bhowmick, B.; Kimbahune, S. Non-destructive method to detect artificially ripened banana using hyperspectral sensing and RGB imaging. Proc. SPIE 2018, 10665. [Google Scholar] [CrossRef]

- Yang, M.D.; Su, T.C.; Pan, N.F.; Liu, P. Feature extraction of sewer pipe defects using wavelet transform and co-occurrence matrix. Int. J. Wavelets Multiresolution Inf. Process. 2011, 9, 211–225. [Google Scholar] [CrossRef] [Green Version]

- Yang, M.D.; Boubin, J.G.; Tsai, H.P.; Tseng, H.H.; Hsu, Y.C.; Stewart, C.C. Adaptive autonomous UAV scouting for rice lodging assessment using edge computing with deep learning EDANet. Comput. Electron. Agric. 2020, 179, 105817. [Google Scholar] [CrossRef]

- Yang, M.D.; Tseng, H.H.; Hsu, Y.C.; Tsai, H.P. Semantic segmentation using deep learning with vegetation indices for rice lodging identification in multi-date UAV visible images. Remote Sens. 2020, 12, 633. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.; Xun, Y.; Li, W.; Zhang, J. Combining discriminant analysis and neural networks for corn variety identification. Comput. Electron. Agric. 2010, 71, S48–S53. [Google Scholar] [CrossRef]

- Kaiser, H.F. The application of electronic computers to factor analysis. Educ. Psychol. Meas. 1960, 20, 141–151. [Google Scholar] [CrossRef]

- Ben-Zeev, S.; Rabinovitz, O.; Orlov-Levin, V.; Chen, A.; Graff, N.; Goldwasser, Y.; Saranga, Y. Less is more: Lower sowing rate of irrigated tef (Eragrostis tef) alters plant morphology and reduces lodging. Agronomy 2020, 10, 570. [Google Scholar] [CrossRef]

- Plant Protection Information System. Available online: https://otserv2.tactri.gov.tw/ppm/PLC0101.aspx?CropNo=00003B162 (accessed on 5 May 2021).

- Crop Diseases, Pests and Fertilizer Management Technical Information CD. Available online: https://web.tari.gov.tw/techcd/%E7%A8%BB%E4%BD%9C/%E6%B0%B4%E7%A8%BB/%E7%97%85%E5%AE%B3/%E6%B0%B4%E7%A8%BB-%E8%82%B2%E8%8B%97%E7%AE%B1%E7%A7%A7%E8%8B%97%E7%AB%8B%E6%9E%AF%E7%97%85.htm (accessed on 5 May 2021).

- Siebert, A. Retrieval of gamma corrected images. Pattern Recognit. Lett. 2001, 22, 249–256. [Google Scholar] [CrossRef]

- Ishii, M.; Kusada, I.; Yamane, H. Quantitative decision method of appropriate apple harvest time using color information. Electr. Commun. Jpn. 2018, 101, 61–73. [Google Scholar] [CrossRef]

- García-Mateos, G.; Hernández-Hernández, J.L.; Escarabajal-Henarejos, D.; Jaén-Terrones, S.; Molina-Martínez, J.M. Study and comparison of color models for automatic image analysis in irrigation management applications. Agric. Water Manag. 2015, 151, 158–166. [Google Scholar] [CrossRef]

- Color Conversions. Available online: https://docs.opencv.org/3.4/de/d25/imgproc_color_conversions.html (accessed on 11 August 2021).

- Xie, C.; He, Y. Spectrum and image texture features analysis for early blight disease detection on eggplant leaves. Sensors 2016, 16, 676. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pôças, I.; Rodrigues, A.; Gonçalves, S.; Costa, P.M.; Gonçalves, I.; Pereira, L.S.; Cunha, M. Predicting grapevine water status based on hyperspectral reflectance vegetation indices. Remote Sens. 2015, 7, 16460–16479. [Google Scholar] [CrossRef] [Green Version]

- Haque, P.; Das, B.; Kaspy, N.N. Two-handed bangla sign language recognition using principal component analysis (PCA) and KNN algorithm. In Proceedings of the 2019 International Conference on Electrical, Computer and Communication Engineering (ECCE), Cox’s Bazar, Bangladesh, 7–9 February 2019; pp. 1–4. [Google Scholar]

- Marill, K.A. Advanced statistics: Linear regression, Part II: Multiple linear regression. Acad. Emerg. Med. 2004, 11, 94–102. [Google Scholar] [CrossRef]

- Shei, H.J.; Lin, C.S. An optical automatic measurement method for the moisture content of rough rice using image processing techniques. Comput. Electron. Agric. 2012, 85, 134–139. [Google Scholar] [CrossRef]

| HMC (%) | Purchase Price (TWD/600 g) | Note |

|---|---|---|

| >32% | ineligible | Volume weight > 560 (g/L) (non-weather abnormality, ineligible) |

| 31–31.9% | 997 | Volume weight > 550 (g/L) (GIGR > 17%, ineligible) |

| 30–30.9% | 1025 | |

| 29–29.9% | 1046 | |

| 28–28.9% | 1067 | |

| 27–27.9% | 1081 | Volume weight > 540 (g/L) (GIGR > 17%, ineligible) |

| 26–26.9% | 1095 | |

| <25.9% | 1109 |

| Parameters | Values |

|---|---|

| Smart phone | Apple iPhone 8 |

| Camera resolution | 4032 × 3024 (12.1 M pixel) |

| ISO value | 25 |

| f/number | f/1.8 |

| Shutter Speed | 1/400 s |

| Still image aspect ratio | 4:3 |

| Spectral bands | 3 (Red, Green, Blue) |

| Output formats | JPEG |

| Distance from lens to rice panicle | 27.5 cm |

| Factor | Comp.1 | Comp.2 | Comp.3 |

|---|---|---|---|

| R | −0.246 | 0.303 | 0.050 |

| G | 0.126 | 0.392 | −0.084 |

| B | −0.098 | 0.057 | −0.454 |

| H1 | 0.337 | 0.118 | 0.008 |

| S1 | −0.016 | 0.100 | 0.464 |

| V1 | −0.234 | 0.316 | 0.049 |

| H2 | 0.337 | 0.118 | 0.008 |

| L2 | −0.211 | 0.234 | −0.278 |

| S2 | −0.187 | 0.323 | 0.176 |

| L* | 0.025 | 0.421 | −0.074 |

| a* | −0.338 | −0.117 | 0.030 |

| b* | 0.096 | 0.226 | 0.384 |

| Y | −0.292 | 0.185 | −0.141 |

| Cr | −0.082 | −0.251 | −0.370 |

| Cb | 0.039 | 0.307 | −0.326 |

| NDI | 0.334 | 0.086 | −0.117 |

| GI | 0.335 | 0.087 | −0.111 |

| RGRI | −0.333 | −0.086 | 0.124 |

| Component | Eigenvalues | Cumulative Proportion (%) | |

| Comp.1 | 8.049 | 44.71 | |

| Comp.2 | 5.466 | 75.08 | |

| Comp.3 | 4.381 | 99.42 | |

| GMC Interval | Statistics Value | RF | MLP | SVR | MLR |

|---|---|---|---|---|---|

| All (n = 103) | RMSE | 2.98 | 2.69 | 2.86 | 2.49 |

| MAE | 2.04 | 1.77 | 1.79 | 1.71 | |

| MAPE | 6.28% | 5.36% | 5.24% | 5.39% | |

| Below 40 (%) (n = 86) | RMSE | 2.15 | 1.82 | 1.74 | 1.90 |

| MAE | 1.63 | 1.29 | 1.23 | 1.38 | |

| MAPE | 5.87% | 4.71% | 4.41% | 5.04% | |

| Below 32 (%) (n = 77) | RMSE | 1.80 | 1.66 | 1.53 | 1.73 |

| MAE | 1.41 | 1.20 | 1.08 | 1.31 | |

| MAPE | 5.37% | 4.55% | 4.10% | 4.96% |

| Operation Principle | Portable Resistance | Resistance | Capacitance | Smartphone Image |

|---|---|---|---|---|

| Model | Kett Electric Laboratory FQ-527 | Kett Electric Laboratory PQ-520 | Kett Electric Laboratory PM-450 | Apple Inc. iPhone 8 |

| Recommended range | <20% w.b. | <20% w.b. | <20% w.b. | 40–20% w.b. |

| Applicable scenarios | outdoor | indoor | indoor | outdoor |

| Weight | 450 g | >9000 g | 1300 g | 148 g |

| Testing method | Destructive | Destructive | Destructive | Non-destructive |

| Sampling condition | Threshing | Threshing | Threshing | Directly shooting |

| Testing Samples | Image-Based GMC Dataset | Samples of Different Growing Conditions | Samples of Different Varieties |

|---|---|---|---|

| Year | 2019 | 2020 | 2020 |

| Crop season | II | I | II |

| Variety | TNG71 | TNG71 | TN11 |

| Characteristics | Middle-late maturity | Middle-late maturity | Early maturity |

| Assessment model | Image-GMC assessment model | ||

| Testing MAE(% w.b.) | 1.71 | 3.31 | 3.66 |

| Image-Based GMC Dataset | Multi-Day GMC Dataset | |

|---|---|---|

| Target model | Image-GMC assessment model | Multi-day GMC prediction model |

| Sampling scope | Single panicle | 1 m × 1 m paddy |

| Feature | High variation GMC data | Homogeneous GMC data |

| Sampling frequency | 2–3 days | 1–2 days |

| Sampling (each time) | 70–122 | 12 |

| GMC distribution | 60–13% w.b. | 37.5–20.2% w.b. |

| Method | Drying | Drying |

| Drying spec | 80 °C 7 days/each sample | 80 °C 7 days/each sample |

| Labor costs | Three person/each day | Four person/each day |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, M.-D.; Hsu, Y.-C.; Tseng, W.-C.; Lu, C.-Y.; Yang, C.-Y.; Lai, M.-H.; Wu, D.-H. Assessment of Grain Harvest Moisture Content Using Machine Learning on Smartphone Images for Optimal Harvest Timing. Sensors 2021, 21, 5875. https://doi.org/10.3390/s21175875

Yang M-D, Hsu Y-C, Tseng W-C, Lu C-Y, Yang C-Y, Lai M-H, Wu D-H. Assessment of Grain Harvest Moisture Content Using Machine Learning on Smartphone Images for Optimal Harvest Timing. Sensors. 2021; 21(17):5875. https://doi.org/10.3390/s21175875

Chicago/Turabian StyleYang, Ming-Der, Yu-Chun Hsu, Wei-Cheng Tseng, Chian-Yu Lu, Chin-Ying Yang, Ming-Hsin Lai, and Dong-Hong Wu. 2021. "Assessment of Grain Harvest Moisture Content Using Machine Learning on Smartphone Images for Optimal Harvest Timing" Sensors 21, no. 17: 5875. https://doi.org/10.3390/s21175875

APA StyleYang, M. -D., Hsu, Y. -C., Tseng, W. -C., Lu, C. -Y., Yang, C. -Y., Lai, M. -H., & Wu, D. -H. (2021). Assessment of Grain Harvest Moisture Content Using Machine Learning on Smartphone Images for Optimal Harvest Timing. Sensors, 21(17), 5875. https://doi.org/10.3390/s21175875