A Portable Triboelectric Nanogenerator Based on Dehydrated Nopal Powder for Powering Electronic Devices

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Working Mechanism

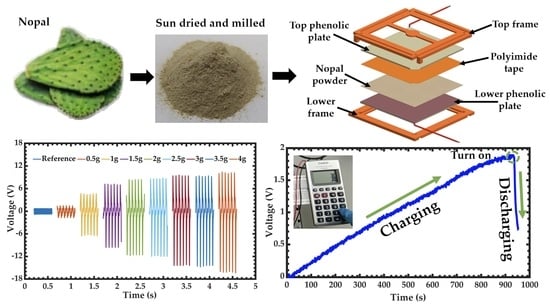

2.3. NOP-TENG Fabrication

2.4. Setup

3. Results and Discussion

3.1. SEM, AFM, and EDS Characterization

3.2. Output Performance

3.3. Advantages and Weaknesses

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kim, W.-G.; Kim, D.-W.; Tcho, I.-W.; Kim, J.-K.; Kim, M.-S.; Choi, Y.-K. Triboelectric Nanogenerator: Structure, Mechanism, and Applications. ACS Nano 2021, 15, 258–287. [Google Scholar] [CrossRef]

- Feng, L.; Wang, Z.L.; Cao, X.; Zhang, L. Accordion-Inspired Parallelly Assembled Triboelectric Nanogenerator: For Efficient Biomechanical Energy Harvesting and Music Responding. Nano Today 2023, 49, 101760. [Google Scholar] [CrossRef]

- Wu, Y.; Luo, Y.; Cuthbert, T.J.; Shokurov, A.V.; Chu, P.K.; Feng, S.-P.; Menon, C. Hydrogels as Soft Ionic Conductors in Flexible and Wearable Triboelectric Nanogenerators. Adv. Sci. 2022, 9, 2106008. [Google Scholar] [CrossRef] [PubMed]

- Martinez-Lopez, A.G.; Tinoco, J.C.; Elvira-Hernández, E.A.; Herrera-May, A.L. Solution-Processed ZnO Energy Harvester Devices Based on Flexible Substrates. Microsyst. Technol. 2023, 29, 205–210. [Google Scholar] [CrossRef]

- Ye, C.; Liu, D.; Chen, P.; Cao, L.N.Y.; Li, X.; Jiang, T.; Wang, Z.L. An Integrated Solar Panel with a Triboelectric Nanogenerator Array for Synergistic Harvesting of Raindrop and Solar Energy. Adv. Mater. 2023, 35, 2209713. [Google Scholar] [CrossRef]

- Hu, S.; Han, J.; Shi, Z.; Chen, K.; Xu, N.; Wang, Y.; Zheng, R.; Tao, Y.; Sun, Q.; Wang, Z.L.; et al. Biodegradable, super-strong, and conductive cellulose macrofibers for fabric-based triboelectric nanogenerator. Nano-Micro Lett. 2022, 14, 115. [Google Scholar] [CrossRef]

- Hao, D.; Qi, L.; Tairab, A.M.; Ahmed, A.; Azam, A.; Luo, D.; Pan, Y.; Zhang, Z.; Yan, J. Solar Energy Harvesting Technologies for PV Self-Powered Applications: A Comprehensive Review. Renew. Energy 2022, 188, 678–697. [Google Scholar] [CrossRef]

- Muscat, A.; Bhattacharya, S.; Zhu, Y. Electromagnetic Vibrational Energy Harvesters: A Review. Sensors 2022, 22, 5555. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Meng, B.; Tian, Y.; Meng, X.; Lin, X.; He, Y.; Xing, C.; Dai, H.; Wang, L. Vortex-Induced Vibration Triboelectric Nanogenerator for Low Speed Wind Energy Harvesting. Nano Energy 2022, 95, 107029. [Google Scholar] [CrossRef]

- Askari, H.; Hashemi, E.; Khajepour, A.; Khamesee, M.B.; Wang, Z.L. Towards self-powered sensing using nanogenerators for automotive systems. Nano Energy 2018, 53, 1003–1019. [Google Scholar] [CrossRef]

- Sahoo, S.; Ratha, S.; Rout, C.S.; Nayak, S.K. Self-charging supercapacitors for smart electronic devices: A concise review on the recent trends and future sustainability. J. Mater. Sci. 2022, 57, 4399–4440. [Google Scholar] [CrossRef]

- Rani, G.M.; Wu, C.-M.; Motora, K.G.; Umapathi, R. Waste-to-Energy: Utilization of Recycled Waste Materials to Fabricate Triboelectric Nanogenerator for Mechanical Energy Harvesting. J. Clean. Prod. 2022, 363, 132532. [Google Scholar] [CrossRef]

- He, C.; Yang, T.; Fang, J.; Pu, X.; Shang, K.; Tian, G.; Lu, X.; Wu, J.; Yang, W.; Qian, L. Tensegrity-Inspired Triboelectric Nanogenerator for Broadband and Impact-Resistive Vibration Sensing. Nano Energy 2023, 109, 108279. [Google Scholar] [CrossRef]

- Zi, Y.; Niu, S.; Wang, J.; Wen, Z.; Tang, W.; Wang, Z.L. Standards and Figure-of-Merits for Quantifying the Performance of Triboelectric Nanogenerators. Nat. Commun. 2015, 6, 8376. [Google Scholar] [CrossRef] [PubMed]

- Delgado-Alvarado, E.; Elvira-Hernández, E.A.; Hernández-Hernández, J.; Huerta-Chua, J.; Vázquez-Leal, H.; Martínez-Castillo, J.; García-Ramírez, P.; Herrera-May, A.L. Recent Progress of Nanogenerators for Green Energy Harvesting: Performance, Applications, and Challenges. Nanomaterials 2022, 12, 2549. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Guo, X.; Zhu, M.; Sun, Z.; Zhang, Z.; He, T.; Lee, C. Triboelectric Nanogenerator Enabled Wearable Sensors and Electronics for Sustainable Internet of Things Integrated Green Earth. Adv. Energy Mater. 2023, 13, 2203040. [Google Scholar] [CrossRef]

- Kamal, V.V.; Kiran, A.; Francis, J.; Hemanth; Arackal, A.J.; Mathew, J.N.; Rani, S. Comparative Analysis of Variation in Macroscopic Design Process Parameters of Triboelectric Nanogenerators. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Chen, X.; Han, C.; Wen, Z.; Liu, Y. Theoretical Boundary and Optimization Methodology of Contact-Separation Triboelectric Nanogenerator. Appl. Mater. Today 2022, 29, 101685. [Google Scholar] [CrossRef]

- Shaukat, R.A.; Saqib, Q.M.; Khan, M.U.; Chougale, M.Y.; Bae, J. Bio-Waste Sunflower Husks Powder Based Recycled Triboelectric Nanogenerator for Energy Harvesting. Energy Rep. 2021, 7, 724–731. [Google Scholar] [CrossRef]

- Kaur, J.; Sawhney, R.S.; Singh, H.; Singh, M. Electricity Nanogenerator From Egg Shell Membrane: A Natural Waste Bioproduct. Int. J. Green Energy 2020, 17, 309–318. [Google Scholar] [CrossRef]

- Han, Y.; Han, Y.; Zhang, X.; Li, L.; Zhang, C.; Liu, J.; Lu, G.; Yu, H.-D.; Huang, W. Fish Gelatin Based Triboelectric Nanogenerator for Harvesting Biomechanical Energy and Self-Powered Sensing of Human Physiological Signals. ACS Appl. Mater. Interfaces 2020, 12, 16442–16450. [Google Scholar] [CrossRef] [PubMed]

- Ma, J.; Zhu, J.; Ma, P.; Jie, Y.; Wang, Z.L.; Cao, X. Fish Bladder Film-Based Triboelectric Nanogenerator for Noncontact Position Monitoring. ACS Energy Lett. 2020, 5, 3005–3011. [Google Scholar] [CrossRef]

- Chi, Y.; Xia, K.; Zhu, Z.; Fu, J.; Zhang, H.; Du, C.; Xu, Z. Rice Paper-Based Biodegradable Triboelectric Nanogenerator. Microelectron. Eng. 2019, 216, 111059. [Google Scholar] [CrossRef]

- Saqib, Q.M.; Chougale, M.Y.; Khan, M.U.; Shaukat, R.A.; Kim, J.; Bhat, K.S.; Bae, J. Triboelectric Nanogenerator Based on Lignocellulosic Waste Fruit Shell Tribopositive Material: Comparative Analysis. Mater. Today Sustain. 2022, 18, 100146. [Google Scholar] [CrossRef]

- Jie, Y.; Jia, X.T.; Zou, J.D.; Chen, Y.D.; Wang, N.; Wang, Z.L.; Cao, X. Natural Leaf Made Triboelectric Nanogenerator for Harvesting Environmental Mechanical Energy. Adv. Energy Mater. 2018, 8, 1703133. [Google Scholar] [CrossRef]

- Saqib, Q.M.; Shaukat, R.A.; Khan, M.U.; Chougale, M.; Bae, J. Biowaste Peanut Shell Powder-Based Triboelectric Nanogenerator for Biomechanical Energy Scavenging and Sustainably Powering Electronic Supplies. ACS Appl. Electron. Mater. 2020, 2, 3953–3963. [Google Scholar] [CrossRef]

- Meder, F.; Must, I.; Sadeghi, A.; Mondini, A.; Filippeschi, C.; Beccai, L.; Mattoli, V.; Pingue, P.; Mazzolai, B. Energy Conversion at the Cuticle of Living Plants. Adv. Funct. Mater. 2018, 28, 1806689. [Google Scholar] [CrossRef]

- Kim, J.-N.; Lee, J.; Go, T.W.; Rajabi-Abhari, A.; Mahato, M.; Park, J.Y.; Lee, H.; Oh, I.-K. Skin-Attachable and Biofriendly Chitosan-Diatom Triboelectric Nanogenerator. Nano Energy 2020, 75, 104904. [Google Scholar] [CrossRef]

- Pang, Y.; Xi, F.; Luo, J.; Liu, G.; Gul, T.; Zhang, C. An Alginate Film-Based Degradable Triboelectric Nanogenerator. RSC Adv. 2018, 8, 6719–6726. [Google Scholar] [CrossRef]

- Khandelwal, G.; Minocha, T.; Yadav, S.K.; Chandrasekhar, A.; Joseph Raj, N.P.M.; Gupta, S.C.; Kim, S.-J. All Edible Materials Derived Biocompatible and Biodegradable Triboelectric Nanogenerator. Nano Energy 2019, 65, 104016. [Google Scholar] [CrossRef]

- Babu, A.; Rakesh, D.; Supraja, P.; Mishra, S.; Kumar, K.U.; Kumar, R.R.; Haranath, D.; Mamidala, E.; Nagapuri, R. Plant-Based Triboelectric Nanogenerator for Biomechanical Energy Harvesting. Results Surf. Interfaces 2022, 8, 100075. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, L.; Zheng, Y.; Wang, D.; Zhou, F.; Liu, W. Leaves based triboelectric nanogenerator (TENG) and TENG tree for wind energy harvesting. Nano Energy 2019, 55, 260–268. [Google Scholar] [CrossRef]

- Dai, S.; Li, X.; Jiang, C.; Ping, J.; Ying, Y. Triboelectric Nanogenerators for Smart Agriculture. InfoMat 2023, 5, e12391. [Google Scholar] [CrossRef]

- Lan, L.; Xiong, J.; Gao, D.; Li, Y.; Chen, J.; Lv, J.; Ping, J.; Ying, Y.; Lee, P.S. Breathable Nanogenerators for an On-Plant Self-Powered Sustainable Agriculture System. ACS Nano 2021, 15, 5307–5315. [Google Scholar] [CrossRef]

- Xia, K.; Zhu, Z.; Fu, J.; Li, Y.; Chi, Y.; Zhang, H.; Du, C.; Xu, Z. A Triboelectric Nanogenerator Based on Waste Tea Leaves and Packaging Bags for Powering Electronic Office Supplies and Behavior Monitoring. Nano Energy 2019, 60, 61–71. [Google Scholar] [CrossRef]

- Saqib, Q.M.; Khan, M.U.; Song, H.; Chougale, M.Y.; Shaukat, R.A.; Kim, J.; Bae, J.; Choi, M.K.; Kim, S.C.; Kwon, O.; et al. Natural Hierarchically Structured Highly Porous Tomato Peel Based Tribo- and Piezo-electric Nanogenerator for Efficient Energy Harvesting. Adv. Sustain. Syst. 2021, 5, 2100066. [Google Scholar] [CrossRef]

- Butera, D.; Tesoriere, L.; di Gaudio, F.; Bongiorno, A.; Allegra, M.; Pintaudi, A.M.; Kohen, R.; Livrea, M.A. Antioxidant Activities of Sicilian Prickly Pear (Opuntia Ficus Indica) Fruit Extracts and Reducing Properties of its Betalains: Betanin and Indicaxanthin. J. Agric. Food Chem. 2022, 50, 6895–6901. [Google Scholar] [CrossRef]

- El-Mostafa, K.; El Kharrassi, Y.; Badreddine, A.; Andreoletti, P.; Vamecq, J.; El Kebbaj, M.S.; Latruffe, N.; Lizard, G.; Nasser, B.; Cherkaoui-Malki, M. Nopal Cactus (Opuntia Ficus-Indica) as a Source of Bioactive Compounds for Nutrition, Health and Disease. Molecules 2014, 19, 14879–14901. [Google Scholar] [CrossRef]

- NBF. Available online: https://nbfmarket.com/producto/nopal-deshidratado-organico-454-gr/ (accessed on 9 October 2022).

- NBF. Available online: https://nbfmarket.com/wp-content/uploads/2021/01/FT2021_NOPALDESHIDRATADO1.pdf (accessed on 9 October 2022).

- Steren. Available online: https://www.steren.com.pa/cinta-termica-tipo-kapton-de-2.html (accessed on 12 October 2022).

- Morel, A.; Brenes, A.; Gibus, D.; Lefeuvre, E.; Gasnier, P.; Pillonnet, G.; Badel, A. A comparative study of electrical interfaces for tunable piezoelectric vibration energy harvesting. Smart Mater. Struct. 2022, 31, 045016. [Google Scholar] [CrossRef]

- Rincón-Mora, G.A.; Yang, S. Tiny piezoelectric harvesters: Principles, constraints, and power conversion. IEEE Trans. Circuits Syst. I Regul. Pap. 2016, 63, 639–649. [Google Scholar] [CrossRef]

| Organic Triboelectric Material | Opposite Triboelectric Film | Triboelectric Layer Area | Output Power Density | Open-circuit Voltage | Advantages | Weaknesses | Ref. |

|---|---|---|---|---|---|---|---|

| Sunflower husk powder | PET | 5 × 5 cm2 | 480 mW·m−2 at RL of 3 MΩ | 488 V | Cost-effective and eco-friendly TENG | Wear of film by friction | [19] |

| Egg shell membrane | PTFE | 6 × 8 cm2 | 250 mW·m−2 at RL of 2.3 MΩ | -- * | Low-cost fabrication and simple structure | Fragile structure | [20] |

| Fish gelatin film | PFTE/Polydimethylsiloxane (PDMS) composite film | 5 × 5 cm2 | 458 mW·m−2 at RL of 10 MΩ | 130 V | Economical, simple, and environmental-friendly structure | Wear of film by friction | [21] |

| Grass carp fish bladder film | Fluorinated ethylene propylene (FEP) film | 4 × 4 cm2 | 243.75 mW·m−2 at RL of 10 MΩ | 106 V | Flexible, biodegradable, and durable TENG structure | Depend on the availability of grass carp fish bladder | [22] |

| Rice paper | Polyvinyl chloride (PVC) | 3 × 3 cm2 | 376.4 mW·m−2 at RL of 70 MΩ | 244 V | Biodegradable, stable, and recyclable TENG structure | Wear of film by friction | [23] |

| Pistachio | PTFE | 4.5 × 4.5 cm2 | 4161.4 mW·m−2 at RL of 3 MΩ | 700 | Cost-effective performance and environmental-friendly structure | Wear of film by friction | [24] |

| Hosta leaf | Poly(methyl metracrylate) (PMMA) | 8 × 8 cm2 | 45 mW·m−2 at RL of 10 MΩ | 230 V | Environmental-friendly structure | Fragile structure and without portable frame structure. | [25] |

| Peanut shell powder | PET | 4.5 × 4.5 cm2 | 577 mW·m−2 at RL of 5 MΩ | 390 V | Bio-waste and non-toxic material used as a triboelectric layer | Decreased device performance due to the hydrophilic nature of the peanut shell powder | [26] |

| Rhododendron leaves | Ecoflex pad | 5 × 5 cm2 | ~150 mW·m−2 at RL of 200–300 MΩ | 140 V | Simple structure and easy working principle | Fragile structure and without portable frame structure. | [27] |

| Diatom frustule chitosan | FEP | 3 × 4 cm2 | 15.7 mW·m−2 at RL of 5 MΩ | 150 V | Simple structure and low-cost manufacturing | Stability performance tests are required | [28] |

| Alginate film | Aluminum | 5 × 5 cm2 | 3.8 mW·m−2 at RL of 20 MΩ | 33 V | Low toxicity, good biocompatibility, and biodegradability triboelectric film | Fragile structure and without portable frame structure. | [29] |

| Laver (Korean seaweed) | FEP | 2 × 2 cm2 | 2 mW·m−2 at RL of 500 MΩ | - | Flexible, lightweight, and edible structure | Wear of film by friction and without portable frame structure. | [30] |

| Rumex vesicarius leaves powder | Poly(ethylene terephthalate)(PET)/Polytetrafluoroethylene (PTFE) film | 5 × 5 cm2 | 1.894 mW·m−2 at RL of 20 MΩ | 3.86 V | Simple structure, low-cost fabrication, and stable output performance | Fragile structure | [31] |

| Dehydrated nopal powder | Polyimide film | 5.22 × 5.22 cm2 | 0.556 mW·m−2 at RL of 76.89 MΩ a 2.309 mW·m−2 at RL of 76.89 MΩ b | 16.4 V 38 V | Potable and simple structure, low-cost fabrication, and stable performance | Wear of film by friction | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elvira-Hernández, E.A.; Nava-Galindo, O.I.; Martínez-Lara, E.K.; Delgado-Alvarado, E.; López-Huerta, F.; De León, A.; Gallardo-Vega, C.; Herrera-May, A.L. A Portable Triboelectric Nanogenerator Based on Dehydrated Nopal Powder for Powering Electronic Devices. Sensors 2023, 23, 4195. https://doi.org/10.3390/s23094195

Elvira-Hernández EA, Nava-Galindo OI, Martínez-Lara EK, Delgado-Alvarado E, López-Huerta F, De León A, Gallardo-Vega C, Herrera-May AL. A Portable Triboelectric Nanogenerator Based on Dehydrated Nopal Powder for Powering Electronic Devices. Sensors. 2023; 23(9):4195. https://doi.org/10.3390/s23094195

Chicago/Turabian StyleElvira-Hernández, Ernesto A., Omar I. Nava-Galindo, Elisa K. Martínez-Lara, Enrique Delgado-Alvarado, Francisco López-Huerta, Arxel De León, Carlos Gallardo-Vega, and Agustín L. Herrera-May. 2023. "A Portable Triboelectric Nanogenerator Based on Dehydrated Nopal Powder for Powering Electronic Devices" Sensors 23, no. 9: 4195. https://doi.org/10.3390/s23094195

APA StyleElvira-Hernández, E. A., Nava-Galindo, O. I., Martínez-Lara, E. K., Delgado-Alvarado, E., López-Huerta, F., De León, A., Gallardo-Vega, C., & Herrera-May, A. L. (2023). A Portable Triboelectric Nanogenerator Based on Dehydrated Nopal Powder for Powering Electronic Devices. Sensors, 23(9), 4195. https://doi.org/10.3390/s23094195