Electrochemical Performance of a Carbon Nanotube/La-Doped TiO2 Nanocomposite and its Use for Preparation of an Electrochemical Nicotinic Acid Sensor

Abstract

:1. Introduction

2. Results and Discussion

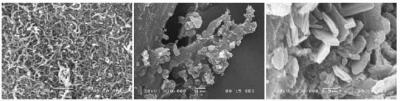

2.1. Characteristics of CLTN

2.2. Electrochemical characteristics of CLTNPE

2.3. Electrochemical characteristics of NA on CLTNPE

3. Experimental Section

4. Conclusions

Acknowledgments

References and Notes

- Ray, H.B.; Zakhidov, A.A.; Heer, W.A. Carbon Nanotubes--the Route Toward Applications. Science 2002, 297, 787. [Google Scholar]

- Wang, J.X.; Li, M.X.; Shi, Z.J.; Li, N.Q.; Gu, Z.N. Direct electrochemistry of cytochrome c at a glassy carbon electrode modified with single-wall carbon nanotubes. Anal. Chem. 2002, 74, 1993–1997. [Google Scholar]

- Lin, Y.H.; Lu, F.; Tu, Y.; Ren, Z.F. Glucose biosensors based on carbon nanotube nanoelectrode ensembles. Nano. Lett. 2004, 4, 191–195. [Google Scholar]

- Gong, K.P.; Zhang, M. N.; Yan, Y. M.; Su, L.; Mao, L. Q.; Xiong, S. X.; Chen, Y. Sol–gelderived ceramic-carbon nanotube nanocomposite electrodes: tunable electrode dimension and potential electrochemical applications. Anal. Chem. 2004, 76, 6500–6505. [Google Scholar]

- Liu, G.D.; Riechers, S.L.; Mellen, M.C.; Lin, Y. Sensitive electrochemical detection of enzymatically generated thiocholine at carbon nanotube modified glassy carbon electrode. Electrochem. Commun. 2005, 7, 1163–1169. [Google Scholar]

- Wang, J.; Dai, J.H.; Yarlagadda, T. Carbon nanotube-conductingpolymer composite nanowires. Langmuir 2005, 21, 9–12. [Google Scholar]

- Zhang, M.G.; Smith, A.; Gorski, W. Carbon nanotube-chitosan system for electrochemical sensing based on dehydrogenase enzymes. Anal. Chem. 2004, 76, 5045–5050. [Google Scholar]

- Quinn, B.M.; Dekker, C.; Lemay, S.G. Electrodeposition of noble metal nanoparticles on carbon nanotubes. J. Am. Chem. Soc. 2005, 127, 6146–6147. [Google Scholar]

- Yang, M.; Jiang, J.; Yang, Y.; Cheng, X.; Shen, G.L.; Yu, R.Q. Carbon nanotube/cobalt hexacyanoferrate nanoparticle-biopolymer system for the fabrication of biosensors. Biosens. Bioelectron. 2006, 21, 1791–1797. [Google Scholar]

- Wu, J.; Zou, Y.; Gao, N.; Jiang, J.; Shen, G.L.; Yu, R.Q. Electrochemical performances of C/Fe nanocomposite and its use for mediator-free glucose biosensor preparation. Talanta 2005, 68, 12–18. [Google Scholar]

- Yang, X.; Ma, J.; Zhu, M.; Li, L.; Wu, Y. Anti-oxygen free radicals and anti-lipoperoxidation of nicotinic acid on hyperlipodem in quail. Chin. Phamacol. Bull. 2005, 993–995. [Google Scholar]

- Goldberg, A.; Alagona, P.J.; Capuzzi, D.M. Multiple-dose efficacy and safety of an extended-release form of niacin in the management of hyperlipidemia. Am. J. Cardiol. 2000, 85, 1100–1105. [Google Scholar]

- Carlson, L.A. Nicotinic acid and other therapies for raising high-density lipoprotein. Curr. Opin. Cardiol. 2006, 21, 336–344. [Google Scholar]

- Shibata, K.; Fukuwatari, T.; Sugimoto, E. Reversed-phase high-performance liquid chromatography of nicotinic acid mononucleotide for measurement of quinolinate phosphoribosyltransferase. J. Chrom. B 2000, 749, 281–285. [Google Scholar]

- Moreno, P.; Salvado, V. Determination of eight water- and fat-soluble vitamins in multi-vitamin pharmaceutical formulations by high-performance liquid chromatography. J. Chrom. A 2000, 870, 207–215. [Google Scholar]

- Chen, Z.; Chen, B.; Yao, S. High-performance liquid chromatography/electrospray ionization-mass spectrometry for simultaneous determination of taurine and 10 water-soluble vitamins in multivitamin tablets. Anal. Chim. Acta 2006, 569, 169–175. [Google Scholar]

- Capella-Peiró, E.; Monferrer-Pons, L.; García-Alvarez-Coque, C.; Esteve-Romero, J. Flow-injection spectrophotometric determination of nicotinic acid in micellar medium of N-cetylpyridinium chloride. Anal. Chim. Acta 2001, 427, 93–100. [Google Scholar]

- Lu, Y.; Wu, C.; Yuan, Z. Determination of hesperetin, cinnamic acid and nicotinic acid in propolis with micellar electrokinetic capillary chromatography. Fitoterapia 2004, 75, 267–276. [Google Scholar]

- Iwaki, M.; Murakami, E.; Kikuchi, M.; Wada, A.; Ogiso, T.; Oda, Y.; Kubo, K.; Kakehi, K. Simultaneous determination of nicotinic acid and its metabolites in rat urine by micellar electrokinetic chromatography with photodiode array detection. J. Chrom. B 1998, 716, 335–342. [Google Scholar]

- Lahely, S.; Bergaentzle, M.; Hasselmann, C. Fluorimetric determination of niacin in foods by high-performance liquid chromatography with post-column derivatization. Food Chem. 1999, 65, 129–133. [Google Scholar]

- Rose-Sallin, C.; Blake, C.J. Comparison of microbiological and HPLC–Fluorescence detection methods for determination of niacin in fortified food products. Food Chem. 2001, 73, 473–480. [Google Scholar]

- Okamoto, H.; Nakajima, T.; Ito, Y. Simultaneous determination of water-soluble vitamins in a vitamin-enriched drink by an in-capillary enzyme reaction method. J. Chrom. A 2003, 986, 153–161. [Google Scholar]

- Krasnova, A.I.; Aguilar-Caballos, M.P.; Gómez-Hens, A. Selective determination of nicotinic acid and nicotinamide using terbium(III) sensitised luminescence. Anal. Chim. Acta. 2001, 441, 249–256. [Google Scholar]

- Takayama, K.; Kurosaki, T.; Ikeda, T.; Nagasawa, T. Bioelectrocatalytic hydroxylation of nicotinic acid at an electrode modified with immobilized bacterial cells of Pseudomonas fluorescens in the presence of electron transfer mediators. J. Electroanal. Chem. 1995, 381, 47–53. [Google Scholar]

- Peng, T.; Zhao, D.; Song, H.; Yan, C. Preparation of lanthana-doped titania nanoparticles with anatase mesoporous walls and high photocatalytic activity. J. Mol. Cat. A: Chem. 2005, 238, 119–126. [Google Scholar]

- Ajayan, P.M.; Ebbesen, T.W.; Ichihashi, T.; Iijima, S.; Tanigaki, K.; Hiura, H. Opening carbon nanotubes with oxygen and implications for filling. Nature 1993, 362, 522–525. [Google Scholar]

- Tsang, S.C.; Harris, P.; Green, M. Thinning and opening of carbon nanotubes by oxidation using carbon dioxide. Nature 1993, 362, 520–522. [Google Scholar]

- Liu, G.D.; Wu, Z.W.; Wang, S.P.; Shen, G.L.; Yu, R.Q. Renewable amperometric immunosensor for schistosoma japonium antiboby immunoassay. Anal. Chem. 2001, 73, 321. [Google Scholar]

| Interfering chemicals | Interference level |

|---|---|

| VB1 | No interference |

| VB2 | No interference |

| VB6 | No interference |

| L-cysteine | No interference |

| Ascorbic acid | Too low |

| Uric acid | No interference |

| H2O2 | Too low |

| Dopamine | No interference |

| Isonicotinic acid | High |

| NA added (μmol L-1) | NA found (μmol·L-1) | RSD (%) | Recovery (%) | Mean (%) |

|---|---|---|---|---|

| 10.00 | 9.832 | 3.4 | 98.3 | 101.8 |

| 40.00 | 41.03 | 2.1 | 102.6 | |

| 50.00 | 52.23 | 2.7 | 104.5 | |

| 70.00 | 69.42 | 1.9 | 99.2 | |

| 90.00 | 93.78 | 2.9 | 104.2 |

© 2008 by the authors; licensee Molecular Diversity Preservation International, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Wu, J.; Liu, H.; Lin, Z. Electrochemical Performance of a Carbon Nanotube/La-Doped TiO2 Nanocomposite and its Use for Preparation of an Electrochemical Nicotinic Acid Sensor. Sensors 2008, 8, 7085-7096. https://doi.org/10.3390/s8117085

Wu J, Liu H, Lin Z. Electrochemical Performance of a Carbon Nanotube/La-Doped TiO2 Nanocomposite and its Use for Preparation of an Electrochemical Nicotinic Acid Sensor. Sensors. 2008; 8(11):7085-7096. https://doi.org/10.3390/s8117085

Chicago/Turabian StyleWu, Jing, Hanxing Liu, and Zhidong Lin. 2008. "Electrochemical Performance of a Carbon Nanotube/La-Doped TiO2 Nanocomposite and its Use for Preparation of an Electrochemical Nicotinic Acid Sensor" Sensors 8, no. 11: 7085-7096. https://doi.org/10.3390/s8117085

APA StyleWu, J., Liu, H., & Lin, Z. (2008). Electrochemical Performance of a Carbon Nanotube/La-Doped TiO2 Nanocomposite and its Use for Preparation of an Electrochemical Nicotinic Acid Sensor. Sensors, 8(11), 7085-7096. https://doi.org/10.3390/s8117085