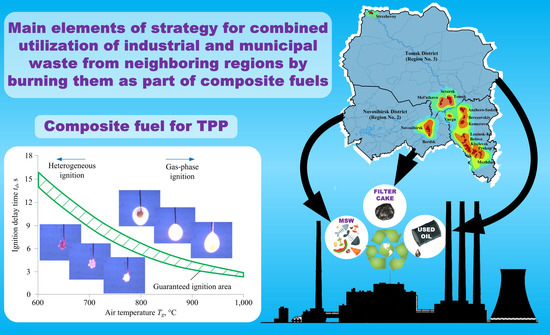

The Main Elements of a Strategy for Combined Utilization of Industrial and Municipal Waste from Neighboring Regions by Burning it as Part of Composite Fuels

Abstract

:1. Introduction

2. Experimental Investigation

2.1. Materials Preparation

2.2. Experimental Setup and Procedure

2.3. Experimental Results and Discussion

3. Prospects for Utilization of Industrial and Municipal Waste from Several Regions by Burning with Energy Generation

3.1. General Information

3.2. Energy Potential of Industrial Waste and Municipal Solid Waste (MSW)

- in Kemerovo region—54.0 Mt;

- in Novosibirsk region—70.0 Mt;

- in Tomsk region—21.0 Mt.

- in Kemerovo region—0.9 Mt;

- in Novosibirsk region—1.3 Mt;

- in Tomsk region—0.4 Mt.

- in Kemerovo region—0.5;

- in Novosibirsk region—0.7;

- in Tomsk region—0.6.

- in Kemerovo region—14.1 MJ/kg;

- in Novosibirsk region—12.0 MJ/kg;

- in Tomsk region—10.0 MJ/kg.

- in Kemerovo region Q0MSW = 54.0 × 106 × 103 × 14.1 × 106 = 761 PJ;

- in Novosibirsk region Q0MSW = 70.0 × 106 × 103 × 12.0 × 106 = 830 PJ;

- in Tomsk region Q0MSW = 21.0 ×106 × 103 × 10.0 × 106 = 209 PJ.

- in Kemerovo region QMSW = 0.5 × 0.9 × 106 × 103 × 14.1 × 106 = 13 PJ;

- in Novosibirsk region QMSW = 0.7 × 1.3 × 106 × 103 × 12.0 × 106 = 15 PJ;

- in Tomsk region QMSW = 0.6 × 0.4 × 106 × 103 × 10.0 × 106 = 2 PJ.

3.3. Energy Potential of Coal Processing and Oil Refining

- in Kemerovo region—368.6 Mt;

- in Novosibirsk region—5.8 Mt;

- in Tomsk region, coal is not extracted or processed.

- in Kemerovo region—8.1 Mt;

- in Novosibirsk region—0.4 Mt;

- in Tomsk region, coal is not extracted or processed.

- in Kemerovo region Q0fc = 368.6 × 106 × 103 × 24.8 × 106 × 0.6 = 5485 PJ;

- in Novosibirsk region Q0fc = 5.8 × 106 × 103 × 24.8 × 106 × 0.6 = 86 PJ;

- in Tomsk region Q0fc = 0 J.

- in Kemerovo region Qfc = 8.1 × 106 × 103 × 24.8 × 106 × 0.6 = 201 PJ;

- in Novosibirsk region Qfc = 0.4 × 106 × 103 × 24.8 × 106 × 0.6 = 10 PJ;

- in Tomsk region Qfc = 0 J.

- in Kemerovo region, there is no liquid combustible waste;

- in Novosibirsk region—97.3 kt;

- in Tomsk region—2219 kt.

- in Kemerovo region—0.5 kt;

- in Novosibirsk region—0.7 kt;

- in Tomsk region—11.5 kt.

- in Kemerovo region Q0oil = 0 J;

- in Novosibirsk region Q0oil = 97.3 × 103 × 103 × 44.0 × 106 = 4 PJ;

- in Tomsk region Q0oil = 2219.4 × 103 × 103 × 44.0 × 106 = 98 PJ.

- in Kemerovo region Qoil = 0.4 × 0.5 × 103 × 103 × 44.0 × 106 = 0.009 PJ;

- in Novosibirsk region Qoil = 0.4 × 0.7 × 103 × 103 × 44.0 × 106 = 0.012 PJ;

- in Tomsk region Qoil = 0.4 × 11.5 × 103 × 103 × 44.0 × 106 = 2 PJ.

3.4. Need for Energy Resources of Coal-Fired Thermal Power Engineering

3.5. Strategy of Combined Recovery of Industrial Waste and MSW with Power Generation

- (1)

- Saving on high-grade solid fossil fuels (more than 280 Mt over 25 years) due to reducing their consumption by thermal power engineering through the replacement by composite fuels in the amount equivalent by energy performance indicators (about 315 Mt).

- (2)

- Reducing environmental pollution due to solid waste disposal as part of an environmentally friendly electricity and heat production technology.

- (3)

- Reducing the intensity of landfill site area growth due to scheduled disposal of municipal solid waste.

- (4)

- Efficient investment of financial means saved by reducing energy resource acquisition costs into the development of cutting-edge technologies in commercial thermal power engineering and modernization of thermal power plants.

4. Conclusions

- (1)

- The theoretical analysis showed that implementing the strategy of combined recovery of industrial and municipal waste by burning it as part of composite fuels at local thermal power plants is a promising approach for neighboring regions to deal with the waste management issue. One of the regions is characterized by a high level of solid and liquid fossil fuel extraction. In the neighboring regions, fossil fuel mining is underdeveloped, whereas the level of social advancement and industrial output is high. The energy potential of industrial waste and MSW determines the prospects of its recovery by means of burning it as part of composite fuels. Burning technologies of composite fuels is characterized by positive economic and environmental effects. That is why consistent patterns and necessary conditions have been experimentally discovered for the ignition of typical composite fuel consists of filter cakes with 10% of typical MSW (rubber, or wood, or plastic) and 5% of used motor oil under heating conditions similar to those of fuel combustion in boiler furnaces.

- (2)

- The fuel compositions under study (85% of filter cakes + 10% of MSW + 5% of used oil) were used as examples to experimentally validate sustainable ignition and combustion of composite fuel droplets up to their complete burnout in the conditions typical of conventional boiler furnaces. A software system for high-speed video recording outlined the main interdependent stages of process: heating; moisture evaporation; thermal decomposition of solid combustible components (MSW and coal); formation of combustible mixture; gas-phase ignition and burnout; heating of the solid combustible residue; heterogeneous ignition and combustion of the latter.

- (3)

- The values of the guaranteed ignition delay times for droplets with a size (diameter) of about 2 mm have been established for the composite fuel compositions under study in a wide range of the ambient temperature variation 600–1000 °C. The minimum values of ignition delay times are about 3 s, the maximum values are about 15 s. The maximum difference in ignition delay times of fuel compositions with different components is less than 20% at the ambient temperature 600–1000 °C. An approximation equation td = f(Tg) has been derived for a rapid evaluation of mean ignition delay time values of composite fuel droplets (filter cakes 85% + MSW 10% + oil 5%).

Author Contributions

Funding

Conflicts of Interest

References

- Lishtvan, I.I.; Dudarchik, V.M.; Kraiko, V.M.; Anufrieva, E.V.; Smolyachkova, E.A. Utilization of polymer wastes by joint pyrolysis with peat to produce high-calorific gas. Solid Fuel Chem. 2017, 51, 273–277. [Google Scholar] [CrossRef]

- Rizwan, M.; Saif, Y.; Almansoori, A.; Elkamel, A. Optimal processing route for the utilization and conversion of municipal solid waste into energy and valuable products. J. Clean. Prod. 2018, 174, 857–867. [Google Scholar] [CrossRef]

- Ministry of Natural Resources and Environment of the Russian Federation. Available online: www.mnr.gov.ru/docs/o_sostoyanii_i_ob_okhrane_okruzhayushchey_sredy_rossiyskoy_federatsii/gosudarstvennyy_doklad_o_sostoyanii_i_ob_okhrane_okruzhayushchey_sredy_rossiyskoy_federatsii_v_2016_/ (accessed on 13 February 2018). (In Russian)

- Anifowose, B.A.; Odubela, M.T. Oil facility operations: A multivariate analyses of water pollution parameters. J. Clean. Prod. 2018, 187, 180–189. [Google Scholar] [CrossRef]

- The Federal Service for Supervision in the Sphere of Nature Management. Available online: rpn.gov.ru/sites/all/files/users/rpnglavred/filebrowser/docs/doklad_po_tbo.pdf (accessed on 26 February 2018). (In Russian)

- Touš, M.; Pavlas, M.; Putna, O.; Stehlík, P.; Crha, L. Combined heat and power production planning in a waste-to-energy plant on a short-term basis. Energy 2015, 90, 137–147. [Google Scholar] [CrossRef]

- Sun, R.; Ismail, T.M.; Ren, X.; Abd El-Salam, M. Numerical simulation of gas concentration and dioxin formation for MSW combustion in a fixed bed. J. Environ. Manag. 2015, 157, 111–117. [Google Scholar] [CrossRef] [PubMed]

- Song, J.; Song, D.; Zhang, X.; Sun, Y. Risk identification for PPP waste-to-energy incineration projects in China. Energy Policy 2013, 61, 953–962. [Google Scholar] [CrossRef]

- Faitli, J.; Magyar, T.; Erdélyi, A.; Murányi, A. Characterization of thermal properties of municipal solid waste landfills. Waste Manag. 2015, 36, 213–221. [Google Scholar] [CrossRef] [PubMed]

- Tabakaev, R.; Shanenkov, I.; Kazakov, A.; Zavorin, A. Thermal processing of biomass into high-calorific solid composite fuel. J. Anal. Appl. Pyrolysis 2017, 124, 94–102. [Google Scholar] [CrossRef]

- Dmitrienko, M.A.; Strizhak, P.A.; Tsygankova, Y.S. Technoeconomic analysis of prospects of use of organic coal-water fuels of various component compositions. Chem. Pet. Eng. 2017, 53, 195–202. [Google Scholar] [CrossRef]

- Nyashina, G.S.; Legros, J.C.; Strizhak, P.A. Environmental potential of using coal-processing waste as the primary and secondary fuel for energy providers. Energies 2017, 10, 405. [Google Scholar] [CrossRef]

- Valiullin, T.R.; Vershinina, K.Y.; Glushkov, D.O.; Shevyrev, S.A. Droplet ignition of coal–water slurries prepared from typical coal- and oil-processing wastes. Coke Chem. 2017, 60, 211–218. [Google Scholar] [CrossRef]

- Glushkov, D.O.; Strizhak, P.A.; Chernetskii, M.Y. Organic coal-water fuel: Problems and advances (Review). Therm. Eng. 2016, 63, 707–717. [Google Scholar] [CrossRef]

- Ilinykh, G.V. Evaluation of thermotechnical properties of solid waste from their morphological composition. Vestnik Permskogo natsionalnogo issledovatelskogo politekhnicheskogo universiteta. Urbanistika 2013, 3, 125–137. (In Russian) [Google Scholar]

- Bazyn, T.; Krier, H.; Glumac, N. Combustion of nanoaluminum at elevated pressure and temperature behind reflected shock waves. Combust. Flame 2006, 145, 703–713. [Google Scholar] [CrossRef]

- Glushkov, D.O.; Shabardin, D.P.; Strizhak, P.A.; Vershinina, K.Yu. Influence of organic coal-water fuel composition on the characteristics of sustainable droplet ignition. Fuel Process. Technol. 2016, 143, 60–68. [Google Scholar] [CrossRef]

- Mishra, D.P.; Patyal, A.; Padhwal, M. Effects of gellant concentration on the burning and flame structure of organic gel propellant droplets. Fuel 2011, 90, 1805–1810. [Google Scholar] [CrossRef]

- Glushkov, D.O.; Paushkina, K.K.; Shabardin, D.P.; Strizhak, P.A. Environmental aspects of converting municipal solid waste into energy as part of composite fuels. J. Clean. Prod. 2018, 201, 1029–1042. [Google Scholar] [CrossRef]

| Component | Wa, % | Ad, % | Vdaf, % | Qas,V, MJ/kg | References |

|---|---|---|---|---|---|

| Filter cake | - | 26.5 | 23.1 | 24.83 | [14] |

| Wood | 20.0 | 2.0 | 83.1 | 16.45 | [15] |

| Rubber | 2.0 | 1.8 | 67.4 | 33.50 | [9] |

| Plastic | 2.0 | 0.2 | 99.5 | 22.00 | [9] |

| Motor oil | 0.3 | 0.8 | 100.0 | 44.02 | [15] |

| Component | Cdaf, % | Hdaf, % | Ndaf, % | Sdaf, % | Odaf, % | References |

|---|---|---|---|---|---|---|

| Filter cake | 87.2 | 5.1 | 2.1 | 1.1 | 4.5 | [14] |

| Wood | 50.3 | 6.0 | 0.2 | 0.1 | 43.4 | [15] |

| Rubber | 97.9 | 1.2 | 0.3 | 0.6 | - | [9] |

| Plastic | 66.7 | 7.9 | - | - | 25.4 | [9] |

| Component | Flash Temperature, °C | Ignition Temperature, °C |

|---|---|---|

| Filter cake | - | 450 |

| Wood | 230 | 340 |

| Rubber | - | 350 |

| Plastic | 306 | 415 |

| Motor oil | 132 | 218 |

| Characteristics | Kemerovo Region (No. 1) | Novosibirsk Region (No. 2) | Tomsk Region (No. 3) |

|---|---|---|---|

| Total volume of waste, Mt/y | 2801 | 3.9 | 1.3 |

| Industrial waste, Mt/y | 2800 | 2.6 | 0.9 |

| Structure of industrial waste: | |||

| 99.5% | 43.8% | 17.2% |

| 0.2% | 8.1% | 32.8% |

| 0.1% | 24.5% | 7.2% |

| <0.01% | 0.1% | 1.0% |

| 0.04% | 16.0% | 32.9% |

| 0.15% | 7.5% | 8.9% |

| Re-use/recovery, Mt/y | 1876.0 (67.0%) | 0.9 (34.1%) | 0.3 (28.0%) |

| Burial/stockpiling at disposal sites, Mt/y | 924.0 (33.0%) | 1.7 (65.9%) | 0.6 (72.0%) |

| Municipal solid waste (MSW), Mt/y | 0.9 | 1.3 | 0.4 |

The structure of MSW:

| 45% 29% 13% 2% 2% 1% 5% 3% | 35% 32% 6% 4% 6% 6% 2.5% 8.5% | 47% 19% 6% 9% 5% 8% 1% 5% |

| Re-use/recovery, Mt/y | 0.02 (1.9%) | 0.3 (22%) | 0.008 (2.0%) |

| Burial/stockpiling at disposal sites, Mt/y | 0.88 (98.1%) | 1.0 (78%) | 0.392 (98.0%) |

| Type of Plant | Volume of Sewage Water Produced, m3/t of Oil | |

|---|---|---|

| of the First System | of the Second System | |

| Fuel refinery plant | 0.23–0.25 | 0.10–0.20 |

| Lube and fuel refinery plant | 0.40–1.50 | 0.10–0.25 |

| Petrochemical plant | 2.00–3.00 | 1.20–2.00 |

| Type of Waste | Heat of Combustion, MJ/kg |

|---|---|

| Food waste | 5–10 |

| Paper | 15–20 |

| Plastic | 20–25 |

| Leather, rubber, textiles | 20–35 |

| Wood | 15–20 |

| Other | <10 |

| Energy Resources | Accumulated in Total | Annual Growth | ||

|---|---|---|---|---|

| G0, Mt | Q0, PJ | G, Mt | Q, PJ | |

| Kemerovo region (No. 1) | ||||

| Filter cakes | 368.8 | 5485 | 8.1 | 121 |

| MSW | 54.0 | 761 | 0.9 | 13 |

| Petroleum products | - | - | 0.0005 | 0.009 |

| Novosibirsk region (No. 2) | ||||

| Filter cakes | 5.8 | 86 | 0.4 | 6 |

| MSW | 70.0 | 830 | 1.3 | 15 |

| Petroleum products | 0.0973 | 4 | 0.0007 | 0.012 |

| Tomsk region (No. 3) | ||||

| Filter cakes | - | - | - | - |

| MSW | 21 | 209 | 0.4 | 2 |

| Petroleum products | 2.2 | 98 | 0.0115 | 2 |

| Overall data for three regions | ||||

| Filter cakes | 374.6 | 5571 | 8.5 | 127 |

| MSW | 145.0 | 1800 | 2.6 | 30 |

| Petroleum products | 2.3 | 102 | 0.0127 | 2 |

| Thermal Power Plant (TPP) | Installed Capacity | Installed Heat Power | Electric Power Generation | Thermal Power Generation | Specific Consumption of Fuel Equivalent per Electric Power Supply | Specific Consumption of Fuel Equivalent per Thermal Power Supply | Fuel Balance | Produced Thermal Power from Burning Coals in Boiler Furnace | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Coal | Gas | Fuel Oil | ||||||||

| MW | Gcal/h | GW·h | Tcal | g of Fuel Equivalent/kW·h | kg of Fuel Equivalent/Gcal | % | % | % | PJ | |

| Kemerovo region (No. 1) | ||||||||||

| TPP 1 | 485 | 1540 | 2053 | 2524 | 362 | 152 | 76.8 | 22.8 | <0.1 | 25 |

| TPP 2 | 80 | 749 | 175 | 725 | 383 | 168 | 91.3 | 8.7 | 0 | 5 |

| TPP 3 | 565 | 1449 | 1946 | 2911 | 370 | 160 | 99.4 | 0.5 | <0.1 | 35 |

| Novosibirsk region (No. 2) | ||||||||||

| TPP 1 | 345 | 920 | 1122 | 1899 | 328.5 | 146.8 | 91.1 | 8.8 | 0.1 | 17 |

| TPP 2 | 511.5 | 1115 | 2246 | 2390 | 293.5 | 143.6 | 99.7 | 0 | 0.3 | 29 |

| TPP 3 | 384 | 1120 | 1363 | 2251 | 314.8 | 143.8 | 80.9 | 19.1 | 0 | 18 |

| TPP 4 | 1200 | 2730 | 7065 | 4652 | 292.9 | 138 | 99.5 | 0.1 | 0.4 | 79 |

| Tomsk region (No. 3) | ||||||||||

| TPP 1 | 14.7 | 795 | 3.3 | 651 | 326 | 138 | 0 | 99.9 | <0.1 | 0 |

| TPP 2 | 140 | 780 | 746 | 1694 | 268.5 | 131 | 0 | 99.9 | <0.1 | 0 |

| TPP 3 | 331 | 815 | 1104 | 2154 | 249 | 159.6 | 47.6 | 52.4 | 0 | 9 |

| Overall data for three regions | ||||||||||

| - | 4056 | 12,013 | 17,823 | 21,851 | - | - | - | - | - | 217 |

| Coal-Fired TPP | Coal | Qas,V, MJ/kg | Wa, % | Ad, % | Vdaf, % |

|---|---|---|---|---|---|

| Kemerovo region (No. 1) | |||||

| TPP 1 | Low-caking coal | 21.8 | 13.7 | 17.2 | 27 |

| TPP 2 | Long-flame coal | 21.8 | 14.7 | 15.4 | 42.3 |

| TPP 3 | Flame coal | 21.4 | 14.1 | 13.1 | 41.2 |

| Boiler plants | Flame coal | 21.4 | 14.1 | 13.1 | 41.2 |

| Novosibirsk region (No. 2) | |||||

| TPP 1 | Low-caking and nonbaking coals | 24.7 | 8.3 | 16.9 | 23.9 |

| TPP 2 | Low-caking and nonbaking coals | 22.1 | 17.5 | 15.5 | 19.1 |

| Brown coal | 14.8 | 35.7 | 7.6 | 46.4 | |

| TPP 3 | Low-caking and nonbaking coals | 25 | 9 | 15.7 | 19 |

| TPP 4 | Gas coal and flame coal | 21.6 | 14.7 | 13.1 | 41.4 |

| Boiler plants | Low-caking and nonbaking coals | 24.9 | 8.3 | 16.9 | 23.9 |

| Brown coal | 14.8 | 35.7 | 7.6 | 46.4 | |

| Low-caking and nonbaking coals | 21.8 | 14.7 | 13.1 | 41.4 | |

| Tomsk region (No. 3) | |||||

| TPP 3 | Flame coal | 21.4 | 14.1 | 13.1 | 41.2 |

| Boiler plants | Flame coal | 21.2 | 13.9 | 14.5 | 44.7 |

| Long-flame coal | 21.8 | 12 | 15.9 | 48 | |

| Year | Energy from Fuel Combustion, PJ | Coal Consumption, Mt | Composite Fuel Consumption (by Component) | |||

|---|---|---|---|---|---|---|

| Filter Cakes, Mt | MSW, Mt | Oil, Mt | Total, Mt | |||

| 1 | 217.0 | 10.22 | 11.13 | 1.31 | 0.65 | 13.10 |

| 2 | 219.2 | 10.32 | 11.24 | 1.32 | 0.66 | 13.23 |

| 3 | 221.4 | 10.42 | 11.36 | 1.34 | 0.67 | 13.36 |

| 4 | 223.6 | 10.53 | 11.47 | 1.35 | 0.67 | 13.49 |

| 5 | 225.8 | 10.63 | 11.58 | 2.04 | - | 13.63 |

| 6 | 228.1 | 10.74 | 11.70 | 2.06 | - | 13.77 |

| 7 | 230.3 | 10.84 | 11.81 | 2.08 | - | 13.90 |

| 8 | 232.7 | 10.96 | 11.94 | 2.11 | - | 14.04 |

| 9 | 235.0 | 11.06 | 12.05 | 2.13 | - | 14.18 |

| 10 | 237.3 | 11.17 | 12.17 | 2.15 | - | 14.32 |

| 11 | 239.7 | 11.29 | 12.30 | 2.17 | - | 14.47 |

| 12 | 242.1 | 11.40 | 12.42 | 2.19 | - | 14.61 |

| 13 | 244.5 | 11.51 | 12.54 | 2.21 | - | 14.76 |

| 14 | 247.0 | 11.63 | 12.67 | 2.24 | - | 14.91 |

| 15 | 249.4 | 11.74 | 12.79 | 2.26 | - | 15.05 |

| 16 | 251.9 | 11.86 | 12.92 | 2.28 | - | 15.20 |

| 17 | 254.4 | 11.98 | 13.05 | 2.30 | - | 15.35 |

| 18 | 257.0 | 12.10 | 13.18 | 2.33 | - | 15.51 |

| 19 | 259.6 | 12.22 | 13.32 | 2.35 | - | 15.67 |

| 20 | 262.2 | 12.34 | 13.45 | 2.37 | - | 15.82 |

| 21 | 264.9 | 12.47 | 13.59 | 2.40 | - | 15.99 |

| 22 | 267.4 | 12.59 | 13.72 | 2.42 | - | 16.14 |

| 23 | 270.1 | 12.72 | 13.86 | 2.45 | - | 16.30 |

| 24 | 272.8 | 12.84 | 13.99 | 2.47 | - | 16.46 |

| 25 | 275.5 | 12.97 | 14.13 | 2.49 | - | 16.63 |

| Total: | 6129 | 288.55 | 314.39 | 52.82 | 2.66 | 369.87 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Glushkov, D.; Kuznetsov, G.; Paushkina, K.; Shabardin, D. The Main Elements of a Strategy for Combined Utilization of Industrial and Municipal Waste from Neighboring Regions by Burning it as Part of Composite Fuels. Energies 2018, 11, 2534. https://doi.org/10.3390/en11102534

Glushkov D, Kuznetsov G, Paushkina K, Shabardin D. The Main Elements of a Strategy for Combined Utilization of Industrial and Municipal Waste from Neighboring Regions by Burning it as Part of Composite Fuels. Energies. 2018; 11(10):2534. https://doi.org/10.3390/en11102534

Chicago/Turabian StyleGlushkov, Dmitrii, Geniy Kuznetsov, Kristina Paushkina, and Dmitrii Shabardin. 2018. "The Main Elements of a Strategy for Combined Utilization of Industrial and Municipal Waste from Neighboring Regions by Burning it as Part of Composite Fuels" Energies 11, no. 10: 2534. https://doi.org/10.3390/en11102534

APA StyleGlushkov, D., Kuznetsov, G., Paushkina, K., & Shabardin, D. (2018). The Main Elements of a Strategy for Combined Utilization of Industrial and Municipal Waste from Neighboring Regions by Burning it as Part of Composite Fuels. Energies, 11(10), 2534. https://doi.org/10.3390/en11102534