Breakdown Characteristics of Oil-Pressboard Insulation under AC-DC Combined Voltage and Its Mathematical Model

Abstract

:1. Introduction

2. Experimental Method

2.1. Sample Preparation and Test Model

2.2. Test System

3. Test Results

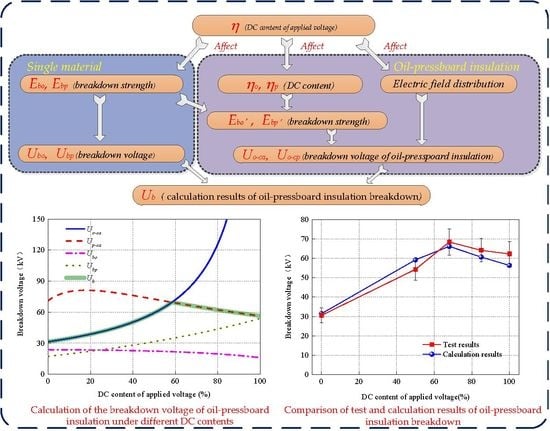

4. Mathematical Model of Breakdown of Oil-Pressboard Insulation

4.1. Simplified Model

4.2. Mathematical Expression of Electric Field Distribution

4.3. Mathematical Model of Breakdown Voltage of Oil-Pressboard Insulation

5. Conclusions

- (1)

- With the increase in the DC content of the applied voltage, the breakdown strength of the transformer oil decreases, whereas that of the pressboard increases. Moreover, the breakdown voltage of the oil-pressboard insulation increases first and then decreases.

- (2)

- With the increase in the DC content of the applied voltage, the electric field strength of the transformer oil decreases, whereas that of the pressboard increases.

- (3)

- Under AC-DC combined voltage, the DC content of the pressboard is higher than that of the applied voltage, whereas the DC content of the transformer is lower than that of the applied voltage.

- (4)

- When the DC content is same, the breakdown strength corresponding to the DC contents of the transformer oil and pressboard of the composite insulation is lower than that corresponding to the DC content of the applied voltage.

- (5)

- The breakdown voltage calculated by the proposed model is in good agreement with the experimental results.

Author Contributions

Funding

Conflicts of Interest

References

- Amoiralis, E.I.; Tsili, M.A.; Kladas, A.G. Power transformer economic evaluation in decentralized electricity markets. IEEE Trans. Ind. Electron. 2012, 59, 2329–2341. [Google Scholar] [CrossRef]

- Fabian, J.; Jocham, B.; Nader, B.; Woschitz, R.; Muhr, M. Current challenges and issues of designing HVDC converter transformers. In Proceedings of the 2011 Annual Report Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Cancun, Mexico, 16–19 October 2011; pp. 432–435. [Google Scholar] [CrossRef]

- Morshuis, P.; Cavallini, A.; Fabiani, D.; Montanari, G.C.; Azcarraga, C. Stress conditions in HVDC equipment and routes to in service failure. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 81–91. [Google Scholar] [CrossRef]

- Li, Y.; Luo, L.; Rehtanz, C.; Nakamura, K.; Xu, J.; Liu, F. Study on characteristic parameters of a new converter transformer for HVDC systems. IEEE Trans. Power Deliv. 2015, 24, 2125–2131. [Google Scholar] [CrossRef]

- Ebisawa, Y.; Yamada, S.; Mori, S.; Teranishi, T. DC creepage breakdown characteristics of oil-immersed insulation. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 1686–1692. [Google Scholar] [CrossRef]

- Gafvert, U.; Jaksts, A.; Tornkvist, C.; Walfridsson, L. Electrical field distribution in transformer oil. IEEE Trans. Electr. Insul. 1992, 27, 647–660. [Google Scholar] [CrossRef]

- Qi, B.; Zhao, X.; Li, C.; Wu, H. Electric field distribution in oil-pressboard insulation under AC-DC combined voltages. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1935–1941. [Google Scholar] [CrossRef]

- CIGRE Joint Working Group A2/B4.28. HVDC Converter Transformers Design Review, Test Procedures, Ageing Evaluation and Reliability in Service; CIGRE: Paris, France, 2010. [Google Scholar]

- Sima, W.; Wu, J.; Sun, P.; Yang, M.; Hua, J. Breakdown characteristics of oil-impregnated paper and influential factors for damped alternating oscillation waveforms. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2079–2087. [Google Scholar] [CrossRef]

- Wang, Y.; Wei, X.; Chen, Q.; Huang, Y.; Nie, H. Breakdown characteristics of converter transformer insulation under composite AC and DC voltage. In Proceedings of the IEEE 9th International Conference on the Properties and Applications of Dielectric Materials, ICPADM 2009, Harbin, China, 19–23 July 2009; pp. 634–637. [Google Scholar] [CrossRef]

- Wei, X.; Wang, Y.; Chen, Q. The electric field distribution in oil-cardboard composited insulation system under a polarity reversed voltage. In Proceedings of the IEEE 9th International Conference on the Properties and Applications of Dielectric Materials, ICPADM 2009, Harbin, China, 19–23 July 2009; pp. 20–23. [Google Scholar] [CrossRef]

- Li, W.; Zhang, Z.; Li, X.; Huang, Y.; Chen, Z.; Wang, B. Field analysis of 800 kV converter transformer for DC Transmission. Transformer 2009, 46, 1–5. (In Chinese) [Google Scholar] [CrossRef]

- Gao, Y.; Chen, Q.; Li, G.; Wei, X.; Wang, Y. Analysis of electrical field on valve side winding of converter transformer. In Proceedings of the IEEE 9th International Conference on the Properties and Applications of Dielectric Materials, ICPADM 2009, Harbin, China, 19–23 July 2009; pp. 85–88. [Google Scholar] [CrossRef]

- Li, J.; Bao, L.; Zhang, J.; Li, X. Adequacy of dual-variable Weibull failure distribution for oil-impregnated paper under pulsating DC voltage. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1555–1561. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, F.; Li, J.; Ran, H.; Li, X.; Fu, Q. Breakdown Voltage and Its Influencing Factors of Thermally Aged Oil-Impregnated Paper at Pulsating DC Voltag. Enegies 2017, 10, 1411. [Google Scholar] [CrossRef]

- Li, X.; Li, J.; Xiang, C.; Zhang, J.; Bao, L.; Ran, H. The influence of oil-impregnated insulation paper’s thickness on electrical breakdown strength. In Proceedings of the 2016 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Toronto, ON, Canada, 16–19 October 2016; pp. 392–395. [Google Scholar] [CrossRef]

- Sajan, J.S.; Dwarakanath, K.; Moorching, S.N. Comparative evaluation of dielectric strength of paper-oil insulation under AC, DC, combined, composite AC/DC and impulse voltages. In Proceedings of the Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Atlanta, GA, USA, 25–28 October 1998; pp. 236–239. [Google Scholar] [CrossRef]

- Rajan, J.S.; Viswanatha, C.; Dwarakanath, K. A new approach to study the electric strength of insulating materials. In Proceedings of the Conference Record of the 2000 IEEE International Symposium on Electrical Insulation, Anaheim, CA, USA, 5 April 2000; pp. 97–100. [Google Scholar] [CrossRef]

- Zhu, Y.; Min, D.; Li, S. Space charge modulated electrical breakdown of oil impregnated paper under AC-DC combined voltages in frequencies of 50~600 Hz. In Proceedings of the 2016 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Toronto, ON, Canada, 16–19 October 2016; pp. 441–444. [Google Scholar] [CrossRef]

- Chi, M.; Chen, Q.; Gao, Y.; Wei, X.; Wang, Y. Influence of oil-flow to the breakdown characteristics of oil-pressboard insulation in converter transformer under compound electrical field. In Proceedings of the 2011 6th International Forum on Strategic Technology (IFOST), Harbin, China, 22–24 August 2011; pp. 589–592. [Google Scholar] [CrossRef]

- IEC 60641: Specification for Pressboard and Presspaper for Electrical Purposes; IEC: Geneva, Switzerland, 2008.

| Parameters | Pressboard | Transformer Oil |

|---|---|---|

| Moisture content | 0.43% | 6.3 mg/kg |

| Resistivity | 4.93 × 1014 Ω·m | 1.15 × 1013 Ω·m |

| Relative permittivity | 3.22 | 2.08 |

| Symbols | Parameters | Unit |

|---|---|---|

| εr | Relative permittivity | - |

| ρ | Resistivity | Ω·m |

| d | Thickness | m |

| C | Capacitance | F |

| R | Resistance | Ω |

| E | Electric field strengths | kV/mm |

| Eb | Breakdown strength | kV/mm |

| U | Voltage | V |

| η | DC content | - |

| Medium | Fitted Expression | Correlation Coefficient |

|---|---|---|

| Transformer oil | Ebo = 48.24 − 0.65 × exp(3.22 × η) | 0.98 |

| Pressboard | Ebp = −18.39 + 86.45 × exp(1.04 × η) | 0.97 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Q.; Zhang, J.; Chi, M.; Guo, C. Breakdown Characteristics of Oil-Pressboard Insulation under AC-DC Combined Voltage and Its Mathematical Model. Energies 2018, 11, 1319. https://doi.org/10.3390/en11051319

Chen Q, Zhang J, Chi M, Guo C. Breakdown Characteristics of Oil-Pressboard Insulation under AC-DC Combined Voltage and Its Mathematical Model. Energies. 2018; 11(5):1319. https://doi.org/10.3390/en11051319

Chicago/Turabian StyleChen, Qingguo, Jinfeng Zhang, Minghe Chi, and Chong Guo. 2018. "Breakdown Characteristics of Oil-Pressboard Insulation under AC-DC Combined Voltage and Its Mathematical Model" Energies 11, no. 5: 1319. https://doi.org/10.3390/en11051319

APA StyleChen, Q., Zhang, J., Chi, M., & Guo, C. (2018). Breakdown Characteristics of Oil-Pressboard Insulation under AC-DC Combined Voltage and Its Mathematical Model. Energies, 11(5), 1319. https://doi.org/10.3390/en11051319