Optimization Design of Injection Strategy for Surfactant-Polymer Flooding Process in Heterogeneous Reservoir under Low Oil Prices

Abstract

:1. Introduction

2. Experimental Study

2.1. Materials

2.2. Methods

2.2.1. Solution Preparation

2.2.2. Parallel Sand Pack Flooding Test

2.2.3. Plate Sand Pack Flooding Test

3. Results and Discussion

3.1. EOR Efficiency of SP Flooding Process under Different Injection Strategies

3.1.1. Fractional Flow Analysis

3.1.2. Incremental Oil Recovery Analysis

- (1).

- At the stage of the water flooding period, there exists a water-free oil production period. As the injected pore volume of the injection water increases, due to the permeability difference, the injected water enters into the high permeability layer and the water cut increases quickly. When the water cut reaches 95%, the water flooding is terminated and the total cumulative oil recovery is about 40%.

- (2).

- As the chemical slugs are injected through different injection strategies, due to the mobility control ability, the polymer increases the viscosity of the injection water and enlarges the sweep efficiency, which reduces the water intake volume of the high permeability sand pack and mobilizes the remaining oil in the low permeability sand pack.

- (3).

- Then, after SP flooding, as shown in Table 4 and Figure 9, the total incremental oil recovery of SP flooding under the simultaneous injection strategy was 30.6%, while that of SP flooding under the alternating injection strategy ranged from 35.06% to 39.86%. It was demonstrated that the alternation injection of polymer and surfactant-polymer (PASP) had a higher total incremental oil recovery than the simultaneous injection of the surfactant and polymer (SP). Moreover, as the alternating cycle increases, the incremental oil recovery increases. Based on the fractional flow analysis results, the alternating injection of the polymer and surfactant–polymer (PASP) showed a better sweep efficiency improvement ability than the simultaneous injection of the surfactant and polymer (SP). This indicates that more SP slugs were diverted into the low permeability sand pack. By combining the mobility control and oil displacement ability, more remaining oil in the low permeability sand pack can be recovered after water flooding.

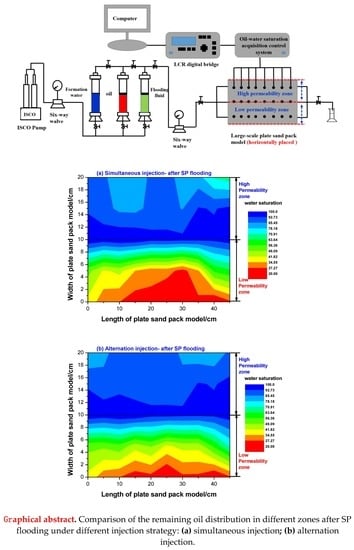

3.2. Comparison of the Remaining Oil Distribution under Different Injection Strategies

3.2.1. The Remaining Oil Distribution after Water Flooding

3.2.2. The Remaining Oil Distribution after SP Flooding

3.3. Mechanism Analysis

4. Conclusions

- (1).

- On the basis of parallel sand pack flooding results for different injection strategies, it was demonstrated that the alternating injection of the polymer and surfactant–polymer (PASP) showed a better sweep efficiency improvement ability than that of the simultaneous injection of the surfactant and polymer (SP). Moreover, the EOR efficiency of the polymer alternating surfactant–polymer flooding was higher. As the alternating cycle increased, the incremental oil recovery increased.

- (2).

- The comparison of the remaining oil distribution after water flooding and SP flooding under different injection strategies demonstrated that in comparison with water flooding, the remaining oil saturation after SP flooding was lower. It was found that SP flooding can improve oil displacement efficiency and enlarge the swept volume. Compared with the conventional simultaneous injection of the surfactant and polymer, alternating injection of the polymer and surfactant–polymer (PASP) showed a better sweep efficiency improvement and recovered more remaining oil trapped in the low permeability zone.

- (3).

- To maximize the incremental oil recovery of the SP flooding process after water flooding by using the equal chemical cost, it is crucial to enlarge the swept volume and mobilize the trapped oil in the low permeability zone. The proposed mechanism governing the differences in SP flooding under different injection strategies has been proposed.

Author Contributions

Funding

Conflicts of Interest

References

- Liao, G.; Wang, Q.; Wang, H.; Liu, W.D.; Wang, Z. Chemical flooding development status and prospect. Acta Pet. Sin. 2017, 38, 196–207. [Google Scholar]

- Wang, D.; Seright, R.S.; Shao, Z.; Wang, J. Key aspects of project design for polymer flooding at the Daqing Oilfield. SPE Reserv. Eval. Eng. 2008, 11, 1–117. [Google Scholar] [CrossRef]

- Sheng, J.J.; Leonhardt, B.; Azri, N. Status of polymer-flooding technology. J. Can. Pet. Technol. 2015, 54, 116–126. [Google Scholar] [CrossRef]

- Alsofi, A.M.; Blunt, M.J. Polymer flooding design and optimization under economic uncertainty. J. Pet. Sci. Eng. 2014, 124, 46–59. [Google Scholar] [CrossRef]

- Kamal, M.S.; Sultan, A.S.; Al-Mubaiyedh, U.A.; Hussein, I.A. Review on polymer flooding: Rheology, adsorption, stability, and field applications of various polymer systems. Polym. Rev. 2015, 55, 491–530. [Google Scholar] [CrossRef]

- Hirasaki, G.; Miller, C.A.; Puerto, M. Recent advances in surfactant EOR. SPE J. 2011, 16, 889–907. [Google Scholar] [CrossRef]

- Kamal, M.S.; Hussein, I.A.; Sultan, A.S. Review on surfactant flooding: Phase behavior, retention, IFT, and field applications. Energy Fuels 2017, 31, 7701–7720. [Google Scholar] [CrossRef]

- Hussain, S.S.; Kamal, M.S.; Fogang, L.T. Effect of internal olefin on the properties of betaine-type zwitterionic surfactants for enhanced oil recovery. J. Mol. Liq. 2018, 266, 43–50. [Google Scholar] [CrossRef]

- Alzahid, Y.A.; Mostaghimi, P.; Walsh, S.D.; Armstrong, R.T. Flow regimes during surfactant flooding: The influence of phase behaviour. Fuel 2019, 236, 851–860. [Google Scholar] [CrossRef]

- Qi, Z.; Han, M.; Fuseni, A.; Alsofi, A.; Zhang, F.; Peng, Y.; Cai, H. Laboratory study on surfactant induced spontaneous imbibition for carbonate reservoir. In Proceedings of SPE Asia Pacific Oil & Gas Conference and Exhibition; Society of Petroleum Engineers: Perth, Australia, 2016. [Google Scholar]

- Pei, H.; Zhang, G.; Ge, J.; Zhang, J.; Zhang, Q. Investigation of synergy between nanoparticle and surfactant in stabilizing oil-in-water emulsions for improved heavy oil recovery. Colloids Surf. A Physicochem. Eng. Asp. 2015, 484, 478–484. [Google Scholar] [CrossRef]

- Pei, H.; Shu, Z.; Zhang, G.; Ge, J.; Jiang, P.; Qin, Y.; Cao, X. Experimental study of nanoparticle and surfactant stabilized emulsion flooding to enhance heavy oil recovery. J. Pet. Sci. Eng. 2018, 163, 476–483. [Google Scholar] [CrossRef]

- Kumar, N.; Mandal, A. Surfactant Stabilized Oil-in-Water Nanoemulsion: Stability, Interfacial Tension, and Rheology Study for Enhanced Oil Recovery Application. Energy Fuels 2018, 32, 6452–6466. [Google Scholar] [CrossRef]

- Pal, N.; Kumar, N.; Verma, A.; Ojha, K.; Mandal, A. Performance Evaluation of Novel Sunflower Oil-Based Gemini Surfactant(s) with Different Spacer Lengths: Application in Enhanced Oil Recovery. Energy Fuels 2018, 32, 11344–11361. [Google Scholar] [CrossRef]

- Kumar, S.; Ahmad, T.; Shankhwar, S.; Mandal, A. Evaluation of Interfacial Properties of Aqueous Solutions of Anionic, Cationic and Non-ionic Surfactants for Application in Enhanced Oil Recovery. Tenside Surfactants Deterg. 2019, 56, 138–149. [Google Scholar] [CrossRef]

- Hongyan, W.; Xulong, C.; Jichao, Z.; Aimei, Z. Development and application of dilute surfactant–polymer flooding system for Shengli oilfield. J. Pet. Sci. Eng. 2009, 65, 45–50. [Google Scholar] [CrossRef]

- Zhenquan, L.; Aimei, Z.; Cui, X.; Li, Z.; Lanlei, G.; Liantao, S. A successful pilot of dilute surfactant-polymer flooding in Shengli oilfield. In Proceedings of SPE Improved Oil Recovery Symposium; Paper SPE 154034; Society of Petroleum Engineers: Tulsa, OK, USA, 2012. [Google Scholar]

- Kamal, M.S.; Shakil Hussain, S.M.; Sultan, A.S. Development of novel amidosulfobetaine surfactant–polymer systems for EOR applications. J. Surfactants Deterg. 2016, 19, 989–997. [Google Scholar] [CrossRef]

- Guo, H.; Wang, Z. Lessons Learned from Surfactant-Polymer Flooding Field Tests in China. In Proceedings of SPE Kuwait Oil & Gas Show and Conference; Paper SPE 187571; Society of Petroleum Engineers: Kuwait City, Kuwait, 2017. [Google Scholar]

- Liu, Z.; Cheng, H.; Li, Y.; Li, Y.; Chen, X.; Zhuang, Y. Experimental Investigation of Synergy of Components in Surfactant/Polymer Flooding Using Three-Dimensional Core Model. Transport. Porous Media 2019, 126, 317–335. [Google Scholar] [CrossRef]

- Sharma, H.; Panthi, K.; Mohanty, K.K. Surfactant-less alkali-cosolvent-polymer floods for an acidic crude oil. Fuel 2018, 215, 484–491. [Google Scholar] [CrossRef]

- Guo, H.; Li, Y.; Kong, D.; Ma, R.; Li, B.; Wang, F. Lessons Learned from Alkali/Surfactant/Polymer-Flooding Field Tests in China. SPE Reserv. Eval. Eng. 2019, 22, 78–99. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, D.; Yan, W.; Puerto, M.; Hirasaki, G.J.; Miller, C.A. Favorable attributes of alkaline-surfactant-polymer flooding. SPE J. 2008, 13, 5–16. [Google Scholar] [CrossRef]

- Ma, Y.; Hou, J.; Zhao, F.; Song, Z. Linearly descending viscosity for alkaline–surfactant–polymer flooding mobility modification in multilayer heterogeneous reservoirs. RSC Adv. 2018, 8, 8269–8284. [Google Scholar] [CrossRef]

- Pal, N.; Saxena, N.; Mandal, A. Characterization of alkali-surfactant-polymer slugs using synthesized Gemini surfactant for potential application in enhanced oil recovery. J. Pet. Sci. Eng. 2018, 168, 283–300. [Google Scholar] [CrossRef]

- Alkhatib, A.; Babaei, M. Applying the Multilevel Monte Carlo method for heterogeneity-induced uncertainty quantification of surfactant/polymer flooding. SPE J. 2016, 21, 1–192. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, H.; Wang, J.; Dong, X.; Chen, F. Formulation development and visualized investigation of temperature-resistant and salt-tolerant surfactant-polymer flooding to enhance oil recovery. J. Pet. Sci. Eng. 2019, 174, 584–598. [Google Scholar] [CrossRef]

- Al-Murayri, M.T.; Hassan, A.A.; Abdullah, M.B.; Abdulrahim, A.M.; Marlière, C.; Hocine, S.; Tabary, R.; Suzanne, G.P. Surfactant/Polymer Flooding: Chemical-Formulation Design and Evaluation for Raudhatain Lower Burgan Reservoir, Kuwait. SPE Reserv. Eval. Eng. 2018. [Google Scholar] [CrossRef]

- Aramideh, S.; Borgohain, R.; Naik, P.K.; Johnston, C.T.; Vlachos, P.P.; Ardekani, A.M. Multi-objective history matching of surfactant-polymer flooding. Fuel 2018, 228, 418–428. [Google Scholar] [CrossRef]

- Druetta, P.; Picchioni, F. Surfactant–Polymer Flooding: Influence of the Injection Scheme. Energy Fuels 2018, 32, 12231–12246. [Google Scholar] [CrossRef] [PubMed]

- Zhou, K.; Hou, J.; Ren, X.; Yu, B. Economic Design of Surfactant-Polymer Flooding Under Low Oil Price. In Proceedings of SPE Oil and Gas India Conference and Exhibition; Paper SPE 185406-MS; Society of Petroleum Engineers: Mumbai, India, 2017. [Google Scholar]

- Kamari, A.; Gharagheizi, F.; Shokrollahi, A.; Arabloo, M.; Mohammadi, A.H. Integrating a robust model for predicting surfactant–polymer flooding performance. J. Pet. Sci. Eng. 2016, 137, 87–96. [Google Scholar] [CrossRef]

- Daripa, P.; Ding, X. A numerical study of instability control for the design of an optimal policy of enhanced oil recovery by tertiary displacement processes. Transp. Porous Media 2012, 93, 675–703. [Google Scholar] [CrossRef]

- Daripa, P.; Dutta, S. Modeling and simulation of surfactant–polymer flooding using a new hybrid method. J. Comput. Phys. 2017, 335, 249–282. [Google Scholar] [CrossRef]

- Daripa, P.; Dutta, S. On the convergence analysis of a hybrid numerical method for multicomponent transport in porous media. Appl. Numer. Math. 2019, 146, 199–220. [Google Scholar] [CrossRef] [Green Version]

- He, H.; Wang, Y.; Qi, Z.; Sun, X. Gelation Performance and Feasibility Study of an Environmental Friendly Improved Inorganic Aluminum Gel for Conformance Control under Harsh Reservoir Conditions. J. Energy Resour. Technol. 2016, 139, 012911. [Google Scholar] [CrossRef]

- He, H.; Fu, J.; Hou, B.; Yuan, F.; Guo, L.; Li, Z.; You, Q. Investigation of Injection Strategy of Branched-Preformed Particle Gel/Polymer/Surfactant for Enhanced Oil Recovery after Polymer Flooding in Heterogeneous Reservoirs. Energies 2018, 11, 1950. [Google Scholar] [CrossRef]

- He, H.; Fu, J.; Zhao, H.; Yuan, F.; Guo, L.; Li, Z.; Wang, X.; Peng, H. Synergistic Mechanism of Hydrolyzed Polyacrylamide Enhanced Branched-Preformed Particle Gel for Enhanced Oil Recovery in Mature Oilfields. Energy Fuels 2018, 32, 11093–11104. [Google Scholar] [CrossRef]

| Ionic Composition | Na+ | Ca2+ | Mg2+ | Cl− | HCO3− |

|---|---|---|---|---|---|

| Concentration/mg·L−1 | 2502 | 82 | 25 | 3502 | 990 |

| TDS/mg·L−1 | 7101 | ||||

| Test No. | Injection Strategy | Chemical Slug | ||

|---|---|---|---|---|

| Pre-Slug | Main SP Slug | |||

| 1 | Surfactant–polymer (SP) | Simultaneous injection | 0.1PV 2200 mg·L−1 HPAM | 0.5 PV (2000 mg·L−1 HPAM + 0.4 wt% surfactant) |

| 2 | Polymer alternating surfactant–polymer (PASP) | Alternating injection- 1-cycle | 0.364 PV 2200 mg·L−1 HPAM + 0.364 PV (1800 mg·L−1 HPAM + 0.4 wt% surfactant) | |

| 3 | Alternating injection- 2-cycles | 0.182 PV 2200 mg·L−1 HPAM + 0.182 PV (1800 mg·L−1 HPAM + 0.4 wt% surfactant) | ||

| 4 | Alternating injection- 4-cycles | 0.091 PV 2200 mg·L−1 HPAM + 0.091 PV (1800 mg·L−1 HPAM + 0.4 wt% surfactant) | ||

| Test No. | Injection Strategy | Sand Packs | Permeability (μm2) | Porosity (%) |

|---|---|---|---|---|

| 1# | Simultaneous injection | High permeability | 3.64 | 42.1 |

| Low permeability | 0.91 | 35.6 | ||

| 2# | Alternation injection-1-cycle | High permeability | 3.97 | 41.44 |

| Low permeability | 1.18 | 36.52 | ||

| 3# | Alternation injection-2-cycles | High permeability | 4.21 | 41.17 |

| Low permeability | 1.25 | 38.73 | ||

| 4# | Alternation injection-4-cycles | High permeability | 4.15 | 40.36 |

| Low permeability | 1.08 | 35.87 |

| Test No. | Chemical Slug | Injection Strategy | Enhanced Oil Recovery (%OOIP) | |||

|---|---|---|---|---|---|---|

| Sand Pack Type | Water Flooding | After SP Flooding | Incremental Oil Recovery of SP Flooding | |||

| 1 | Surfactant-polymer (SP) | Simultaneous injection | High permeability | 64.63 | 95.56 | 30.93 |

| Low permeability | 7.83 | 39.57 | 31.74 | |||

| Total | 38.50 | 69.10 | 30.60 | |||

| 2 | Polymer alternating surfactant-polymer (PASP) | Alternation injection-1-cycle | High permeability | 62.86 | 94.76 | 31.90 |

| Low permeability | 15.61 | 53.90 | 38.29 | |||

| Total | 39.52 | 74.58 | 35.06 | |||

| 3 | Alternation injection-2-cycles | High permeability | 54.63 | 97.20 | 42.56 | |

| Low permeability | 20.57 | 55.00 | 34.43 | |||

| Total | 38.68 | 77.50 | 38.82 | |||

| 4 | Alternation injection-4-cycles | High permeability | 58.59 | 97.29 | 38.71 | |

| Low permeability | 12.88 | 54.41 | 41.53 | |||

| Total | 40.28 | 80.14 | 39.86 | |||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, H.; Chen, Y.; Yu, Q.; Wen, X.; Liu, H. Optimization Design of Injection Strategy for Surfactant-Polymer Flooding Process in Heterogeneous Reservoir under Low Oil Prices. Energies 2019, 12, 3789. https://doi.org/10.3390/en12193789

He H, Chen Y, Yu Q, Wen X, Liu H. Optimization Design of Injection Strategy for Surfactant-Polymer Flooding Process in Heterogeneous Reservoir under Low Oil Prices. Energies. 2019; 12(19):3789. https://doi.org/10.3390/en12193789

Chicago/Turabian StyleHe, Hong, Yuqiu Chen, Qun Yu, Xianli Wen, and Haocheng Liu. 2019. "Optimization Design of Injection Strategy for Surfactant-Polymer Flooding Process in Heterogeneous Reservoir under Low Oil Prices" Energies 12, no. 19: 3789. https://doi.org/10.3390/en12193789

APA StyleHe, H., Chen, Y., Yu, Q., Wen, X., & Liu, H. (2019). Optimization Design of Injection Strategy for Surfactant-Polymer Flooding Process in Heterogeneous Reservoir under Low Oil Prices. Energies, 12(19), 3789. https://doi.org/10.3390/en12193789