Performance Evaluation of an Anti Gas-Channeling System (Asphalt-Rigid Particle-Xanthan Gum) Applied in High-Temperature and High-Salinity Fractured Reservoir

Abstract

:1. Introduction

2. Experimental Methodology

2.1. Materials and Instruments

2.2. Preparation of the Temperature- and Salinity-Resistance Anti Gas-Channeling System

2.3. Screening and Determination of Asphalt and Rigid Particle Sizes

2.4. Asphalt Viscosity in High Temperature and Performance of Bonding with Rigid Particles

2.4.1. Apparent Viscosity of Different Softening Points of Asphalts and High-Temperature Aging Properties

2.4.2. Properties of Asphalt-Bonded Rigid Particles

- Influence of asphalt content on the bonding effect: The asphalt softening point was 105 °C, the rigid particle content was 8 wt%, and the asphalt contents were 2 wt%, 4 wt%, 6 wt%, and 8 wt%.

- Influence of rigid particle content on the bonding effect: The asphalt softening point was 105 °C, the asphalt content was 8 wt%, and the rigid particle contents were 2 wt%, 4 wt%, 6 wt% and 8 wt%.

- Influence of asphalt softening point on the bonding effect: The content of asphalt and rigid particles was 8 wt%, and the asphalt softening points were 60 °C, 90 °C, 105 °C, and 130 °C.

2.5. Optimization of Thickener Type and Concentration

2.5.1. Selection of Thickener Types

2.5.2. Optimization of Suspending Agent Concentration

2.6. Research on Anti Gas-Channeling Performance of the Asphalt Bonding System

2.6.1. Optimization of Maximum Injection Concentration

2.6.2. Distribution of Solid Particles in Xanthan Gum Solution

2.6.3. Investigation of Anti Gas-Channeling Performance and the Influencing Factors

- Fill the simulated core that has been cemented well to the core-holder and use a hand pump to exert a confining pressure of 5 MPa. High-pressure N2 was used as the air source for displacement, and an electronic flowmeter was utilized to measure the N2 velocity (v0, L·min−1) under different gas-flooding pressures at the tail end of the core-holder. The outlet flow rate of N2 was measured three times and the mean value was calculated, the same below (See the supplementary materials Tables S1 and S2 for detailed data).

- Inject the anti gas-channeling system at 0.25 mL·min−1 until the tail end of the core-holder flows out of the system. Close the inlet and outlet valves of the core holder, and perform aging at a high-temperature for 48 h.

- Open the inlet and outlet valves and displace them by N2. Measure the N2 velocity again (v1, L·min−1), and obtain the data on blocking performance.

2.6.4. Research of Anti Gas-Channeling Performance for Long Term

2.7. Observation of Plugging Zone Micromorphology in the Fracture Interior

3. Results and Discussion

3.1. Bonding Performance of Asphalt in High Temperature

3.1.1. Apparent Viscosity of Asphalt in High Temperature

3.1.2. Bonding Performance of Asphalt and its Influencing Factors

3.2. Suspension Performance of Rigid Particles

3.2.1. Selection of Thickeners

3.2.2. Suspension Properties of Xanthan Gum

3.3. Study of the Anti Gas-Channeling Capability of the Asphalt Bonding System and Its Influencing Factors

3.3.1. Determination of the Maximum Injected Concentration of the Anti Gas-Channeling System

3.3.2. Dispersion of the Blocking Channeling System

3.3.3. Orthogonal Experiment Results and Analysis of Anti Gas-Channeling Performance

3.3.4. The Long-Term Performance of Anti Gas-Channeling of Asphalt Bonding System

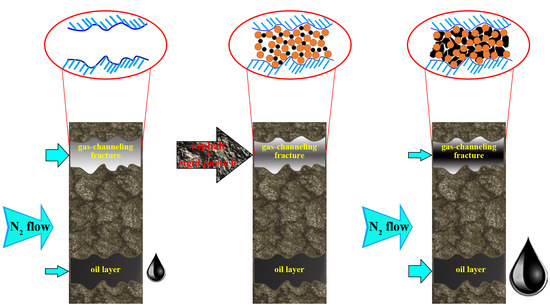

3.4. Distribution of the Anti Gas-Channeling System in Network Fractures

3.5. Observation of the Micromorphology of the Bonding System inside the Fractures

4. Conclusions

Supplementary Materials

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Abedini, A.; Torabi, F. On the CO2 storage potential injection process for enhanced oil recovery. Fuel 2014, 124, 14–27. [Google Scholar] [CrossRef]

- Wei, B.; Gao, H.; Pu, W.; Zhao, F.; Li, Y.; Jin, F.; Sun, L.; Li, K. Interactions and phase behaviors between oleic phase and CO2 from swelling to miscibility in CO2-based enhanced oil recovery (EOR) progress: A comprehensive visualization study. J. Mol. Liq. 2017, 232, 277–284. [Google Scholar] [CrossRef]

- Bardon, C.; Corlay, P.; Longeron, D.; Miller, B. CO2 huff ‘n’ puff revives shallow light oil-depleted reservoirs. SPE Reserv. Eng. 1994, 9, 92–100. [Google Scholar] [CrossRef]

- Haskin, H.K.; Alston, R.B. An evaluation of CO2 huff ‘n’ puff tests in Texas. J. Pet. Technol. 1989, 41, 177–184. [Google Scholar] [CrossRef]

- Wei, Y.; Lashgari, H.R.; Wu, K.; Sepehrnoori, K. CO2 injection for enhanced oil recovery in Bakken tight oil reservoirs. Fuel 2015, 159, 354–363. [Google Scholar]

- Yang, F.; Sun, Y.; Shen, Y.; Zhang, L. Using diagenetic facies to analyze heterogeneous reservoir of Donghe sandstone of east slope of Lunnan, Tarim Basin. Pet. Explor. Dev. 2006, 33, 136–140. [Google Scholar]

- Zhong, G.; Wu, N. Development lithofacies analysis: A whole new approach to studying diagenetic heterogeneity. Pet. Explor. Dev. 1997, 24, 62–66. [Google Scholar]

- Hu, Z.; Ma, K.; Liu, Z.; Huang, K.; Zhang, J. An Research and application of the properties variation regularity of water injection reservoirs in S offshore oilfield. Sci. Technol. Eng. 2014, 14, 164–168. [Google Scholar]

- Li, X.; Sun, C.; Zhao, Y. Research on variation rule of reservoir microscopic and features in Lamadian oilfield. Pet. Geol. Oilfield Dev. Daqing 2007, 26, 79–82. [Google Scholar]

- Jin, F.; Tian, Y.; Pu, W.; Yuan, C.; Guo, Y.; Liu, Z. An experiment study of gas-channeling blocking by salt precipitation. Nat. Gas Ind. 2013, 33, 74–78. [Google Scholar]

- Lin, S.; Peng, W.; Pu, W.; Wang, B.; Wu, Y.; Tan, T. The oil recovery enhancement by nitrogen foam in high-temperature and high-salinity environments. J. Pet. Sci. Eng. 2016, 147, 485–494. [Google Scholar]

- Cao, X.; Liu, D.; Zhang, Z.; Wang, S.; Wang, Q.; Xia, D. Steam channeling control in the steam flooding of super heavy oil reservoirs, Shengli Oilfields. Pet. Explor. Dev. 2012, 39, 785–790. [Google Scholar] [CrossRef]

- Jones, S.A.; van der Bent, V.; Farajzadeh, R.; Rossen, W.R.; Bonnieu, V. Surfactant screening for foam EOR: Correlation between bulk and core-flood experiments. Colloids Surf. A Physicochem. Eng. Asp. 2016, 500, 166–176. [Google Scholar] [CrossRef]

- Jun, Y.; Wang, X.; Peng, X.; Du, Z.; Zeng, F. Experimental studies on CO2 foam performance in the tight cores. J. Pet. Sci. Eng. 2019, 175, 1136–1149. [Google Scholar]

- Sun, L.; Bai, B.; Wei, B.; Pu, W.; Wei, P.; Li, D.; Zhang, C. Recent advances of surfactant-stabilized N2/CO2 foams in enhanced oil recovery. Fuel 2019, 241, 83–93. [Google Scholar] [CrossRef]

- Hunter, B.L.; Buell, R.S.; Abate, T.A. Application of polymer gel system to control steam breakthrough and channeling. In Proceedings of the SPE Western Regional Meeting, Bakersfield, CA, USA, 30 March–1 April 1992. [Google Scholar]

- Eson, R.L.; Cooke, R.W. A successful high-temperature gel system to reduce steam channeling. In Proceedings of the SPE Annual Technical Conference and Exhibition, Washington, DC, USA, 4–7 October 1992. [Google Scholar]

- Wang, C.; Liu, H.; Wang, J.; Hong, C.; Dong, X.; Meng, Q.; Liu, Y. A novel high-temperature gel to control the steam channeling in heavy oil reservoir. In Proceedings of the SPE Heavy Oil Conference, Calgary, AB, Canada, 10–12 June 2014. [Google Scholar]

- Anzhu, A.X.; Mu, L.; Bo, B.; Shan, F.; Li, X. Development and application of a modified superheated steam flooding assisted by N2 foam and high-temperature resistant gel. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, UAE, 13–16 November 2017. [Google Scholar]

- Hou, Y.; Yue, X. Research on a novel composite gel system for CO2 through. Pet. Sci. 2010, 7, 245–250. [Google Scholar] [CrossRef] [Green Version]

- Hughes, T.L.; Friedmann, F.; Johnson, D.; Hild, G.P.; Wilson, A.; Davies, S.N. Large-volume foam-gel treatments to improve conformance of the Rangely CO2 flood. SPE Reserv. Eval. Eng. 1999, 2, 14–24. [Google Scholar] [CrossRef]

- Romero-Zeron, L.B.; Kanzatzas, A. Flow visualization studies on the effect of foamed gel microstructure on gas-blockage effectiveness and its importance on foamed gel trapping in porous media. In Proceedings of the Canadian International Petroleum Conference, Calgary, AB, Canada, 11–13 June 2002. [Google Scholar]

- Kanzatzas, A.; Allsopp, K.; Marentette, D. Utilization of polymer gels polymer enhanced foams and foamed gels for improving reservoir conformance. In Proceedings of the Annual Technical Meeting, Calgary, AB, Canada, 8–11 June 1997. [Google Scholar]

- Romero, L.; Kanzatzas, A. The effect of wettability and pore geometry on foamed gel blockage performance in gas and water producing zones. In Proceedings of the SPE/DOE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 17–21 April 2004. [Google Scholar]

- Han, X.; Zou, J.; Wang, Q.; Liu, Y.; Meng, X. A study of gel-plugging agents used in gas channels with multi-thermal fluids in offshore oilfields. J. Southwest Pet. Univ. (Sci. Technol. Ed.) 2017, 39, 167–172. [Google Scholar]

- Yu, H.; Li, L.; Zheng, J.; Ji, W.; Qin, X.; Fu, X.; Gao, W. New method of steam channeling plugging on horizontal wells of heavy oil stimulation. In Proceedings of the SPE Latin America and Caribbean Heavy and Extra Heavy Oil Conference, Lima, Peru, 19–20 October 2016. [Google Scholar]

- Zhou, Y.; Li, Z.; Zhang, L.; Jing, C.; Zhang, Z.; Li, X. Carbon dioxide flooding channeling blocking technology in fractured low permeability reservoirs. Oilfield Chem. 2017, 34, 64–68. [Google Scholar]

- Wang, Z.; Bai, B.; Liu, Y.; Wang, L. An investigation of CO2-responsive preformed particles gel for conformance control of CO2 flooding in reservoirs with fractures or fracture-like channels. SPE J. 2019, 24, 2398–2408. [Google Scholar] [CrossRef]

- Hu, L.; Zhao, J.; Wei, P.; Zhang, Y. Experimental study on enhanced foam anti-gas channeling in the Yumen H low permeability fractured reservoir. J. Southwest Pet. Univ. (Sci. Technol. Ed.) 2019, 41, 96–104. [Google Scholar]

- Shi, L.; Dang, H.; Kang, S.; Wang, W.; Wang, Q. Effects of injection pressure on gas channeling during CO2 flooding and a study on sealing of cracks. J. Southwest Pet. Univ. (Sci. Technol. Ed.) 2018, 40, 149–156. [Google Scholar]

- Yang, H.; Jiang, S.; Wang, H.; Li, P.; Nan, Y.; Du, X. Research of adaptability of gas channeling controlling methods in CO2 flooding of fractured ultra-low permeability reservoir. J. Xi’an Shiyou Univ. (Nat. Sci. Ed.) 2017, 32, 105–115. [Google Scholar]

- Liu, Z.; Li, Z. An experimental study on anti-channeling technology with foam in CO2 flooding. J. Southwest Pet. Univ. (Sci. Technol. Ed.) 2015, 37, 117–122. [Google Scholar]

- Wang, F. Numerical simulation research of asphalt profile development mode and mechanism after polymer flooding. Fault-Block Oil Gas Field 2015, 22, 364–368. [Google Scholar]

- Gao, B. Bitumen particles profile control technique in Lamadian oilfield. Pet. Geol. Oilfield Dev. Daqing 2006, 25, 96–98. [Google Scholar]

- Bai, Y. Parameters Optimization for Asphalt Particle Profile Control in Lamadian Oilfield. Master’s Thesis, Northeast Petroleum University, Daqing, China, 2017. [Google Scholar]

- Xiao, K.; Jiang, H.; Wang, Q.; Wang, H.; Zhao, D. Adaptability study on plugging thief zones with asphalt particle in polymer flooding offshore field. In Proceedings of the SPE Energy Resources Conference, Port of Spain, Trinidad and Tobago, 9–11 June 2014. [Google Scholar]

- Liu, G.; Jiang, H.; Li, J.; Wang, M.; Chen, F.; Ding, S.; Lu, X. Evaluation of the performance of polymer gels mixed with asphalt particle as a novel composite profile control system. J. Ind. Eng. Chem. 2015, 26, 309–314. [Google Scholar] [CrossRef]

- Li, Y.; Xiang, G.; Wang, Y.; Li, Y.; Li, J. Matching of asphalt particles and formation pores for conformance control treatment in Lamadian oilfield in Daqing. J. China Univ. Pet. (Ed. Nat. Sci.) 2015, 39, 92–96. [Google Scholar]

- Cao, G.; Bai, Y.; Li, X.; Zhou, Z.; Ren, C.; Li, Z.; Li, C. Size optimization of asphalt particles for profile for profile control in Lamadian oilfield P reservoir. In Proceedings of the 5th International Conference on Advanced Engineering Materials and Technology, Guangzhou, China, 22–23 August 2015. [Google Scholar]

- Abrams, A. Mud design to minimize rock impairment due to particle invasion. J. Pet. Technol. 1977, 29, 586–592. [Google Scholar] [CrossRef]

- Oort, E.V.; Velzen, J.F.G.; Leerlooijer, K. Impairment by suspended solids invasion: Testing and prediction. Spe Prod. Facil. 1993, 8, 178–184. [Google Scholar] [CrossRef]

- Zhang, J.; Yan, J. New theory and method for optimizing the particle size distribution of bridging agents in drilling fluids. Acta Pet. Sin. 2004, 25, 88–95. [Google Scholar]

- Guo, Y.; Hu, J.; Zhang, X.; Feng, R.; Li, H. Flow behavior through porous media and microdisplacemnet performance of hydrophobically modified partially hydrolyzed polyacrylamide. SPE J. 2016, 21, 688–705. [Google Scholar] [CrossRef]

- Gao, J.; Li, Y.; Li, J.; Li, J.; Yin, D.; Wang, H. Experimental study on optimal polymer injection timing in offshore oilfields. In Proceedings of the Offshore Technology Conference Asia, Kuala Lumpur, Malaysia, 25–28 March 2014. [Google Scholar]

- Han, M.; Xiang, W.; Zhang, J.; Wei, J.; Sun, F. Application of EOR technology by means of polymer flooding in Bohai oilfields. In Proceedings of the International Oil & Gas Conference and Exhibition, Beijing, China, 5–7 December 2006. [Google Scholar]

- Wang, D.; Han, P.; Shao, Z.; Hou, W.; Seright, R.S. Sweep-improvement options for the Daqing oil field. SPE J. 2008, 11, 18–26. [Google Scholar] [CrossRef]

- Ohen, H.A.; Blick, E.F. Golden section search method for determining parameters in Robertson-stiff non-Newtonian fluid model. J. Pet. Sci. Eng. 1990, 4, 309–316. [Google Scholar] [CrossRef]

- Kheldoun, A.; Bradai, R.; Boukenoui, R.; Mellit, A. A new golden section method-based maximum power point tracking algorithm for photovoltaic systems. Energy Convers. Manag. 2016, 111, 125–136. [Google Scholar] [CrossRef]

- Curvas, E.; Enriquez, L.; Zaldivar, D.; Perez-Cisneros, M. A selection method for evolutionary algorithms based on the golden section. Expert Syst. Appl. 2018, 106, 183–196. [Google Scholar]

- Li, Y.; Hu, C. Experiment Design and Data Processing; Chemical Industry Press: Beijing, China, 2008; pp. 114–115. [Google Scholar]

- Zhao, F.; Zhang, L.; Hou, J.; Cao, S. Profile improvement during CO2 flooding in ultra-low permeability reservoirs. Pet. Sci. 2014, 11, 279–284. [Google Scholar] [CrossRef] [Green Version]

- Jiang, S.; Wang, W.; Huang, C.; Yang, H.; Yu, H. Application of modified starch gel system to prevent CO2 breakthrough. Spec. Oil Gas Reserv. 2016, 23, 136–140. [Google Scholar]

- Zhang, H.; Cao, Y.; Liu, F.; Zhang, A.; Liu, T.; Yong, Q. Microstructure and formula optimization of CO2 flooding composite gel channeling sealing system. Oilfield Chem. 2017, 34, 64–68. [Google Scholar]

- Wei, B.; Romero-Zer, N.L.; Rodrigue, D. Improved viscoelasticity of xanthan gum through self-association with surfactant: β-cyclodextrin inclusion complexes for application in enhanced oil recovery. Polym. Eng. Sci. 2015, 55, 523–532. [Google Scholar] [CrossRef]

- Li, C.; Zhu, S.; Liu, D.; Nie, K.; Deng, P. Another discussion on slippage effect. Lithol. Reserv. 2016, 28, 123–129. [Google Scholar]

- Wang, J.; Zhou, F.; Fan, F.; Zhang, L.; Yao, E. Study on the influence of CO2 finger-channeling flooding on oil displacement efficiency and anti-channeling method. In Proceedings of the ARMA-CUPB Geothermal International Conference, Beijing, China, 5–8 August 2019. [Google Scholar]

| Components | NaCl | Na2SO4 | CaCl2 | MgCl2·6H2O | NaHCO3 | Total Salinity |

|---|---|---|---|---|---|---|

| g·L−1 | 181.88 | 0.22 | 31.22 | 9.70 | 0.05 | 223.07 |

| Factors | Rigid Particles Content/wt% | Asphalt Content/wt% | Asphalt Coftening Point/°C |

|---|---|---|---|

| 1 | (A1)2 | (B1)2 | (C1)60 |

| 2 | (A2)4 | (B2)4 | (C2)90 |

| 3 | (A3)6 | (B3)6 | (C3)105 |

| 4 | (A4)8 | (B4)8 | (C4)130 |

| No. | Rigid Particles Content/% | Asphalt Content/% | Asphalt Softening Point/°C | Blocking Ratio/% |

|---|---|---|---|---|

| 1# | 2 | 2 | 60 | W1 |

| 2# | 2 | 4 | 90 | W2 |

| 3# | 2 | 6 | 105 | W3 |

| 4# | 2 | 8 | 130 | W4 |

| 5# | 4 | 2 | 90 | W5 |

| 6# | 4 | 4 | 60 | W6 |

| 7# | 4 | 6 | 130 | W7 |

| 8# | 4 | 8 | 105 | W8 |

| 9# | 6 | 2 | 105 | W9 |

| 10# | 6 | 4 | 130 | W10 |

| 11# | 6 | 6 | 60 | W11 |

| 12# | 6 | 8 | 90 | W12 |

| 13# | 8 | 2 | 130 | W13 |

| 14# | 8 | 4 | 105 | W14 |

| 15# | 8 | 6 | 90 | W15 |

| 16# | 8 | 8 | 60 | W16 |

| No. | 0.25 MPa | 1 MPa | 0.25 MPa | 1 MPa | ||

|---|---|---|---|---|---|---|

| V0/(L·min−1) | V1/(L·min−1) | V0*/(L·min−1) | V1*/(L·min−1) | Wi/% | Wi*/% | |

| 1# | 25.85 | 20.34 | 76.73 | 61.68 | 21.32 | 19.61 |

| 2# | 25.15 | 18.76 | 74.91 | 57.52 | 25.42 | 23.21 |

| 3# | 24.32 | 17.75 | 75.62 | 56.96 | 27.01 | 24.67 |

| 4# | 24.66 | 17.56 | 75.19 | 55.47 | 28.78 | 26.23 |

| 5# | 25.16 | 11.81 | 76.03 | 39.30 | 53.08 | 48.31 |

| 6# | 25.33 | 5.86 | 75.77 | 23.33 | 76.87 | 69.21 |

| 7# | 26.39 | 8.88 | 76.52 | 30.55 | 66.34 | 60.08 |

| 8# | 26.86 | 8.68 | 75.19 | 29.11 | 67.67 | 61.29 |

| 9# | 26.57 | 10.25 | 76.28 | 34.09 | 61.43 | 55.31 |

| 10# | 25.73 | 7.30 | 75.23 | 26.08 | 71.64 | 65.33 |

| 11# | 26.04 | 13.33 | 76.40 | 42.36 | 48.82 | 44.56 |

| 12# | 24.73 | 5.97 | 75.61 | 23.42 | 75.86 | 69.02 |

| 13# | 25.61 | 11.72 | 76.21 | 37.86 | 54.23 | 50.32 |

| 14# | 25.22 | 8.21 | 75.31 | 28.78 | 67.43 | 61.79 |

| 15# | 25.01 | 3.28 | 75.44 | 15.25 | 84.90 | 79.79 |

| 16# | 25.77 | 4.07 | 76.09 | 17.49 | 84.22 | 77.02 |

| Factors | A | B | C | |

|---|---|---|---|---|

| ki | k1-0.25MPa | 25.633 | 47.515 | 57.807 |

| k1-1MPa | 19.635 | 43.388 | 52.600 | |

| k2-0.25MPa | 65.990 | 60.340 | 60.315 | |

| k2-1MPa | 58.617 | 54.885 | 55.083 | |

| k3-0.25MPa | 64.438 | 57.268 | 55.885 | |

| k3-1MPa | 56.580 | 52.275 | 50.765 | |

| k4-0.25MPa | 73.195 | 64.132 | 55.247 | |

| k4-1MPa | 65.472 | 58.390 | 50.490 | |

| Range R0.25MPa | 47.562 | 16.617 | 5.068 | |

| Range R1MPa | 45.837 | 15.002 | 4.593 | |

| Major-minor sequence | 1 | 2 | 3 | |

| Optimal scheme | A4B4C2 | |||

| 0.25 MPa | 1 MPa | 0.25 MPa | 1 MPa | ||

|---|---|---|---|---|---|

| V0/((L·min−1) | V1/(L·min−1) | V0*/(L·min−1) | V1*/(L·min−1) | W/% | W*/% |

| 25.49 | 2.29 | 76.73 | 10.56 | 91.02 | 86.24 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, N.; Wen, Y.; Wen, X.; He, W.; Lin, X.; Jia, C.; Hu, D. Performance Evaluation of an Anti Gas-Channeling System (Asphalt-Rigid Particle-Xanthan Gum) Applied in High-Temperature and High-Salinity Fractured Reservoir. Energies 2019, 12, 4766. https://doi.org/10.3390/en12244766

Lai N, Wen Y, Wen X, He W, Lin X, Jia C, Hu D. Performance Evaluation of an Anti Gas-Channeling System (Asphalt-Rigid Particle-Xanthan Gum) Applied in High-Temperature and High-Salinity Fractured Reservoir. Energies. 2019; 12(24):4766. https://doi.org/10.3390/en12244766

Chicago/Turabian StyleLai, Nanjun, Yiping Wen, Xiaohu Wen, Wei He, Xiaosha Lin, Chao Jia, and Dong Hu. 2019. "Performance Evaluation of an Anti Gas-Channeling System (Asphalt-Rigid Particle-Xanthan Gum) Applied in High-Temperature and High-Salinity Fractured Reservoir" Energies 12, no. 24: 4766. https://doi.org/10.3390/en12244766

APA StyleLai, N., Wen, Y., Wen, X., He, W., Lin, X., Jia, C., & Hu, D. (2019). Performance Evaluation of an Anti Gas-Channeling System (Asphalt-Rigid Particle-Xanthan Gum) Applied in High-Temperature and High-Salinity Fractured Reservoir. Energies, 12(24), 4766. https://doi.org/10.3390/en12244766