Study on the Possibility of Improving the Environmental Performance of Diesel Engine Using Carbon Nanotubes as a Petroleum Diesel Fuel Additive

Abstract

:1. Introduction

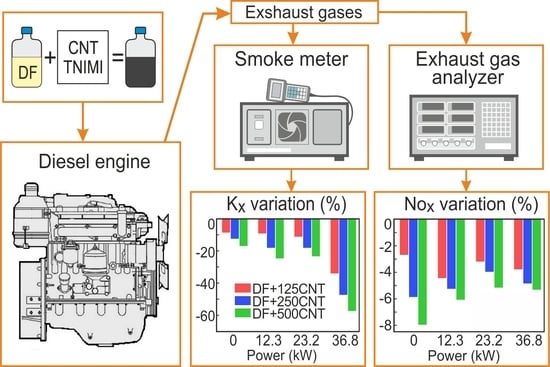

2. Materials and Methods

Experimental Setup and Procedure

3. Results and Discussion

3.1. Engine Performance: Fuel Consumption, Air Consumption, Air–Fuel Equivalence Ratio, and Brake-Specific Fuel Consumption (BSFC)

3.2. Exhaust Gas Emission Measurements: Carbon Monoxide, Carbon Dioxide, Hydrocarbon, Nitrogen Oxides, and Smoke

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Aleksandrov, A.A.; Arkharov, I.A.; Bagrov, V.V.; Gaivoronskii, A.I.; Grekhov, L.V.; Devianin, S.N.; Ivashchenko, N.A.; Markov, V.A. Alternative Fuels for Internal Combustion Engines; LLC NITS “Inzhener” Publ., LLC “Oniko-M.” Publ.: Moscow, Russia, 2012. [Google Scholar]

- Shatrov, M.G.; Khachiyan, A.S.; Golubkov, L.N.; Dunin, A.Y. Improvement of Working Processes of Automotive Diesel Engines and their Fuel Systems Running on Alternative Fuels; MADI: Moscow, Russia, 2012. [Google Scholar]

- Vasiliev, I.P. Effect of Vegetable Fuels on the Ecological and Economic Indicators of Diesel; V. Dahl EUNU: Lugansk, Russia, 2009. [Google Scholar]

- Lotko, W.; Lukanin, V.N.; Khatchiyan, A.S. Usage of Alternative Fuels in Internal Combustion Engines; MADI: Moscow, Russia, 2000. [Google Scholar]

- Arkharov, I.; Markov, V.; Bagrov, V.; Devyanin, S.; Ksenofontov, B.; Neverova, V.; Sereda, A.; Sharin, E.; Zykov, S.; Sa, B. Petroleum Motor Fuels: Ecological Aspects of Application; LLC NITS “Inzhener” Publ.: Moscow, Russia, 2019. [Google Scholar]

- Markov, V.A.; Devyanin, S.N.; Semenov, V.G.; Bagrov, V.V.; Zykov, S.A. Motor Fuels Manufactured from Vegetable Oils; Lambert Academic Publishing: Riga, Latvia, 2019. [Google Scholar]

- Wang, X.; Xu, X.; Choi, S.U.S. Thermal Conductivity of Nanoparticle-Fluid Mixture. J. Thermophys. Heat Transf. 1999, 13, 474–480. [Google Scholar] [CrossRef]

- Choi, S.U.S. Nanofluids: From Vision to Reality Through Research. J. Heat Trans. 2009, 131, 033106–033115. [Google Scholar] [CrossRef]

- Naddaf, A.; Heris, S.Z. Density and Rheological Properties of Different Nanofluids Based on Diesel Oil at Different Mass Concentrations. An experimental study. J. Thermal Anal. Calorim. 2019, 135, 1229–1242. [Google Scholar] [CrossRef]

- Heydari-Maleney, K.; Taghizadeh-Alisaraei, A.; Ghobadian, B.; Abbaszadeh-Mayvan, A. Analyzing and Evaluation of Carbon Nanotubes Additives to Diesohol-B2 Fuels on Performance and Emission of Diesel Engines. Fuel 2017, 196, 110–123. [Google Scholar] [CrossRef]

- Gardy, J.; Nourafkan, E.; Osatiashtiani, A.; Lee, A.F.; Wilson, K.; Hassanpour, A.; Lai, X. A core-shell SO4/Mg-Al-Fe3O4 catalyst for biodiesel production. Appl. Catal. B Environ. 2019, 259, 118093. [Google Scholar] [CrossRef]

- Gardy, J.; Rehan, M.; Hassanpour, A.; Lai, X.; Nizami, A.-S. Advances in nano-catalysts based biodiesel production from non-food feedstocks. J. Environ. Manag. 2019, 249, 109316. [Google Scholar] [CrossRef]

- Sadhik Basha, J.; Anand, R.B. Performance, Emission and Combustion Characteristics of a Diesel Engine using Carbon Nanotubes Blended Jatropha Methyl Ester Emulsions. Alex. Eng. J. 2014, 53, 259–273. [Google Scholar] [CrossRef]

- Balaji, G.; Cheralathan, M. Effect of CNT as Additive with Biodiesel on the Performance and Emission Characteristics of a DI Diesel Engine. Int. J. ChemTech Res. 2015, 7, 1230–1236. [Google Scholar]

- El-Seesy, A.I.; Abdel-Rahman, A.K.; Bady, M.; Ookawara, S. Performance, Combustion and Emission Characteristics of a Diesel Engine Fueled by Biodiesel-Diesel Mixtures with Multi-Walled Carbon Nanotubes Additives. Energy Convers. Manag. 2017, 135, 373–393. [Google Scholar] [CrossRef]

- Sadhik Basha, J.; Anand, R.B. An Experimental Investigation in a Diesel Engine Using Carbon Nanotubes Blended Water-Diesel Emulsion Fuel. Proc. Inst. Mech. Eng. Part A J. Power Energy 2011, 225, 279–288. [Google Scholar] [CrossRef]

- Chengdu Organic Chemicals Co. Ltd. Chinese Academy of Sciences: Industrial Multi-wall Carbon Nanotubes. Available online: http://www.timesnano.com/en/view.php?prt=3,30,87,187 (accessed on 15 October 2019).

- Sadhik Basha, J.; Anand, R.B. Role of nanoadditive blended biodiesel emulsion fuel on the working charcteristics of a diesel engine. J. Renew. Sustain. Energy 2011, 3, 023106. [Google Scholar] [CrossRef]

- Chen, A.F.; Adzmi, M.A.; Adam, A.; Othman, M.F.; Kamaruzzaman, M.K.; Mrwan, A.G. Combustion Characteristics, Engine Performances and Emissions of a Diesel Engine Using Nanoparticle-Diesel Fuel Blends with Aluminium Oxide, Carbon Nanotubes and Silicon Oxide. Energy Convers. Manag. 2018, 171, 461–477. [Google Scholar] [CrossRef]

- Liu, M.S.; Lin, M.C.C.; Huang, I.T.; Wang, C.C. Enhancement of Thermal Conductivity with Carbon Nanotube for Nanofluids. Int. Commun. Heat Mass Transf. 2005, 32, 1202–1210. [Google Scholar] [CrossRef]

- Hosseini, S.H.; Taghizadeh-Alisaraei, A.; Ghobadian, B.; Abbaszadeh-Mayvan, A. Performance and Emission Characteristics of a CI Engine Fuelled with Carbon Nanotubes and Diesel-Biodiesel Blends. Renew. Energy 2017, 111, 201–213. [Google Scholar] [CrossRef]

- El-Seesy, A.I.; Hamdy Hassan, H. Investigation of the Effect of Adding Graphene oxide, Grapheme Nanoplatelet, and Multiwalled Carbon Nanotube Additives with n-Butanol-Jatropha Methyl Ester on a Diesel Engine Performance. Renew. Energy 2019, 132, 558–574. [Google Scholar] [CrossRef]

- Karthikeyan, S.; Prathima, A. Emission Analysis of the Effect of Doped Nano-Additives on Biofuel in a Diesel Engine. Energy Sources Part A Recov. Utiliz. Environ. Eff. 2016, 38, 3702–3708. [Google Scholar] [CrossRef]

- Selvan, V.A.M.; Anand, R.B.; Udayakumar, M. Effect of Cerium Oxide Nanoparticles and Carbon Nanotubes as Fuel-Borne Additives in Diesterol Blends on the Performance, Combustion and Emission Characteristics of a Variable Compression Ratio Engine. Fuel 2014, 130, 160–167. [Google Scholar] [CrossRef]

- Naddaf, A.; Heris, S.Z. Experimental Study on Thermal Conductivity and Electrical Conductivity of Diesel Oil-Based Nanofluids of Graphene Nanoplatelets and Carbon Nanotubes. Int. Commun. Heat Mass Transf. 2018, 95, 116–122. [Google Scholar] [CrossRef]

- Ooi, J.B.; Ismail, H.M.; Tan, B.T.; Wang, X. Effects of Graphite Oxide and Single-Walled Carbon Nanotubes as Diesel Additives on the Performance, Combustion, and Emission Characteristics of a Light-Duty Diesel Engine. Energy 2018, 161, 70–80. [Google Scholar] [CrossRef]

- Markov, V.A.; Bashirov, R.M.; Gabitov, I.I. Toxicity of Diesel Engines Exhaust Gases; BMSTU Publ.: Moscow, Russia, 2002. [Google Scholar]

- Praveen, A.; Narayana Rao, G.L.N.; Balakrishna, B. The Combined Effect of Multiwalled Carbon Nanotubes and Exhaust Gas Recirculation on the Performance and Emission Characteristics of a Diesel Engine. Int. J. Ambient Energy 2018, 40, 791–799. [Google Scholar] [CrossRef]

- Velumani, V.; Lawrence, P.; Sivaprakasam, S. Performance and Emission Analysis on DI Diesel Engine with Multi-walled Carbon Nanotubes. Int. J. Appl. Eng. Res. 2018, 13, 16697–16700. [Google Scholar]

| Parameters | Value |

|---|---|

| Engine type | Four-stroke, in-line, diesel |

| Number of cylinders | 4 |

| Cylinder diameter D, mm | 110 |

| Piston stroke S, mm | 125 |

| Total cylinder capacity iVh, L | 4.32 |

| Compression ratio ε | 16.0 |

| Combustion chamber (CC) type, air–fuel mixing method | CC of type CNIDI (Central Diesel Engine Research Institute), space atomization and film evaporation |

| Nominal speed n, rpm | 1500 |

| Nominal power Ne, kW | 36 |

| Fuel supply system type | Separate fuel system |

| High-pressure oil pump | In-line plunger pump Motorpal PP4M10U1f with centrifugal governor |

| Diameter of plunger dpl, mm | 10 |

| Plunger stroke hpl, mm | 10 |

| Length of high-pressure oil pipe Lh, mm | 540 |

| Injector | Type FDM-22 OJSC “Corapporteur” (Vilnius) |

| Injector sprayer | Motorpal DOP 119S534 with five nozzles of diameter 0.34 mm and effective flow area 0.250 mm2 |

| Initial injection pressure, MPa | 21.5 |

| Measured Parameter | Measuring Range | Accuracy | Uncertainty |

|---|---|---|---|

| Engine speed | 0–2500 rpm | ±2.5 rpm | ±0.1% |

| Engine power | 0–40 kW | ±0.4 kW | ±1% |

| Fuel consumption | 0–12 kg/h | ±0.05 kg/h | ±0.4% |

| Air consumption | 0–250 kg/h | ±2.5 kg/h | ±1% |

| O2 | 0–21 vol % | <3.3 vol %: ±0.1 vol % | ≥3.3 vol %: ±3 vol % |

| CO2 | 0–16 vol % | <12.5 vol %: ±0.5 vol % | ≥12 vol %: ±4 vol % |

| NOx | 0–4000 ppm | <1000 ppm: ±100 ppm | ≥1000 ppm: ±10 ppm |

| CO | 0–5 vol % | <1 vol %: ±0.03 vol % | ≥1 vol %: ±3 vol % |

| HC | 0–2000 ppm | <200 ppm: ±10 ppm | ≥200 ppm: ±5% |

| Exhaust gas smoke | 0–100% | ±1% full-scale reading | – |

| Operation on Petroleum Diesel Fuel | |||||||

|---|---|---|---|---|---|---|---|

| № Mode | n, rpm | Ne, kW | Gf, kg/h | Ga, kg/h | λ | BSFC, g/kW·h | KX, % (Hartridge) |

| 1 | 1480 | 36.8 | 10.09 | 212 | 1.47 | 274.2 | 26.0 |

| 2 | 1510 | 23.2 | 6.90 | 216 | 2.19 | 297.4 | 7.3 |

| 3 | 1540 | 12.3 | 4.69 | 220 | 3.28 | 381.3 | 4.5 |

| 4 | 1590 | 0 | 2.52 | 228 | 6.33 | – | 2.4 |

| Operation on petroleum diesel fuel mixed with CNT in the dose level of 125 mg/L | |||||||

| 1 | 1480 | 36.8 | 10.07 | 211 | 1.47 | 273.6 | 17.2 |

| 2 | 1510 | 23.2 | 6.85 | 216 | 2.21 | 295.3 | 6.5 |

| 3 | 1540 | 12.3 | 4.65 | 220 | 3.31 | 378.0 | 4.1 |

| 4 | 1590 | 0 | 2.48 | 228 | 6.43 | – | 2.2 |

| Operation on petroleum diesel fuel mixed with CNT in the dose level of 250 mg/L | |||||||

| 1 | 1480 | 36.8 | 10.06 | 211 | 1.47 | 273.4 | 13.8 |

| 2 | 1510 | 23.2 | 6.80 | 215 | 2.21 | 293.1 | 6.0 |

| 3 | 1540 | 12.3 | 4.60 | 219 | 3.33 | 374.0 | 3.7 |

| 4 | 1590 | 0 | 2.48 | 227 | 6.40 | – | 2.1 |

| Operation on petroleum diesel fuel mixed with CNT in the dose level of 500 mg/L | |||||||

| 1 | 1480 | 36.8 | 10.06 | 210 | 1.46 | 273.4 | 11.2 |

| 2 | 1510 | 23.2 | 6.78 | 214 | 2.21 | 292.2 | 5.6 |

| 3 | 1540 | 12.3 | 4.58 | 219 | 3.34 | 372.4 | 3.4 |

| 4 | 1590 | 0 | 2.46 | 227 | 6.45 | – | 2.0 |

| Operation on Petroleum Diesel Fuel | |||||||

|---|---|---|---|---|---|---|---|

| № Mode | n, rpm | Ne, kW | CCO, % | CHC, ppm | |||

| 1 | 1480 | 36.8 | 7.74 | 9.59 | 1763 | 0.013 | 9 |

| 2 | 1510 | 23.2 | 12.47 | 5.96 | 1270 | 0.014 | 9 |

| 3 | 1540 | 12.3 | 15.67 | 3.73 | 612 | 0.015 | 10 |

| 4 | 1590 | 0 | 18.31 | 1.80 | 189 | 0.020 | 10 |

| Operation on petroleum diesel fuel mixed with CNT at the dose level of 125 mg/L | |||||||

| 1 | 1480 | 36.8 | 7.80 | 9.58 | 1697 | 0.013 | 10 |

| 2 | 1510 | 23.2 | 12.63 | 5.74 | 1230 | 0.013 | 10 |

| 3 | 1540 | 12.3 | 15.70 | 3.60 | 585 | 0.014 | 10 |

| 4 | 1590 | 0 | 18.33 | 1.78 | 184 | 0.015 | 9 |

| Operation on petroleum diesel fuel mixed with CNT at the dose level of 250 mg/L | |||||||

| 1 | 1480 | 36.8 | 7.88 | 9.55 | 1678 | 0.014 | 10 |

| 2 | 1510 | 23.2 | 12.70 | 5.65 | 1220 | 0.014 | 10 |

| 3 | 1540 | 12.3 | 15.72 | 3.54 | 580 | 0.014 | 11 |

| 4 | 1590 | 0 | 18.34 | 1.76 | 178 | 0.015 | 10 |

| Operation on petroleum diesel fuel mixed with CNT in the dose level of 500 mg/L | |||||||

| 1 | 1480 | 36.8 | 7.90 | 9.50 | 1670 | 0.013 | 10 |

| 2 | 1510 | 23.2 | 12.83 | 5.65 | 1205 | 0.013 | 10 |

| 3 | 1540 | 12.3 | 15.72 | 3.23 | 575 | 0.014 | 10 |

| 4 | 1590 | 0 | 18.34 | 1.72 | 174 | 0.015 | 11 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Markov, V.; Kamaltdinov, V.; Zherdev, A.; Furman, V.; Sa, B.; Neverov, V. Study on the Possibility of Improving the Environmental Performance of Diesel Engine Using Carbon Nanotubes as a Petroleum Diesel Fuel Additive. Energies 2019, 12, 4345. https://doi.org/10.3390/en12224345

Markov V, Kamaltdinov V, Zherdev A, Furman V, Sa B, Neverov V. Study on the Possibility of Improving the Environmental Performance of Diesel Engine Using Carbon Nanotubes as a Petroleum Diesel Fuel Additive. Energies. 2019; 12(22):4345. https://doi.org/10.3390/en12224345

Chicago/Turabian StyleMarkov, Vladimir, Vyacheslav Kamaltdinov, Anatoliy Zherdev, Viktor Furman, Bowen Sa, and Vsevolod Neverov. 2019. "Study on the Possibility of Improving the Environmental Performance of Diesel Engine Using Carbon Nanotubes as a Petroleum Diesel Fuel Additive" Energies 12, no. 22: 4345. https://doi.org/10.3390/en12224345

APA StyleMarkov, V., Kamaltdinov, V., Zherdev, A., Furman, V., Sa, B., & Neverov, V. (2019). Study on the Possibility of Improving the Environmental Performance of Diesel Engine Using Carbon Nanotubes as a Petroleum Diesel Fuel Additive. Energies, 12(22), 4345. https://doi.org/10.3390/en12224345