Energy Multiphase Model for Biocoal Conversion Systems by Means of a Nodal Network

Abstract

:1. Introduction

- Production of electricity either by co-combustion or direct combustion;

- Thermal applications for domestic or industrial consumers;

- Production of solid biofuels to be used in the cement or steel industry.

2. Materials and Methods

2.1. Study Area and Mine Nodes

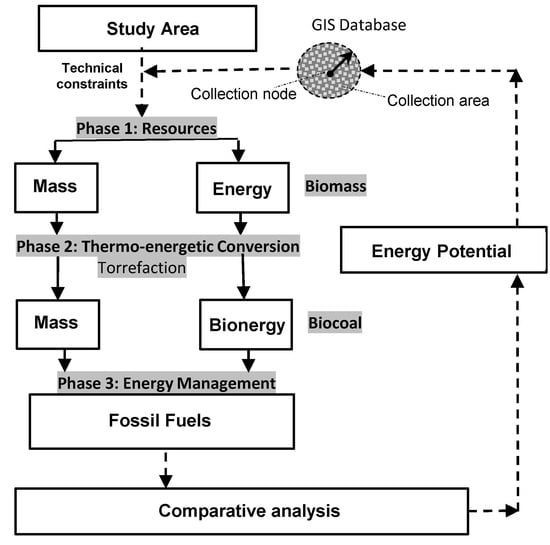

2.2. Multiphase Mathematical Model

2.2.1. Phase 1: Resources

- m is total available mass (dry t/year); and

- mi is total available mass of conifers, hardwood and mixtures (dry t/year).

- E is energy from available mass (GJ/year);

- mi is total available mass of conifers, hardwood and mixtures (dry t/year); and

- LHVi is Lower Heating Value of conifers, hardwood and mixtures (GJ/dry t).

2.2.2. Phase 2: Thermo-Energetic Conversion

- “βy” is the yield referred to the LHV parameter already considered in Phase 1;

- “αy” is mass yield; and

- LHVb and LHV are lower heating value of biocoal mass and raw material, respectively [36].

- mb is biocoal mass from available mass per node (dry t/year);

- mi is mass of available biomass (dry t/year); and

- αy is mass yield.

- Eb is bioenergy as biocoal per node (GJ/year);

- mi is available mass (dry t/year);

- LHVi is lower heating value of conifers, hardwood and mixtures (GJ/dry t); and

- βy is energy yield.

2.2.3. Phase 3: Energy Management

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Heras-Saizarbitoria, I.; Sáez, L.; Allur, E.; Morandeira, J. The emergence of renewable energy cooperatives in Spain: A review. Renew. Sustain. Energy Rev. 2018, 94, 1036–1043. [Google Scholar] [CrossRef]

- Sánchez-Durán, R.; Luque, J.; Barbancho, J. Long-term demand forecasting in a scenario of energy transition. Energies 2019, 12, 3095. [Google Scholar] [CrossRef] [Green Version]

- MITECO (Ministerio para la Transición Ecológica y el Reto Demográfico). Plan de Energías Renovables (PER) 2011–2020, Primera Parte. (In Spanish). Available online: https://www.miteco.gob.es/es/cambio-climatico/legislacion/documentacion/PER_2011-2020_VOL_I_tcm30-178649.pdf (accessed on 18 March 2020).

- MITECO (Ministerio para la Transición Ecológica y el Reto Demográfico). La Energía en España 2017. (In Spanish). Available online: https://energia.gob.es/balances/Balances/LibrosEnergia/Libro-Energia-2017.pdf (accessed on 18 March 2020).

- Directive 2003/30/EC of the European Parliament and of the Council of 8 May 2003 on the Promotion of the Use of Biofuels or Other Renewable Fuels for Transport. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A32003L0030 (accessed on 19 March 2020).

- European Union Forest Action Plan. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=LEGISSUM%3Al24277 (accessed on 18 March 2020).

- Paredes-Sánchez, J.P.; Gutiérrez-Trashorras, A.J.; Xiberta-Bernat, J. Wood residue to energy from forests in the Central Metropolitan Area of Asturias (NW Spain). Urban For. Urban Green. 2015, 14, 195–199. [Google Scholar] [CrossRef]

- Paredes-Sánchez, J.P.; Gutiérrez-Trashorras, A.J.; Xiberta-Bernat, J. Energy potential of residue from wood transformation industry in the central metropolitan area of the Principality of Asturias (northwest Spain). Waste Manag. Res. 2014, 32, 241–244. [Google Scholar] [CrossRef] [PubMed]

- SADEI (Sociedad Asturiana de Estudios Industriales). Datos Básicos de Asturias 2019 (In Spanish). Available online: http://www.sadei.es/datos/catalogo/m00/dabaas/2019/datos-basicos-asturias-2019.pdf (accessed on 19 March 2020).

- Moreno, B.; López, A.J. The effect of renewable energy on employment. The case of Asturias (Spain). Renew. Sustain. Energy Rev. 2008, 12, 732–751. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Wright, C.T.; Kenney, K.L.; Hess, J.R. A Technical Review on Biomass Processing: Densification, Preprocessing, Modeling, and Optimization; Idaho National Laboratory (INL): Idaho Falls, IA, USA, 2010.

- Dai, L.; Wang, Y.; Liu, Y.; Ruan, R.; He, C.; Yu, Z.; Jiang, L.; Zeng, Z.; Tian, X. Integrated process of lignocellulosic biomass torrefaction and pyrolysis for upgrading bio-oil production: A state-of-the-art review. Renew. Sustain. Energy Rev. 2019, 107, 20–36. [Google Scholar] [CrossRef]

- Batidzirai, B.; Mignot, A.P.R.; Schakel, W.B.; Junginger, H.M.; Faaij, A.P.C. Biomass torrefaction technology: Techno-economic status and future prospects. Energy 2013, 62, 196–214. [Google Scholar] [CrossRef]

- Niu, Y.; Lv, Y.; Lei, Y.; Liu, S.; Liang, Y.; Wang, D.; Hui, S. Biomass torrefaction: Properties, applications, challenges, and economy. Renew. Sustain. Energy Rev. 2019, 115, 109395. [Google Scholar] [CrossRef]

- Oztemel, E.; Gursev, S. Literature review of Industry 4.0 and related technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Causer, T.P.; Ciolkosz, D. Biomass for energy: A review on supply chain management models. Renew. Sustain. Energy Rev. 2020, 120, 109658. [Google Scholar] [CrossRef]

- Visa, I.; Duta, A.; Moldovan, M.; Burduhos, B.; Neagoe, M. Solar Energy Conversion Systems in the Built Environment. Green Energy and Technology; Springer: Cham, Switzerland, 2020; pp. 59–158. [Google Scholar]

- Paredes-Sánchez, J.P.; López-Ochoa, L.M. Bioenergy as an Alternative to Fossil Fuels in Thermal Systems. In Advances in Sustainable Energy; Vasel-Be-Hagh, A., Ting, D., Eds.; Springer: Cham, Switzerland, 2019; pp. 149–168. [Google Scholar]

- Murele, O.C.; Zulkafli, N.I.; Kopanos, G.; Hart, P.; Hanak, D.P. Integrating biomass into energy supply chain networks. J. Clean. Prod. 2020, 248, 119246. [Google Scholar] [CrossRef]

- Azevedo, S.G.; Sequeira, T.; Santos, M.; Mendes, L. Biomass-related sustainability: A review of the literature and interpretive structural modeling. Energy 2019, 171, 1107–1125. [Google Scholar] [CrossRef]

- García Nieto, P.J.; García-Gonzalo, E.; Sánchez Lasheras, F.; Paredes-Sánchez, J.P.; Riesgo Fernández, P. Forecast of the higher heating value in biomass torrefaction by means of machine learning techniques. J. Comput. Appl. Math. 2019, 357, 284–301. [Google Scholar] [CrossRef]

- Aalto, M.; Raghu, K.C.; Korpinen, O.J.; Karttunen, K.; Ranta, T. Modeling of biomass supply system by combining computational methods—A review article. Appl. Energy 2019, 243, 145–154. [Google Scholar] [CrossRef]

- Cahyanti, M.N.; Doddapaneni, T.R.K.C.; Kikas, T. Biomass torrefaction: An overview on process parameters, economic and environmental aspects and recent advancements. Bioresour. Technol. 2020, 301, 122737. [Google Scholar] [CrossRef] [PubMed]

- Hu, J.; Song, Y.; Liu, J.; Evrendilek, F.; Buyukada, M.; Yan, Y.; Li, L. Combustions of torrefaction-pretreated bamboo forest residues: Physicochemical properties, evolved gases, and kinetic mechanisms. Bioresour. Technol. 2020, 304, 122960. [Google Scholar] [CrossRef] [PubMed]

- Nunes, L.J.; Matias, J.C. Biomass Torrefaction as a Key Driver for the Sustainable Development and Decarbonization of Energy Production. Sustainability 2020, 12, 922. [Google Scholar] [CrossRef] [Green Version]

- Ribeiro, J.M.C.; Godina, R.; Matias, J.C.D.O.; Nunes, L.J.R. Future perspectives of biomass torrefaction: Review of the current state-of-the-art and research development. Sustainability 2018, 10, 2323. [Google Scholar] [CrossRef] [Green Version]

- Kumar, B.; Bhardwaj, N.; Agrawal, K.; Chaturvedi, V.; Verma, P. Current perspective on pretreatment technologies using lignocellulosic biomass: An emerging biorefinery concept. Fuel Process. Technol. 2020, 199, 106244. [Google Scholar] [CrossRef]

- Huntington, T.; Cui, X.; Mishra, U.; Scown, C.D. Machine learning to predict biomass sorghum yields under future climate scenarios. Biofuel Bioprod. Biorefining 2020, 14, 14. [Google Scholar] [CrossRef]

- Paredes-Sánchez, J.P.; Conde, M.; Gómez, M.A.; Alves, D. Modelling hybrid thermal systems for district heating: A pilot project in wood transformation industry. J. Clean. Prod. 2018, 194, 726–734. [Google Scholar] [CrossRef]

- Bach, Q.V.; Skreiberg, Ø.; Lee, C.J. Process modeling and optimization for torrefaction of forest residues. Energy 2017, 138, 348–354. [Google Scholar] [CrossRef]

- Piedad-Sánchez, N.; Suárez-Ruiz, I.; Martínez, L.; Izart, A.; Elie, M.; Keravis, D. Organic petrology and geochemistry of the Carboniferous coal seams from the Central Asturian Coal Basin (NW Spain). Int. J. Coal Geol. 2004, 57, 211–242. [Google Scholar] [CrossRef]

- Fritsche, U.R.; Iriarte, L. Sustainability criteria and indicators for the bio-based economy in Europe: State of discussion and way forward. Energies 2014, 7, 6825–6836. [Google Scholar] [CrossRef] [Green Version]

- Forbord, M.; Vik, J.; Hillring, B.G. Development of local and regional forest based bioenergy in Norway—Supply networks, financial support and political commitment. Biomass Bioenergy 2012, 47, 164–176. [Google Scholar] [CrossRef] [Green Version]

- Soliño, M.; Prada, A.; Vázquez, M.X. Green electricity externalities: Forest biomass in an Atlantic European Region. Biomass Bioenergy 2009, 33, 407–414. [Google Scholar] [CrossRef]

- BIORAISE. Biomass Database. Available online: http://bioraise.ciemat.es/Bioraise/home/main (accessed on 10 March 2020).

- Verhoeff, F.; Pels, J.R.; Boersma, A.R.; Zwart, R.W.R.; Kiel, J.H.A. ECN Torrefaction Technology Heading for Demonstration; ECN (Energy Research Centre of the Netherlands): Petten, The Netherlands, 2011; pp. 1–8. [Google Scholar]

- Bergman, P.C.A.; Boersma, A.R.; Zwart, R.W.R.; Kiel, J.H.A. Torrefaction for Biomass Co-Firing in Existing Coal-Fired Power Stations; ECN (Energy Research Centre of the Netherlands): Petten, The Netherlands, 2005; pp. 1–71. [Google Scholar]

- Paredes-Sánchez, J.P.; López-Ochoa, L.M.; López-González, L.M.; Las-Heras-Casas, J.; Xiberta-Bernat, J. Evolution and perspectives of the bioenergy applications in Spain. J. Clean. Prod. 2019, 213, 553–568. [Google Scholar] [CrossRef]

- Derčan, B.; Lukić, T.; Bubalo-Živković, M.; Durev, B.; Stojsavljević, R.; Pantelić, M. Possibility of efficient utilization of wood waste as a renewable energy resource in Serbia. Renew. Sustain. Energy Rev. 2012, 16, 1516–1527. [Google Scholar] [CrossRef]

- Paredes-Sánchez, J.P.; García-Elcoro, V.E.; Rosillo-Calle, F.; Xiberta-Bernat, J. Assessment of forest bioenergy potential in a coal-producing area in Asturias (Spain) and recommendations for setting up a Biomass Logistic Centre (BLC). Appl. Energy 2016, 171, 133–141. [Google Scholar] [CrossRef]

- Li, H.X.; Edwards, D.J.; Hosseini, M.R.; Costin, G.P. A review on renewable energy transition in Australia: An updated depiction. J. Clean. Prod. 2020, 242, 118475. [Google Scholar] [CrossRef]

- Festel, G.; Würmseher, M.; Rammer, C.; Boles, E.; Bellof, M. Modelling production cost scenarios for biofuels and fossil fuels in Europe. J. Clean. Prod. 2014, 66, 242–253. [Google Scholar] [CrossRef] [Green Version]

- Proskurina, S.; Heinimö, J.; Schipfer, F.; Vakkilainen, E. Biomass for industrial applications: The role of torrefaction. Renew. Energy 2017, 111, 265–274. [Google Scholar] [CrossRef]

- Lee, S.Y.; Sankaran, R.; Chew, K.W.; Tan, C.H.; Krishnamoorthy, R.; Chu, D.T.; Show, P.L. Waste to bioenergy: A review on the recent conversion technologies. BMC Energy 2019, 1, 1–22. [Google Scholar] [CrossRef]

- Moya, R.; Tenorio, C.; Oporto, G. Short rotation wood crops in Latin American: A review on status and potential uses as biofuel. Energies 2019, 12, 705. [Google Scholar] [CrossRef] [Green Version]

- Ubando, A.T.; Felix, C.B.; Chen, W. Biorefineries in circular bioeconomy: A comprehensive review. Bioresour. Technol. 2020, 299, 122585. [Google Scholar] [CrossRef] [PubMed]

- Sahu, S.G.; Chakraborty, N.; Sarkar, P. Coal–biomass co-combustion: An overview. Renew. Sustain. Energy Rev. 2014, 39, 575–586. [Google Scholar] [CrossRef]

- Paredes-Sánchez, J.P.; Míguez, J.L.; Blanco, D.; Rodríguez, M.A.; Collazo, J. Assessment of micro-cogeneration network in European mining areas: A prototype system. Energy 2019, 174, 350–359. [Google Scholar] [CrossRef]

- San Cristóbal, J.R. Multi-criteria decision-making in the selection of a renewable energy project in Spain: The Vikor method. Renew. Energy 2011, 36, 498–502. [Google Scholar] [CrossRef]

- Moiseyev, A.; Solberg, B.; Kallio, A.M.I. Wood biomass use for energy in Europe under different assumptions of coal, gas and CO2 emission prices and market conditions. J. For. Econ. 2013, 19, 432–449. [Google Scholar] [CrossRef]

| Code | Name of the Node | Municipality |

|---|---|---|

| PM | Pozo María Luisa-Samuño | Langreo |

| PSo | Pozo Sotón | San Martín del Rey Aurelio |

| PSa | Pozo Santiago | Aller |

| PMo | Pozo Montsacro | Riosa |

| PS | Pozo San Nicolás | Mieres |

| PC | Pozo Candín | Langreo |

| PCa | Pozo Carrio | Laviana |

| Type of Fuel | Calorific Value (CVi) (GJ/t) |

|---|---|

| Brown coal | 18.8 |

| Distilled oil | 41.2 |

| Natural gas | 45.6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paredes-Sánchez, B.M.; Paredes-Sánchez, J.P.; García-Nieto, P.J. Energy Multiphase Model for Biocoal Conversion Systems by Means of a Nodal Network. Energies 2020, 13, 2728. https://doi.org/10.3390/en13112728

Paredes-Sánchez BM, Paredes-Sánchez JP, García-Nieto PJ. Energy Multiphase Model for Biocoal Conversion Systems by Means of a Nodal Network. Energies. 2020; 13(11):2728. https://doi.org/10.3390/en13112728

Chicago/Turabian StyleParedes-Sánchez, Beatriz M., José P. Paredes-Sánchez, and Paulino J. García-Nieto. 2020. "Energy Multiphase Model for Biocoal Conversion Systems by Means of a Nodal Network" Energies 13, no. 11: 2728. https://doi.org/10.3390/en13112728

APA StyleParedes-Sánchez, B. M., Paredes-Sánchez, J. P., & García-Nieto, P. J. (2020). Energy Multiphase Model for Biocoal Conversion Systems by Means of a Nodal Network. Energies, 13(11), 2728. https://doi.org/10.3390/en13112728