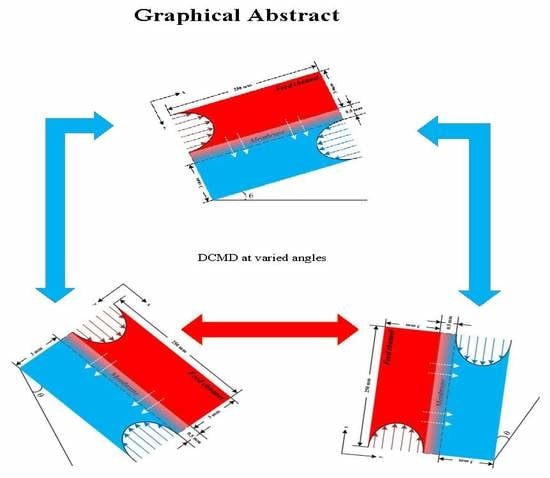

The Effect of Inclination Angle and Reynolds Number on the Performance of a Direct Contact Membrane Distillation (DCMD) Process

Abstract

:1. Introduction

- (1)

- The operating temperature and pressure are lower than the conventional processes.

- (2)

- The ability to produce high-quality pure water.

- (3)

- The renewable energy can be used as a source of energy for driving the process.

- (4)

- The operation, and utilization, of the solvents is simple.

- (5)

- It is a compact process with scalability and economic viability.

- (6)

- It has the ability for rejections, colloids, and other non-volatile components, at a rate of 100 percent.

- (7)

- It is fully automated, and it does not have any moving configuration compared to the MSF process.

2. Problem Statement

3. Governing Equations and Assumptions

4. Modeling Approach

4.1. Grid-Independent Study

4.2. Validation

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Alhathal Alanezi, A.; Sharif, A.O.; Sanduk, M.I.; Khan, A.R. Potential of membrane distillation—A comprehensive review. Int. J. Water 2013, 7, 317. [Google Scholar] [CrossRef]

- Elhenawy, Y.; Elminshawy, N.A.; Bassyouni, M.; Alhathal Alanezi, A.; Drioli, E. Experimental and theoretical investigation of a new air gap membrane distillation module with a corrugated feed channel. J. Membr. Sci. 2020, 594, 117461. [Google Scholar] [CrossRef]

- Alklaibi, A.; Lior, N. Membrane-distillation desalination: Status and potential. Desalination 2005, 171, 111–131. [Google Scholar] [CrossRef]

- Elmarghany, M.R.; El-Shazly, A.H.; Salem, M.S.; Sabry, M.N.; Nady, N. Thermal analysis evaluation of direct contact membrane distillation system. Case Stud. Therm. Eng. 2019, 13, 100377. [Google Scholar] [CrossRef]

- Shirazi, M.M.A.; Kargari, A.; Shirazi, M.J.A. Direct contact membrane distillation for seawater desalination. Desalination Water Treat. 2012, 49, 368–375. [Google Scholar] [CrossRef]

- Alhathal Alanezi, A.; Sharif, A.O.; Sanduk, M.I.; Khan, A.R. Experimental Investigation of Heat and Mass Transfer in Tubular Membrane Distillation Module for Desalination. ISRN Chem. Eng. 2012, 2012, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Li, Q.; Beier, L.-J.; Tan, J.; Brown, C.; Lian, B.; Zhong, W.; Wang, Y.; Ji, C.; Dai, P.; Li, T.; et al. An integrated, solar-driven membrane distillation system for water purification and energy generation. Appl. Energy 2019, 237, 534–548. [Google Scholar] [CrossRef]

- Abdallah, H.; Moustafa, A.; Alhathal Alanezi, A.; El-Sayed, H. Performance of a newly developed titanium oxide nanotubes/polyethersulfone blend membrane for water desalination using vacuum membrane distillation. Desalination 2014, 346, 30–36. [Google Scholar] [CrossRef]

- Qtaishat, M.R.; Banat, F. Desalination by solar powered membrane distillation systems. Desalination 2013, 308, 186–197. [Google Scholar] [CrossRef]

- Koschikowski, J.; Wieghaus, M.; Rommel, M.; Ortín, V.S.; Suarez, B.P.; Rodríguez, J.R.B. Experimental investigations on solar driven stand-alone membrane distillation systems for remote areas. Desalination 2009, 248, 125–131. [Google Scholar] [CrossRef]

- Saffarini, R.B.; Summers, E.K.; Arafat, H.A. Technical evaluation of stand-alone solar powered membrane distillation systems. Desalination 2012, 286, 332–341. [Google Scholar] [CrossRef]

- Camacho, L.M.; Dumée, L.F.; Zhang, J.; Li, J.-D.; Duke, M.; Gomez, J.; Gray, S. Advances in Membrane Distillation for Water Desalination and Purification Applications. Water 2013, 5, 94–196. [Google Scholar] [CrossRef] [Green Version]

- Curcio, E.; Drioli, E. Membrane Distillation and Related Operations—A Review. Sep. Purif. Rev. 2005, 34, 35–86. [Google Scholar] [CrossRef]

- Fane, A. (Tony) A grand challenge for membrane desalination: More water, less carbon. Desalination 2018, 426, 155–163. [Google Scholar] [CrossRef]

- Alhathal Alanezi, A. Performance Enhancement of Air Bubbling and Vacuum Membrane Distillation for Water Desalination. Ph.D. Thesis, University of Surrey, Guildford, UK, 2013. Available online: https://ethos.bl.uk/OrderDetails.do?uin=uk.bl.ethos.576164 (accessed on 18 April 2013).

- Fath, H.E.; Elsherbiny, S.M.; Hassan, A.A.; Rommel, M.; Wieghaus, M.; Koschikowski, J.; Vatansever, M. PV and thermally driven small-scale, stand-alone solar desalination systems with very low maintenance needs. Desalination 2008, 225, 58–69. [Google Scholar] [CrossRef]

- Alsalhy, Q.F.; Ibrahim, S.S.; Khaleel, S.R. Performance of vacuum poly(propylene) membrane distillation (VMD) for saline water desalination. Chem. Eng. Process. Process. Intensif. 2017, 120, 68–80. [Google Scholar] [CrossRef]

- Jamed, M.J.; Alhathal Alanezi, A.; Alsalhy, Q.F. Effects of embedding functionalized multi-walled carbon nanotubes and alumina on the direct contact poly(vinylidene fluoride-co-hexafluoropropylene) membrane distillation performance. Chem. Eng. Commun. 2018, 206, 1035–1057. [Google Scholar] [CrossRef]

- Schofield, R.; Fane, A.; Fell, C. Heat and mass transfer in membrane distillation. J. Membr. Sci. 1987, 33, 299–313. [Google Scholar] [CrossRef]

- Alhathal Alanezi, A.; Abdallah, H.; El Zanati, E.; Ahmad, A.; Sharif, A.O. Performance Investigation of O-Ring Vacuum Membrane Distillation Module for Water Desalination. J. Chem. 2016, 2016, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Duong, H.; Chivas, A.; Nelemans, B.; Duke, M.; Gray, S.; Cath, T.Y.; Nghiem, L.D. Treatment of RO brine from CSG produced water by spiral-wound air gap membrane distillation—A pilot study. Desalination 2015, 366, 121–129. [Google Scholar] [CrossRef] [Green Version]

- Wang, P.; Chung, T.-S.; Chung, T.-S. Recent advances in membrane distillation processes: Membrane development, configuration design and application exploring. J. Membr. Sci. 2015, 474, 39–56. [Google Scholar] [CrossRef]

- Shirazi, M.M.A.; Kargari, A.; Ismail, A.F.; Matsuura, T. Computational Fluid Dynamic (CFD) opportunities applied to the membrane distillation process: State-of-the-art and perspectives. Desalination 2016, 377, 73–90. [Google Scholar] [CrossRef]

- Summers, E.K.; Arafat, H.A.; Lienhard, J.H. Energy efficiency comparison of single-stage membrane distillation (MD) desalination cycles in different configurations. Desalination 2012, 290, 54–66. [Google Scholar] [CrossRef]

- Alhathal Alanezi, A.; Sharif, A. Membrane Distillation: An Attractive Alternative. Arab Water World (AWW) 2012, 36, 16–18. [Google Scholar]

- Ibrahim, S.S.; Alsalhy, Q.F. Modeling and simulation for direct contact membrane distillation in hollow fiber modules. AIChE J. 2012, 59, 589–603. [Google Scholar] [CrossRef]

- Ramlow, H.; Machado, R.A.F.; Marangoni, C. Direct contact membrane distillation for textile wastewater treatment: A state of the art review. Water Sci. Technol. 2017, 76, 2565–2579. [Google Scholar] [CrossRef]

- Mokhtar, N.; Lau, W.; Ismail, A.F.; Veerasamy, D. Membrane Distillation Technology for Treatment of Wastewater from Rubber Industry in Malaysia. Procedia CIRP 2015, 26, 792–796. [Google Scholar] [CrossRef] [Green Version]

- Zakrzewska-Trznadel, G. Membrane processes in nuclear technology-application for liquid radioactive waste treatment. Sep. Purif. Technol. 2001, 22, 617–625. [Google Scholar] [CrossRef]

- El-Abbassi, A.; Hafidi, A.; Khayet, M.; García-Payo, M.C. Integrated direct contact membrane distillation for olive mill wastewater treatment. Desalination 2013, 323, 31–38. [Google Scholar] [CrossRef]

- Hausmann, A.; Sanciolo, P.; Vasiljevic, T.; Kulozik, U.; Duke, M. Performance assessment of membrane distillation for skim milk and whey processing. J. Dairy Sci. 2014, 97, 56–71. [Google Scholar] [CrossRef] [Green Version]

- Hitsov, I.; Maere, T.; De Sitter, K.; Dotremont, C.; Nopens, I. Modelling approaches in membrane distillation: A critical review. Sep. Purif. Technol. 2015, 142, 48–64. [Google Scholar] [CrossRef]

- Ali, A.; Macedonio, F.; Drioli, E.; Aljlil, S.; Alharbi, O. Experimental and theoretical evaluation of temperature polarization phenomenon in direct contact membrane distillation. Chem. Eng. Res. Des. 2013, 91, 1966–1977. [Google Scholar] [CrossRef]

- Tamburini, G.A.; Micale, M.; Ciofalo, A. Cipollina, Experimental analysis via thermochromic liquid crystals of the temperature local distribution in membrane distillation modules. Chem. Eng. Trans. 2013, 32, 2041–2046. [Google Scholar]

- Tamburini, A.; Pitò, P.; Cipollina, A.; Micale, G.; Ciofalo, M. A Thermochromic Liquid Crystals Image Analysis technique to investigate temperature polarization in spacer-filled channels for Membrane Distillation. J. Membr. Sci. 2013, 447, 260–273. [Google Scholar] [CrossRef] [Green Version]

- Rezakazemi, M. CFD simulation of seawater purification using direct contact membrane desalination (DCMD) system. Desalination 2018, 443, 323–332. [Google Scholar] [CrossRef]

- Shakaib, M.; Hasani, S.; Ahmed, I.; Yunus, R.M. A CFD study on the effect of spacer orientation on temperature polarization in membrane distillation modules. Desalination 2012, 284, 332–340. [Google Scholar] [CrossRef]

- Al-Sharif, S.; Albeirutty, M.; Cipollina, A.; Micale, G. Modelling flow and heat transfer in spacer-filled membrane distillation channels using open source CFD code. Desalination 2013, 311, 103–112. [Google Scholar] [CrossRef]

- Mabrouk, A.N.; Elhenawy, Y.; Abdelkader, M.; Shatat, M. The impact of baffle orientation on the performance of the hollow fiber membrane distillation. Desalin. Water Treat. 2017, 58, 35–45. [Google Scholar] [CrossRef]

- Bui, V.A.; Vu, L.; Nguyen, M.H. Modelling the simultaneous heat and mass transfer of direct contact membrane distillation in hollow fibre modules. J. Membr. Sci. 2010, 353, 85–93. [Google Scholar] [CrossRef]

- Janajreh, I.; Suwwan, D. Numerical simulation of Direct Contact Membrane Desalination in conjugate heat transfer configuration: Role of Membrane Conductivity. Sustain. Water Environ. Syst. 2014, 6, 81–87. [Google Scholar]

- Tang, N.; Zhang, H.; Wang, W. Computational fluid dynamics numerical simulation of vacuum membrane distillation for aqueous NaCl solution. Desalination 2011, 274, 120–129. [Google Scholar] [CrossRef]

- Awad, M.; Janajreh, I.; Fath, H.; Awad, M. Low Energy Direct Contact Membrane Distillation: Towards optimal flow configuration. In Proceedings of the 2013 International Renewable and Sustainable Energy Conference (IRSEC), Ouarzazate, Morocco, 7–9 March 2013; pp. 471–476. [Google Scholar]

- Janajreh, I.; El Kadi, K.; Al Hammadie, N.; Hashaikeh, R. Direct contact membrane distillation: The role of membrane porosity. Desalination Water Treat. 2017, 100, 258–267. [Google Scholar] [CrossRef]

- Chen, T.-C.; Ho, C.-D.; Yeh, H.-M. Theoretical modeling and experimental analysis of direct contact membrane distillation. J. Membr. Sci. 2009, 330, 279–287. [Google Scholar] [CrossRef]

- Bahmanyar, A.; Asghari, M.; Khoobi, N. Numerical simulation and theoretical study on simultaneously effects of operating parameters in direct contact membrane distillation. Chem. Eng. Process. Process. Intensif. 2012, 61, 42–50. [Google Scholar] [CrossRef]

- Janajreh, I.; Hussain, M.N.; Hashaikeh, R.; Ahmed, R. Thermal efficiency enhancement of the direct contact membrane distillation: Conductive layer integration and geometrical undulation. Appl. Energy 2018, 227, 7–17. [Google Scholar] [CrossRef]

- Gopi, G.; Arthanareeswaran, G.; Ismail, A.F. Perspective of renewable desalination by using membrane distillation. Chem. Eng. Res. Des. 2019, 144, 520–537. [Google Scholar] [CrossRef]

- Khayet, M.; Matsuura, T. Membrane Distillation: Principles and Applications; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Janajreh, I.; El Kadi, K.; Hashaikeh, R.; Ahmed, R. Numerical investigation of air gap membrane distillation (AGMD): Seeking optimal performance. Desalination 2017, 424, 122–130. [Google Scholar] [CrossRef]

- Ho, C.-D.; Chang, H.; Chang, C.-L.; Huang, C.-H. Theoretical and experimental studies of flux enhancement with roughened surface in direct contact membrane distillation desalination. J. Membr. Sci. 2013, 433, 160–166. [Google Scholar] [CrossRef]

- Karimipour, A. A novel case study for thermal radiation through a nanofluid as a semitransparent medium via discrete ordinates method to consider the absorption and scattering of nanoparticles along the radiation beams coupled with natural convection. Int. Commun. Heat Mass Transf. 2017, 87, 256–269. [Google Scholar] [CrossRef]

- Janajreh, I.; Suwwan, D.; Hashaikeh, R. Theoretical and experimental study of direct contact membrane distillation. Desalination Water Treat. 2015, 57, 15660–15675. [Google Scholar] [CrossRef]

- Goodarzi, M.; Safaei, M.R.; Vafai, K.; Ahmadi, G.; Dahari, M.; Kazi, S.; Jomhari, N. Investigation of nanofluid mixed convection in a shallow cavity using a two-phase mixture model. Int. J. Therm. Sci. 2014, 75, 204–220. [Google Scholar] [CrossRef]

- Safaei, M.R.; Togun, H.; Vafai, K.; Kazi, S.N.; Badarudin, A. Investigation of Heat Transfer Enhancement in a Forward-Facing Contracting Channel Using FMWCNT Nanofluids. Numer. Heat Transfer Part A Appl. 2014, 66, 1321–1340. [Google Scholar] [CrossRef]

- Gheynani, A.R.; Akbari, O.A.; Zarringhalam, M.; Shabani, G.A.S.; A Alnaqi, A.; Goodarzi, M.; Toghraie, D. Investigating the effect of nanoparticles diameter on turbulent flow and heat transfer properties of non-Newtonian carboxymethyl cellulose/CuO fluid in a microtube. Int. J. Numer. Methods Heat Fluid Flow 2019, 29, 1699–1723. [Google Scholar] [CrossRef]

- Amiri, M.H.; Keshavarzi, A.; Karimipour, A.; Bahiraei, M.; Goodarzi, M.; Esfahani, J.A. A 3-D numerical simulation of non-Newtonian blood flow through femoral artery bifurcation with a moderate arteriosclerosis: Investigating Newtonian/non-Newtonian flow and its effects on elastic vessel walls. Heat Mass Transf. 2019, 55, 2037–2047. [Google Scholar] [CrossRef]

- Goodarzi, M.; Javid, S.; Sajadifar, A.; Nojoomizadeh, M.; Motaharipour, S.H.; Bach, Q.-V.; Karimipour, A. Slip velocity and temperature jump of a non-Newtonian nanofluid, aqueous solution of carboxy-methyl cellulose/aluminum oxide nanoparticles, through a microtube. Int. J. Numer. Methods Heat Fluid Flow 2019, 29, 1606–1628. [Google Scholar] [CrossRef]

- Singh, D.; Sirkar, K.K. Performance of PVDF flat membranes and hollow fibers in desalination by direct contact membrane distillation at high temperatures. Sep. Purif. Technol. 2017, 187, 264–273. [Google Scholar] [CrossRef]

- Kamalgharibi, M.; Hormozi, F.; Zamzamian, S.A.; Sarafraz, M.M. Experimental studies on the stability of CuO nanoparticles dispersed in different base fluids: Influence of stirring, sonication and surface active agents. Heat Mass Transf. 2015, 52, 55–62. [Google Scholar] [CrossRef]

- Nakhjavani, M.; Nikkhah, V.; Shoja, S.; Sarafraz, M.M.; Sarafraz, M. Green synthesis of silver nanoparticles using green tea leaves: Experimental study on the morphological, rheological and antibacterial behaviour. Heat Mass Transf. 2017, 53, 3201–3209. [Google Scholar] [CrossRef]

- Salari, E.; Peyghambarzadeh, S.; Sarafraz, M.M.; Hormozi, F.; Nikkhah, V. Thermal behavior of aqueous iron oxide nano-fluid as a coolant on a flat disc heater under the pool boiling condition. Heat Mass Transf. 2016, 53, 265–275. [Google Scholar] [CrossRef]

- Sarafraz, M.M. Experimental Investigation on Pool Boiling Heat Transfer to Formic Acid, Propanol and 2-Butanol Pure Liquids under the Atmospheric Pressure. J. Appl. Fluids 2013, 6, 73–79. [Google Scholar]

- Sarafraz, M.M.; Arjomandi, M. Thermal performance analysis of a microchannel heat sink cooling with copper oxide-indium (CuO/In) nano-suspensions at high-temperatures. Appl. Therm. Eng. 2018, 137, 700–709. [Google Scholar] [CrossRef]

- Sarafraz, M.M.; Arya, A.; Hormozi, F.; Nikkhah, V. On the convective thermal performance of a CPU cooler working with liquid gallium and CuO/water nanofluid: A comparative study. Appl. Therm. Eng. 2017, 112, 1373–1381. [Google Scholar] [CrossRef]

- Sarafraz, M.M. Thermal Performance and Viscosity of Biologically Produced Silver/Coconut Oil Nanofluids. Chem. Biochem. Eng. Q. 2017, 30, 489–500. [Google Scholar] [CrossRef]

- Sarafraz, M.M.; Hormozi, F. Intensification of forced convection heat transfer using biological nanofluid in a double-pipe heat exchanger. Exp. Therm. Fluid Sci. 2015, 66, 279–289. [Google Scholar] [CrossRef]

- Sarafraz, M.M.; Hormozi, F.; Kamalgharibi, M. Sedimentation and convective boiling heat transfer of CuO-water/ethylene glycol nanofluids. Heat Mass Transf. 2014, 50, 1237–1249. [Google Scholar] [CrossRef]

- Sarafraz, M.M.; Hormozi, F.; Peyghambarzadeh, S. Role of nanofluid fouling on thermal performance of a thermosyphon: Are nanofluids reliable working fluid? Appl. Therm. Eng. 2015, 82, 212–224. [Google Scholar] [CrossRef]

- Alhathal Alanezi, A.; Altaee, A.; Sharif, A.O. The effect of energy recovery device and feed flow rate on the energy efficiency of reverse osmosis process. Chem. Eng. Res. Des. 2020, 158, 12–23. [Google Scholar] [CrossRef]

- Sarafraz, M.M.; Nikkhah, V.; Nakhjavani, M.; Arya, A. Thermal performance of a heat sink microchannel working with biologically produced silver-water nanofluid: Experimental assessment. Exp. Therm. Fluid Sci. 2018, 91, 509–519. [Google Scholar] [CrossRef]

- Sarafraz, M.M.; Hormozi, F. Convective boiling and particulate fouling of stabilized CuO-ethylene glycol nanofluids inside the annular heat exchanger. Int. Commun. Heat Mass Transf. 2014, 53, 116–123. [Google Scholar] [CrossRef]

- Manawi, Y.; Khraisheh, M.; Fard, A.K.; Benyahia, F.; Adham, S. Effect of operational parameters on distillate flux in direct contact membrane distillation (DCMD): Comparison between experimental and model predicted performance. Desalination 2014, 336, 110–120. [Google Scholar] [CrossRef]

| Material | Density (kg/m3) | Heat Capacity (J/kg K) | Thermal Conductivity (W/m K) | Viscosity (pas) |

|---|---|---|---|---|

| Polyvinylidene fluoride (PVDF) | 1175 | 1325 | 0.2622 | - |

| Vapor | 0.554 | 2014 | 0.0261 | - |

| Membrane | 302.2 | 1896.9 | 0.0662 | - |

| Saline sea water | 1013.2 | 4064.8 | 0.642 | 5.86 × 10−4 |

| Pure water | 995.2 | 4182.1 | 0.613 | 8.38 × 10−4 |

| Number of Meshes | Position | h (W/m2 K) |

|---|---|---|

| 262,500 | Bottom | 1035.2397 |

| Top | 1052.0011 | |

| 350,000 | Bottom | 999.0980 |

| Top | 980.1226 | |

| 420,000 | Bottom | 1032.7790 |

| Top | 1049.6522 | |

| 525,000 | Bottom | 1031.4225 |

| Top | 1048.5602 | |

| 700,000 | Bottom | 1031.0755 |

| Top | 1048.1479 | |

| 960,000 | Bottom | 1030.9573 |

| Top | 1048.0280 |

| Section | Simulation Temperature (K) | Ref. [50] | Difference (%) | |||

|---|---|---|---|---|---|---|

| - | Top Membrane | Top Bulk | Top Membrane | Top Bulk | Top Membrane | Top Bulk |

| 0.05 | 346.4882 | 347.5521 | 342.467 | 348.136 | 1.174 | 0.167 |

| 0.1 | 346.0447 | 347.20441 | 341.017 | 347.872 | 1.47 | 0.19 |

| 0.15 | 345.6948 | 346.88848 | 339.831 | 346.817 | 1.72 | 0.02 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alanezi, A.A.; Safaei, M.R.; Goodarzi, M.; Elhenawy, Y. The Effect of Inclination Angle and Reynolds Number on the Performance of a Direct Contact Membrane Distillation (DCMD) Process. Energies 2020, 13, 2824. https://doi.org/10.3390/en13112824

Alanezi AA, Safaei MR, Goodarzi M, Elhenawy Y. The Effect of Inclination Angle and Reynolds Number on the Performance of a Direct Contact Membrane Distillation (DCMD) Process. Energies. 2020; 13(11):2824. https://doi.org/10.3390/en13112824

Chicago/Turabian StyleAlanezi, Adnan Alhathal, Mohammad Reza Safaei, Marjan Goodarzi, and Yasser Elhenawy. 2020. "The Effect of Inclination Angle and Reynolds Number on the Performance of a Direct Contact Membrane Distillation (DCMD) Process" Energies 13, no. 11: 2824. https://doi.org/10.3390/en13112824

APA StyleAlanezi, A. A., Safaei, M. R., Goodarzi, M., & Elhenawy, Y. (2020). The Effect of Inclination Angle and Reynolds Number on the Performance of a Direct Contact Membrane Distillation (DCMD) Process. Energies, 13(11), 2824. https://doi.org/10.3390/en13112824