Classification of Three-Phase Grid-Tied Microinverters in Photovoltaic Applications

Abstract

:1. Introduction

2. Traditional and Recent PV Architectures

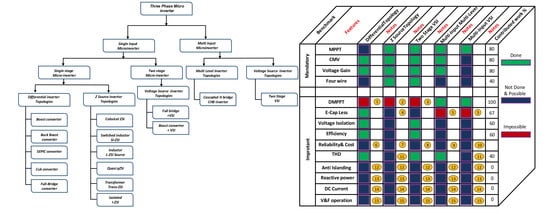

- ✓

- Low cost powered by mass production.

- ✓

- High modularity and simple design.

- ✓

- Minimum installation time due to easy plug-and-play feature.

- ✓

- Low mismatch losses.

- ✓

- High safety without hazardous high voltage DC cables.

3. Why Three-Phase Microinverters

- ○

- This exciting feature opens the way for using small and low cost film capacitors to damp high switching frequency harmonics that expand the life and reliability of the PV architecture.

- ○

- The low voltage ripple enhances the tracking efficiency of the MPPT controller.

- ○

- Multiple units are not required due to inherent three-phase balancing feature.

- ○

- Reduction of cost by using single three-phase microinverter instead of three single-phase microinverter units in high power applications.

- ○

- Naturally controlled through three-phase central power system operation.

- ○

- Three-phase microinverters process more power with the additional four-wire operation.

- ○

- The unbalance that may occur between the different single-phase inverters complicates the system planning, which does not exist in three-phase microinverter topologies.

- ○

- The multiple-input three-phase microinverters have a feature of load sharing which results in high system performance.

4. Three-Phase Microinverters, Architectures, Standards, and Requirements

4.1. Required Features of PV Modules

4.1.1. MPPT Operation

- ✓

- High tracking efficiency: This is accomplished using microinverters having continuous input current with minimal input voltage and current ripple because there is an inverse relationship between MPPT tracking efficiency and input PV module ripples.

- ✓

- Robust dynamic response: This factor depends on the control performance rather than selected topology. That is why the authors focused on topologies with simple controls.

- ✓

- High speed and low processing power: This defines the used control boards and the computational time which is also related to reliability.

4.1.2. Common Mode Voltage

4.2. Required Internal Features of Three-Phase Microinverters

4.2.1. DMPPT

4.2.2. Electrolyte-Less Capacitor

4.2.3. High Voltage Gain

4.2.4. Four-Wire System

4.2.5. Voltage Isolation

4.2.6. Conversion Efficiency

4.2.7. Component Cost and Reliability

- ○

- The number of components and their ratings.

- ○

- Low power loss and low heat dissipation will diminish heat sinks, which decrease the overall cost.

- ○

- Operating switching frequency because it determines the size and cost of passive elements.

- ○

- Power density improves the consumed printed circuit board (PCB) area and its packaging technology.

- ○

- Type of the implemented controller: analog or digital, its effective MPP tracking, and number of used loops can improve the overall system efficiency and related cost.

4.3. Required Features of Grid Side

4.3.1. Total Harmonic Distortion

4.3.2. DC Current Injection

4.3.3. Anti-Islanding Operation

4.3.4. Reactive Power Control

4.3.5. Voltage and Frequency Operation

4.4. Required Features Summary

5. Recent Topologies of Three-Phase Microinverters

5.1. Single-Input Single-Stage Microinverter Topologies

5.1.1. Three-Phase Differential Inverter

- ○

- ○

- ○

- High voltage gain: High voltage gain is necessary for microinverter topologies because of the low voltage of PV modules. In buck-boost and boost converters, high voltage can be effectively achieved. Moreover, a very high voltage gain is possible in isolated topologies utilizing the turn ratio of HFL transformer in addition to the conversion gain of the converter keeping in mind the relationship between HFL transformer turns ratio and its efficiency.

- ○

- ○

- DMPPT: DMPPT techniques have not been issued in these topologies because they use a single-input PV module(s).

- ○

- Electrolytic-less capacitor (E-less cap): Since differential three-phase inverters share small capacitors, they can be used with an electrolytic-less capacitor. Moreover, the parallel connection of theses converters on the input side cancels inherent double line frequency, which leads to the use of small input film capacitors.

- ○

- Voltage isolation: HFL transformer integration is proposed in topologies shown in Figure 9a,b to increase the power density and achieve voltage isolation. This also increases safety.

- ○

- Conversion efficiency: The reported maximum efficiency is about 95% for SEPIC topology shown in Figure 8c.

- ○

- Component count: Figure 10 shows a detailed element counts comparison of differential three-phase microinverters. All passive elements, inductors, and capacitors of DC-DC converters, HFL transformers, and switches are counted. Table 2 gives the switches voltage stresses. It can be noticed that the topology of Figure 8d has the lowest components count among the presented topologies.

- ○

- Reliability: To support reliability issues, many control techniques such as sliding mode control (SMC) and proportional resonant (PR) have been proposed for topologies shown in Figure 8a and Figure 8b, respectively. From Table 2, the SEPIC converter has the lowest voltage stress. For reliable operation, DCM is proposed in topology D5, and soft switching is proposed in topology D6.

- ○

- THD: The lowest THD is performed in topology D3, and the maximum reported THD is in topology D1.

- ○

- Anti-islanding operation: Concerning the previously mentioned PV based differential inverter topologies, there is no discussion about anti-islanding operation. Therefore, it could be of interest to discuss this issue for these topologies in future work.

- ○

- Reactive power control: Reactive power increases as circulating currents exist and so it is important to assure a good control design that presents the existence of current circulating. The selected topologies D1–D6 should be examined for the existence of circulating current and the reactive power.

- ○

- DC current injection: This feature should be tested, especially for transformer-less topologies D1–D4.

- ○

- Voltage and frequency operation: In topologies D1–D6, this issue should be tested in different conditions and different scenarios.

5.1.2. Three-Phase Z Source Inverter

- ○

- MPPT operation: For high tracking efficiency, continuous input Z-source microinverter topologies such as qZSI [100] are preferred.

- ○

- ○

- ○

- ○

- DMPPT: Based on the authors’ knowledge, DMPPT-related research for PV modules with Z-source inverters was not reported in the literature as it uses a single-input PV source.

- ○

- Electrolytic-less capacitor (E-less cap): The most effective topology among Z-source microinverter topologies is L-ZSI because the capacitor is totally omitted, resulting in less electrolytic-less capacitor topology. On the other hand, in traditional Z-source microinverters [88,89,94], the Z network’s capacitor is still large and requires an electrolytic capacitor. Finally, for qZSI topology and trans-Z-source topologies [100,102], this capacitor is still 25% larger than the electrolytic-less capacitor.

- ○

- Voltage isolation: Isolated ZSI [103] is considered a good solution for three-phase microinverters, but it has a high number of components.

- ○

- Conversion efficiency: The conversion efficiency of Z-source microinverter topologies is still lower than VSI microinverter.

- ○

- Component cost:Figure 17 presents the number of components of each topology. Classical ZSI, L-ZSI, and QZSI have the lowest number of components, which decrease the overall cost.

- ○

- ○

- ○

- Anti-islanding operation: According to the previously discussed PV-fed Z-source topologies, there is no discussion about the anti-islanding operation. However, a proper control design, which detects anti-islanding conditions, requires careful integration and design for the previously discussed topologies.

- ○

- ○

- ○

- Voltage and frequency operation: These features should be tested and improved by using different voltage controllers and different modulation techniques.

5.2. Single-Input Two-Stage Microinverter Topologies

Voltage Source Inverter Topologies

- ○

- MPPT operation: For V1, the CPI MPPT algorithm is proposed for high tracking efficiency. For V3, the incremental conductance MPPT controller is reported.

- ○

- CMV: CMV in V1 and V2 is low due to the utilization of HFL transformer in the full-bridge DC-DC converter. However, CMV is high in V3.

- ○

- High voltage gain: The most interesting topology is V1, where high gain is attained by using resonance frequency of the LLC resonant DC-DC full-bridge converter.

- ○

- Four-wire system: Four-wire system approach was adopted in V1 using a split DC capacitor for PV modules.

- ○

- DMPPT: DMPPT has not been discussed in two-stage VSI inverter topologies V1–V3, as they have a single input PV source. On the other hand, since the first stage can be utilized with multi-input, DMPPT can be achieved.

- ○

- Electrolytic-less capacitor (E-less cap): For topology V1, the DC link capacitor is only about 35 μF, so that the film capacitor can be used. For topologies V2 and V3, an electrolytic-less capacitor is still needed.

- ○

- Voltage isolation: HFL isolation can be implemented in topologies V1 and V2.

- ○

- Conversion efficiency: The highest conversion efficiency, 95.5%, is reported for topology V1. For topology V2, the efficiency is 91.5%.

- ○

- Component cost: Figure 21 presents the number of components of each topology. V3 topology has the lowest number of components, hence the lowest overall cost.

- ○

- Reliability: It depends on the component count, voltage stress, and component values. The switching techniques developed in V1 and V2 can improve the overall system reliability.

- ○

- THD: The reported THD is 5% for all topologies.

- ○

- Anti-islanding operation: At weak grid operation, the previously discussed two-stage VSI topologies V1–V3 cannot operate in islanding operation mode to feed local loads. Therefore, adding this property for these topologies can enhance conversion power performance, especially in DG applications.

- ○

- Reactive power control: For all previously discussed topologies V1–V3, several modifications of PWM techniques can enhance these topologies to perform active and reactive power control.

- ○

- DC Current injection: This feature should be tested for all aforementioned discussed two-stage VSI inverter V1–V3 topologies.

- ○

- Voltage and frequency operation: In topologies V1–V3, the output voltage control was applied, but it needs more tests and investigation.

5.3. Multi-Input Microinverter Topologies

- ○

- Staircase output voltage waveform partially following a sine wave template leads to a low THD with high voltage levels and low voltage stress.

- ○

- Using MLI reduces the voltage transient stresses.

- ○

- Low CMV is introduced in MLIs utilizing split capacitors and proper PWM modulation techniques.

- ○

- Low switching loss is due to low switching frequency.

- ○

- Low distortion in the input current leads to high tracking efficiency of PV modules.

- ○

- Low voltage gains less than unity; therefore, a boost stage is added to increase the voltage hence leading to the use of more components.

- ○

- Reliability concerns due to non-uniform voltage stress and distributed losses.

- ○

- The high transient voltage across the clamped switches is introduced for grid-connected PV architectures.

5.3.1. Cascaded H-Bridge (CHB) Inverter Topologies

- ○

- MPPT operation: MPPT is applied due to independent control of DC-link voltage. However, at severe PV mismatching conditions, this control can fail to select optimum weighing factors between MPPT efficiency of each PV module and output current balance on the grid side [112].

- ○

- CMV: CMV in each H-bridge exists, then different control techniques are used to improve it.

- ○

- High voltage gain: the high voltage conversion ratio can be increased by adding PV modules to increase output voltage stairs with high modularity and flexibility.

- ○

- Four-wire operation: The four-wire operation approach was not reported in these topologies. Although, implementing a four-wire multi-input multi-level three-phase microinverter could be interesting in future PV applications.

- ○

- ○

- Electrolytic-less capacitor (E-less cap): Unfortunately, the aforementioned modular CHB inverter topologies have large electrolyte capacitors due to independent control of each phase, which is similar to single-phase inverter topologies. Therefore, novel solutions to decouple these capacitors could be the subject of future work.

- ○

- Voltage isolation: Up to date, utilizing HFL in multi-input multi-level CHB three-phase inverters has not been proposed.

- ○

- Conversion efficiency: Higher efficiency is expected for most MLIs due to the absence of passive elements. However, no information about this was reported in the literature.

- ○

- Component cost: All the discussed topologies have the same component count, so they have the same cost for the power stage. However, the controller complexity and its cost could be different.

- ○

- Reliability: Although these topologies could enhance the overall reliability by eliminating boost DC-DC converters, they have complex controllers which pose reliability problems. Therefore, working on control simplicity could be a topic of interesting research work.

- ○

- THD: the reported THD is 3.3% according to [61].

- ○

- Anti-islanding operation: According to the existing works on the previous CHB topologies, there is no discussion about anti-islanding operation. However, proper control design with high accurate anti-islanding detection is preferred.

- ○

- Reactive power control: Good controller design can improve the reactive power control.

- ○

- DC current injection: It is not reported here and based on IEEE 1547 standard; it is specified to be less than 0.5% of the rated output current of up to 1% based on IEC 61727.

- ○

- Voltage and frequency operation: IEC 62446 for PV system and IEC 61683 standard for inverter testing, in addition to the IEEE 1547 standard, defines the range of voltage frequency variation at the coupling point with the grid. Then, all systems should control its generated power with the voltage control and frequency limit.

5.3.2. Two-Stage Multi-Input VSI Topologies

- ○

- MPPT operation: MPPT is applied and controlled by the boost converter on each input.

- ○

- CMV: CMV can be obtained by using a proper controller.

- ○

- High voltage gain: A high voltage gain can be obtained by increasing the voltage gain of the conventional (boost) DC optimizer or by using isolated DC-DC converters with a high turns ratio for their HFL transformer.

- ○

- Four-wire operation: Four-wire operation approach was not reported for this topology.

- ○

- DMPPT: DMPPT in the proposed topology is obtained by control of the DC optimizer boost on each input. Therefore, at partial shading conditions, each boost converter operates independently to extract the maximum power that the corresponding source can provide independently of the other sources.

- ○

- Electrolytic-less capacitor (E-less cap): DC link capacitor is similar to the capacitor utilized in single-input two-stage microinverters.

- ○

- Voltage isolation: This feature is not reported for this topology. This can be obtained by using isolated DC-DC converters such as flyback and isolated SEPIC converters.

- ○

- Conversion efficiency: The reported conversion efficiency is about 87% [106].

- ○

- Component cost: It is considered a low cost compared to the traditional two stages of VSI-based PV systems.

- ○

- Reliability: The control has two loops, the internal one for current and the external one for voltage. Simplifying this control can enhance overall reliability.

- ○

- THD: No information was reported about the THD for this topology.

- ○

- Anti-islanding operation: No information was reported about the anti-islanding operation in this topology.

- ○

- Reactive power control: This feature is not reported for this topology.

- ○

- DC current injection: It is not reported here and based on IEEE 1547 standard; it is specified to be less than 0.5% of the rated output current of up to 1% based on IEC 61727.

- ○

- Voltage and frequency operation: This issue should be tested in different conditions and different scenarios.

6. Discussion of Three-Phase Microinverter Topologies

- The best topologies of differential microinverters are HFL-based SEPIC and Cuk differential topologies.

- The best topology at Z-source microinverters is L-ZSI topology.

- The best topology at two-stage VSIs is LLC resonant microinverter.

- ✓

- Level 1 (done): This means that this topology implemented this feature in the literature. It gets a full mark.

- ✓

- Level 2 (not done but it is possible): This level examines the topology’s capability to achieve the required feature through extension by added circuit/technique in the future. It gets an average mark.

- ✓

- Level 3 (impossible): This means the impossibility of the topology to fulfill the required three-phase microinverter features. It gets a zero mark.

- ✓

- The primary weakness of single-input microinverters (including differential, Z-source, and two-stage VSI topologies) is the DMPPT because it could lead to phase unbalances.

- ✓

- The main shortcoming of multi-input inverter topology is its disability to minimize the employed electrolytic capacitor. Solving this issue using different decoupling techniques will enhance converter reliability.

- ✓

- As illustrated in Figure 25, mandatory features are fulfilled in the Z-source and two-stage VSI topologies. However, most topologies of Z-source inverters still suffer from the use of electrolytic capacitors, which increase size and cost (low mark) in addition to efficiency and other essential factors.

- ✓

- Two-stage VSI topologies need more attention for the last four essential features in addition to reliability and cost. Differential inverter topologies seem to prevail in price and size due to the utilization of the small passive elements of DC-DC converters, which improve efficiency. This target can be achieved by devoting more focus on voltage stress and circulating current and its resultant power losses.

- ✓

- Moreover, four-wire systems, MPPT, and other important features open the door for research and industry to introduce better solutions.

- ✓

- Multi-input multi-level microinverter topologies show the high mark in DMPPT eliminations, reducing the use of electrolyte capacitors, and improving overall efficiency.

- ✓

- The last essential features, such as anti-islanding, reactive power, DC injected current and voltage and frequency operation, have not been reported and examined for all groups.

- ✓

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hasanuzzaman, M.; Zubir, U.S.; Ilham, N.I.; Che, H.S. Global electricity demand, generation, grid system, and renewable energy polices: A review. Wiley Interdiscip. Rev. Energy Environ. 2016, 6, e222. [Google Scholar] [CrossRef]

- Nadeau, M. World Energy Scenarios World Energy Council. 2016. Available online: www.worldenergy.org (accessed on 1 January 2016).

- US Energy Information Administration (EIA). International Energy Outlook 2013 with Projection to 2040. Available online: http://www.eia.gov/forecasts/ieo/ (accessed on 1 July 2013).

- US Energy Information Administration (EIA). Annual Energy Outlook 2017 with Projections to 2050; EIA: Washington, DC, USA, 2017.

- European Photovoltaic Industry Association (EPIA). Global Market Outlook for Photovoltaic until 2016; European Photovoltaic Industry association (EPIA): Brussels, Belgium, May 2012. [Google Scholar]

- Moutinho, V.; Robaina, M. Is the share of renewable energy sources determining the CO2 kWh and income relation in electricity generation? Renew. Sustain. Energy Rev. 2016, 65, 902–914. [Google Scholar] [CrossRef]

- Ardian, K. Solar Technologies Market Report; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2010. [Google Scholar]

- Hoffmann, W. PV on the Way from a few lead markets to a world market. In Proceedings of the 4th IEEE World Conference on Photovoltaic Energy Conversion, Waikoloa, HI, USA, 7–12 May 2006; pp. 2454–2456. [Google Scholar] [CrossRef]

- Feldman, D.; Barbose, G.; Margolis, R.; Wiser, R.; Darghouth, N.; Goodrich1, A. Photovoltaic (PV) Pricing Trends: Historical, Recent, and Near-Term Projections; Report, SunShot; US Department of Energy: Washington, DC, USA, 2012. [Google Scholar]

- Petrakopoulou, F. On the economics of stand-alone renewable hybrid power plants in remote regions. Energy Convers. Manag. 2016, 118, 63–74. [Google Scholar] [CrossRef] [Green Version]

- Torreglosa, J.P.; Garcia-Trivino, P.; Fernandez-Ramirez, L.M.; Jurado, F. Control based on techno-economic optimization of renewable hybrid energy system for stand-alone applications. Expert Syst. Appl. 2016, 51, 59–75. [Google Scholar] [CrossRef]

- Cristóbal-Monreal, I.R.; Dufo-López, R. Optimization of photovoltaic–diesel–battery stand-alone systems minimising system weight. Energy Convers. Manag. 2016, 119, 279–288. [Google Scholar] [CrossRef]

- Sujitha, N.; Krithiga, S. RES based EV battery charging system: A review. Renew. Sustain. Energy Rev. 2017, 75, 978–988. [Google Scholar] [CrossRef]

- Ackermann, T.; Andersson, G.; Söder, L. Distributed generation: A definition. Electr. Power Syst. Res. 2001, 57, 195–204. [Google Scholar] [CrossRef]

- Zhao, Z.; Yin, L.; Sun, X.; Yuan, L.; Lu, T. Recent Development of Technology and Market of Grid-connected PV System in China. In Proceedings of the International Conference on Electrical Machines and Systems, (ICEMS), Incheon, Korea, 10–13 October 2010; pp. 1–6. [Google Scholar]

- Kouro, S.; Leon, J.I.; Vinnikov, D.; Franquelo, L.G. Grid-Connected Photovoltaic Systems: An Overview of Recent Research and Emerging PV Converter Technology. IEEE Ind. Electron. Mag. 2015, 9, 47–61. [Google Scholar] [CrossRef]

- Alluhaybi, K.; Batarseh, I. Review and Comparison of Single-Phase Grid-Tied Photovoltaic Microinverters. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE), Portland, OR, USA, 23–27 September 2018. [Google Scholar]

- Shawky, A. Development of Power Management Systems for Advanced Photovoltaic Architectures. Master’s Thesis, Aswan University, Aswan, Egypt, May 2014. Chapter 1. [Google Scholar]

- Li, Q.; Wolfs, P. A Review of the Single-phase Photovoltaic Module Integrated Converter Topologies with Three Different DC Link Configurations. IEEE Trans. Power Electron. 2008, 23, 1320–1333. [Google Scholar]

- Meneses, D.; Blaabjerg, F.; Garcia, O.; Cobos, J.A. Review and Comparison of Step-Up Transformer less Topologies for Photovoltaic AC-Module Application. IEEE Trans. Power Electron. 2013, 28, 2649–2663. [Google Scholar] [CrossRef] [Green Version]

- Shawky, A.; Shier, A.; Orabi, M.; Qahouq, J.A.M. Youssef High Efficiency Single-stage Current Source Inverter for Photovoltaic Applications. In Proceedings of the 35th IEEE International Telecommunication Energy Conference (INTELEC 2013), Hamburg, Germany, 13–17 October 2013. [Google Scholar]

- Shawky, A.; Orabi, M.; Qahouq, J.A.; Youssef, M. Development and comparative evaluation of power management systems for advanced photovoltaic architectures. In Proceedings of the International Telecommunication Energy Conference (INTELEC 2014), Vancouver, BC, Canada, 28 September–2 October 2014. [Google Scholar]

- Petrone, G.; Spagnuolo, G.; Teodorescu, R.; Veerachary, M.; Vitelli, M. Reliability Issues in Photovoltaic Power Processing Systems. IEEE Trans. Ind. Electron. 2008, 55, 2569–2580. [Google Scholar] [CrossRef]

- Pilawa-Podgurski, R.C.N.; Perreault, D.J. Submodule Integrated Distributed Maximum Power Point Tracking for Solar Photovoltaic Applications. IEEE Trans. Power Electron. 2012, 28, 2957–2967. [Google Scholar] [CrossRef] [Green Version]

- Shenoy, P.S.; Kim, K.; Johnson, B.B.; Krein, P.T. Differential Power Processing for Increased Energy Production and Reliability of Photovoltaic Systems. IEEE Trans. Power Electron. 2013, 28, 1795–1806. [Google Scholar] [CrossRef]

- Shawky, A.; Helmy, F.; Orabi, M.; Qahouq, J.A.; Dang, Z. On chip integrated Cell-Level power management Architecture with MPPT for PV Solar System. In Proceedings of the IEEE Applied Power Electronics Conference, APEC, Fort Worth, TX, USA, 16–20 March 2014. [Google Scholar]

- Shawky, A.; Helmy, F.; Orabi, M.; Ahmed, E.M.; Qahouq, J.A.A. A Single Cell Integrated Photovoltaic Converter Based on Buck-Boost Topology with RCC MPPT Control. In Proceedings of the IEEE International Telecommunication Energy Conference (INTELEC), Hamburg, Germany, 13–17 October 2013. [Google Scholar]

- Orabi, M.; Hilmy, F.; Shawky, A.; Abu Qahouq, J.A.; Hasaneen, E.-S.; Gomaa, E. On-chip integrated power management MPPT controller utilizing cell-level architecture for PV solar system. Sol. Energy 2015, 117, 10–28. [Google Scholar] [CrossRef] [Green Version]

- Shawky, A.; Radwan, H.; Orabi, M.; Youssef, M. A Novel Platform for an Accurate Modeling and Precise Control of Photovoltaic Modules with Maximum Operating Efficiency. In Proceedings of the IEEE Applied Power Electronics Conference & Exposition, Charlotte, NC, USA, 15–19 March 2015. [Google Scholar]

- Zhou, H.; Zhao, J.; Han, Y. PV Balancers: Concept, Architectures, and Realization. IEEE Trans. Power Electron. 2015, 30, 3479–3487. [Google Scholar] [CrossRef]

- MacAlpine, S.; Deline, C. Modeling Microinverters and DC Power Optimizers in PVWatts; Technical Report NREL/TP-5J00-63463; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2015. [Google Scholar]

- Reinders, A.; Verlinden, P.; van Sark, W.; Freundlich, A. Photovoltaic Solar Energy: From Fundamentals to Applications. In Inverters, Power Optimizers and Microinverters, 1st ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2017; Chapter 11. [Google Scholar]

- Deline, C.; MacAlpine, S. Use conditions and efficiency measurements of DC power optimizers for photovoltaic systems. In Proceedings of the 2013 IEEE Energy Conversion Congress and Exposition, Denver, CO, USA, 15–19 September 2013; pp. 4801–4807. [Google Scholar]

- Strache, S.; Wunderlich, R.; Heinen, S. A Comprehensive, Quantitative Comparison of Inverter Architectures for Various PV Systems, PV Cells, and Irradiance Profiles. IEEE Trans. Sustain. Energy 2014, 5, 813–822. [Google Scholar] [CrossRef]

- Mazumdar, P.; Enjeti, P.N.; Balog, R.S. Analysis and Design of Smart PV Modules. IEEE J. Emerg. Sel. Top. Power Electron. 2014, 2, 451–459. [Google Scholar] [CrossRef]

- Beng, J.M. Advances in Commercial Applications of Photovoltaic Technology in North America: 2009 Update. In Proceedings of the IEEE PES General Meeting, Providence, RI, USA, 25-29 July 2010. [Google Scholar]

- SMA Solar Inverters “SB5000TL21 SMA 5 kW Single Phase TL Solar Inverter”. Available online: https://www.sma-america.com/products/solarinverters.html (accessed on 19 May 2017).

- Enphase Energy. Enphase Energy Commercial PV Using the Enphase M-Series Microinverter System; Design Guide: California CA, USA, 2015. [Google Scholar]

- Hu, H.; Harb, S.; Kutkut, N.; Batarseh, I.; Shen, Z.J. A Review of Power Decoupling Techniques for Microinverters with Three Different Decoupling Capacitor Locations in PV Systems. IEEE Trans. Power Electron. 2012, 28, 2711–2726. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, Y.; Su, M.; Xiong, W.; Yang, J. Review of Active Power Decoupling Topologies in Single-Phase Systems. IEEE Trans. Power Electron. 2015, 31, 4778–4794. [Google Scholar] [CrossRef]

- Hasan, R.; Mekhilef, S.; Seyedmahmoudian, M.; Horan, B. Grid-connected isolated PV microinverters: A review. Renew. Sustain. Energy Rev. 2017, 67, 1065–1080. [Google Scholar] [CrossRef]

- Bush, C.R.; Wang, B. A single-phase current source solar inverter with reduced-size dc link. In Proceedings of the IEEE Energy Conversion Congress & Exposition, San Jose, CA, USA, 20–24 September 2009; pp. 54–59. [Google Scholar]

- Somani, U. Design Optimization of LLC Topology and Phase Skipping Control of Three-phase Inverter for PV Applications. Master’s Thesis, University of Central Florida, Orlando, FL, USA, September 2013. [Google Scholar]

- Ji, Y.-H.; Jung, D.-Y.; Kim, J.-G.; Lee, T.-W.; Kim, J.-H.; Won, C.-Y. A Real Maximum Power Point Tracking Method for Mismatching Compensation in PV Array under Partially Shaded Conditions. IEEE Trans. Power Electron. 2010, 26, 1001–1009. [Google Scholar] [CrossRef]

- Manickam, C.; Raman, G.P.; Raman, G.; Ganesan, S.I.; Chilakapati, N. Fireworks Enriched P&O Algorithm for GMPPT and Detection of Partial Shading in PV Systems. IEEE Trans. Power Electron. 2016, 32, 4432–4443. [Google Scholar]

- Nguyen, T.-K.T.; Nguyen, N.-V.; Prasad, N.R. Eliminated common-mode voltage pulsewidth modulation to reduce output current ripple for multilevel inverters. IEEE Trans. Power Electron. 2015, 31, 5952–5966. [Google Scholar] [CrossRef]

- Le, Q.A.; Lee, D.C. Modified SVPWM to eliminate common-mode voltages for five-level ANPC inverters. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE), Milwaukee, WI, USA, 18–22 September 2016; pp. 1–6. [Google Scholar]

- Videt, A.; Messaoudi, M.; Idir, N.; Boulharts, H.; Vang, H. PWM Strategy for the Cancellation of Common-Mode Voltage Generated by Three-Phase Back-to-Back Inverters. IEEE Trans. Power Electron. 2016, 32, 2675–2686. [Google Scholar] [CrossRef]

- Basu, K.; Umarikar, A.C.; Mohapatra, K.K.; Mohan, N. High-frequency transformer-link three-level inverter drive with common-mode voltage elimination. In Proceedings of the 2008 IEEE Power Electronics Specialists Conference, Rhodes, Greece, 15–19 June 2008; pp. 4413–4418. [Google Scholar]

- Lyden, S.; Haque, M.E. Comparison of the perturb and observe and simulated annealing approaches for maximum power point tracking in a photovoltaic system under partial shading conditions. In Proceedings of the IEEE Energy Convers Congress Exposition, Pittsburgh, PA, USA, 14–18 September 2014; pp. 2517–2523. [Google Scholar]

- Tey, K.S.; Mekhilef, S. Modified Incremental Conductance Algorithm for Photovoltaic System under Partial Shading Conditions and Load Variation. IEEE Trans. Ind. Electron. 2014, 61, 5384–5392. [Google Scholar]

- Sen, T.; Pragallapati, N.; Agarwal, V.; Kumar, R. Global maximum power point tracking of PV arrays under partial shading conditions using a modified particle velocity-based PSO technique. IET Renew. Power Gener. 2018, 12, 555–564. [Google Scholar] [CrossRef]

- Li, H.; Yang, D.; Su, W.; Lu, J.; Yu, X. An Overall Distribution Particle Swarm Optimization MPPT Algorithm for Photovoltaic System under Partial Shading. IEEE Trans. Ind. Electron. 2019, 66, 265–275. [Google Scholar] [CrossRef]

- Bossche, A.P.V.D.; Haddad, S.; Mordjaoui, M. Power electronic converters without electrolytic capacitors. Int. J. Renew. Energy Technol. 2019, 10, 83–92. [Google Scholar] [CrossRef] [Green Version]

- Hu, H.; Harb, S.; Kutkut, N.; Shen, Z.J.; Batarseh, I. A Single-Stage Microinverter without Using Eletrolytic Capacitors. IEEE Trans. Power Electron. 2013, 28, 2677–2687. [Google Scholar] [CrossRef]

- Da Fonseca, Z.P.; Badin, A.A.; Nascimento, C.B. Single stage high power factor converter using coupled input boost inductor BCM without eletrolytic capacitor to drive power LED. In Proceedings of the 2016 12th IEEE International Conference on Industry Applications (INDUSCON), Curitiba, Brazil, 20–23 November 2016. [Google Scholar]

- Azizi, M.; Mohamadian, M.; Beiranvand, R. A New Family of Multi-Input Converters Based on Three Switches Leg. IEEE Trans. Ind. Electron. 2016, 63, 6812–6822. [Google Scholar] [CrossRef]

- Hu, Y.; Wu, J.; Cao, W.; Xiao, W.; Li, P.; Finney, S.J.; Li, Y. Ultra-High Step-up DC-DC Converter for Distributed Generation by Three Degrees of Freedom (3DoF) Approach. IEEE Trans. Power Electron. 2015, 31, 4930–4941. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.; Hu, H.; Wu, H.; Xing, Y.; Batarseh, I. Overview of High-Step-Up Coupled-Inductor Boost Converters. IEEE J. Emerg. Sel. Top. Power Electron. 2016, 4, 689–704. [Google Scholar] [CrossRef]

- Melo, F.C.; Garcia, L.S.; De Freitas, L.C.; Coelho, E.A.A.; Farias, V.J.; De Freitas, L.C.G. Proposal of a Photovoltaic AC-Module With a Single-Stage Transformerless Grid-Connected Boost Microinverter. IEEE Trans. Ind. Electron. 2018, 65, 2289–2301. [Google Scholar] [CrossRef]

- Xiao, B.; Hang, L.; Mei, J.; Riley, C.; Tolbert, L.M.; Ozpineci, B. Modular Cascaded H-Bridge Multilevel PV Inverter With Distributed MPPT for Grid-Connected Applications. IEEE Trans. Ind. Appl. 2014, 51, 1722–1731. [Google Scholar] [CrossRef]

- Dai, M.; Marwali, M.N.; Jung, J.-W.; Keyhani, A. A Three-Phase Four-Wire Inverter Control Technique for a Single Distributed Generation Unit in Island Mode. IEEE Trans. Power Electron. 2008, 23, 322–331. [Google Scholar] [CrossRef]

- Sinsukthavorn, W.; Ortjohann, E.; Mohd, A.; Hamsic, N.; Morton, D. Control Strategy for Three-/Four-Wire-Inverter-Based Distributed Generation. IEEE Trans. Ind. Electron. 2012, 59, 3890–3899. [Google Scholar] [CrossRef]

- Meersman, B.; Renders, B.; Degroote, L.; Vandoorn, T.; Kooning, J.D.; Vandevelde, L. Overview of three-phase inverter topologies for distributed generation purposes. In Proceedings of the Innovation for Sustainable Production conference, i-SUP 2010, Bruges, Belgium, 18–21 April 2010. [Google Scholar]

- Zong, Q.C.; Liang, J.; Weiss, G.; Feng, C.; Timothy, T.C. H ∞ Control of the Neutral Point in Four-Wire Three-phase DC-AC converters. IEEE Trans. Ind. Electron. 2006, 53, 1594–1602. [Google Scholar] [CrossRef]

- Bifaretti, S.; Lidozzi, A.; Solero, L.; Crescimbini, F. Modulation with Sinusoidal Third-Harmonic Injection for Active Split DC-Bus Four-Leg Inverters. IEEE Trans. Power Electron. 2015, 31, 6226–6236. [Google Scholar] [CrossRef]

- De, D.; Ramanarayanan, V. A DC-to-Three-Phase-AC High-Frequency Link Converter with Compensation for Nonlinear Distortion. IEEE Trans. Ind. Electron. 2010, 57, 3669–3677. [Google Scholar] [CrossRef]

- Zhao, C.; Trento, B.; Jiang, L.; Jones, E.A.; Liu, B.; Zhang, Z.; Costinett, D.; Wang, F.F.; Tolbert, L.M.; Jansen, J.F.; et al. Design and Implementation of GaN-Based, 100 kHz, 102W/in3 Single-Phase Inverter. IEEE J. Emerg. Sel. Top. Power Electron. 2016, 4, 824–840. [Google Scholar] [CrossRef]

- Almasoudi, F.M.; Alatawi, K.S.; Matin, M. Design of isolated interleaved boost DC-DC converter based on SiC power devices for microinverter applications. In Proceedings of the 2016 North American Power Symposium (NAPS), Denver, CO, USA, 18–20 September 2016; pp. 1–6. [Google Scholar]

- Suda, J. SiC and GaN from the viewpoint of vertical power devices. In Proceedings of the 2016 74th Annual Device Research Conference (DRC), Newark, DE, USA, 19–22 June 2016. [Google Scholar]

- Orabi, M.; Shawky, A. Proposed Switching Losses Model for Integrated Point-of-Load Synchronous Buck Converters. IEEE Trans. Power Electron. 2014, 30, 5136–5150. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, Q.; Grishina, A.; Amirahmadi, A.; Hu, H.; Shen, J.; Batarseh, I. A comparison of soft and hard-switching losses in three-phase microinverters. In Proceedings of the 2011 IEEE Energy Conversion Congress and Exposition, Phoenix, AZ, USA, 17–22 September 2011; pp. 1076–1082. [Google Scholar]

- Cha, H.J.; Enjeti, P.N. A new soft switching direct converter for residential fuel cell power system. In Proceedings of the 39th IAS Annual Meeting of IEEE Industry Applications Society, Seattle, WA, USA, 3–7 October 2004; pp. 1172–1177. [Google Scholar]

- Sidrach-De-Cardona, M.; Carretero, J. Analysis of the current total harmonic distortion for different single-phase inverters for grid-connected pv-systems. Sol. Energy Mater. Sol. Cells 2005, 87, 529–540. [Google Scholar] [CrossRef]

- Ahmed, M.; Orabi, M.; Ghoneim, S.; Alharthi, M.; Salem, F.; Alamri, B.; Mekhilef, S. General Mathematical Solution for Selective Harmonic Elimination. IEEE J. Emerg. Sel. Top. Power Electron. 2019, 1. [Google Scholar] [CrossRef]

- Estébanez, E.J.; Moreno, V.M.; Pigazo, A.; Liserre, M. An overview of anti-islanding detection algorithms in photovoltaic systems in case of multiple current-controlled inverters. In Proceedings of the 2009 35th Annual Conference of IEEE Industrial Electronics, Porto, Portugal, 3–5 November 2009; pp. 4555–4560. [Google Scholar]

- Morstyn, T.; Hredzak, B.; Agelidis, V. Control Strategies for Microgrids with Distributed Energy Storage Systems: An Overview. IEEE Trans. Smart Grid 2016, 9, 3652–3666. [Google Scholar] [CrossRef] [Green Version]

- Ndiaye, I.; Wu, X.; Agamy, M. Impact of microinverter reactive power support capability in high penetration residential PV networks. In Proceedings of the 2015 IEEE 42nd Photovoltaic Specialist Conference (PVSC), New Orleans, LA, USA, 14–19 June 2015; pp. 1–6. [Google Scholar]

- Yan, G.; Cai, Y.; Jia, Q.; Liang, S. Stability analysis of grid-connected PV generation with an adapted reactive power control strategy. J. Eng. 2019, 2019, 2980–2985. [Google Scholar] [CrossRef]

- Hashemi, S.; Ostergaard, J. Methods and strategies for overvoltage prevention in low voltage distribution systems with PV. IET Renew. Power Gener. 2017, 11, 205–214. [Google Scholar] [CrossRef] [Green Version]

- Bouzid, A.E.; Sicard, P.; Yamane, A.; Paquin, J.N. Simulation of droop control strategy for parallel inverters in autonomous AC microgrids. In Proceedings of the 2016 8th International Conference on Modelling, Identification and Control (ICMIC), Algiers, Algeria, 15–17 November 2016; pp. 701–706. [Google Scholar]

- Laaksonen, H.; Saari, P.; Komulainen, R. Voltage and frequency control of inverter based weak LV network micro grid. In Proceedings of the International Conference on Future Power Systems, Amsterdam, The Netherlands, 18 November 2005. [Google Scholar]

- Cecati, C.; Dell’Aquila, A.; Liserre, M. A Novel Three-Phase Single-Stage Distributed Power Inverter. IEEE Trans. Power Electron. 2004, 19, 1226–1233. [Google Scholar] [CrossRef]

- Darwish, A.; Holliday, D.; Ahmed, S.; Massoud, A.; Williams, B.W. A Single-Stage Three-Phase Inverter Based on Cuk Converters for PV Applications. IEEE J. Emerg. Sel. Top. Power Electron. 2014, 2, 797–807. [Google Scholar] [CrossRef]

- Darwish, A.; Massoud, A.; Holliday, D.; Ahmed, S.; Williams, B. Single-stage Three-phase Differential-mode Buck-Boost Inverters with Continuous Input Current for PV Applications. IEEE Trans. Power Electron. 2016, 31, 8218–8236. [Google Scholar] [CrossRef] [Green Version]

- Diab, M.S.; Elserougi, A.; Massoud, A.; Abdel-Khalik, A.S.; Ahmed, S. A Four-Switch Three-Phase SEPIC-Based Inverter. IEEE Trans. Power Electron. 2015, 30, 4891–4905. [Google Scholar] [CrossRef]

- Mehrnami, S.; Mazumder, S.K.; Soni, H. Modulation Scheme for Three-Phase Differential-Mode Ćuk Inverter. IEEE Trans. Power Electron. 2015, 31, 2654–2668. [Google Scholar] [CrossRef]

- Basu, K.; Mohan, N. A High-Frequency Link Single-Stage PWM Inverter with Common-Mode Voltage Suppression and Source-Based Commutation of Leakage Energy. IEEE Trans. Power Electron. 2013, 29, 3907–3918. [Google Scholar] [CrossRef]

- Shawky, A.; Ahmed, M.E.; Orabi, M. Performance analysis of isolated DC-DC converters utilized in Three-phase differential inverter. In Proceedings of the 2016 Eighteenth International Middle East Power Systems Conference (MEPCON), Cairo, Egypt, 27–29 December 2016; pp. 821–826. [Google Scholar]

- Koushki, B.; Safaee, A.; Jain, P.; Bakhshai, A. Zero voltage switching differential inverters. In Proceedings of the 2015 IEEE Applied Power Electronics Conference and Exposition (APEC), Charlotte, NC, USA, 15–19 March 2015; pp. 1905–1910. [Google Scholar]

- Koushki, B.; Khajehoddin, S.A.; Saghaian-Nejad, S.M.; Ghaisari, J.; Jain, P.; Bakhshai, A. A voltage reference design for three-phase differential inverters. In Proceedings of the 40th Annual Conference of the IEEE Industrial Electronics Society, Dallas, TX, USA, 29 October–1 November 2014; pp. 1167–1173. [Google Scholar]

- Sivasubramanian, P.T.; Mazumder, S.K.; Soni, H.; Gupta, A.; Kumar, N.; Sivasubramanian, P.T. A DC/DC Modular Current-Source Differential-Mode Inverter. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 4, 489–503. [Google Scholar] [CrossRef]

- Dia, K.K.H.; Choudhury, M.A. A single-phase differential Zeta rectifier-inverter. In Proceedings of the 2015 IEEE International WIE Conference on Electrical and Computer Engineering (WIECON-ECE), Dhaka, Bangladesh, 19–20 December 2015; pp. 284–288. [Google Scholar]

- Peng, F.Z. Z-source inverter. In Proceedings of the Industry Applications Conference, Pittsburgh, PA, USA, 13–18 October 2002; Volume 2, pp. 775–781. [Google Scholar]

- Siwakoti, Y.P.; Peng, F.Z.; Blaabjerg, F.; Loh, P.C.; Town, G. Impedance-Source Networks for Electric Power Conversion Part I: A Topological Review. IEEE Trans. Power Electron. 2014, 30, 699–716. [Google Scholar] [CrossRef]

- Siwakoti, Y.P.; Peng, F.Z.; Blaabjerg, F.; Loh, P.C.; Town, G.; Yang, S. Impedance-Source Networks for Electric Power Conversion Part II: Review of Control and Modulation Techniques. IEEE Trans. Power Electron. 2014, 30, 1887–1906. [Google Scholar] [CrossRef]

- Ellabban, O.; Abu-Rub, H. Z-Source Inverter: Topology Improvements Review. IEEE Ind. Electron. Mag. 2016, 10, 6–24. [Google Scholar] [CrossRef]

- Diab, M.S.; Elserougi, A.A.; Massoud, A.; Abdel-Khalik, A.S.; Ahmed, S. A Pulsewidth Modulation Technique for High-Voltage Gain Operation of Three-Phase Z-Source Inverters. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 4, 521–533. [Google Scholar] [CrossRef]

- Barathy, B.; Viswanathan, T.; Kavitha, A. Effective space vector modulation switching sequence for three phase Z source inverters. IET Power Electron. 2014, 7, 2695–2703. [Google Scholar] [CrossRef]

- Bakeer, A.; Ismeil, M.A.; Orabi, M. A Powerful Finite Control Set-Model Predictive Control Algorithm for Quasi Z-Source Inverter. IEEE Trans. Ind. Informatics 2016, 12, 1371–1379. [Google Scholar] [CrossRef]

- Pan, L. L-Z-Source Inverter. IEEE Trans. Power Electron. 2014, 29, 6534–6543. [Google Scholar] [CrossRef]

- Qian, W.; Peng, F.Z.; Cha, H. Trans-Z-Source Inverters. IEEE Trans. Power Electron. 2011, 26, 3453–3463. [Google Scholar] [CrossRef]

- Jiang, S.; Cao, D.; Peng, F.Z. High frequency transformer isolated Z-source inverters. In Proceedings of the 2011 Twenty-Sixth Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Fort Worth, TX, USA, 6–11 March 2011; pp. 442–449. [Google Scholar]

- Bayhan, S.; Abu-Rub, H.; Balog, R. Model Predictive Control of Quasi-Z-Source Four-Leg Inverter. IEEE Trans. Ind. Electron. 2016, 63, 4506–4516. [Google Scholar] [CrossRef]

- Chen, L.; Amirahmadi, A.; Zhang, Q.; Kutkut, N.; Batarseh, I. Design and Implementation of Three-Phase Two-Stage Grid-Connected Module Integrated Converter. IEEE Trans. Power Electron. 2013, 29, 3881–3892. [Google Scholar] [CrossRef]

- Chen, L.; Hu, C.; Zhang, Q.; Zhang, K.; Batarseh, I. Modeling and Triple-Loop Control of ZVS Grid-Connected DC/AC Converters for Three-Phase Balanced Microinverter Application. IEEE Trans. Power Electron. 2014, 30, 2010–2023. [Google Scholar] [CrossRef]

- Huang, R.; Mazumder, S. A Soft-Switching Scheme for an Isolated DC/DC Converter with Pulsating DC Output for a Three-Phase High-Frequency-Link PWM Converter. IEEE Trans. Power Electron. 2009, 24, 2276–2288. [Google Scholar] [CrossRef]

- Jain, C.; Singh, B. A Three-Phase Grid Tied SPV System with Adaptive DC Link Voltage for CPI Voltage Variations. IEEE Trans. Sustain. Energy 2015, 7, 337–344. [Google Scholar] [CrossRef]

- Rodriguez, J.; Lai, J.-S.; Peng, F.Z. Multilevel inverters: A survey of topologies, controls, and applications. IEEE Trans. Ind. Electron. 2002, 49, 724–738. [Google Scholar] [CrossRef] [Green Version]

- Gupta, K.K.; Ranjan, A.; Bhatnagar, P.; Sahu, L.K.; Jain, S.; Ranjan, A. Multilevel Inverter Topologies With Reduced Device Count: A Review. IEEE Trans. Power Electron. 2015, 31, 135–151. [Google Scholar] [CrossRef]

- Rodriguez, J.; Bernet, S.; Steimer, P.K.; E Lizama, I. A Survey on Neutral-Point-Clamped Inverters. IEEE Trans. Ind. Electron. 2009, 57, 2219–2230. [Google Scholar] [CrossRef]

- Ye, Z.; Jiang, L.; Zhang, Z.; Yu, D.; Wang, Z.; Deng, X.; Fernando, T. A Novel DC-Power Control Method for Cascaded H-Bridge Multilevel Inverter. IEEE Trans. Ind. Electron. 2017, 64, 6874–6884. [Google Scholar] [CrossRef]

- Rivera, S.; Wu, B.; Kouro, S.; Wang, H.; Zhang, D. Cascaded H-bridge multilevel converter topology and three-phase balance control for large scale photovoltaic systems. In Proceedings of the 2012 3rd IEEE International Symposium on Power Electronics for Distributed Generation Systems (PEDG), Aalborg, Denmark, 25–28 June 2012; pp. 690–697. [Google Scholar]

- Sochor, P.; Akagi, H. Theoretical Comparison in Energy-Balancing Capability between Star- and Delta-Configured Modular Multilevel Cascade Inverters for Utility-Scale Photovoltaic Systems. IEEE Trans. Power Electron. 2015, 31, 1980–1992. [Google Scholar] [CrossRef]

| Topology | Power Rating kW | HFL Isolation | THD % | CMV | Four-Wire | η | Reliability | Cost | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Ref. | Solution DC-DC | Control | Operating Mode | Switching | |||||||

| [83] | D1 (Boost) n1 | 1–1.5 | No | 6–7 n2 | High | Pn3 | NA | Sliding mode | CCM | Hard | Low |

| [85] | D3 (5 buck-boost) | 2.5 | Yesn3 | 1.8 | Low | Pn3 | 95 | 3 control loopsn4 | CCM | Hard | Low |

| [86] | D4 (SEPIC) | 2 | No | NR | High | Pn3 | NA | DI sliding mode | CCM | Hard | Very low |

| [87] | D5 (Cuk) | 0.5 | Yes | 6 | Low | Pn5 | 93 | PR + SLM FF control | CMS DMS | Hard | Low |

| [88] | D6 (Full bridge) | NR | Yes | NR | Low | Pn5 | 89 | CSVPWM | CCM | Soft | High |

| Topology | Switch A | Switch B | Capacitor CA | Capacitor CB | |

|---|---|---|---|---|---|

| Ref. | Solution | ||||

| [83] | D1 (Boost) | -- | |||

| [84] | D2 (Cuk) | ||||

| [85] | D3 (5 buck-boosts) n1 | ||||

| [86] | D4 (SEPIC) | ||||

| [87] | D5 (Cuk) | ||||

| [88] | D6 (Full bridge) | -- | |||

| Topology | Power Rating kW | CMV | Four-Wire | η | Gainn2 | Reliability | Cost | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Fig. Ref. | Solution Topology | Control | Switching | THD % | ||||||

| Figure 9 [99] | Z1 classical | 0.26 | No | Pn1 | NA | D < 0.5 | SVM | Hard | 11 | low |

| Figure 10 [100] | Z2 qZSI | 0.45 | No | Pn1 | NA | D < 0.5 | FCS-MPC | Hard | NA | low |

| Figure 11 [101] | Z3 L-ZSI | ~0.15 | No | Pn1 | NA | D < 1 | Maximum Boost control | Hard | NA | Very low |

| Figure 12 [102] | Z4 Tran-ZSI | NR | No | Pn1 | NA | D < 0.5 | Constant Boost control | Hard | NA | Very low |

| Figure 13 [103] | Z5 I-ZSI | 2.88 | Yes | Pn1 | NA | D < 0.5 | Constant B 3rd inject | Hard | NA | High |

| Figure 14 [104] | Z6 QZSI | ~0.4 | No | Four leg | NA | D < 0.5 | MPC | Hard | 8.7 | low |

| Topology | Switch Stress | Capacitor Stress | |

|---|---|---|---|

| Fig./Ref. | Solution | ||

| Figure 14/[99] | Z1 Classical | ||

| Figure 15/[100] | Z2 QZSI | ||

| Figure 16/[101] | Z3 L-ZSI | No capacitors | |

| Figure 17/[102] | Z4 Trans-ZSI | ||

| Figure 18/[103] | Z5 I-ZSI | ||

| Figure 19/[104] | Z6 QZSI | ||

| Topology | Power Rating kW | CMV | Four-Wire | η | MPPT | Reliability | Cost | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Fig./Ref. | Solution Topology | Control | Switching | THD % | ||||||

| Figure 21/[105] | V1 FB + VSI | 0.4 | Low | Split Capacitor | 95.5% | CPI | PWM + ZVS | Soft | 5 | High |

| Figure 22/[107] | V2 FB + VSI | ~1 | Low | Pn1 | 91.5% | - | PWM + ZVZCS | Soft | 5 | High |

| Figure 23/[108] | V3 Boost | 6.5 | High | Pn1 | NR | INC | PWMn2 | Hard | 5 | Low |

| Notes Number | Discussion |

|---|---|

| ① | The main issue of applying DMPPT with this differential topology is stability. This topology depends on the input voltage to cancel the DC offset and make the differential connection, so using PV and MPPT for each DC-DC converter will change the offset and make the whole topology prone to instability. |

| ② | The main issue of applying DMPPT with this topology is reliability. MPPT technique will increase the complexity of the converter. |

| ③ | The DMPPT technique can be applied by using cascaded DC optimizers with independent PV modules. A centralized inverter is used for grid connection. If the same DMPPT technique is applied to different sub-modules and one converter for the PV module, the cost will increase. |

| ④ | L-ZSI is the only topology in this group which can be used without E-caps; therefore, most of the other Z-source inverter topologies need more efforts to reduce the use of these types of capacitors. |

| ⑤ | The main issue is the independent DMPPT operation of each phase which creates the imbalance between instantaneous input power and sinusoidal output power and results in an AC double line frequency. |

| ⑥ | In this topology, the main issue is the voltage stress and circulating power which threatens the reliability and cost. |

| ⑦ | In this topology, the main issue is the use of E-cap and other passive components in the Z network. This threatens the reliability. |

| ⑧ | In this topology, the main issue is component count and power processing through the two stages. This threatens the reliability. |

| ⑨ | In this topology, the component count is reduced; but the main issue which threatens the reliability is the control complexity: DC link control of each phase and MPPT operation of each PV module. |

| ⑩ | In this topology, the main issue which menaces the reliability is the limitation of the boost converter gain. |

| ⑪ | There still room for more improvement for THD (less than 5%). |

| ⑫ | Anti-islanding is a research topic for all topologies. |

| ⑬ | Reactive power control techniques are important to convey the high penetration of the PV module architectures in grid resources. |

| ⑭ | DC injection elimination satisfies standards. |

| ⑮ | Voltage and frequency control should be investigated for this topology to dismiss the defect of PV architectures on the whole grid reliability and its power quality. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shawky, A.; Ahmed, M.; Orabi, M.; Aroudi, A.E. Classification of Three-Phase Grid-Tied Microinverters in Photovoltaic Applications. Energies 2020, 13, 2929. https://doi.org/10.3390/en13112929

Shawky A, Ahmed M, Orabi M, Aroudi AE. Classification of Three-Phase Grid-Tied Microinverters in Photovoltaic Applications. Energies. 2020; 13(11):2929. https://doi.org/10.3390/en13112929

Chicago/Turabian StyleShawky, Ahmed, Mahrous Ahmed, Mohamed Orabi, and Abdelali El Aroudi. 2020. "Classification of Three-Phase Grid-Tied Microinverters in Photovoltaic Applications" Energies 13, no. 11: 2929. https://doi.org/10.3390/en13112929

APA StyleShawky, A., Ahmed, M., Orabi, M., & Aroudi, A. E. (2020). Classification of Three-Phase Grid-Tied Microinverters in Photovoltaic Applications. Energies, 13(11), 2929. https://doi.org/10.3390/en13112929