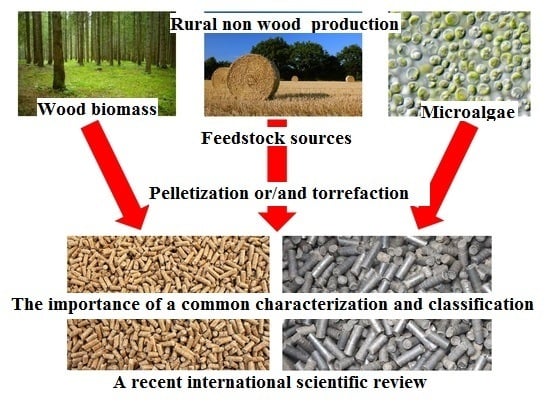

Pellet Production from Woody and Non-Woody Feedstocks: A Review on Biomass Quality Evaluation

Abstract

:1. Introduction

2. Materials and Methods

3. Pellet Quality Standards

4. Influence of Agro-Forest Management System on Pellet Quality

5. Pure Feedstock for Pellet Production

6. Effects of Blending and Binders on Pellet Quality

7. Pre- and Post-Treatments

8. Some Ideas for Future Research Directions

9. Conclusions

- Very few studies have investigated the relationship between different agroforest management systems and the quality of obtained pellets. This could be interesting focus for future research to give a better understanding of this topic.

- As reported in many other studies, including the most recent ones, wood pellets have a higher quality than agropellets, particularly in terms of their bulk density, ash content, heating value, and chemical composition.

- However, agropellets are an interesting way to valorize agricultural waste—mostly for industrial use.

- Blending and using binders are possible methods to improve pellet quality, but their use must be evaluated on a case-by-case basis.

- There have been very interesting findings regarding the blending of woody biomass and microalgae, showing a consistent improvement in pellet quality.

- Torrefaction seems to be the most investigated treatment to improve pellet quality, and recent studies tried to further improve such processes (ultrasonic torrefaction, pressurized steam torrefaction).

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Civitarese, V.; Acampora, A.; Sperandio, G.; Assirelli, A.; Picchio, R. Production of wood pellets from poplar trees managed as coppices with Different harvesting cycles. Energies 2019, 12, 2973–2988. [Google Scholar] [CrossRef] [Green Version]

- Verma, V.K.; Bram, S.; De Ruyck, J. Small scale biomass heating systems: Standards, quality labelling and market driving factors—An EU outlook. Biomass Bioenergy 2009, 33, 1393–1402. [Google Scholar] [CrossRef]

- Kaliyan, N.; Vance Morey, R. Factors affecting strength and durability of densified biomass products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Matias, J.C.O.; Catalão, J.P.S. Mixed biomass pellets for thermal energy production: A review of combustion models. Appl. Energy 2014, 127, 135–140. [Google Scholar] [CrossRef]

- Puig-Arnavat, M.; Shang, L.; Sárossy, Z.; Ahrenfeldt, J.; Henriksen, U.B. From a single pellet press to a bench scale pellet mill—Pelletizing six different biomass feedstocks. Fuel Process. Technol. 2016, 142, 27–33. [Google Scholar] [CrossRef] [Green Version]

- Rentizelas, A.A.; Tolis, A.J.; Tatsiopoulos, I.P. Logistics issues of biomass: The storage problem and the multi-biomass supply chain. Renew. Sustain. Energy Rev. 2009, 13, 887–894. [Google Scholar] [CrossRef] [Green Version]

- Sánchez, J.; Curt, M.D.; Sanz, M.; Fernández, J. A proposal for pellet production from residual woody biomass in the island of Majorca (Spain). AIMS Energy 2015, 3, 480. [Google Scholar] [CrossRef] [Green Version]

- Whittaker, C.; Shield, I. Factors affecting wood, energy grass and straw pellet durability—A review. Renew. Sustain. Energy Rev. 2017, 71, 1–11. [Google Scholar] [CrossRef]

- Gilbert, P.; Ryu, C.; Sharifi, V.; Swithenbank, J. Effect of process parameters on pelletisation of herbaceous crops. Fuel 2009, 88, 1491–1497. [Google Scholar] [CrossRef]

- Stasiak, M.; Molenda, M.; Bańda, M.; Wiącek, J.; Parafiniuk, P.; Gondek, E. Mechanical and combustion properties of sawdust—Straw pellets blended in different proportions. Fuel Process. Technol. 2017, 156, 366–375. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, Z.; Zhang, Y.; Wang, Y.; Yu, Y.; Ji, F.; Ahmad, R.; Dong, R. A comprehensive review on densified solid biofuel industry in China. Renew. Sustain. Energy Rev. 2016, 54, 1412–1428. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Natural binders and solid bridge type binding mechanisms in briquettes and pellets made from corn stover and switchgrass. Bioresour. Technol. 2010, 101, 1082–1090. [Google Scholar] [CrossRef] [PubMed]

- Van der Stelt, M.J.C.; Gerhauser, H.; Kiel, J.H.A.; Ptasinski, K.J. Biomass upgrading by torrefaction for the production of biofuels: A review. Biomass Bioenergy 2011, 35, 3748–3762. [Google Scholar] [CrossRef]

- Calderòn, C.; Colla, M.; Jossart, J.-M.; Hemeleers, N.; Cancian, G.; Aveni, N.; Caferri, C. Bioenergy Europe, Statistical report on pellet. In Proceedings of the European Biomass Conference and Exhibition, Stockholm Sweden, 12–15 June 2017. [Google Scholar]

- Samuelsson, R.; Thyrel, M.; Sjöström, M.; Lestander, T.A. Effect of biomaterial characteristics on pelletizing properties and biofuel pellet quality. Fuel Process. Technol. 2009, 90, 1129–1134. [Google Scholar] [CrossRef]

- Larsson, S.H.; Thyrel, M.; Geladi, P.; Lestander, T.A. High quality biofuel pellet production from pre-compacted low density raw materials. Bioresour. Technol. 2008, 99, 7176–7182. [Google Scholar] [CrossRef]

- Lestander, T.A.; Finell, M.; Samuelsson, R.; Arshadi, M.; Thyrel, M. Industrial scale biofuel pellet production from blends of unbarked softwood and hardwood stems—the effects of raw material composition and moisture content on pellet quality. Fuel Process. Technol. 2012, 95, 73–77. [Google Scholar] [CrossRef]

- Nizamuddin, S.; Mubarak, N.M.; Tiripathi, M.; Jayakumar, N.S.; Sahu, J.N.; Ganesan, P. Chemical, dielectric and structural characterization of optimized hydrochar produced from hydrothermal carbonization of palm shell. Fuel 2016, 163, 88–97. [Google Scholar] [CrossRef]

- Toscano, G.; Riva, G.; Pedretti, E.F.; Corinaldesi, F.; Mengarelli, C.; Duca, D. Investigation on wood pellet quality and relationship between ash content and the most important chemical elements. Biomass Bioenergy 2013, 56, 317–322. [Google Scholar] [CrossRef]

- Ahn, B.J.; Chang, H.; Lee, S.M.; Choi, D.H.; Cho, S.T.; Han, G.; Yang, I. Effect of binders on the durability of wood pellets fabricated from Larix kaemferi C. and Liriodendron tulipifera L. sawdust. Renew. Energy 2014, 62, 18–23. [Google Scholar] [CrossRef]

- Križan, P.; Matú, M.; Šooš, L’.; Beniak, J. Behavior of beech sawdust during densification into a solid biofuel. Energies 2015, 8, 6382–6398. [Google Scholar]

- Stelte, W.; Sanadi, A.R.; Shang, L.; Holm, J.K.; Ahrenfeldt, J.; Henriksen, U.B. Recent developments in biomass pelletization–A review. BioResources 2012, 7, 4451–4490. [Google Scholar]

- Picchio, R.; Spina, R.; Sirna, A.; Monaco, A.L.; Civitarese, V.; Giudice, A.D.; Suardi, A.; Pari, L. Characterization of woodchips for energy from forestry and agroforestry production. Energies 2012, 5, 3803–3816. [Google Scholar] [CrossRef]

- Mostafa, M.E.; Hu, S.; Wang, Y.; Su, S.; Hu, X.; Elsayed, S.A.; Xiang, J. The significance of pelletization operating conditions: An analysis of physical and mechanical characteristics as well as energy consumption of biomass pellets. Renew. Sustain. Energy Rev. 2019, 105, 332–348. [Google Scholar] [CrossRef]

- Tenorio, C.; Moya, R.; Valaert, J. Characterisation of pellets made from oil palm residues in Costa Rica. J. Oil Palm Res. 2016, 28, 198–210. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Jiang, L.-B.; Li, C.-Z.; Liang, J.; Yuan, X.-Z.; Xiao, Z.-H.; Xiao, Z.-H.; Wang, H. Co-pelletization of sewage sludge and biomass: The energy input and properties of pellets. Fuel Process. Technol. 2015, 132, 55–61. [Google Scholar] [CrossRef]

- Cheng, J.; Zhou, F.; Si, T.; Zhou, J.; Cen, K. Mechanical strength and combustion properties of biomass pellets prepared with coal tar residue as a binder. Fuel Process. Technol. 2018, 179, 229–237. [Google Scholar] [CrossRef]

- Kijo-Kleczkowska, A.; Środa, K.; Kosowska-Golachowska, M.; Musiał, T.; Wolski, K. Combustion of pelleted sewage sludge with reference to coal and biomass. Fuel 2016, 170, 141–160. [Google Scholar] [CrossRef]

- Azargohar, R.; Nanda, S.; Dalai, A.K. Densification of agricultural wastes and forest residues: A review on influential parameters and treatments. Recent Adv. Biofuels Bioenergy Util. 2018, 27–51. [Google Scholar] [CrossRef]

- Kumar, P.; Barrett, D.M.; Delwiche, M.J.; Stroeve, P. Methods for pretreatment of lignocellulosic biomass for efficient hydrolysis and biofuel production. Ind. Eng. Chem. Res. 2009, 48, 3713–3729. [Google Scholar] [CrossRef]

- Ramos, L.P. The chemistry involved in the steam treatment of lignocellulosic materials. Quim. Nova 2003, 26, 863–871. [Google Scholar] [CrossRef] [Green Version]

- Sun, Y.; Cheng, J. Hydrolysis of lignocellulosic materials for ethanol production: A review. Bioresour. Technol. 2002, 83, 1–11. [Google Scholar] [CrossRef]

- Stelte, W.; Holm, J.K.; Sanadi, A.R.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U.B. Fuel pellets from biomass: The importance of the pelletizing pressure and its dependency on the processing conditions. Fuel 2011, 90, 3285–3290. [Google Scholar] [CrossRef] [Green Version]

- Mei, Y.; Liu, R.; Yang, Q.; Yang, H.; Shao, J.; Draper, C.; Zhang, S.; Chen, H. Torrefaction of cedarwood in a pilot scale rotary kiln and the influence of industrial flue gas. Bioresour. Technol. 2015, 177, 355–360. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Liu, X.; Legros, R.; Bi, X.T.; Lim, C.J.; Sokhansanj, S. Pelletization of torrefied sawdust and properties of torrefied pellets. Appl. Energy 2012, 93, 680–685. [Google Scholar] [CrossRef]

- Kumar, L.; Koukoulas, A.A.; Mani, S.; Satyavolu, J. Integrating torrefaction in the wood pellet industry: A critical review. Energy Fuels 2017, 31, 37–54. [Google Scholar] [CrossRef]

- Picchio, R.; Proto, A.R.; Civitarese, V.; Di Marzio, N.; Latterini, F. Recent Contributions of Some Fields of the Electronics in Development of Forest Operations Technologies. Electronics 2019, 8, 1465. [Google Scholar] [CrossRef] [Green Version]

- García-Maraver, A.; Popov, V.; Zamorano, M. A review of European standards for pellet quality. Renew. Energy 2011, 36, 3537–3540. [Google Scholar] [CrossRef]

- Alakangas, E. Solid biofuels for energy: A lower greenhouse gas alternative. Green Energy Technol. 2014, 28, 1–3. [Google Scholar]

- Rhén, C.; Gref, R.; Sjöström, M.; Wästerlund, I. Effects of raw material moisture content, densification pressure and temperature on some properties of Norway spruce pellets. Fuel Process. Technol. 2005, 87, 11–16. [Google Scholar] [CrossRef]

- Masche, M.; Puig-Arnavat, M.; Jensen, P.A.; Holm, J.K.; Clausen, S.; Ahrenfeldt, J.; Henriksen, U.B. From wood chips to pellets to milled pellets: The mechanical processing pathway of Austrian pine and European beech. Powder Technol. 2019, 350, 134–145. [Google Scholar] [CrossRef]

- Monedero, E.; Portero, H.; Lapuerta, M. Combustion of poplar and pine pellet blends in a 50 kw domestic boiler: Emissions and combustion efficiency. Energies 2018, 11, 1580. [Google Scholar] [CrossRef] [Green Version]

- Santos, L.B.; Striebeck, M.V.; Crespi, M.S.; Capela, J.M.V.; Ribeiro, C.A.; De Julio, M. Energy evaluation of biochar obtained from the pyrolysis of pine pellets. J. Anal. Calorim. 2016, 126, 1879–1887. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Jiang, Z.; Fei, B.; Cai, Z.; Liu, X. Comparative properties of bamboo and pine pellets. Wood Fiber Sci. 2014, 46, 510–518. [Google Scholar]

- Rabaçal, M.; Fernandes, U.; Costa, M. Combustion and emission characteristics of a domestic boiler fired with pellets of pine, industrial wood wastes and peach stones. Renew. Energy 2013, 51, 220–226. [Google Scholar] [CrossRef]

- Stelte, W.; Clemons, C.; Holm, J.K.; Sanadi, A.R.; Ahrenfeldt, J.; Shang, L.; Henriksen, U.B. Pelletizing properties of torrefied spruce. Biomass Bioenergy 2011, 35, 4690–4698. [Google Scholar] [CrossRef] [Green Version]

- Brackley, A.M.; Parrent, D.J. Production of wood pellets from Alaska-grown white spruce and hemlock. Usda. Serv. 2011. [Google Scholar] [CrossRef]

- Savelli, S.; Cavalli, R.; Baldini, S.; Picchio, R. Small scale mechanization of thinning in artificial coniferous plantation. Croat. J. Eng. 2010, 31, 11–21. [Google Scholar]

- Lerma-Arce, V.; Oliver-Villanueva, J.V.; Segura-Orenga, G. Influence of raw material composition of Mediterranean pinewood on pellet quality. Biomass Bioenergy 2017, 99, 90–96. [Google Scholar] [CrossRef] [Green Version]

- Agar, D.A.; Rudolfsson, M.; Kalén, G.; Campargue, M.; Da Silva Perez, D.; Larsson, S.H. A systematic study of ring-die pellet production from forest and agricultural biomass. Fuel Process. Technol. 2018, 180, 47–55. [Google Scholar] [CrossRef]

- Picchio, R.; Spina, R.; Calienno, L.; Venanzi, R.; Lo Monaco, A. Forest operations for implementing silvicultural treatments for multiple purposes. Ital. J. Agron. 2016, 11, 156–161. [Google Scholar]

- Gündüz, G.; Saraçoğlu, N.; Aydemir, D. Characterization and elemental analysis of wood pellets obtained from low-valued types of wood. Energy Sources 2016, 38, 2211–2216. [Google Scholar] [CrossRef]

- Zawiślak, K.; Sobczak, P.; Kraszkiewicz, A.; Niedziółka, I.; Parafiniuk, S.; Kuna-Broniowska, I.; Tanaś, W.; Żukiewicz-Sobczak, W.; Obidziński, S. The use of lignocellulosic waste in the production of pellets for energy purposes. Renew. Energy 2020, 145, 997–1003. [Google Scholar] [CrossRef]

- Artemio, C.P.; Maginot, N.H.; Serafín, C.U.; Rahim, F.P.; Guadalupe, R.Q.J.; Fermín, C.M. Physical, mechanical and energy characterization of wood pellets obtained from three common tropical species. PeerJ 2018, 2018, 1–16. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bados, R.; Esteban, L.S.; Pérez, P.; Mediavilla, I.; Fernández, M.J.; Barro, R.; Corredor, R.; Carrasco, J.E. Study of the production of pelletized biofuels from Mediterranean scrub biomass. In Proceedings of the European Biomass Conference and Exhibition, Stockholm Sweden, 12–15 June 2017. [Google Scholar]

- Aragón-Garita, S.; Moya, R.; Bond, B.; Valaert, J.; Tomazello Filho, M. Production and quality analysis of pellets manufactured from five potential energy crops in the Northern Region of Costa Rica. Biomass Bioenergy 2016, 87, 84–95. [Google Scholar] [CrossRef] [Green Version]

- Ramírez, V.; Martí-Herrero, J.; Romero, M.; Rivadeneira, D. Energy use of Jatropha oil extraction wastes: Pellets from biochar and Jatropha shell blends. J. Clean. Prod. 2019, 215, 1095–1102. [Google Scholar] [CrossRef]

- Romuli, S.; Karaj, S.; Correa, C.R.; Kruse, A.; Müller, J. Physico-mechanical properties and thermal decomposition characteristics of pellets from Jatropha curcas L. residues as affected by water addition. Biofuels 2019, 1–8. [Google Scholar] [CrossRef]

- Alarcon, M.; Santos, C.; Cevallos, M.; Eyzaguirre, R.; Ponce, S. Study of the Mechanical and Energetic Properties of Pellets Produce from Agricultural Biomass of Quinoa, Beans, Oat, Cattail and Wheat. Waste Biomass Valori 2017, 8, 2881–2888. [Google Scholar] [CrossRef]

- Burg, P.; Masan, V.; Ludin, D. Possibilities of using grape marc for making fuel pellets. Eng. Rural Dev. 2017, 16, 1333–1338. [Google Scholar]

- Stelte, W.; Barsberg, S.T.; Clemons, C.; Morais, J.P.S.; de Freitas Rosa, M.; Sanadi, A.R. Coir Fibers as Valuable Raw Material for Biofuel Pellet Production. Waste Biomass Valori 2019, 10, 3535–3543. [Google Scholar] [CrossRef] [Green Version]

- Royo, J.; Canalís, P.; Quintana, D.; Díaz-Ramírez, M.; Sin, A.; Rezeau, A. Experimental study on the ash behaviour in combustion of pelletized residual agricultural biomass. Fuel 2019, 239, 991–1000. [Google Scholar] [CrossRef] [Green Version]

- Marrugo, G.; Valdés, C.F.; Gómez, C.; Chejne, F. Pelletizing of Colombian agro-industrial biomasses with crude glycerol. Renew. Energy 2019, 134, 558–568. [Google Scholar] [CrossRef]

- Yang, I.; Kim, S.-H.; Sagong, M.; Han, G.S. Fuel characteristics of agropellets fabricated with rice straw and husk. KoreanJ. Chem. Eng. 2016, 33, 851–857. [Google Scholar] [CrossRef]

- Ríos-Badrán, I.M.; Luzardo-Ocampo, I.; García-Trejo, J.F.; Santos-Cruz, J.; Gutiérrez-Antonio, C. Production and characterization of fuel pellets from rice husk and wheat straw. Renew. Energy 2020, 145, 500–507. [Google Scholar] [CrossRef]

- Park, S.; Kim, S.J.; Oh, K.C.; Cho, L.; Kim, M.J.; Jeong, I.S.; Lee, C.G.; Kim, D.H. Investigation of agro-byproduct pellet properties and improvement in pellet quality through mixing. Energy 2019, 190, 116380. [Google Scholar] [CrossRef]

- Djatkov, D.; Martinov, M.; Kaltschmitt, M. Influencing parameters on mechanical–physical properties of pellet fuel made from corn harvest residues. Biomass Bioenergy 2018, 119, 418–428. [Google Scholar] [CrossRef]

- Miranda, M.T.; Sepúlveda, F.J.; Arranz, J.I.; Montero, I.; Rojas, C.V. Physical-energy characterization of microalgae Scenedesmus and experimental pellets. Fuel 2018, 226, 121–126. [Google Scholar] [CrossRef]

- Wattana, W.; Phetklung, S.; Jakaew, W.; Chumuthai, S.; Sriam, P.; Chanurai, N. Characterization of Mixed Biomass Pellet Made from Oil Palm and Para-rubber Tree Residues. Energy Procedia 2017, 138, 1128–1133. [Google Scholar] [CrossRef]

- Brunerová, A.; Müller, M.; Šleger, V.; Ambarita, H.; Valášek, P. Bio-pellet fuel from oil palm empty fruit bunches (EFB): Using European standards for quality testing. Sustainability 2018, 10, 4443. [Google Scholar]

- Jeguirim, M.; Limousy, L.; Fossard, E. Characterization of coffee residues pellets and their performance in a residential combustor. Int. J. Green Energy 2016, 13, 608–615. [Google Scholar] [CrossRef]

- Fernández-Puratich, H.; Hernández, D.; Lerma Arce, V. Characterization and cost savings of pellets fabricated from Zea mays waste from corn mills combined with Pinus radiata. Renew. Energy 2017, 114, 448–454. [Google Scholar] [CrossRef]

- Toscano, G.; Alfano, V.; Scarfone, A.; Pari, L. Pelleting vineyard pruning at low cost with a mobile technology. Energies 2018, 11, 2477. [Google Scholar] [CrossRef] [Green Version]

- Brand, M.A.; Jacinto, R.C. Apple pruning residues: Potential for burning in boiler systems and pellet production. Renew. Energy 2020, 152, 458–466. [Google Scholar] [CrossRef]

- Suardi, A.; Latterini, F.; Alfano, V.; Palmieri, N.; Bergonzli, S.; Pari, L. Analysis of the Work Productivity and Costs of a Stationary Chipper Applied to the Harvesting of Olive Tree Pruning for Bio-Energy Production. Energies 2020, 13, 1359. [Google Scholar] [CrossRef] [Green Version]

- Suardi, A.; Latterini, F.; Alfano, V.; Palmieri, N.; Bergonzoli, S.; Karampinis, E.; Kougioumtzis, M.A.; Grammelis, P.; Pari, L. Machine Performance and Hog Fuel Quality Evaluation in Olive Tree Pruning Harvesting Conducted Using a Towed Shredder on Flat and Hilly Fields. Energies 2020, 13, 1713–1728. [Google Scholar] [CrossRef] [Green Version]

- Pradhan, P.; Mahajani, S.M.; Arora, A. Production and utilization of fuel pellets from biomass: A review. Fuel Process. Technol. 2018, 181, 215–232. [Google Scholar] [CrossRef]

- Scatolino, M.V.; Neto, L.F.C.; Protásio, T.P.; Carneiro, A.C.O.; Andrade, C.R.; Guimarães Júnior, J.B.; Mendes, L.M. Options for Generation of Sustainable Energy: Production of Pellets Based on Combinations Between Lignocellulosic Biomasses. Waste Biomass Valori 2018, 9, 479–489. [Google Scholar] [CrossRef]

- Dołzyńska, M.; Obidziński, S.; Kowczyk-Sadowy, M.; Krasowska, M. Densification and combustion of cherry stones. Energies 2019, 12, 1–15. [Google Scholar] [CrossRef] [Green Version]

- González, W.A.; López, D.; Pérez, J.F. Biofuel quality analysis of fallen leaf pellets: Effect of moisture and glycerol contents as binders. Renew. Energy 2020, 147, 1139–1150. [Google Scholar] [CrossRef]

- Peng, J.; Bi, X.T.; Lim, C.J.; Peng, H.; Kim, C.S.; Jia, D.; Zuo, H. Sawdust as an effective binder for making torrefied pellets. Appl. Energy 2015, 157, 491–498. [Google Scholar] [CrossRef]

- Harun, N.Y.; Parvez, A.M.; Afzal, M.T. Process and energy analysis of pelleting agricultural and woody biomass blends. Sustainability 2018, 10, 1–9. [Google Scholar]

- Liu, Z.; Mi, B.; Jiang, Z.; Fei, B.; Cai, Z.; Liu, X. Improved bulk density of bamboo pellets as biomass for energy production. Renew. Energy 2016, 86, 1–7. [Google Scholar] [CrossRef] [Green Version]

- García, R.; Gil, M.V.; Rubiera, F.; Pevida, C. Pelletization of wood and alternative residual biomass blends for producing industrial quality pellets. Fuel 2019, 251, 739–753. [Google Scholar] [CrossRef]

- Platace, R.; Adamovics, A.; Kalnacs, J. Engineering for Rural Development Production of Reed Canary Grass-Wood Pellets. Eng. Rural Dev. 2016, 371–374. [Google Scholar]

- Barbanera, M.; Lascaro, E.; Stanzione, V.; Esposito, A.; Altieri, R.; Bufacchi, M. Characterization of pellets from mixing olive pomace and olive tree pruning. Renew. Energy 2016, 88, 185–191. [Google Scholar] [CrossRef]

- Hosseinizand, H.; Sokhansanj, S.; Lim, C.J. Co-pelletization of microalgae Chlorella vulgaris and pine sawdust to produce solid fuels. Fuel Process. Technol. 2018, 177, 129–139. [Google Scholar] [CrossRef]

- Cui, X.; Yang, J.; Shi, X.; Lei, W.; Huang, T.; Bai, C. Experimental investigation on the energy consumption, physical, and thermal properties of a novel pellet fuel made from wood residues with microalgae as a binder. Energies 2019, 12, 3425. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Wu, K.; Sun, Y. Pelletizing Properties of Wheat Straw Blending with Rice Straw. Energy Fuels 2017, 31, 5126–5134. [Google Scholar] [CrossRef]

- Lisowski, A.; Matkowski, P.; Dąbrowska, M.; Piątek, M.; Świętochowski, A.; Klonowski, J.; Mieszkalski, L.; Reshetiuk, V. Particle Size Distribution and Physicochemical Properties of Pellets Made of Straw, Hay, and Their Blends. Waste Biomass Valori 2018, 11, 63–75. [Google Scholar] [CrossRef] [Green Version]

- Jiang, L.; Yuan, X.; Xiao, Z.; Liang, J.; Li, H.; Cao, L.; Wang, H.; Chen, X.; Zeng, G. A comparative study of biomass pellet and biomass-sludge mixed pellet: Energy input and pellet properties. Energy Convers. Manag. 2016, 126, 509–515. [Google Scholar] [CrossRef]

- Abedi, A.; Dalai, A.K. Study on the quality of oat hull fuel pellets using bio-additives. Biomass Bioenergy 2017, 106, 166–175. [Google Scholar] [CrossRef]

- Abedi, A.; Cheng, H.; Dalai, A.K. Effects of Natural Additives on the Properties of Sawdust Fuel Pellets. Energy Fuels 2018, 32, 1863–1873. [Google Scholar] [CrossRef]

- Zhang, T.; Qiu, L.; Wang, Y.; Zhang, C.; Kang, K. Comparison of Bio-Oil and Waste Cooking Oil as Binders during the Codensification of Biomass: Analysis of the Pellet Quality. Bioenergy Res. 2019, 12, 558–569. [Google Scholar] [CrossRef]

- Obidziński, S.; Piekut, J.; Dec, D. The influence of potato pulp content on the properties of pellets from buckwheat hulls. Renew. Energy 2016, 87, 289–297. [Google Scholar] [CrossRef]

- Obidziński, S.; Dołżyńska, M.; Kowczyk-Sadowy, M.; Jadwisieńczak, K.; Sobczak, P. Densification and Fuel Properties of Onion Husks. Energies 2019, 12, 4687. [Google Scholar]

- Gageanu, I.; Cujbescu, D.; Persu, C.; Voicu, G. Impact of using additives on quality of agricultural biomass pellets. Eng. Rural Dev. 2018, 17, 1632–1638. [Google Scholar]

- Gageanu, I.; Persu, C.; Cujbescu, D.; Gheorghe, G.; Voicu, G. Influence of using additives on quality of pelletized fodder. Eng. Rural Dev. 2019, 18, 362–367. [Google Scholar]

- Mišljenović, N.; Čolović, R.; Vukmirović, D.; Brlek, T.; Bringas, C.S. The effects of sugar beet molasses on wheat straw pelleting and pellet quality. A comparative study of pelleting by using a single pellet press and a pilot-scale pellet press. Fuel Process. Technol. 2016, 144, 220–229. [Google Scholar]

- Jamradloedluk, J.; Lertsatitthanakorn, C. Influences of Mixing Ratios and Binder Types on Properties of Biomass Pellets. Energy Procedia 2017, 138, 1147–1152. [Google Scholar] [CrossRef]

- Si, Y.; Hu, J.; Wang, X.; Yang, H.; Chen, Y.; Shao, J.; Chen, H. Effect of Carboxymethyl Cellulose Binder on the Quality of Biomass Pellets. Energy Fuels 2016, 30, 5799–5808. [Google Scholar] [CrossRef]

- Dąbrowska-Salwin, M.; Lisowski, A.; Kostrubiec, M.; Swietochowski, A. Pressure agglomeration of biomass with addition of calcium carbonate. Eng. Rural Dev. 2016, 542–546. [Google Scholar]

- Iftikhar, M.; Asghar, A.; Ramzan, N.; Sajjadi, B.; Chen, W. Biomass densification: Effect of cow dung on the physicochemical properties of wheat straw and rice husk based biomass pellets. Biomass Bioenergy 2019, 122, 1–16. [Google Scholar] [CrossRef]

- Gehrig, M.; Wöhler, M.; Pelz, S.; Steinbrink, J.; Thorwarth, H. Kaolin as additive in wood pellet combustion with several mixtures of spruce and short-rotation-coppice willow and its influence on emissions and ashes. Fuel 2019, 235, 610–616. [Google Scholar] [CrossRef]

- García, R.; González-Vázquez, M.P.; Martín, A.J.; Pevida, C.; Rubiera, F. Pelletization of torrefied biomass with solid and liquid bio-additives. Renew. Energy 2020, 151, 175–183. [Google Scholar] [CrossRef]

- Tang, Y.; Chandra, R.P.; Sokhansanj, S.; Saddler, J.N. The Role of Biomass Composition and Steam Treatment on Durability of Pellets. Bioenergy Res. 2018, 11, 341–350. [Google Scholar] [CrossRef]

- Pirraglia, A.; Gonzalez, R.; Saloni, D.; Denig, J. Technical and economic assessment for the production of torrefied ligno-cellulosic biomass pellets in the US. Energy Convers. Manag. 2013, 66, 153–164. [Google Scholar] [CrossRef]

- Kizuka, R.; Ishii, K.; Sato, M.; Fujiyama, A. Characteristics of wood pellets mixed with torrefied rice straw as a biomass fuel. Int. J. Energy Env. Eng. 2019, 10, 357–365. [Google Scholar] [CrossRef] [Green Version]

- Gaitán-Alvarez, J.; Moya, R.; Puente-Urbina, A.; Rodriguez-Zuñiga, A. Physical and compression properties of pellets manufactured with the biomass of five woody tropical species of Costa Rica torrefied at different temperatures and times. Energies 2017, 10, 1205. [Google Scholar] [CrossRef] [Green Version]

- Azócar, L.; Hermosilla, N.; Gay, A.; Rocha, S.; Díaz, J.; Jara, P. Brown pellet production using wheat straw from southern cities in Chile. Fuel 2019, 237, 823–832. [Google Scholar] [CrossRef]

- Puy, N.; Alier, S.; Bartrolí, J. Production of torrefied pellets from agroforestry biomass for local and regional use. In Proceedings of the 24th European Biomass Conference and Exhibition, Amsterdam, The Netherlands, 6–9 June 2016. [Google Scholar]

- Manouchehrinejad, M.; Mani, S. Torrefaction after pelletization (TAP): Analysis of torrefied pellet quality and co-products. Biomass Bioenergy 2018, 118, 93–104. [Google Scholar] [CrossRef]

- Song, X.; Yang, Y.; Zhang, M.; Zhang, K.; Wang, D. Ultrasonic pelleting of torrefied lignocellulosic biomass for bioenergy production. Renew. Energy 2018, 129, 56–62. [Google Scholar] [CrossRef]

- Kudo, S.; Okada, J.; Ikeda, S.; Yoshida, T.; Asano, S.; Hayashi, J.I. Improvement of Pelletability of Woody Biomass by Torrefaction under Pressurized Steam. Energy Fuels 2019, 33, 11253–11262. [Google Scholar] [CrossRef]

- Gong, S.H.; Im, H.S.; Um, M.; Lee, H.W.; Lee, J.W. Enhancement of waste biomass fuel properties by sequential leaching and wet torrefaction. Fuel 2019, 239, 693–700. [Google Scholar] [CrossRef]

- Rejdak, M.; Czardybon, A.; Ignasiak, K.; Robak, J. Utilization of waste forest biomass: Pelletization studies of torrefied sawmill wood chips. In Proceedings of the 11th Conference on Interdisciplinary Problems in Environmental Protection and Engineering EKO-DOK 2019, Polanica-Zdroj, Poland, 8–10 April 2019; E3S Web Conferences: Les Ulis, France, 2019; Volume 100. [Google Scholar]

- Shahrukh, H.; Oyedun, A.O.; Kumar, A.; Ghiasi, B.; Kumar, L.; Sokhansanj, S. Techno-economic assessment of pellets produced from steam pretreated biomass feedstock. Biomass Bioenergy 2016, 87, 131–143. [Google Scholar] [CrossRef]

- Obernberger, I.; Thek, G. The Pellet Handbook: The Production and Thermal Utilisation of Pellets; Routledge: Abingdon, UK, 2010; ISBN 1844076318. [Google Scholar]

- Mobini, M.; Sowlati, T.; Sokhansanj, S. A simulation model for the design and analysis of wood pellet supply chains. Appl. Energy 2013, 111, 1239–1249. [Google Scholar] [CrossRef]

- Mobini Dehkordi, M.M. On the design and analysis of forest biomass to biofuel and bioenergy supply chains. Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, April 2015. [Google Scholar]

- Trømborg, E.; Ranta, T.; Schweinle, J.; Solberg, B.; Skjevrak, G.; Tiffany, D.G. Economic sustainability for wood pellets production–A comparative study between Finland, Germany, Norway, Sweden and the US. Biomass Bioenergy 2013, 57, 68–77. [Google Scholar] [CrossRef]

- Koppejan, J.; Sokhansanj, S.; Melin, S.; Madrali, S. Status overview of torrefaction technologies. IEA Bioenergy Task 2012, 32, 1–54. [Google Scholar]

- Radics, R.I.; Gonzalez, R.; Bilek, E.T.M.; Kelley, S.S. Systematic review of torrefied wood economics. BioResources 2017, 12, 6868–6884. [Google Scholar] [CrossRef] [Green Version]

- Beets, M. A Torrefied Wood Pellet Supply Chain. A detailed cost analysis of the comptetitiveness of torrefied wood pellets compared to white wood pellets. Master’s Thesis, Utrecht University, Utrecht, The Netherlands, 2017. [Google Scholar]

- Yun, H.; Clift, R.; Bi, X. Process simulation, techno-economic evaluation and market analysis of supply chains for torrefied wood pellets from British Columbia: Impacts of plant configuration and distance to market. Renew. Sustain. Energy Rev. 2020, 127, 109745. [Google Scholar] [CrossRef]

| LHV MJ kg−1 | Bulk Density (kg m−3) | Moisture (%) | Durability (%) | Ash Content (%) | N (%) | S (%) | Cl (%) | Feedstock | |

|---|---|---|---|---|---|---|---|---|---|

| [41] | --- | 603.00 | 8.50 | 98.50 | Pinus spp | ||||

| [42] | 18.50 | 709.00 | 9.60 | 97.80 | 0.70 | 0.06 | 0.02 | 0.01 | Pinus spp |

| [43] | 18.13 | 540.90 | --- | --- | --- | --- | --- | --- | Pinus spp |

| [44] | --- | 680.00 | 8.86 | --- | 0.78 | 1.43 | 0.02 | 0.02 | Pinus spp |

| [45] | 16.90 | --- | 7.30 | --- | 1.30 | 0.50 | <0.01 | --- | Pinus spp |

| [46] | --- | --- | --- | --- | 0.10 | --- | --- | --- | Picea spp |

| [47] | 18.69 | 709.46 | 7.84 | 93.60 | 0.70 | 0.09 | <0.01 | <0.01 | Picea spp |

| [47] | 18.28 | 756.23 | 5.79 | 96.80 | 0.35 | 0.07 | 0.01 | <0.001 | Tsuga spp |

| EN ISO 17225-2 A1 | ≥16.50 | ≥600 | ≤10.00 | ≥97.50 | ≤0.70 | ≤0.30 | ≤0.04 | ≤0.02 | |

| EN ISO 17225-2 A2 | ≥16.50 | ≥600 | ≤10.00 | ≥97.50 | ≤1.20 | ≤0.50 | ≤0.05 | ≤0.02 | |

| EN ISO 17225-2 B | ≥16.50 | ≥600 | ≤10.00 | ≥96.50 | ≤2.00 | ≤1.00 | ≤0.05 | ≤0.03 |

| Feedstock | Reference | Positive Aspects | Negative Aspects |

|---|---|---|---|

| Wheat straw | [50] | Lower Heating Value (LHV), ash, all chemical parameters except for chlorine | Chlorine |

| Scenedesmus microalgae | [68] | Durability and LHV | Ash, Nitrogen, Chlorine |

| Garden waste | [77] | LHV | Ash, Moisture |

| Soybean | [78] | --- | Ash, LHV (very important shortfall) |

| Sugarcane bagasse | [78] | --- | Ash, LHV (very important shortfall) |

| Cherry stones | [79] | LHV, all chemical parameters | Bulk density |

| Fallen leaves | [80] | Durability | Bulk density, LHV |

| Chamomile wastes | [53] | LHV, and Ash (mostly LHV) | Bulk density |

| Reference | Treatment | LHV | BD | Dur | Ash | RE | Hyd | Moi | Cl | N | S | Al | Pb | CO | SO2 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Blending | Binding | |||||||||||||||

| [27] | X | ● | ● | ● | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| [82] | x | ● | ○ | ○ | ● | ● | ○ | ○ | ● | ● | ○ | ○ | ○ | ○ | ○ | |

| [83] | x | ● | ● | ○ | ● | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| [85] | x | ● | ○ | ○ | ● | ○ | ○ | ○ | ● | ○ | ○ | ○ | ○ | ○ | ○ | |

| [86] | x | ○ | ○ | ● | ● | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| [87] | x | ○ | ● | ● | ○ | ● | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| [88] | X | ○ | ● | ● | ○ | ● | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| [89] | x | ● | ● | ● | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| [90] | X | ● | ● | ● | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| [91] | x | ○ | ● | ● | ● | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| [92] | x | ● | ○ | ○ | ● | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| [93] | x | ● | ○ | ○ | ● | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| [94] | X | ○ | ○ | ○ | ○ | ○ | ● | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| [95] | x | ● | ○ | ○ | ○ | ● | ○ | ● | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| [96] | X | ● | ○ | ○ | ○ | ● | ○ | ● | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| [97] | X | ● | ● | ○ | ● | ○ | ○ | ● | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| [98] | X | ● | ● | ○ | ● | ○ | ○ | ● | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| [99] | X | ○ | ● | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| [100] | X | ○ | ● | ● | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| [101] | X | ○ | ● | ● | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| [102] | X | ○ | ● | ● | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| [103] | X | ○ | ● | ● | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |

| [104] | x | ● | ○ | ○ | ● | ○ | ○ | ○ | ● | ○ | ● | ● | ● | ● | ● | |

| Analysis % | 19.4 | 20.9 | 16.4 | 14.9 | 7.5 | 1.5 | 6.0 | 4.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | ||

| Success % | 30.8 | 100.0 | 100.0 | 60.0 | 100.0 | 100.0 | 50.0 | 100.0 | 100.0 | 100 | 0.0 | 0.0 | 100.0 | 0.0 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Picchio, R.; Latterini, F.; Venanzi, R.; Stefanoni, W.; Suardi, A.; Tocci, D.; Pari, L. Pellet Production from Woody and Non-Woody Feedstocks: A Review on Biomass Quality Evaluation. Energies 2020, 13, 2937. https://doi.org/10.3390/en13112937

Picchio R, Latterini F, Venanzi R, Stefanoni W, Suardi A, Tocci D, Pari L. Pellet Production from Woody and Non-Woody Feedstocks: A Review on Biomass Quality Evaluation. Energies. 2020; 13(11):2937. https://doi.org/10.3390/en13112937

Chicago/Turabian StylePicchio, Rodolfo, Francesco Latterini, Rachele Venanzi, Walter Stefanoni, Alessandro Suardi, Damiano Tocci, and Luigi Pari. 2020. "Pellet Production from Woody and Non-Woody Feedstocks: A Review on Biomass Quality Evaluation" Energies 13, no. 11: 2937. https://doi.org/10.3390/en13112937

APA StylePicchio, R., Latterini, F., Venanzi, R., Stefanoni, W., Suardi, A., Tocci, D., & Pari, L. (2020). Pellet Production from Woody and Non-Woody Feedstocks: A Review on Biomass Quality Evaluation. Energies, 13(11), 2937. https://doi.org/10.3390/en13112937