Enhanced Cooling of LED Filament Bulbs Using an Embedded Tri-Needle/Ring Ionic Wind Device

Abstract

:1. Introduction

2. Materials and Methods

2.1. Tri-Needle/Ring Electrode Ionic Wind Device

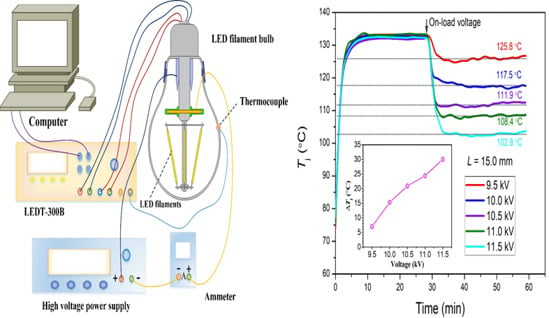

2.2. Experimental Setup for Measuring Junction Temperature of LED Filament Bulb

3. Results and Discussion

3.1. Operating Characteristics of the Ionic Wind Device

3.2. Cooling Performance of LED Filaments with Ionic Wind

3.3. Luminous Efficiency of LED Chips

4. Conclusions

- When voltage applied on electrodes is higher than the inception voltage, the current increases quickly when increasing the value of voltage. The inception voltage of ionic wind is increased if the electrode gap L increases. The ionic wind discharge current is increased with the addition of applied voltage. For the same voltage applied, the current is larger if the electrode gap is smaller. The larger electrode gap can also accommodate larger discharge current with higher voltage being applied.

- It is found that ionic wind is strengthened by applying higher voltage. For the same voltage applied, the ionic wind velocity with a larger electrode gap is lower. However, a larger electrode gap can enlarge the range of ionic wind operation voltage and generate higher velocity ionic wind. The range of ionic wind operation voltage is increased from range [3.7 kV, 6.5 kV] to [5.9 kV, 11.9 kV] when the electrode gap is increased from 6.0 mm to 15.0 mm. The largest ionic wind velocity obtained when the electrode gap is 15.0 mm and the applied voltage is 11.5 kV.

- The junction temperature of the LED filament bulb is also influenced by the electrode gap L. A larger gap can enlarge the voltage applied on electrode and increase the ionic wind velocity within the bulb. The heat dissipation ability is improved due to higher velocity. The temperature fall with the electrode distance of 6.0 mm is very poor, because the ionic wind velocity is small. The junction temperature can be reduced to about 115.2 °C, at best, with the electrode gap of 10.0 mm. The enhancement ratio of the cooling performance is about 20% as compared with that of natural convection condition. The junction temperature can be reduced to about 102.8 °C at best when the gap increases to 15.0 mm and the enhancement ratio of the cooling performance reaches 40% when compared with that of natural convection condition.

- The stability and adjustability of using ionic wind generator for cooling LED are confirmed by investigating the junction temperature under ionic wind in long-term tests. The values of temperature drops are consistent with the former measurement results. The LED filament bulb can work safety and reliably under ionic wind cooling.

- The light efficiency of the LED filament bulb is improved with regard to junction temperature drop. The electric power and luminous power of the bulb are also increased when the junction temperature is reduced. The maximum increase rate of luminous flux reaches 7.3% when the junction temperature reduction of LED reaches 30 °C.

Author Contributions

Funding

Conflicts of Interest

Appendix A

Appendix A.1. Analysis of Measurement Error on LED Junction Temperature Tj

Appendix A.2. Analysis of Measurement Error on Environmental Temperature Ta

Appendix A.3. Analysis of Measurement Error on Ionic Wind Velocity v

Appendix A.4. Analysis of Measurement Error on Discharge Current of Ionic Wind I

Appendix A.5. Analysis of Measurement Error on Electric Power of LED

Appendix A.6. Analysis of Measurement Error on Luminous Power of LED

Appendix A.7. Analysis of Measurement Error on Luminous Flux of LED

References

- Luo, X.; Hu, R.; Liu, S.; Wang, K. Heat and fluid flow in high-power LED packaging and applications. Prog. Energy Combust. Sci. 2016, 56, 1–32. [Google Scholar] [CrossRef] [Green Version]

- Yang, L.; Zhang, Q.; Li, F.; Xie, A.; Mao, L.; Ma, J. Thermally stable lead-free phosphor in glass enhancement performance of light emitting diodes application. Appl. Opt. 2019, 58, 4099–4104. [Google Scholar] [CrossRef] [PubMed]

- Weng, C.-J. Advanced thermal enhancement and management of LED packages. Int. Commun. Heat Mass Transf. 2009, 36, 245–248. [Google Scholar] [CrossRef]

- Lei, X.; Zheng, H.; Guo, X.; Zhang, Z.; Wu, J.; Xu, C.; Liu, S. Reduction of die-bonding interface thermal resistance for high-power LEDs through embedding packaging structure. IEEE Trans. Power Electron. 2017, 32, 5520–5526. [Google Scholar] [CrossRef]

- Wang, H.-C.; Jewell-Larsen, N.E.; Mamishev, A.V. Thermal management of microelectronics with electrostatic fluid accelerators. Appl. Therm. Eng. 2013, 51, 190–211. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, T.; Cai, Y.-X.; Zhang, J.-F.; Wang, J.-B. Review on the recent development of corona wind and its application in heat transfer enhancement. Int. J. Heat Mass Transf. 2020, 152, 119545. [Google Scholar] [CrossRef]

- Hsu, C.-P.; Jewell-Larsen, N.E.; Krichtafovitch, I.A.; Mamishev, A.V. Heat-Transfer-Enhancement Measurement for Microfabricated Electrostatic Fluid Accelerators. J. Microelectromech. Syst. 2009, 18, 111–118. [Google Scholar]

- Mei, L.; Zhang, H.; Meng, H.; Qian, S. Electroosmotic Flow of Viscoelastic Fluid in a Nanoslit. Micromachines 2018, 9, 155. [Google Scholar] [CrossRef] [Green Version]

- Jewell-Larsen, N.E.; Ran, H.; Zhang, Y.; Schwiebert, M.K.; Tessera, K.A.H.; Mamishev, A.V. Electrohydrodynamic (EHD) cooled laptop. In Proceedings of the 25th Annual IEEE Semiconductor Thermal Measurement and Management Symposium, San Jose, CA, USA, 15–19 March 2009; pp. 261–266. [Google Scholar]

- Chen, I.Y.; Guo, M.-Z.; Yang, K.-S.; Wang, C.-C. Enhanced cooling for LED lighting using ionic wind. Int. J. Heat Mass Transf. 2013, 57, 285–291. [Google Scholar] [CrossRef]

- Chen, I.Y.; Chen, C.-J.; Wang, C.-C. Influence of electrode configuration on the heat transfer performance of a LED heat source. Int. J. Heat Mass Transf. 2014, 77, 795–801. [Google Scholar] [CrossRef]

- Qu, J.; Kong, L.; Zhang, J. Experimental Investigation on Flow and Heat Transfer Characteristics of a Needle-Cylinder Type Ionic Wind Generator for LED Cooling. Energies 2018, 11, 1149. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Zhao, C.; Li, H.; Tao, W. 3D Numerical Simulation of Heat Transfer of a Heated Plate under the Electric Field Generated by a Needle Electrode. Math. Probl. Eng. 2014, 2014, 354180. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.F.; Wang, S.; Li, H.Y.; Qu, Z.G. Parametric Study and Optimization of Flow Characteristics of Wire-Nonparallel Plate-Type Electrostatic Air Accelerators. J. Fluids Eng. 2018, 140, 101105. [Google Scholar] [CrossRef] [PubMed]

- Shin, D.H.; Baek, S.H.; Ko, H.S. Development of heat sink with ionic wind for LED cooling. Int. J. Heat Mass Transf. 2016, 93, 516–528. [Google Scholar] [CrossRef]

- Shin, D.H.; Sohn, D.K.; Ko, H.S. Analysis of thermal flow around heat sink with ionic wind for high-power LED. Appl. Therm. Eng. 2018, 143, 376–384. [Google Scholar] [CrossRef]

- Wang, J.; Cai, Y.-X.; Bao, W.-W.; Li, H.-X.; Liu, Q. Experimental study of high power LEDs heat dissipation based on corona discharge. Appl. Therm. Eng. 2016, 98, 420–429. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, T.; Cai, Y.-X.; Wang, J.-B.; Wang, J. Development and application of a solid-state fan for enhanced heat dissipation. Appl. Therm. Eng. 2020, 169, 114922. [Google Scholar] [CrossRef]

- Wang, L.; Li, W.; Xu, Y.; Yang, B.; Shi, M.; Zou, J.; Li, Y.; Qian, X.; Zheng, F.; Yang, L. Effect of different bending shapes on thermal properties of flexible light-emitting diode filament. Chin. Phys. B 2018, 27, 110701. [Google Scholar] [CrossRef]

- Madias, E.N.D.; Doulos, L.T.; Kontaxis, P.A.; Topalis, F.V. A decision support system for techno-economic evaluation of indoor lighting systems with LED luminaires. Oper. Res. 2019. [Google Scholar] [CrossRef]

- Doulos, L.T.; Sioutis, I.; Kontaxis, P.; Zissis, G.; Faidas, K. A decision support system for assessment of street lighting tenders based on energy performance indicators and environmental criteria: Overview, methodology and case study. Sustain. Cities Soc. 2019, 51, 101759. [Google Scholar] [CrossRef]

- Kagel, H.; Jacobs, H.; Bier, F.F.; Glökler, J.; Frohme, M. A Novel Microtiter Plate Format High Power Open Source LED Array. Photonics 2019, 6, 17. [Google Scholar] [CrossRef] [Green Version]

- Feng, W.; Feng, B.; Zhao, F.; Shieh, B.; Lee, R. Simulation and optimization on thermal performance of LED filament light bulb. In Proceedings of the 12th China International Forum on Solid State Lighting (SSLCHINA), Shenzhen, China, 2–4 November 2015; pp. 88–92. [Google Scholar]

- Liu, J.; Xu, C.; Zheng, H.; Liu, S. Numerical Analysis and Optimization of Thermal Performance of LED Filament Light Bulb. In Proceedings of the IEEE 67th Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 30 May–2 June 2017; pp. 2243–2248. [Google Scholar]

- Wang, W.; Zou, J.; Zheng, Q.; Li, Y.; Yang, B.; Shi, M.; Li, Y.; Li, X.; Zhang, C.; Li, C.; et al. The Effect of Different Filament Arrangements on Thermal and Optical Performances of LED Bulbs. Appl. Sci. 2020, 10, 1373. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.P.; Zou, J.; Yang, B.B.; Li, W.B.; Li, Y.; Shi, M.M.; Zhu, W.; Zhang, C.Y.; Wang, F.C.; Lin, Y.J. Optical and electrical properties of a spiral LED filament. J. Semicond. 2018, 39, 024003. [Google Scholar] [CrossRef]

- Xu, C.; Zhang, Z.; Chu, J.; Wu, J.; Lei, X.; Zheng, H.; Liu, S. Thermal dissipation enhancement of LED filament bulb by ionic wind. In Proceedings of the 17th International Conference on Electronic Packaging Technology (ICEPT), Wuhan, China, 16–19 August 2016; pp. 1212–1215. [Google Scholar]

- Luo, X.B.; Mao, Z.M.; Liu, S. Thermal design of a 16W LED bulb based on thermal analysis of a 4W LED bulb. In Proceedings of the Electronic Components and Technology Conference, Las Vegas, NV, USA, 1–4 June 2010; pp. 1906–1911. [Google Scholar]

- Petroski, J. Advanced natural convection cooling designs LED bulb systems. J. Electron. Packag. 2014, 136, 041005. [Google Scholar] [CrossRef]

- Yang, X.F.; Liu, J.; Chen, Q.; Shen, Y.P.; Liu, H.Z.; Lai, G.Q. A low temperature vulcanized transparent silane modified epoxy resins for LED filament bulb package. Chin. J. Polym. Sci. 2018, 36, 114–121. [Google Scholar] [CrossRef]

- Jang, D.; Park, S.J.; Yook, S.J.; Lee, K.S. The orientation effect for cylindrical heat sinks with application to LED light bulb. Int. J. Heat Mass Transf. 2014, 71, 496–502. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, L.; Chen, Y.; Ouyang, J. Characteristics of ionic wind in needle-to-ring corona discharge. J. Electrost. 2015, 74, 15–20. [Google Scholar] [CrossRef]

- Shin, D.H.; Yoon, J.S.; Ko, H.S. Experimental optimization of ion wind generator with needle to parallel plates for cooling device. Int. J. Heat Mass Transf. 2015, 84, 35–45. [Google Scholar] [CrossRef]

| Instruments | Parameters and Accuracy |

|---|---|

| LEDT-300B (Shanghai LEETS LIGHTING Co., Ltd., Shanghai, China) | Output voltage: 0–500 V Output Current: 0–5 A Resolution: 0.0001 V, 0.001 A Operation temperature: 0–150 °C Calibration current: 1.0 mA ± 0.2% Temperature calibration accuracy: ±0.5 °C Junction temperature measuring error: ±1 °C |

| High voltage power supply (Dong wen high voltage Co. Ltd., Tianjin, China) | Voltage: 0–30 kV Resolution: 0.001 kV, 0.01 mA Accuracy: ±(1% f.s. 1 + 1 V), ±(1% f.s.1 + 0.01 mA) |

| Hot wire anemometer (HT-9829, Dongguan Xintai Instrument Co., Ltd., Dongguan, China) | Velocity: 0.1–25 m/s Resolution: 0.01 m/s Accuracy: ±(5% rdg 2 + 1dgt 3)/±(1% f.s. 1 +1dgt 3) |

| T-type thermocouple | Temperature: 0–350 °C Accuracy: ±0.5 °C |

| Microammeter (AD5/1-7 Digital-dc galvanometer, Shanghai Dongmao Electronic Technology Co., Ltd., Shanghai, China) | Measurement range: 0–20 µA/0–200 µA Resolution: 0.01 µA/0.1 µA Accuracy: ±(0.5% f.s. 1 + 0.01 µA)/±(0.5% f.s. 1 + 0.1 µA) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, C.; Zheng, H.; Liu, J.; Chu, J.; Zeng, X.; Sun, R.; Liu, S. Enhanced Cooling of LED Filament Bulbs Using an Embedded Tri-Needle/Ring Ionic Wind Device. Energies 2020, 13, 3008. https://doi.org/10.3390/en13113008

Xu C, Zheng H, Liu J, Chu J, Zeng X, Sun R, Liu S. Enhanced Cooling of LED Filament Bulbs Using an Embedded Tri-Needle/Ring Ionic Wind Device. Energies. 2020; 13(11):3008. https://doi.org/10.3390/en13113008

Chicago/Turabian StyleXu, Chunlin, Huai Zheng, Jie Liu, Jingcao Chu, Xiaoliang Zeng, Rong Sun, and Sheng Liu. 2020. "Enhanced Cooling of LED Filament Bulbs Using an Embedded Tri-Needle/Ring Ionic Wind Device" Energies 13, no. 11: 3008. https://doi.org/10.3390/en13113008

APA StyleXu, C., Zheng, H., Liu, J., Chu, J., Zeng, X., Sun, R., & Liu, S. (2020). Enhanced Cooling of LED Filament Bulbs Using an Embedded Tri-Needle/Ring Ionic Wind Device. Energies, 13(11), 3008. https://doi.org/10.3390/en13113008