1. Introduction

With the overexploitation of fossil energy such as oil and coal, the problem of energy exhaustion is becoming more and more serious [

1]. Moreover, the economy is developing rapidly all over the world, and the population is growing too fast, resulting in an increasing demand for resources. Therefore, traditional fossil energy has been difficult to meet the needs of economic development. Due to the excessive use of fossil energy, the global ecological environment has been greatly damaged [

2]. In order to deal with the problem of energy depletion, all countries in the world have made great efforts to develop environmentally friendly renewable energy (RE) to replace traditional fossil energy [

3]. Therefore, photovoltaic (PV), wind energy, tidal energy, and other renewable energy appear in people’s vision. Renewable energy exists in nature, which is inexhaustible and widely distributed, and its impact and damage on the environment can be almost ignored. Because of the above advantages, renewable energy has been widely used. Vigorously developing renewable energy is a key step to alleviate the current shortage of fossil resources such as coal, reduce environmental degradation, and reform of energy structure.

Wind generation and photovoltaic generation are two kinds of renewable energy power generation technologies with the best development prospect and the most extensive application in recent years, which have been highly concerned by all countries in the world [

4,

5]. The wind-PV hybrid generation system (WP-HGS), which is a combination of wind and photovoltaic generation technology, can combine the complementarity of wind energy and solar energy in time and space, making full use of the natural advantages of both. There is a good complementarity between the two kinds of energy in time and season. So, compared with the wind or photovoltaic generation alone, the WP-HGS has a better stability. At the same time, wind and PV can also have good complementarity in space, which can effectively save the floor space of the system. Compared with the single PV or wind generation system, the WP-HGS can make up for the shortcomings of continuity and discontinuity in the single energy system [

6].

With the continuous improvement of the installed capacity of WP-HGS, more and more problems are exposed. First of all, wind and PV generation are intermittent and random with the change of wind and solar [

7,

8]. The output power is not easy to control, which has a great impact on the power grid and is not conducive to the stability of the power system. Secondly, the growth rate and installed capacity of wind and photovoltaic generation grow too fast, while the grid connected capacity is limited, resulting in a large number of wind and solar abandonment phenomena, which will also lead to the increase of generation cost. At present, in order to solve the above problems, large-scale energy storage devices are usually used in combination with WP-HGS [

9]. At present, common energy storage methods include pumped energy storage, compressed air energy storage, lead-acid battery energy storage, lithium battery energy storage, and supercapacitor energy storage [

10,

11]. At present, the most widely used is battery energy storage. It can be combined with photovoltaic and wind turbine to form a wind-PV-battery hybrid generation system (WPB-HGS). Through the charging and discharging of energy storage equipment, the energy of wind and solar can be transferred in time and space, the utilization ratio of wind and solar energy can be improved, the fluctuation and intermittence of wind and solar energy can be effectively eliminated, and the stable and safe operation of power grid can be ensured [

12,

13]. Although the energy storage equipment has so many advantages, the cost of energy storage equipment is high [

14]. When the capacity of energy storage equipment in WPB-HGS is too high, the system economy is reduced, and the utilization efficiency of energy storage equipment is low; when the capacity of energy storage equipment is too low, it is difficult to meet the requirements of power supply stability. Therefore, the reasonable allocation of energy storage for WPB-HGS is very important.

For the WPB-HGS, economic benefit is the most direct and important evaluation index. Reasonable planning of wind turbine (WT), photovoltaic (PV), battery energy storage (BES), and other equipment can not only ensure the reliability of energy supply but also effectively improve the economy of the system. At present, there have been some research results on the planning of WPB-HGS. In Reference [

15], a capacity configuration optimization (CCO) model for stand-alone wind–PV–diesel–battery micro-grid based on an improved binary bat algorithm (BBA) is proposed. A power system’s expansion planning model was proposed in Reference [

16] to study the contribution of interconnecting small isolated power systems in promoting renewable penetration levels increase and cost reductions. In Reference [

17], optimal sizing is carried out for a PV-wind-battery hybrid renewable energy system employed in off-grid rural telecom towers to provide an environment-friendly, reliable, and economical power supply.

All the above studies take off-grid WPB-HGS as the research object. However, for grid connected system, Reference [

18] has addressed the optimal allocation (including sizing and sitting) of energy storage system (ESS) and distributed generation (DG) from the perspective of the distribution system operator (DSO). Reference [

19] presents an integrated methodology that considers renewable distributed generation (RDG) and demand responses (DR) as options for planning distribution systems in a transition toward low-carbon sustainability. Reference [

20] presents a methodology for the joint capacity optimization of renewable energy (RE)sources, i.e., wind and solar, and the state-of-the-art hybrid energy storage system (HESS) composed of battery energy storage (BES) and supercapacitor (SC) storage technology, employed in a grid-connected microgrid (MG). In Reference [

21], two constraint-based iterative search algorithms are proposed for optimal sizing of the wind turbine (WT), solar photovoltaic (PV), and the battery energy storage system (BESS) in the grid-connected configuration of a microgrid. The first algorithm, named as sources sizing algorithm, determines the optimal sizes of RE sources, while the second algorithm, called as battery sizing algorithm, determines the optimal capacity of BESS.

All of the above studies on the planning of WPB-HGS use single-level optimization models. For a WPB-HGS, both equipment capacity and system operating conditions can affect its economy. Equipment capacity determines the cost of equipment purchase and system construction in the initial stage of system construction. The operation and maintenance costs and electricity sales revenue are directly related to the operating status of the system. Therefore, when optimizing the WPB-HGS, it is necessary to consider both the equipment capacity and the operating status. Therefore, this problem is a typical bi-level optimization problem. The upper layer determines the structure of the system and the capacity of the system equipment, and the lower layer optimizes the operating state of the system under the upper-layer equipment capacity configuration results. In Reference [

22], a bi-level program was proposed to determine the optimal size of distributed generations and compressed air energy storage (CAES) in an islanded microgrid. In Reference [

23], a bi-level model is proposed to optimize the allocation of photovoltaic (PV), wind turbine (WT), and energy storage system (ESS) in distribution networks. At the upper level, a genetic algorithm (GA) is used to optimize the capacity of PV, WT, and ESS. At the lower level, an operation strategy of ESS is proposed first to smooth the power flow. Aiming at capacity optimization of an isolated microgrid, Reference [

24] establishes a bi-level capacity optimization model that considers load demand management (LDM) while comprehensively considering load and renewable generation uncertainties.

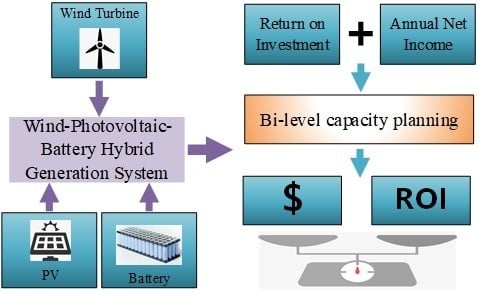

For a specific project of WPB-HGS, the economic benefit is the most important basis for the investment builder to evaluate the system. However, the existing research often uses a single economic index, such as investment cost or net income, which cannot fully consider the economy of the whole life cycle of WPB-HGS. Therefore, this paper puts the return on investment (ROI) into the optimization objective to improve the system economy. Considering the influence of the operation state of the WPB-HGS on the optimal allocation results, a bi-level model of planning operation integration of the WPB-HGS is established. The effectiveness of the proposed planning model is verified by a case study. At last, it is compared with the single-level planning model to verify that the bi-level planning operation integration model has better economy.

The main contributions of this paper are:

Established a bi-level model of planning operation integration of the WPB-HGS. This bi-level planning model can optimize the capacity and operation state of the system equipment to improve the economy of planning results.

Put the return on investment (ROI) into the optimization objective. In consideration of the system revenue, ROI is included in the optimization objective to improve the system economy more comprehensively.

Compared with the traditional single-level planning model, the integrated bi-level planning operation model is more economical.

With the increasing application of WPB-HGS, this paper has a certain guiding significance for the optimal configuration design of WPB-HGS in the future.

The remainder of this paper is organized as follows:

Section 2 introduces the structure and equipment model of WPB-HGS.

Section 3 establishes the double-level programming model of WPB-HGS.

Section 4 uses case to verify the proposed model. The concluding remarks are drawn in

Section 5.

4. Case Study

4.1. Basic Data

In order to verify the effectiveness of the proposed planning scheme, the actual engineering data is selected for simulation. The structure of the whole system is shown in

Figure 1. Typical daily data of solar radiation intensity, wind speed, and temperature are shown in

Figure 4,

Figure 5, and

Figure 6, respectively. All typical daily data are from renewable energy power generation system projects. The system dispatching time is 1 min, the dispatching cycle is 1 day, and the system output fluctuation before and after the unit dispatching time is limited to 120 kW.

The device parameters of the system are shown in

Table 1.

The battery parameters are shown in

Table 2.

4.2. Billing Strategy for Electricity Sales

In this example, all the power generated by the system is sold to the grid. The peak time is 9–22 points every day, and the off-peak time is 0–8 points and 23–24 points. The unit billing time is 15 min. The guaranteed energy at the peak time (

GEp) is 3000 kWh/15 min. The guaranteed energy at the off-peak time is 2000 kWh/15 min. The peak time and the off-peak time (

GEnp) are charged according to different electricity sales rules. The price parameters are shown in

Table 3.

The rules for selling electricity at peak time are shown in

Table 4.

In

Table 4,

is the output electric energy in unit time period, and

is the guaranteed energy in peak time. In peak time, when

is less than 80%

, the output power will be sold according to the basic price, and the part less than 80%

will be fined accordingly. When

is more than 80%

and less than 100%

, all electric energy will be charged according to the basic price. When

is more than 100%

and less than 110%

, the part of 100%

will sell electricity according to the basic price, and the part between 100% and 110%

will be sold according to 50% of the basic price. When

is more than 110%

, the part higher than 110%

will not be calculated as power sale income.

The rules for selling electricity at off-peak time are shown in

Table 5.

In

Table 5,

is the output electric energy in unit time period, and

is the guaranteed energy in off-peak time. In off-peak time, when

is less than 100%

, all electric energy will be charged according to the basic price. When

is more than 100%

and less than 110%

, the part of 100%

will sell electricity according to the basic price, and the part between 100% and 110%

will be sold according to 50% of the basic price. When

is more than 110%

, the part higher than 110%

will not be calculated as power sale income.

4.3. Scene Design

In order to study the impact of ROI optimization goals on planning, two scenarios were set up for comparative analysis. The specific scenarios are as follows:

Scenario 1: Only plan the capacity of WPB-HGS with the goal of maximum annual net income.

Scenario 2: Plan the capacity of WPB-HGS with the goal of combining annual net income and ROI as the goal.

4.4. Results and Discussion

Based on the bi-level planning model established in this paper, the typical data of scenery in

Figure 4 and

Figure 5, the basic parameters of each equipment in

Table 1 and

Table 2, and the electricity sales strategy in

Table 4 and

Table 5, AW-PSO was used to solve the model. The device configuration results are shown in

Table 6.

According to

Table 6, considering ROI, the PV capacity increases from 5763 kW to 7282 kW, with an increase of 1519 kW. The capacity of WT is reduced from 27,500 kW to 23,000 kW, a decrease of 4500 kW. The reduction of the total capacity of PV and WT reduces the system output fluctuation, thereby reducing the energy storage battery capacity. Therefore, the energy storage battery capacity is reduced from 2805 kWh to 2249 kWh, which is reduced by 556 kWh. No matter in scenario 1 or scenario 2, compared with PV, WT capacity is obviously higher, because the wind can be used for a long time throughout the day. According to the typical day data of the scenery in

Figure 4 and

Figure 5, the light resources only exist during the day, and increase with time and then decrease, with uneven distribution. The wind resources can be used no matter day or night, and the distribution is relatively uniform, so the WT with a larger capacity can use renewable resources more reasonably and effectively improve the equipment utilization efficiency.

The economic indicators of the system in each scenario are shown in

Table 7.

It can be seen from

Table 7 that after considering ROI in scenario 2, the total cost decreased from 5.5953 × 10

7 $ to 4.7469 × 10

7 $, a decrease of 15.16%. The ROI increased from 0.1626 to 0.1833, an increase of 12.73%; The investment recovery period has also been shortened from 6.2 years to 5.4 years. However, the overall benefits of the system remain substantially unchanged, decreased from 1.7155 × 10

8 $ to 1.7007 × 10

8$, down only 0.86%.

According to the comparison results in

Table 7 that compared with not considering ROI, after adding ROI to the optimization goal, it can effectively reduce the total investment cost of the system, increase the project ROI, and reduce the investment recovery period, while ensuring that the total system revenue is reduced by a very small percentage.

The cost and distribution of each device of the system in the two scenarios are shown in

Figure 7 and

Figure 8.

It can be seen from the combination of

Figure 7 and

Figure 8 that among all devices, the cost of WT accounts for the largest proportion of the cost of all devices, which is 59% and 58% in two scenarios. The second is energy storage batteries, which are 24% and 22%. Again, it is PV equipment, which accounts for 10% and 14% in the two scenarios, respectively. The smallest percentage is GCI. Although the energy storage battery capacity is lower than the capacity of PV equipment, its equipment cost accounted for more than PV equipment. This is because the service life of PV equipment is the entire project cycle, and there is no replacement cost. The service life of energy storage battery is related to the depth and frequency of charge and discharge. After many charging and discharging processes, the service life of the battery is greatly reduced, resulting in the need to replace the energy storage battery multiple times throughout the project cycle, thereby increasing the total cost of the energy storage battery.

Figure 9 is the output curve of each device of the system in scenario 2.

At 0–7 o’clock, the wind resource is sufficient and the light radiation intensity is 0. At this time, the system output is provided by the WT. At 7–19 o’clock, the wind speed decreased and the output of WT was insufficient, while the PV output increased with the increase of light radiation intensity. After 19 o’clock, the light radiation intensity will be 0 and the wind speed will increase. At this time, the system output will be provided by WT.

It can be seen from the output curve in

Figure 9 that the output of WT and PV have good complementary characteristics.

It can be seen from the energy storage output curve in

Figure 9 that the energy storage battery output has been fluctuating up and down at 0, and has not played the role of peak shaving and valley filling. This is because the investment cost and replacement cost of energy storage batteries are high, and the use of energy storage batteries for peak output and valley filling in system output is not economical. Therefore, the main function of the energy storage battery is to smooth the output of the system. At 7–19 o’clock, the energy storage battery is charged and discharged relatively frequently and the power is relatively high. This is because the superposition of the WT and PV output causes the system output fluctuation to become larger. The energy storage battery needs to be frequently charged and discharged to smooth the system output.

In scenario 2, the output curve of the system before and after stabilizing the fluctuation by the energy storage battery is shown in

Figure 10.

Table 8 shows the maximum power difference in system output before and after unit time.

According to

Figure 10 and

Table 8, the maximum output fluctuation of the system per unit time is 5590 kW before the energy storage battery stabilizes the fluctuation. The maximum output fluctuation per unit time of the system is 120 kW after the energy storage battery stabilizes the fluctuation. This meets the requirements of maximum fluctuation power. The energy storage battery plays a good role in stabilizing the fluctuation.

SOC of energy storage battery is shown in

Figure 11. According to

Figure 9 and

Figure 10, due to the large fluctuation of WT and PV output, the energy storage battery needs to conduct high-frequency charging and discharging to ensure the stability of output power, resulting in high frequency and large fluctuation of energy storage state.

4.5. Verification of Bi-Level Planning Model

In order to verify the effectiveness of the proposed bi-level planning model, it is compared with the traditional single-level planning model. The single-layer planning model adopted only plans of the system equipment capacity and does not consider the system operation state. Compared with the bi-level planning model, the single-level planning model also sets up two scenarios for comparative analysis. The specific scenarios are as follows:

Scenario 3: Based on the single-level programming model, only plan the capacity of WPB-HGS with the goal of maximum annual net income.

Scenario 4: Based on the single-level programming model, plan the capacity of WPB-HGS with the goal of combining annual net income and ROI as the goal.

The single-level planning model is solved, and the equipment configuration results are shown in

Table 9.

The economic indicators of the system in each scenario are shown in

Table 10.

According to the analysis of the economic indicators of the system under the single-level planning model in

Table 10, after considering the ROI in the optimization objective of scenario 4, the total cost of the system is reduced by 11.14%; the ROI is increased by 9.23%; the payback period is also shortened from 6.1 years to 5.5 years; however, the total return of the system is basically unchanged, only reduced by 0.36%.

This shows that, like the bi-level planning model, when the ROI is added to the optimization objective of the single-level planning model, it can effectively reduce the total investment cost of the system and improve the ROI of the project, to improve the overall economy, while ensuring the reduction of the minimum proportion of the total return on investment of the system.

The total income of single-level and bi-level planning models in different scenarios are shown in

Table 11.

It can be seen from

Table 11 that when ROI is not considered in the optimization objective, the total income of the single-level planning model is 5.3 × 10

6$ lower than that of the bi-level planning model. When ROI is considered in the optimization objective, the total income of single-level planning model is 4.4 × 10

6$ lower than that of bi-level planning model.

Therefore, compared with the single-level planning model, the bi-level planning model is more economical.