Anti-Thermal Shock Binding of Liquid-State Food Waste to Non-Wood Pellets

Abstract

:1. Introduction

2. Materials and Methods

2.1. Pre-Production

2.1.1. Infrastructure

2.1.2. Starting Material and Supplement

Characterization

2.2. Production

2.2.1. Experimental Planning

2.2.2. Setup

Pre-Treatment of the Materials

Preparation of Liquid-State Additive

Supplementation of the Starting Material

Pelleting

2.3. Post-Production

2.3.1. Trial of Storage

2.3.2. Technical Analysis

2.4. Data Analysis

3. Results

3.1. Proximal and Elemental Properties of the Materials

3.2. Relative Performance of Addition by Spraying of Liquid-State Food Waste to Produce Freezing–Defrosting-Proof Non-Wood Pellets

3.3. Interactive Effect of Time of Boiling, Method of Addition, and Storage Condition on the Physical–Mechanical Quality of Non-Wood Pellets

3.3.1. Diameter and Length

3.3.2. Apparent Density

3.3.3. Durability and Fines

3.3.4. Resistance to Breaking Down by Water

3.3.5. Hygroscopicity

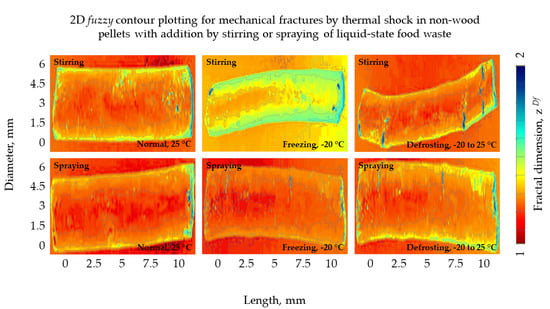

3.3.6. Fractal Dimension of Mechanical Fractures by Thermal Shock

3.3.7. Efficiency of Pelleting

3.4. Collinearities into the Addition of Liquid-State Food Waste to Make Freezing–Defrosting-Proof Pellets

4. Discussion

4.1. Relative Performance of Addition by Spraying of Liquid-State Food Waste to Produce Freezing–Defrosting-Proof Non-Wood Pellets

4.2. Potential Applications for Non-Wood Pellets from Residual Biomass from Distillation of Cellulosic Bioethanol

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Meena, M.D.; Yadav, R.K.; Narjary, B.; Yadav, G.; Jat, H.S.; Sheoran, P.; Meena, M.K.; Antil, R.S.; Meena, B.L.; Singh, H.V.; et al. Municipal solid waste (MSW): Strategies to improve salt affected soil sustainability: A review. Waste Manag. 2019, 84, 38–53. [Google Scholar] [CrossRef] [PubMed]

- Lima, P.D.M.; Colvero, D.A.; Gomes, A.P.; Wenzel, H.; Schalch, V.; Cimpan, C. Environmental assessment of existing and alternative options for management of municipal solid waste in Brazil. Waste Manag. 2018, 78, 857–870. [Google Scholar] [CrossRef]

- Dalmo, F.C.; Simão, N.M.; De Lima, H.Q.; Jimenez, A.C.M.; Nebra, S.; Martins, G.; Palacios-Bereche, R.; De Santana, P.H.M. Energy recovery overview of municipal solid waste in São Paulo State, Brazil. J. Clean. Prod. 2019, 212, 461–474. [Google Scholar] [CrossRef]

- Drudi, K.C.R.; Drudi, R.; Martins, G.; Antonio, G.C.; Leite, J.T.C. Statistical model for heating value of municipal solid waste in Brazil based on gravimetric composition. Waste Manag. 2019, 87, 782–790. [Google Scholar] [CrossRef] [PubMed]

- Ibáñez-Forés, V.; Bovea, M.D.; Coutinho-Nóbrega, C.; De Medeiros, H.R. Assessing the social performance of municipal solid waste management systems in developing countries: Proposal of indicators and a case study. Ecol. Indic. 2019, 98, 164–178. [Google Scholar] [CrossRef]

- Chen, Y.-C. Effects of urbanization on municipal solid waste composition. Waste Manag. 2018, 79, 828–836. [Google Scholar] [CrossRef]

- Cheng, J.; Zhou, F.; Si, T.; Zhou, J.; Cen, K. Mechanical strength and combustion properties of biomass pellets prepared with coal tar residue as a binder. Fuel Process. Technol. 2018, 179, 229–237. [Google Scholar] [CrossRef]

- Chhabra, V.; Bhattacharya, S.; Shastri, Y. Pyrolysis of mixed municipal solid waste: Characterisation, interaction effect and kinetic modelling using the thermogravimetric approach. Waste Manag. 2019, 90, 152–167. [Google Scholar] [CrossRef]

- Glushkov, D.O.; Paushkina, K.; Shabardin, D.; Strizhak, P.; Gutareva, N. Municipal solid waste recycling by burning it as part of composite fuel with energy generation. J. Environ. Manag. 2019, 231, 896–904. [Google Scholar] [CrossRef]

- Whittaker, C.; Shield, I. Factors affecting wood, energy grass and straw pellet durability–A review. Renew. Sustain. Energy Rev. 2017, 71, 1–11. [Google Scholar] [CrossRef]

- Unrean, P.; Fui, B.C.L.; Rianawati, E.; Acda, M. Comparative techno-economic assessment and environmental impacts of rice husk-to-fuel conversion technologies. Energy 2018, 151, 581–593. [Google Scholar] [CrossRef]

- Wang, T.; Li, Y.; Zhang, J.; Zhao, J.; Liu, Y.; Sun, L.; Liu, B.; Mao, H.; Lin, Y.; Li, W.; et al. Evaluation of the potential of pelletized biomass from different municipal solid wastes for use as solid fuel. Waste Manag. 2018, 74, 260–266. [Google Scholar] [CrossRef] [PubMed]

- Jensen, P.D.; Temmerman, M.; Westborg, S. Internal particle size distribution of biofuel pellets. Fuel 2011, 90, 980–986. [Google Scholar] [CrossRef]

- Teixeira, G.; Van De Steene, L.; Martin, E.; Gelix, F.; Salvador, S. Gasification of char from wood pellets and from wood chips: Textural properties and thermochemical conversion along a continuous fixed bed. Fuel 2012, 102, 514–524. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Maraver, A.; Rodriguez, M.L.; Serrano-Bernardo, F.; Diaz, L.F.; Zamorano, M. Factors affecting the quality of pellets made from residual biomass of olive trees. Fuel Process. Technol. 2015, 129, 1–7. [Google Scholar] [CrossRef]

- Lam, P.Y.; Lam, P.S.; Sokhansanj, S.; Bi, X.T.; Lim, C.J.; Melin, S. Effects of pelletization conditions on breaking strength and dimensional stability of Douglas fir pellet. Fuel 2014, 117, 1085–1092. [Google Scholar] [CrossRef]

- Acda, M.N. Physico-chemical properties of wood pellets from coppice of short rotation tropical hardwoods. Fuel 2015, 160, 531–533. [Google Scholar] [CrossRef]

- Arranz, J.I.; Miranda, M.T.; Montero, I.; Sepulveda, F.J.; Rojas, C.V. Characterization and combustion behaviour of commercial and experimental wood pellets in South West Europe. Fuel 2015, 142, 199–207. [Google Scholar] [CrossRef]

- Castellano, J.M.; Gomez, M.; Fernández, M.; Esteban, L.S.; Carrasco, J.E. Study on the effects of raw materials composition and pelletization conditions on the quality and properties of pellets obtained from different woody and non woody biomasses. Fuel 2015, 139, 629–636. [Google Scholar] [CrossRef]

- Ahn, B.J.; Chang, H.-S.; Lee, S.M.; Choi, D.H.; Cho, S.T.; Han, G.-S.; Yang, I. Effect of binders on the durability of wood pellets fabricated from Larix kaemferi C. and Liriodendron tulipifera L. sawdust. Renew. Energy 2014, 62, 18–23. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Natural binders and solid bridge type binding mechanisms in briquettes and pellets made from corn stover and switchgrass. Bioresour. Technol. 2010, 101, 1082–1090. [Google Scholar] [CrossRef]

- Kuokkanen, M.J.; Vilppo, T.; Kuokkanen, T.; Stoor, T.; Niinimäki, J. Additives in wood pellet production—A pilot-scale study of binding agent usage. BioResources 2011, 6, 4331–4355. [Google Scholar]

- Kang, K.; Qiu, L.; Sun, G.; Zhu, M.; Yang, X.; Yao, Y.; Sun, R. Codensification technology as a critical strategy for energy recovery from biomass and other resources—A review. Renew. Sustain. Energy Rev. 2019, 116, 109414. [Google Scholar] [CrossRef]

- Wang, G.; Jiang, Y.; Li, W.; Yin, X. Process Optimization of Corn Stover Compression Molding Experiments Based on Response Surface Method. Available online: https://www.ingentaconnect.com/content/tcsae/tcsae/2016/00000032/00000013/art00032 (accessed on 24 June 2019).

- Adapa, P.; Tabil, L.; Schoenau, G.; Opoku, A. Pelleting characteristics of selected biomass with and without steam explosion pretreatment. Int. J. Agric. Biol. Eng. 2010, 3, 62–79. [Google Scholar] [CrossRef]

- Lam, P.S. Steam Explosion of Biomass to Produce Durable Wood Pellets; University of British Columbia: Vancouver, BC, USA, 2011. [Google Scholar]

- Biswas, A.K.; Rudolfsson, M.; Broström, M.; Umeki, K. Effect of pelletizing conditions on combustion behaviour of single wood pellet. Appl. Energy 2014, 119, 79–84. [Google Scholar] [CrossRef]

- Zhang, K.; Song, S.; Chen, Z.; Zhou, J. Effects of Brown Sugar Water Binder Added by Spraying Method as Solid Bridge on the Physical Characteristics of Biomass Pellets. Polymers 2020, 12, 674. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jiang, L.; Yuan, X.; Xiao, Z.-H.; Liang, J.; Li, H.; Cao, L.; Wang, H.; Chen, X.; Zeng, G. A comparative study of biomass pellet and biomass-sludge mixed pellet: Energy input and pellet properties. Energy Convers. Manag. 2016, 126, 509–515. [Google Scholar] [CrossRef]

- Jonsson, K.H.R.; Rinaldi, F. The impact on global wood-product markets of increasing consumption of wood pellets within the European Union. Energy 2017, 133, 864–878. [Google Scholar] [CrossRef]

- Malico, I.; Pereira, R.N.; Gonçalves, A.C.; Sousa, A.M.O. Current status and future perspectives for energy production from solid biomass in the European industry. Renew. Sustain. Energy Rev. 2019, 112, 960–977. [Google Scholar] [CrossRef]

- Sahoo, K.; Bilek, E.M.T.; Mani, S. Techno-economic and environmental assessments of storing woodchips and pellets for bioenergy applications. Renew. Sustain. Energy Rev. 2018, 98, 27–39. [Google Scholar] [CrossRef]

- Sahoo, K.; Bilek, E.; Bergman, R.; Mani, S. Techno-economic analysis of producing solid biofuels and biochar from forest residues using portable systems. Appl. Energy 2019, 235, 578–590. [Google Scholar] [CrossRef]

- Gilvari, H.; Cutz, L.; Tiringer, U.; Mol, J.M.C.; De Jong, W.; Schott, D.L. The Effect of Environmental Conditions on the Degradation Behavior of Biomass Pellets. Polymers 2020, 12, 970. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, S.; Yuan, X.; Li, C.; Huang, Z.; Leng, L.; Zeng, G.; Li, H. Variation in the physical properties of wood pellets and emission of aldehyde/ketone under different storage conditions. Fuel 2016, 183, 314–321. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Wright, C.T.; Hess, J.R.; Kenney, K.L. A review of biomass densification systems to develop uniform feedstock commodities for bioenergy application. Biofuels Bioprod. Biorefin. 2011, 5, 683–707. [Google Scholar] [CrossRef]

- Obernberger, I.; Thek, G. Physical characterisation and chemical composition of densified biomass fuels with regard to their combustion behaviour. Biomass Bioenergy 2004, 27, 653–669. [Google Scholar] [CrossRef]

- Hedlund, F.H.; Astad, J.; Nichols, J. Inherent hazards, poor reporting and limited learning in the solid biomass energy sector: A case study of a wheel loader igniting wood dust, leading to fatal explosion at wood pellet manufacturer. Biomass Bioenergy 2014, 66, 450–459. [Google Scholar] [CrossRef] [Green Version]

- Järvinen, T.; Agar, D. Experimentally determined storage and handling properties of fuel pellets made from torrefied whole-tree pine chips, logging residues and beech stem wood. Fuel 2014, 129, 330–339. [Google Scholar] [CrossRef]

- Dyjakon, A.; Noszczyk, T. The Influence of Freezing Temperature Storage on the Mechanical Durability of Commercial Pellets from Biomass. Energies 2019, 12, 2627. [Google Scholar] [CrossRef] [Green Version]

- Lehtikangas, P. Storage effects on pelletised sawdust, logging residues and bark. Biomass Bioenergy 2000, 19, 287–293. [Google Scholar] [CrossRef]

- Graham, S.; Eastwick, C.; Snape, C.E.; Quick, W. Mechanical degradation of biomass wood pellets during long term stockpile storage. Fuel Process. Technol. 2017, 160, 143–151. [Google Scholar] [CrossRef]

- Bennamoun, L.; Harun, N.Y.; Afzal, M.T. Effect of Storage Conditions on Moisture Sorption of Mixed Biomass Pellets. Arab. J. Sci. Eng. 2017, 43, 1195–1203. [Google Scholar] [CrossRef]

- Kuang, X.; Shankar, T.J.; Bi, X.T.; Lim, C.J.; Sokhansanj, S.; Melin, S. Rate and Peak Concentrations of Off-Gas Emissions in Stored Wood Pellets—Sensitivities to Temperature, Relative Humidity, and Headspace Volume. Ann. Occup. Hyg. 2009, 53, 789–796. [Google Scholar] [CrossRef] [PubMed]

- Larsson, S.H.; Rudolfsson, M. Temperature control in energy grass pellet production—Effects on process stability and pellet quality. Appl. Energy 2012, 97, 24–29. [Google Scholar] [CrossRef]

- He, X.; Lau, A.K.; Sokhansanj, S.; Lim, C.J.; Bi, X.T.; Melin, S. Investigating gas emissions and dry matter loss from stored biomass residues. Fuel 2014, 134, 159–165. [Google Scholar] [CrossRef]

- Svedberg, U.R.A.; Högberg, H.-E.; Högbegrg, J.; Galle, B. Emission of Hexanal and Carbon Monoxide from Storage of Wood Pellets, a Potential Occupational and Domestic Health Hazard. Ann. Occup. Hyg. 2004, 48, 339–349. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Svedberg, U.; Samuelsson, J.; Melin, S. Hazardous off-gassing of carbon monoxide and oxygen depletion during ocean transportation of wood pellets. Ann. Occup. Hyg. 2008, 52, 259–266. [Google Scholar] [CrossRef]

- Rahman, M.A.; Rossner, A.; Hopke, P.K. Occupational exposure of aldehydes resulting from the storage of wood pellets. J. Occup. Environ. Hyg. 2017, 14, 417–426. [Google Scholar] [CrossRef]

- Deng, T.; Alzahrani, A.M.; Bradley, M.S. Influences of environmental humidity on physical properties and attrition of wood pellets. Fuel Process. Technol. 2019, 185, 126–138. [Google Scholar] [CrossRef]

- Zhai, R.; Hu, J.; Saddler, J.N. What Are the Major Components in Steam Pretreated Lignocellulosic Biomass That Inhibit the Efficacy of Cellulase Enzyme Mixtures? ACS Sustain. Chem. Eng. 2016, 4, 3429–3436. [Google Scholar] [CrossRef]

- Rosales-Calderon, O.; Trajano, H.L.; Posarac, D.; Duff, S.J.B. Modeling of Oxygen Delignified Wheat Straw Enzymatic Hydrolysis as a Function of Hydrolysis Time, Enzyme Concentration, and Lignin Content. Ind. Biotechnol. 2016, 12, 176–186. [Google Scholar] [CrossRef] [Green Version]

- Rastogi, M.; Shrivastava, S. Recent advances in second generation bioethanol production: An insight to pretreatment, saccharification and fermentation processes. Renew. Sustain. Energy Rev. 2017, 80, 330–340. [Google Scholar] [CrossRef]

- Chandel, A.K.; Albarelli, J.Q.; Santos, D.T.; Chundawat, S.P.; Puri, M.; Meireles, M.A.A. Comparative analysis of key technologies for cellulosic ethanol production from Brazilian sugarcane bagasse at a commercial scale. Biofuels Bioprod. Biorefin. 2019, 13, 994–1014. [Google Scholar] [CrossRef]

- Satari, B.; Karimi, K.; Kumar, R. Cellulose solvent-based pretreatment for enhanced second-generation biofuel production: A review. Sustain. Energy Fuels 2019, 3, 11–62. [Google Scholar] [CrossRef]

- Arantes, V.; Saddler, J.N. Access to cellulose limits the efficiency of enzymatic hydrolysis: The role of amorphogenesis. Biotechnol. Biofuels 2010, 3, 4. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Qi, B.; Chen, X.; Su, Y.; Wan, Y. Enzyme adsorption and recycling during hydrolysis of wheat straw lignocellulose. Bioresour. Technol. 2011, 102, 2881–2889. [Google Scholar] [CrossRef]

- Ding, S.-Y.; Liu, Y.-S.; Zeng, Y.; Himmel, M.E.; Baker, J.O.; Bayer, E.A. How Does Plant Cell Wall Nanoscale Architecture Correlate with Enzymatic Digestibility? Science 2012, 338, 1055–1060. [Google Scholar] [CrossRef]

- Balan, V.; Chiaramonti, D.; Kumar, S. Review of US and EU initiatives toward development, demonstration, and commercialization of lignocellulosic biofuels. Biofuels Bioprod. Biorefin. 2013, 7, 732–759. [Google Scholar] [CrossRef]

- Dale, B.E.; Anderson, J.E.; Brown, R.C.; Csonka, S.; Dale, V.H.; Herwick, G.; Jackson, R.D.; Jordan, N.; Kaffka, S.; Kline, K.L.; et al. Take a Closer Look: Biofuels Can Support Environmental, Economic and Social Goals. Environ. Sci. Technol. 2014, 48, 7200–7203. [Google Scholar] [CrossRef]

- Cho, H.-S.; Oh, Y.-K.; Park, S.-C.; Lee, J.-W.; Park, J.-Y. Effects of enzymatic hydrolysis on lipid extraction from Chlorella vulgaris. Renew. Energy 2013, 54, 156–160. [Google Scholar] [CrossRef]

- Kang, Q.; Huybrechts, J.; Van Der Bruggen, B.; Baeyens, J.; Tan, T.; Dewil, R. Hydrophilic membranes to replace molecular sieves in dewatering the bio-ethanol/water azeotropic mixture. Sep. Purif. Technol. 2014, 136, 144–149. [Google Scholar] [CrossRef]

- Tao, L.; Tan, E.C.D.; McCormick, R.L.; Zhang, M.; Aden, A.; He, X.; Zigler, B.T. Techno-economic analysis and life-cycle assessment of cellulosic isobutanol and comparison with cellulosic ethanol and n-butanol. Biofuels Bioprod. Biorefin. 2013, 8, 30–48. [Google Scholar] [CrossRef]

- Lu, D.; Tabil, L.G.; Wang, D.; Wang, G.; Emami, S. Experimental trials to make wheat straw pellets with wood residue and binders. Biomass Bioenergy 2014, 69, 287–296. [Google Scholar] [CrossRef]

- Martinez, C.L.M.; Sermyagina, E.; De Carneiro, A.C.O.; Vakkilainen, E.; Cardoso, M. Production and characterization of coffee-pine wood residue briquettes as an alternative fuel for local firing systems in Brazil. Biomass Bioenergy 2019, 123, 70–77. [Google Scholar] [CrossRef]

- Prado, E.P.; Raetano, C.G.; Pogetto, M.H.F.D.A.D.; Chechetto, R.G.; Filho, P.J.F.; Magalhaes, A.C.; Miasaki, C.T. Effects of agricultural spray adjuvants in surface tension reduction and spray retention on Eucalyptus leaves. Afr. J. Agric. Res. 2016, 11, 3959–3965. [Google Scholar] [CrossRef]

- Stelte, W.; Holm, J.K.; Sanadi, A.R.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U.B. A study of bonding and failure mechanisms in fuel pellets from different biomass resources. Biomass Bioenergy 2011, 35, 910–918. [Google Scholar] [CrossRef] [Green Version]

- Wongsiriamnuay, T.; Tippayawong, N. Effect of densification parameters on the properties of maize residue pellets. Biosyst. Eng. 2015, 139, 111–120. [Google Scholar] [CrossRef]

- Avelar, N.V.; Rezende, A.A.P.; De Cassia Oliveira Carneiro, A.; Silva, C.M. Evaluation of briquettes made from textile industry solid waste. Renew. Energy 2016, 91, 417–424. [Google Scholar] [CrossRef]

- Liu, Z.; Quek, A.; Balasubramanian, R. Preparation and characterization of fuel pellets from woody biomass, agro-residues and their corresponding hydrochars. Appl. Energy 2014, 113, 1315–1322. [Google Scholar] [CrossRef]

- Jackson, J.; Turner, A.; Mark, T.; Montross, M.D. Densification of biomass using a pilot scale flat ring roller pellet mill. Fuel Process. Technol. 2016, 148, 43–49. [Google Scholar] [CrossRef] [Green Version]

- Tumuluru, J.S. Pelleting of Pine and Switchgrass Blends: Effect of Process Variables and Blend Ratio on the Pellet Quality and Energy Consumption. Energies 2019, 12, 1198. [Google Scholar] [CrossRef] [Green Version]

- Law, H.C.; Gan, L.M.; Gan, H.L. Experimental Study on the Mechanical Properties of Biomass Briquettes from Different Agricultural Residues Combination. MATEC Web Conf. 2018, 225, 04026. [Google Scholar] [CrossRef]

- Korolj, A.; Wu, H.-T.; Radisic, M. A healthy dose of chaos: Using fractal frameworks for engineering higher-fidelity biomedical systems. Biomaterials 2019, 219, 119363. [Google Scholar] [CrossRef] [PubMed]

- Panigrahy, C.; Seal, A.; Mahato, N.K.; Bhattacharjee, D. Differential box counting methods for estimating fractal dimension of gray-scale images: A survey. Chaos Solitons Fractals 2019, 126, 178–202. [Google Scholar] [CrossRef]

- Khandare, S.T.; Thakur, N.V. Multi-level thresholding and quantization for segmentation of color images. In Proceedings of the Smart Trends in Computing and Communications; Zhang, Y.-D., Mandal, J.K., So-In, C., Thakur, N.V., Eds.; Springer: Singapore, 2020; pp. 487–496. [Google Scholar]

- R: The R Project for Statistical Computing. Available online: https://www.r-project.org/ (accessed on 27 May 2020).

- Jewiarz, M.; Mudryk, K.; Wróbel, M.; Frączek, J.; Dziedzic, K. Parameters Affecting RDF-Based Pellet Quality. Energies 2020, 13, 910. [Google Scholar] [CrossRef] [Green Version]

- Moliner, C.; Lagazzo, A.; Bosio, B.; Botter, R.; Arato, E. Production, Characterization, and Evaluation of Pellets from Rice Harvest Residues. Energies 2020, 13, 479. [Google Scholar] [CrossRef] [Green Version]

- Gil, M.V.; Oulego, P.; Casal, M.D.; Pevida, C.; Pis, J.J.; Rubiera, F. Mechanical durability and combustion characteristics of pellets from biomass blends. Bioresour. Technol. 2010, 101, 8859–8867. [Google Scholar] [CrossRef] [Green Version]

- Shang, L.; Nielsen, N.P.K.; Dahl, J.; Stelte, W.; Ahrenfeldt, J.; Holm, J.K.; Thomsen, T.P.; Henriksen, U.B. Quality effects caused by torrefaction of pellets made from Scots pine. Fuel Process. Technol. 2012, 101, 23–28. [Google Scholar] [CrossRef]

- Huang, Y.; Finell, M.; Larsson, S.H.; Wang, X.; Zhang, J.; Wei, R.; Liu, L. Biofuel pellets made at low moisture content–Influence of water in the binding mechanism of densified biomass. Biomass Bioenergy 2017, 98, 8–14. [Google Scholar] [CrossRef]

- Williams, O.; Taylor, S.; Lester, E.; Kingman, S.; Giddings, D.; Eastwick, C. Applicability of Mechanical Tests for Biomass Pellet Characterisation for Bioenergy Applications. Materials 2018, 11, 1329. [Google Scholar] [CrossRef] [Green Version]

- Šavija, B. Smart Crack Control in Concrete through Use of Phase Change Materials (PCMs): A Review. Materials 2018, 11, 654. [Google Scholar] [CrossRef] [Green Version]

- Tumuluru, J.S.; Lim, C.J.; Bi, X.T.; Kuang, X.; Melin, S.; Yazdanpanah, F.; Sokhansanj, S. Analysis on Storage Off-Gas Emissions from Woody, Herbaceous, and Torrefied Biomass. Energies 2015, 8, 1745–1759. [Google Scholar] [CrossRef] [Green Version]

- Gilvari, H.; De Jong, W.; Schott, D.L. Quality parameters relevant for densification of bio-materials: Measuring methods and affecting factors—A review. Biomass Bioenergy 2019, 120, 117–134. [Google Scholar] [CrossRef]

- Wang, T.; Zhai, Y.; Li, H.; Zhu, Y.; Li, S.; Peng, C.; Wang, B.; Wang, Z.; Xi, Y.; Wang, S.; et al. Co-hydrothermal carbonization of food waste-woody biomass blend towards biofuel pellets production. Bioresour. Technol. 2018, 267, 371–377. [Google Scholar] [CrossRef] [PubMed]

- Akcaoglu, S.C.; Sun, Z.; Moratti, S.C.; Martinopoulos, G. Investigation of Novel Composite Materials for Thermochemical Heat Storage Systems. Energies 2020, 13, 1042. [Google Scholar] [CrossRef] [Green Version]

- Arranz, J.I.; Miranda, M.T.; Montero, I.; Nogales, S.; Sepulveda, F.J. Influence Factors on Carbon Monoxide Accumulation in Biomass Pellet Storage. Energies 2019, 12, 2323. [Google Scholar] [CrossRef] [Green Version]

- Bennamoun, L.; Simo-Tagne, M.; Ndukwu, M.C. Simulation of Storage Conditions of Mixed Biomass Pellets for Bioenergy Generation: Study of the Thermodynamic Properties. Energies 2020, 13, 2544. [Google Scholar] [CrossRef]

- Dhamodaran, A.; Afzal, M.T. Compression and springback properties of hardwood and softwood pellets. BioResources 2012, 7, 4362–4376. [Google Scholar]

- Barbanera, M.; Lascaro, E.; Stanzione, V.; Esposito, A.; Altieri, R.; Bufacchi, M. Characterization of pellets from mixing olive pomace and olive tree pruning. Renew. Energy 2016, 88, 185–191. [Google Scholar] [CrossRef]

- Gilbert, P.; Ryu, C.; Sharifi, V.; Swithenbank, J. Effect of process parameters on pelletisation of herbaceous crops. Fuel 2009, 88, 1491–1497. [Google Scholar] [CrossRef]

- Missagia, B.; Corrêa, M.F.S.; Ahmed, I.; Krautz, H.-J.; Ay, P. Comparative analysis of Brazilian residual biomass for pellet production. In Implementing Environmental and Resource Management; Schmidt, M., Onyango, V., Palekhov, D., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 7–14. ISBN 978-3-540-77568-3. [Google Scholar]

- Gardner, D.; Tajvidi, M. Hydrogen bonding in wood-based materials: An update. Wood Fiber Sci. 2016, 48, 234–244. [Google Scholar]

- Mostafa, M.E.; Hu, S.; Wang, Y.; Su, S.; Hu, X.; Elsayed, S.A.; Xiang, J. The significance of pelletization operating conditions: An analysis of physical and mechanical characteristics as well as energy consumption of biomass pellets. Renew. Sustain. Energy Rev. 2019, 105, 332–348. [Google Scholar] [CrossRef]

- Peng, J.H.; Bi, H.T.; Lim, C.J.; Sokhansanj, S. Study on Density, Hardness, and Moisture Uptake of Torrefied Wood Pellets. Energy Fuels 2013, 27, 967–974. [Google Scholar] [CrossRef]

- Larsson, S.H.; Samuelsson, R. Prediction of ISO 17831-1:2015 mechanical biofuel pellet durability from single pellet characterization. Fuel Process. Technol. 2017, 163, 8–15. [Google Scholar] [CrossRef]

- Tavares, L.M. Analysis of particle fracture by repeated stressing as damage accumulation. Powder Technol. 2009, 190, 327–339. [Google Scholar] [CrossRef]

- Erlich, C.; Fransson, T.H. Downdraft gasification of pellets made of wood, palm-oil residues respective bagasse: Experimental study. Appl. Energy 2011, 88, 899–908. [Google Scholar] [CrossRef]

- Koppejan, J.; van Loo, S. The Handbook of Biomass Combustion and Co-Firing; Routledge: London, UK, 2012; ISBN 9781849773041. [Google Scholar]

- De Almeida, L.F.P.; Sola, A.V.H.; Behainne, J.J.R. Sugarcane bagasse pellets: Characterization and comparative analysis. Acta Sci. Technol. 2017, 39, 461. [Google Scholar] [CrossRef] [Green Version]

- Gao, W.; Tabil, L.G.; Dumonceaux, T.J.; Rios, S.E.; Zhao, R. Optimization of biological pretreatment to enhance the quality of wheat straw pellets. Biomass Bioenergy 2017, 97, 77–89. [Google Scholar] [CrossRef]

- Djatkov, D.; Martinov, M.; Kaltschmitt, M. Influencing parameters on mechanical–physical properties of pellet fuel made from corn harvest residues. Biomass Bioenergy 2018, 119, 418–428. [Google Scholar] [CrossRef]

- Nguyen, Q.N.; Cloutier, A.; Achim, A.; Stevanovic, T. Effect of process parameters and raw material characteristics on physical and mechanical properties of wood pellets made from sugar maple particles. Biomass Bioenergy 2015, 80, 338–349. [Google Scholar] [CrossRef]

- Hosseinizand, H.; Sokhansanj, S.; Lim, C.J. Co-pelletization of microalgae Chlorella vulgaris and pine sawdust to produce solid fuels. Fuel Process. Technol. 2018, 177, 129–139. [Google Scholar] [CrossRef]

- Pradhan, P.; Arora, A.; Mahajani, S.M. Pilot scale evaluation of fuel pellets production from garden waste biomass. Energy Sustain. Dev. 2018, 43, 1–14. [Google Scholar] [CrossRef]

- Azargohar, R.; Nanda, S.; Kang, K.; Bond, T.; Karunakaran, C.; Dalai, A.K.; Kozinski, J. Effects of bio-additives on the physicochemical properties and mechanical behavior of canola hull fuel pellets. Renew. Energy 2019, 132, 296–307. [Google Scholar] [CrossRef]

| Level | Factor | ||

|---|---|---|---|

| A, Time of Boiling, min | B, Method of Addition | C, Storage Condition | |

| 1 | 0 | Stirring | Normal |

| 2 | 5 | Spraying | Freezing |

| 3 | 10 | Defrosting | |

| Time | Method | Storage Condition | Fluctuation | ||||

|---|---|---|---|---|---|---|---|

| Normal, N | Freezing, F | Defrosting, D | N–F | F–D | N–D | ||

| Diameter, mm | Δ, % | ||||||

| Control | 6.0500 ± 0.1200 | 6.0355 ± 0.1305 | 6.4050 ± 0.1315 | −0.2400 | 5.7690 | 5.5425 | |

| 0 | Stirring | 5.8480 ± 0.0780 | 5.8330 ± 0.0980 | 5.9000 ± 0.1105 | −0.2570 | 1.1300 | 0.8755 |

| 5 | Stirring | 5.9565 ± 0.0330 | 5.9330 ± 0.0530 | 6.0500 ± 0.1000 | −0.3930 | 1.9285 | 1.5425 |

| 10 | Stirring | 5.5235 ± 0.0425 | 5.5165 ± 0.0750 | 5.5500 ± 0.1110 | −0.1270 | 0.6005 | 0.4745 |

| 0 | Spraying | 6.0410 ± 0.0250 | 5.9330 ± 0.0255 | 6.0500 ± 0.0985 | −1.8145 | 1.9285 | 0.1490 |

| 5 | Spraying | 6.0340 ± 0.0185 | 6.0330 ± 0.0205 | 6.0765 ± 0.0705 | −0.0165 | 0.7130 | 0.6965 |

| 10 | Spraying | 6.0355 ± 0.0190 | 6.0015 ± 0.0260 | 6.0535 ± 0.0980 | −0.5635 | 0.8560 | 0.2975 |

| Length, mm | |||||||

| Control | 30.6050 ± 4.0755 | 30.5375 ± 4.1250 | 30.9985 ± 4.2055 | −0.2210 | 1.4870 | 1.2695 | |

| 0 | Stirring | 23.5265 ± 0.7755 | 23.4500 ± 0.7760 | 23.6330 ± 0.8805 | −0.3270 | 0.7755 | 0.4510 |

| 5 | Stirring | 28.6010 ± 0.9705 | 28.5830 ± 0.9905 | 28.6330 ± 0.8810 | −0.0610 | 0.1745 | 0.1135 |

| 10 | Stirring | 21.4850 ± 0.9100 | 21.4830 ± 0.9505 | 21.5165 ± 0.9715 | −0.0070 | 0.1550 | 0.1480 |

| 0 | Spraying | 31.5590 ± 0.1370 | 31.5500 ± 0.1415 | 31.6165 ± 0.2505 | −0.0290 | 0.2110 | 0.1820 |

| 5 | Spraying | 39.7200 ± 0.1365 | 39.4500 ± 0.1405 | 39.8330 ± 0.2510 | −0.6840 | 0.9620 | 0.2850 |

| 10 | Spraying | 29.5900 ± 0.1385 | 29.5480 ± 0.1415 | 29.6830 ± 0.3075 | −0.1415 | 0.4550 | 0.3140 |

| Time | Method | Storage Condition | Fluctuation | ||||

|---|---|---|---|---|---|---|---|

| Normal, N | Freezing, F | Defrosting, D | N–F | F–D | N–D | ||

| Apparent density, kg·m−3 | Δ, % | ||||||

| Control | 800.7505 ± 5.6750 | 793.0055 ± 5.9050 | 782.8750 ± 5.8875 | −0.9765 | −1.2940 | −2.2835 | |

| 0 | Stirring | 805.0695 ± 1.2050 | 800.0500 ± 1.2350 | 787.7165 ± 1.2475 | −0.6275 | −1.5655 | −2.2030 |

| 5 | Stirring | 810.1785 ± 1.3755 | 800.2330 ± 1.4585 | 795.3165 ± 1.5035 | −1.2430 | −0.6180 | −1.8685 |

| 10 | Stirring | 807.2500 ± 1.3695 | 800.0665 ± 1.4090 | 790.5000 ± 1.2510 | −0.8980 | −1.2100 | −2.1190 |

| 0 | Spraying | 1055.2165 ± 1.0050 | 1050.5000 ± 1.0075 | 1050.2330 ± 1.0095 | −0.4490 | −0.0255 | −0.4745 |

| 5 | Spraying | 1250.8500 ± 1.1010 | 1250.3000 ± 1.1025 | 1250.0665 ± 1.1105 | −0.0440 | −0.0185 | −0.0625 |

| 10 | Spraying | 1051.3930 ± 1.0075 | 1050.6330 ± 1.0105 | 1050.0665 ± 1.0155 | −0.0720 | −0.0540 | −0.1260 |

| Time | Method | Storage Condition | Fluctuation | ||||

|---|---|---|---|---|---|---|---|

| Normal, N | Freezing, F | Defrosting, D | N–F | F–D | N–D | ||

| Durability, % | Δ, % | ||||||

| Control | 97.5045 ± 1.0855 | 91.0575 ± 1.1005 | 85.8510 ± 1.1015 | −7.0800 | −6.0645 | −13.5740 | |

| 0 | Stirring | 99.3170 ± 0.0055 | 94.6170 ± 0.0060 | 92.7000 ± 0.0045 | −4.9675 | −2.0675 | −7.1375 |

| 5 | Stirring | 99.5670 ± 0.0040 | 95.8330 ± 0.0075 | 93.8830 ± 0.0105 | −3.8955 | −2.0770 | −6.0535 |

| 10 | Stirring | 99.8000 ± 0.0075 | 93.8000 ± 0.0045 | 90.1000 ± 0.0275 | −6.3965 | −4.1065 | −10.7660 |

| 0 | Spraying | 99.5165 ± 0.0005 | 95.6665 ± 0.0010 | 95.2330 ± 0.0595 | −4.0245 | −0.4550 | −4.4975 |

| 5 | Spraying | 99.7665 ± 0.0010 | 99.2330 ± 0.0025 | 99.1500 ± 0.0020 | −0.5380 | −0.0835 | −0.6220 |

| 10 | Spraying | 99.7335 ± 0.0005 | 98.2000 ± 0.0030 | 97.6500 ± 0.0055 | −1.5615 | −0.5630 | −2.1335 |

| Fines, % | |||||||

| Control | 2.4955 ± 1.0855 | 8.9425 ± 1.1005 | 14.1490 ± 1.1015 | 7.0800 | 6.0645 | 13.5740 | |

| 0 | Stirring | 0.6830 ± 0.0055 | 5.3830 ± 0.0060 | 7.3000 ± 0.0045 | 4.9675 | 2.0675 | 7.1380 |

| 5 | Stirring | 0.4330 ± 0.0040 | 4.1670 ± 0.0075 | 6.1170 ± 0.0105 | 3.8955 | 2.0770 | 6.0540 |

| 10 | Stirring | 0.2000 ± 0.0070 | 6.2000 ± 0.0045 | 9.9000 ± 0.0275 | 6.3965 | 4.1065 | 10.7660 |

| 0 | Spraying | 0.4835 ± 0.0005 | 4.3335 ± 0.0010 | 4.7670 ± 0.0595 | 4.0240 | 0.4550 | 4.4980 |

| 5 | Spraying | 0.2335 ± 0.0010 | 0.7670 ± 0.0025 | 0.8500 ± 0.0020 | 0.5375 | 0.0835 | 0.6220 |

| 10 | Spraying | 0.2665 ± 0.0005 | 1.8000 ± 0.0030 | 2.3500 ± 0.0055 | 1.5615 | 0.5630 | 2.1335 |

| Time | Method | Storage Condition | Fluctuation | ||||

|---|---|---|---|---|---|---|---|

| Normal, N | Freezing, F | Defrosting, D | N–F | F–D | N–D | ||

| Resistance to Breaking Down by Water, min | Δ, % | ||||||

| Control | 45.7500 ± 5.9075 | 37.8950 ± 6.0050 | 33.7505 ± 5.9590 | −20.7285 | −10.9370 | −35.5535 | |

| 0 | Stirring | 58.7665 ± 1.2045 | 52.5000 ± 1.0575 | 52.3330 ± 0.0085 | −11.9365 | −0.3175 | −12.2930 |

| 5 | Stirring | 59.3330 ± 1.0850 | 54.3500 ± 1.3025 | 54.1170 ± 0.0060 | −9.1690 | −0.4290 | −9.6390 |

| 10 | Stirring | 57.5000 ± 1.1260 | 52.1000 ± 1.2665 | 51.5000 ± 0.0095 | −10.3645 | −1.1515 | −11.1505 |

| 0 | Spraying | 58.8830 ± 0.4345 | 52.8665 ± 0.7440 | 52.4330 ± 0.0005 | −11.3810 | −0.8195 | −12.3015 |

| 5 | Spraying | 59.7665 ± 0.3360 | 54.6000 ± 0.7880 | 54.4500 ± 0.0005 | −9.4630 | −0.2745 | −9.7640 |

| 10 | Spraying | 58.5000 ± 0.4505 | 52.7500 ± 0.6575 | 51.6330 ± 0.0010 | −10.9005 | −2.1170 | −13.2990 |

| Time | Method | Storage Condition | Fluctuation | ||||

|---|---|---|---|---|---|---|---|

| Normal, N | Freezing, F | Defrosting, D | N–F | F–D | N–D | ||

| Hygroscopicity, % | Δ, % | ||||||

| Control | 14.5500 ± 1.3425 | 16.7050 ± 1.3385 | 18.8565 ± 1.5665 | 12.9003 | 12.8794 | 22.8380 | |

| 0 | Stirring | 10.4685 ± 0.8750 | 10.5520 ± 0.9155 | 12.3685 ± 0.9045 | 0.7910 | 17.2145 | 15.3615 |

| 5 | Stirring | 10.3375 ± 0.9050 | 10.4590 ± 0.9070 | 12.7880 ± 0.9635 | 1.1615 | 22.2640 | 19.1600 |

| 10 | Stirring | 10.4575 ± 0.9705 | 10.7000 ± 0.9065 | 12.9360 ± 0.9580 | 2.2695 | 20.8920 | 19.1585 |

| 0 | Spraying | 8.1015 ± 0.05050 | 8.1165 ± 0.0510 | 8.8415 ± 0.0615 | 0.1850 | 8.9320 | 8.3695 |

| 5 | Spraying | 6.0215 ± 0.05000 | 6.0570 ± 0.0505 | 6.0770 ± 0.0580 | 0.5890 | 0.3245 | 0.9105 |

| 10 | Spraying | 7.6665 ± 0.05015 | 7.6860 ± 0.0670 | 7.8410 ± 0.0605 | 0.2495 | 2.0190 | 2.2235 |

| Time | Method | Storage Condition | Fluctuation | ||||

|---|---|---|---|---|---|---|---|

| Normal, N | Freezing, F | Defrosting, D | N–F | F–D | N–D | ||

| Fractal Dimension of Fractures by Thermal Shock | Δ, % | ||||||

| Control | 1.9575 ± 0.0355 | 1.9590 ± 0.0320 | 1.9595 ± 0.0340 | 0.0765 | 0.0255 | 0.1020 | |

| 0 | Stirring | 1.9560 ± 0.0055 | 1.9570 ± 0.0055 | 1.9590 ± 0.0055 | 0.0340 | 0.1190 | 0.1530 |

| 5 | Stirring | 1.9555 ± 0.0040 | 1.9560 ± 0.0050 | 1.9580 ± 0.0055 | 0.0170 | 0.1280 | 0.1445 |

| 10 | Stirring | 1.9570 ± 0.0065 | 1.9575 ± 0.0060 | 1.9795 ± 0.0060 | 0.0170 | 1.1240 | 1.1280 |

| 0 | Spraying | 1.7505 ± 0.0045 | 1.7505 ± 0.0045 | 1.7510 ± 0.0045 | 0.0010 | 0.0280 | 0.0285 |

| 5 | Spraying | 1.7490 ± 0.0055 | 1.7495 ± 0.0055 | 1.7495 ± 0.0050 | 0.0095 | 0.0040 | 0.0140 |

| 10 | Spraying | 1.7510 ± 0.0040 | 1.7510 ± 0.0045 | 1.7510 ± 0.0045 | 0.0140 | 0.0030 | 0.0175 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moreira, B.R.d.A.; Silva Viana, R.d.; Cruz, V.H.; Matos Lopes, P.R.; Miasaki, C.T.; Magalhães, A.C.; Figueiredo, P.A.M.d.; Lisboa, L.A.M.; Ramos, S.B.; May, A.; et al. Anti-Thermal Shock Binding of Liquid-State Food Waste to Non-Wood Pellets. Energies 2020, 13, 3280. https://doi.org/10.3390/en13123280

Moreira BRdA, Silva Viana Rd, Cruz VH, Matos Lopes PR, Miasaki CT, Magalhães AC, Figueiredo PAMd, Lisboa LAM, Ramos SB, May A, et al. Anti-Thermal Shock Binding of Liquid-State Food Waste to Non-Wood Pellets. Energies. 2020; 13(12):3280. https://doi.org/10.3390/en13123280

Chicago/Turabian StyleMoreira, Bruno Rafael de Almeida, Ronaldo da Silva Viana, Victor Hugo Cruz, Paulo Renato Matos Lopes, Celso Tadao Miasaki, Anderson Chagas Magalhães, Paulo Alexandre Monteiro de Figueiredo, Lucas Aparecido Manzani Lisboa, Sérgio Bispo Ramos, André May, and et al. 2020. "Anti-Thermal Shock Binding of Liquid-State Food Waste to Non-Wood Pellets" Energies 13, no. 12: 3280. https://doi.org/10.3390/en13123280

APA StyleMoreira, B. R. d. A., Silva Viana, R. d., Cruz, V. H., Matos Lopes, P. R., Miasaki, C. T., Magalhães, A. C., Figueiredo, P. A. M. d., Lisboa, L. A. M., Ramos, S. B., May, A., & Caraschi, J. C. (2020). Anti-Thermal Shock Binding of Liquid-State Food Waste to Non-Wood Pellets. Energies, 13(12), 3280. https://doi.org/10.3390/en13123280