Light Reflection Loss Reduction by Nano-Structured Gratings for Highly Efficient Next-Generation GaAs Solar Cells

Abstract

:1. Introduction

2. Moth’s Eye, Antireflective Coating, and Nano-Gratings

2.1. Principle of Moth’s-Eye

2.2. Antireflection Coating

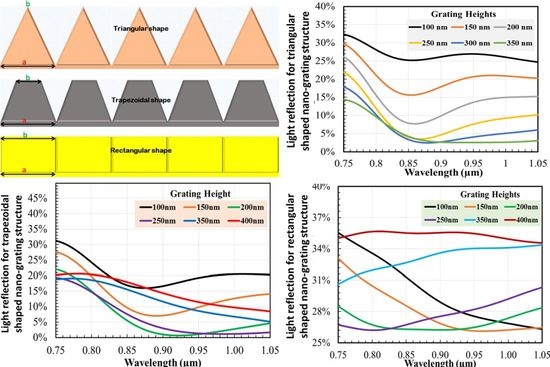

2.3. Different Types of Nano-Grating Shapes

3. Simulation Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- United Nations, Department of Economics and Social Affairs. Available online: https://www.un.org/development/desa/en/news/population/world-population-prospects-2019.html (accessed on 16 June 2020).

- International Energy Outlook 2010, A Report by the Office of Integrated Analysis and Forecasting, U.S. Energy Information Administration, U.S. Department of Energy (July 2010). Available online: https://www.eia.gov/outlooks/archive/ieo10/pdf/0484(2010).pdf (accessed on 11 August 2020).

- Sterling, B. Renewistan. Available online: http://www.wired.com/beyond_the_beyond/2009/01/renewistan/ (accessed on 11 April 2011).

- Wirman, C. Carbon Dioxide Emissions from Electricity Generation in 2015 Were Lowest Since 1993. U.S. Energy Information Administration. Available online: http://www.eia.gov/todayinenergy/detail.cfm?id=26232 (accessed on 10 January 2020).

- IRENA’s Global Renewables Outlook: Energy Transformation 2050. Available online: https://www.irena.org/publications/2020/Apr/Global-Renewables-Outlook-2020 (accessed on 19 June 2020).

- Publication of Council of European Energy Regulators (CEER) “Keeping the Lights on Saves Lives—Energy Sector and Regulators Guarantee Energy Supply during Lockdown” of 14 April 2020. Available online: https://www.ceer.eu/documents/104400/-/-/9ab3bcce-b191-4414-4e1b-97e6545c24fd (accessed on 19 June 2020).

- UK Solar Smashes Generation Records during Covid-19 Pollution Slump. Available online: https://reneweconomy.com.au/uk-solar-smashes-generation-records-during-covid-19-pollution-slump-85451/ (accessed on 19 June 2020).

- Andreev, V.M. GaAs and High-Efficiency Space Cells. In Chapter-1, Practical Handbook of Photovoltaics Fundamentals and Applications, 2nd ed.; Academic Press: Cambridge, CA, USA, 2012; pp. 399–416. [Google Scholar]

- Lam, L.T.; Branstetter, L.; Azevedo, I.L. A sunny future: Expert elicitation of China’s solar photovoltaic technologies. Environ. Res. Lett. 2018, 13, 034038. [Google Scholar] [CrossRef]

- Buitenhuis, A.J.; Pearce, J.M. Open-source development of solar photovoltaic technology. Energy Sustain. Dev. 2012, 16, 379–388. [Google Scholar] [CrossRef] [Green Version]

- Gul, M.; Kotak, Y.; Muneer, T. Review on recent trend of solar photovoltaic technology. Energy Explor. Exploit. 2016, 34, 485–526. [Google Scholar] [CrossRef] [Green Version]

- Vaishnav, P.; Horner, N.; Azevedo, I.L. Was it worthwhile? Where have the benefits of rooftop solar photovoltaic generation exceeded the cost? Environ. Res. Lett. 2017, 12, 094015. [Google Scholar] [CrossRef]

- Davies, J.; Joglekar, N. Supply chain integration, product modularity, and market valuation: Evidence from the solar energy industry. Prod. Oper. Manag. 2013, 22, 1494–1508. [Google Scholar] [CrossRef] [Green Version]

- How is Solar Energy Used? The 5 Most Common Examples of Solar Power. Available online: https://news.energysage.com/most-common-solar-energy-uses/ (accessed on 19 June 2020).

- Bagher, A.M.; Vahid, M.M.A.; Mohsen, M. Types of solar cells and application. Am. J. Opt. Photonics 2015, 3, 94–113. [Google Scholar] [CrossRef] [Green Version]

- Dhal, S.B.; Agarwal, A.; Agarwal, K. Solar powered mobile power bank systems. Am. J. Electr. Electron. Eng. 2016, 4, 148–151. [Google Scholar]

- Gurung, A.; Qiao, Q. Solar charging batteries: Advances, challenges, and opportunities. Joule 2018, 2, 1217–1230. [Google Scholar] [CrossRef] [Green Version]

- Nur-E-Alam, M.; Vasiliev, M. Transparent Solar Windows: From Labs to Industry, Towards Smart Cities. Encyclopedia 2020. [Google Scholar] [CrossRef]

- Vasiliev, M.; Nur-E-Alam, M.; Alameh, K. Recent developments in solar energy-harvesting technologies for building integration and distributed energy generation. Energies 2019, 12, 1080. [Google Scholar] [CrossRef] [Green Version]

- Vasiliev, M.; Nur-E-Alam, M.; Alameh, K. Initial field testing results from building-integrated solar energy harvesting windows installation in Perth, Australia. Appl. Sci. 2019, 9, 4002. [Google Scholar] [CrossRef] [Green Version]

- ClearVue PV. Available online: http://www.clearvuepv.com/products-solutions/technology/ (accessed on 19 June 2020).

- SOLARONIX. Available online: https://www.solaronix.com/solarcells/applications/ (accessed on 18 June 2020).

- Thomas, J.A.; Vasiliev, M.; Nur-E-Alam, M.; Alameh, K. Increasing the yield of Lactuca sativa, L. in glass greenhouses through illumination spectral filtering and development of an optical thin film filter. Sustainability 2020, 12, 3740. [Google Scholar] [CrossRef]

- Ramanujam, J.; Singh, U.P. Copper indium gallium selenide based solar cells—A review. Energy Environ. Sci. 2017, 10, 1306–1319. [Google Scholar] [CrossRef]

- Burgelman, M.; Nollet, P.; Degrave, S. Modelling polycrystalline semiconductor solar cells. Thin Solid Films 2000, 361, 527–532. [Google Scholar] [CrossRef]

- Nakada, T.; Mizutani, M.; Hagiwara, Y.; Kunioka, A. High-efficiency Cu(In,Ga)Se2 thin-film solar cells with a CBD-ZnS buffer layer. Sol. Energy Mater. Sol. Cells 2001, 67, 255–260. [Google Scholar] [CrossRef]

- Matsumoto, H.; Kuribayashi, K.; Uda, H.; Komatsu, Y.; Nakano, A.; Ikegami, S. Screen-printed CdS/CdTe solar cell of 12.8% efficiency for an active area of 0.78 cm2. Sol. Cells 1984, 11, 367–373. [Google Scholar] [CrossRef]

- Khrypunov, G.; Romeo, A.; Kurdesau, F.; Bätzner, D.L.; Zogg, H.; Tiwari, A.N. Recent developments in evaporated CdTe solar cells. Sol. Energy Mater. Sol. Cells 2006, 90, 664–677. [Google Scholar] [CrossRef]

- Morales-Acevedo, A. Thin film CdS/CdTe solar cells: Research perspectives. Sol. Energy 2006, 80, 675–681. [Google Scholar] [CrossRef]

- Oladeji, I.O.; Christos, L.; Ferekides, C.S.; Viswanathan, V.; Zhao, Z. Metal/CdTe/CdS/Cd1−xZnxS/TCO/glass: A new CdTe thin film solar cell structure. Sol. Energy Mater. Sol. Cells 2000, 61, 203–211. [Google Scholar] [CrossRef]

- Snaith, H.J.; Abate, A.; Ball, J.M.; Eperon, G.E.; Leijtens, T.; Noel, N.K.; Stranks, S.D.; Wang, J.T.-W.; Wojciechowski, K.; Zhang, W. Anomalous hysteresis in perovskite solar cells. J. Phys. Chem. Lett. 2014, 5, 1511–1515. [Google Scholar] [CrossRef]

- Meng, L.; You, J.; Guo, T.F.; Yang, Y. Recent advances in the inverted planar structure of perovskite solar cells. Acc. Chem. Res. 2016, 49, 155–165. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Q.; Zhao, Y.; Zhang, X.; Yang, X.; Chen, Y.; Chu, Z.; Ye, Q.; Li, X.; Yin, Z.; You, J. Surface passivation of perovskite film for efficient solar cells. Nat. Photonics 2019, 13, 460–466. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, A.; Altermatt, P.P.; Wenham, S.R.; Green, M.A. 24% efficient perl silicon solar cell: Recent improvements in high efficiency silicon cell research. Sol. Energy Mater. Sol. Cells 1996, 41, 87–99. [Google Scholar] [CrossRef]

- Park, H.; Kwon, S.; Lee, J.S.; Lim, H.J.; Yoon, S.; Kim, D. Improvement on surface texturing of single crystalline silicon for solar cells by saw-damage etching using an acidic solution. Sol. Energy Mater. Sol. Cells 2009, 93, 1773–1778. [Google Scholar] [CrossRef]

- Chen, J.Y.; Huang, C.K.; Hung, W.B.; Sun, K.W.; Chen, T.M. Efficiency improvement of Si solar cells using metal-enhanced nanophosphor fluorescence. Sol. Energy Mater. Sol. Cells 2014, 120, 168–174. [Google Scholar] [CrossRef]

- Mandal, P.; Sharma, S. Progress in plasmonic solar cell efficiency improvement: A status review. Renew. Sustain. Energy Rev. 2016, 65, 537–552. [Google Scholar] [CrossRef]

- Uzum, A.; Kuriyama, M.; Kanda, H.; Kimura, Y.; Tanimoto, K.; Fukui, H.; Izumi, T.; Harada, T.; Ito, S. Sprayed and spin-coated multilayer antireflection coating films for nonvacuum processed crystalline silicon solar cells. Int. J. Photoenergy 2017, 3436271. [Google Scholar] [CrossRef]

- Ateto, E.O.; Konagai, M.; Miyajima, S. Triple layer antireflection design concept for the front side of c-Si heterojunction solar cell based on the antireflective effect of nc-3C-SiC:H emitter layer. Int. J. Photoenergy 2016, 5282851. [Google Scholar] [CrossRef]

- Sagar, R.; Rao, A. Increasing the silicon solar cell efficiency with transition metal oxide nano-thin films as anti-reflection coatings. Mater. Res. Express 2020, 7, 016433. [Google Scholar] [CrossRef] [Green Version]

- Gangopadhyay, U.; Jana, S.; Das, S.; Ghosh, P.; Mondal, A. Anti-reflective nanocomposite based coating for crystalline silicon solar cells with noticeable significance. J. Renew. Sustain. Energy 2013, 5, 031607. [Google Scholar] [CrossRef]

- Chanta, E.; Wongratanaphisan, D.; Gardchareon, A.; Phadungdhitidhada, S.; Ruankham, P.; Choopun, S. Effect of ZnO double layer as anti-reflection coating layer in ZnO dye-sensitized solar cells. Energy Procedia 2015, 79, 879–884. [Google Scholar] [CrossRef] [Green Version]

- Sikdar, D.; Rukhlenko, I.D.; Cheng, W.; Premaratne, M. Effect of number density on optimal design of gold nanoshells for plasmonic photothermal therapy. Biomed. Opt. Express 2013, 4, 15–31. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Masouleh, F.F.; Das, N.; Rozati, S.M. Optimal subwavelength design for efficient light trapping in central slit of plasmonics-based metal-semiconductor-metal photodetector. Opt. Quantum Electron. 2015, 47, 1477–1485. [Google Scholar] [CrossRef]

- Liu, Z.; Durant, S.; Lee, H.; Pikus, Y.; Fang, N.; Xiong, Y.; Sun, C.; Zhang, X. Far-Field Optical Superlens. Nano Lett. 2007, 7, 403–408. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.M.; Lee, Y.T. Simulation of antireflective subwavelength grating structure for optical device applications. In Proceedings of the 9th International Conference on Numerical Simulations of Optoelectronic Devices (NUSOD’09), Gwangju, Korea, 14–17 September 2009; pp. 103–104. [Google Scholar]

- Schmid, J.H.; Cheben, P.; Janz, S.; Lapointe, J.; Post, E.; Delâge, A.; Densmore, A.; Lamontagne, B.; Waldron, P.; Xu, D.X. Subwavelength grating structures in planar waveguide facets for modified reflectivity. In Proceedings of the SPIE, Volume 6796, Photonics North 2007, 67963E, Ottawa, ON, Canada, 26 October 2007. [Google Scholar] [CrossRef]

- Rao, J.; Varlamov, S. Light trapping in thin film polycrystalline silicon solar cell using diffractive gratings. Energy Procedia 2013, 33, 129–136. [Google Scholar] [CrossRef] [Green Version]

- Massiot, I. Design and Fabrication of Nanostructures for Light-Trapping in Ultra-Thin Solar Cells. Ph.D. Thesis, Université Paris Sud-Paris XI, Paris, France, 2013. [Google Scholar]

- Perl, E.E.; McMahon, W.E.; Bowers, J.E.; Friedman, D.J. Design of antireflective nanostructures and optical coatings for next-generation multijunction photovoltaic devices. Opt. Exp. 2014, 22. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.; In, S.J.; Mason, D.R.; Park, N. Incorporation of nanovoids into metallic gratings for broadband plasmonic organic solar cells. Opt. Exp. 2013, 21, 4055–4060. [Google Scholar] [CrossRef]

- Michaels, A.; Yablonovitch, E. Inverse design of near unity efficiency perfectly vertical grating couplers. Opt. Exp. 2018, 26, 4766–4779. [Google Scholar] [CrossRef]

- Tang, Z.; Tress, W.; Inganas, O. Light trapping in thin film organic solar cells. Mater. Today 2014, 17, 389–396. [Google Scholar] [CrossRef]

- Quaranta, G.; Basset, G.; Martin, O.J.F.; Gallinet, B. Recent advances in resonant waveguide gratings. Laser Photonics Rev. 2018, 12, 1800017. [Google Scholar] [CrossRef]

- Jalali, M.; Nadgaran, H.; Erni, D. Semiperiodic Ultra-broadband double-grating to improve c-Si thin-film solar cell’s optical absorption, through numerical structural optimization. Crystals 2019, 9, 264. [Google Scholar] [CrossRef] [Green Version]

- Elshorbagy, M.H.; Cuadrado, A.; Alda, J. Narrow absorption in ITO-free perovskite solar cells for sensing applications analyzed through electromagnetic simulation. Appl. Sci. 2019, 9, 4850. [Google Scholar] [CrossRef] [Green Version]

- Narasimhan, V.K.; Cui, Y. Nanostructures for photon management in solar cells. Nanophotonics 2013. [Google Scholar] [CrossRef]

- Ferry, V.E.; Polman, A.; Atwater, H.A. Modeling light trapping in nanostructured solar cells. ACS Nano 2011, 5, 10055–10064. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Das, N.; Karar, A.; Vasiliev, M.; Alameh, K. Analysis of nano-grating-assisted light absorption enhancement in metal–semiconductor–metal photodetectors patterned using focused ion-beam lithography. Opt. Commun. 2011, 284, 1694–1700. [Google Scholar] [CrossRef]

- OptiFDTD. Technical Background and Tutorials; Version 10; OptiFDTD: Ottawa, ON, Canada, 2008; Available online: http://optiwave.com/wp-content/uploads/2013/06/OptiFDTD_10_Technical_Background_and_Tutorials.pdf (accessed on 24 August 2016).

- Wilson, S.; Hutley, M. The optical properties of moth eye antireflection surfaces. J. Mod. Opt. 1982, 29, 993–1009. [Google Scholar] [CrossRef]

- Lotz, M.R.; Petersen, C.R.; Markos, C.; Bang, O.; Jakobsen, M.H.; Taboryski, R.J. Direct nanoimprinting of moth-eye structures in chalcogenide glass for broadband antireflection in the mid-infrared. Optica 2018, 5, 557–563. [Google Scholar] [CrossRef]

- Yamada, N.; Ijiro, T.; Okamoto, E.; Hayashi, K.; Masuda, H. Characterization of antireflection moth-eye film on crystalline silicon photovoltaic module. Opt. Express 2011, 19, A118–A125. [Google Scholar] [CrossRef]

- Song, Y.M. Design, Fabrication and Characterization of Antireflective Subwavelength Structures (SWSs) for Optical Device Applications. Ph.D. Thesis, School of Information and Mechatronics, Mountain Home, AR, USA, 2011. [Google Scholar]

- Matthew, W. Self-Assembled Nanotextures Create Antireflective Surface on Silicon Solar Cells. Available online: https://www.bnl.gov/newsroom/news.php?a=11685 (accessed on 12 November 2015).

- Albregtsen, F. 2 Reflection, Refraction, Diffraction, and Scattering. Available online: https://www.uio.no/studier/emner/matnat/ifi/INF-GEO4310/h09/undervisningsmateriale/imaging-kap2.pdf (accessed on 9 June 2020).

- Gupta, S.C. Optoelectronic Device and Systems, 2nd ed.; PHI Learning Pvt. Ltd.: Delhi, India, 2014. [Google Scholar]

- Sahoo, K.C.; Li, Y.; Chang, E.Y. Shape effect of silicon nitride subwavelength structure on reflectance for silicon solar cells. IEEE Trans. Electron. Device 2010, 57, 2427–2433. [Google Scholar] [CrossRef] [Green Version]

- Yu, Z.; Raman, A.; Fan, S. Fundamental limit of light trapping in grating structures. Opt. Express 2010, 18, A366–A380. [Google Scholar] [CrossRef]

- Das, N.; Islam, S.M. Optimization of nano-grating structure to reduce the reflection losses in GaAs solar cells. In Proceedings of the Australasian Universities Power Engineering Conference 2012 (AUPEC 2012), Denpasar-Bali, Indonesia, 26–29 September 2012. [Google Scholar]

- Chnadrasekar, D.; Das, N. Modeling and analysis of GaAs solar cells for conversion efficiency improvement by reducing reflection losses. In Proceedings of the 16th International Conference on Numerical Simulation of Optoelectronic Devices (NUSOD 2016), Sydney, Australia, 11–15 July 2016. [Google Scholar]

- Das, N.; Charoenpitaks, K.; Islam, S. Analysis of incident light angles on nanograting structure for minimizing reflection losses in GaAs solar cells. In Proceedings of the Australasian Universities Power Engineering Conference, AUPEC 2013, Hobart, TAS, Australia, 29 September–3 October 2013. [Google Scholar]

- Li, X.; Zhang, S.; Wang, P.; Zhong, H.; Wu, Z.; Chen, H.; Liu, C.; Lin, S. High performance solar cells based on graphene/GaAs hetero-structures. Nano Energy 2015, 16, 310. [Google Scholar] [CrossRef] [Green Version]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Das, N.; Chandrasekar, D.; Nur-E-Alam, M.; K. Khan, M.M. Light Reflection Loss Reduction by Nano-Structured Gratings for Highly Efficient Next-Generation GaAs Solar Cells. Energies 2020, 13, 4198. https://doi.org/10.3390/en13164198

Das N, Chandrasekar D, Nur-E-Alam M, K. Khan MM. Light Reflection Loss Reduction by Nano-Structured Gratings for Highly Efficient Next-Generation GaAs Solar Cells. Energies. 2020; 13(16):4198. https://doi.org/10.3390/en13164198

Chicago/Turabian StyleDas, Narottam, Devanandh Chandrasekar, Mohammad Nur-E-Alam, and M. Masud K. Khan. 2020. "Light Reflection Loss Reduction by Nano-Structured Gratings for Highly Efficient Next-Generation GaAs Solar Cells" Energies 13, no. 16: 4198. https://doi.org/10.3390/en13164198

APA StyleDas, N., Chandrasekar, D., Nur-E-Alam, M., & K. Khan, M. M. (2020). Light Reflection Loss Reduction by Nano-Structured Gratings for Highly Efficient Next-Generation GaAs Solar Cells. Energies, 13(16), 4198. https://doi.org/10.3390/en13164198