Recognition of Variable-Speed Equipment in an Air-Conditioning System Using Numerical Analysis of Energy-Consumption Data

Abstract

:1. Introduction

2. Methodology

2.1. ME in the Studied Air-Conditioning System

2.2. Collection and Processing of ME Energy Consumption Data

2.3. Numerical Analysis of Energy Consumption Data

3. Results

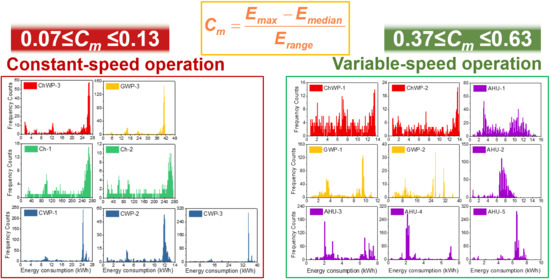

3.1. ME Energy Consumption Distributions

3.2. Numerical Characteristics of Energy Consumption Data

3.3. Recognition of Variable-Speed ME

3.3.1. Recognition of Variable-Speed Pumps

3.3.2. Verifiable Recognition of Variable-Speed AHUs and Constant-Speed Chillers

4. Discussions

4.1. Feature Selection of Numerical Characteristics of Energy Consumption Data

4.2. Construction Process of Cm

4.3. Scope of Application of Cm and Contributions of This Study

- The successful recognition of variable- and constant-speed ME using the proposed Cm in this paper addresses the research gap related to the reverse identification of equipment type through mining the energy consumption data of air-conditioning systems.

- The involved ME in this study had diverse components and brands and thus exhibited different distributions and scales of energy consumption data. Nevertheless, since differences in energy consumption scales were eliminated and made dimensionless in the development of parameter Cm, the method and results were not expected to be influenced by the specific brands, types, models, or power ratings of ME. Consequently, the proposed Cm is supposed to have versatility in general air-conditioning systems other than the specific example of this study.

- In addition, even if the constant- or variable-speed nature of the ME is already known, such an investigation could also diagnose if the variable-speed ME is working properly. In terms of diagnosis, by calculating the actual Cm value for a certain period of time and comparing it with the Cm value of the corresponding design conditions, it is possible to determine whether the operation of the ME is in accordance with the original design or to reflect on whether the design scheme is reasonable.

- The distinguishing results can provide essential information for the subsequent analysis of energy/cost saving potential by optimizing algorithms for different types of ME under their respective practical constraints. Moreover, the proposed Cm can also be of potential use to enhance the automatic processing of data, to reduce the direct involvement of field professionals, and to fundamentally support the automatic computer processing of massive amounts of air-conditioning system energy consumption data.

4.4. Limitations

- The data involved in this study came from the case system’s energy consumption monitoring platform. Therefore, there were no corresponding data available on the platform, such as the water flow rate of pumps, air volume of AHUs, cooling capacity of chillers, or related frequency data of inverters, which could be employed to verify the recognition results of the present case. In addition, energy consumption data were collected at an interval of 1 h, which seemed somewhat long for analysis in this paper, since constant-speed ME might accomplish several on/off cycles or the variable-speed ME might change its speed of rotation several times. This was due to the local preferential tariff for the ice-storage air-conditioning system, where the minimal interval between two adjustments for the ME was 1 h, including on/off control or changes in operating speed related to changes in energy consumption [49]. Therefore, the above limitations had negligible impact on our study, as the probed results demonstrated the effectiveness of the proposed indicator parameter in the recognition of variable-speed ME.

- The proposed coefficient of the median Cm could effectively recognize variable- and constant-speed operation modes for ME in the current study. Theoretically, the value of Cm ranges from 0 to 1. However, as stated in Section 4.2, the operation of real-world ME is influenced by the device and by the system to which it belongs, as well as by the thermal, vibration, and electromagnetic environments and the power quality of the environment in which it is located; hence, it is difficult to theoretically conclude a threshold value for recognition. On the basis of results to date, the confidence interval of the Cm value for ME running at constant speed ranged from 0.07 to 0.13 with 99% confidence, while the confidence interval of the Cm value for ME operating at variable speed ranged from 0.37 to 0.63 in this pilot study. Further study is warranted to collect more energy consumption data from different ME types and to theoretically investigate factors influencing Cm so as to give a more precise threshold value.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pérez-Lombard, L.; Ortiz, J.; Pout, C. A review on buildings energy consumption information. Energy Build. 2008, 40, 394–398. [Google Scholar] [CrossRef]

- Afram, A.; Janabi-Sharifi, F. Theory and applications of HVAC control systems—A review of model predictive control (MPC). Build. Environ. 2014, 72, 343–355. [Google Scholar] [CrossRef]

- Fong, K.F.; Hanby, V.I.; Chow, T.T. HVAC system optimization for energy management by evolutionary programming. Energy Build. 2006, 38, 220–231. [Google Scholar] [CrossRef]

- Qureshi, T.Q.; Tassou, S.A. Variable-speed capacity control in refrigeration systems. Appl. Eng. 1996, 16, 103–113. [Google Scholar] [CrossRef]

- Khalid, N. Efficient energy management: Is variable frequency drives the solution. Procedia Soc. Behav. Sci. 2014, 145, 371–376. [Google Scholar] [CrossRef] [Green Version]

- Bose, B.K. Global energy scenario and impact of power electronics in 21st century. IEEE Trans. Ind. Electron. 2013, 60, 2638–2651. [Google Scholar] [CrossRef]

- Bernier, M.A.; Bourret, B. Pumping energy and variable frequency drives. Ashrae J. 1999, 41, 37–40. [Google Scholar]

- Zhou, Y.P.; Wu, J.Y.; Wang, R.Z.; Shiochi, S. Energy simulation in the variable refrigerant flow air-conditioning system under cooling conditions. Energy Build. 2007, 39, 212–220. [Google Scholar] [CrossRef]

- Ma, Z.; Wang, S. Energy efficient control of variable speed pumps in complex building central air-conditioning systems. Energy Build. 2009, 41, 197–205. [Google Scholar] [CrossRef]

- Roulet, C.A. Indoor environment quality in buildings and its impact on outdoor environment. Energy Build. 2001, 33, 183–191. [Google Scholar] [CrossRef]

- Wang, S.; Jin, X. Model-based optimal control of VAV air-conditioning system using genetic algorithm. Build. Environ. 2000, 35, 471–487. [Google Scholar] [CrossRef]

- Kusiak, A.; Li, M.; Tang, F. Modeling and optimization of HVAC energy consumption. Appl. Energy 2010, 87, 3092–3102. [Google Scholar] [CrossRef]

- Lu, L.; Cai, W.; Soh, Y.C.; Xie, L.; Li, S. HVAC system optimization-Condenser water loop. Energy Convers. Manag. 2004, 45, 613–630. [Google Scholar] [CrossRef]

- Shao, S.; Shi, W.; Li, X.; Chen, H. Performance representation of variable-speed compressor for inverter air conditioners based on experimental data. Int. J. Refrig. 2004, 27, 805–815. [Google Scholar] [CrossRef]

- Kaya, D.; Yagmur, E.A.; Yigit, K.S.; Kilic, F.C.; Eren, A.S.; Celik, C. Energy efficiency in pumps. Energy Convers. Manag. 2008, 49, 1662–1673. [Google Scholar] [CrossRef]

- Lönnberg, M. Variable Speed Drives for energy savings in hospitals. World Pumps 2007, 2007, 20–24. [Google Scholar] [CrossRef]

- Montagud, C.; Corberán, J.M.; Montero, A. In situ optimization methodology for the water circulation pumps frequency of ground source heat pump systems. Energy Build. 2014, 68, 42–53. [Google Scholar] [CrossRef]

- Teitel, M.; Levi, A.; Zhao, Y.; Barak, M.; Bar-lev, E.; Shmuel, D. Energy saving in agricultural buildings through fan motor control by variable frequency drives. Energy Build. 2008, 40, 953–960. [Google Scholar] [CrossRef]

- Schibuola, L.; Scarpa, M.; Tambani, C. Variable speed drive (VSD) technology applied to HVAC systems for energy saving: An experimental investigation. Energy Procedia 2018, 148, 806–813. [Google Scholar] [CrossRef]

- Yu, F.W.; Chan, K.T. Environmental performance and economic analysis of all-variable speed chiller systems with load-based speed control. Appl. Eng. 2009, 29, 1721–1729. [Google Scholar] [CrossRef]

- Hartman, T. All-variable speed centrifugal chiller plants. Ashrae J. 2001, 43, 43–53. [Google Scholar]

- Wang, F.J.; Chang, T.B.; Chen, M.T. Energy conservation for chiller plants by implementation of variable speed driven approach in an industrial building. Energy Procedia 2014, 61, 2537–2540. [Google Scholar] [CrossRef] [Green Version]

- Del Col, D.; Azzolin, M.; Benassi, G.; Mantovan, M. Energy efficiency in a ground source heat pump with variable speed drives. Energy Build. 2015, 91, 105–114. [Google Scholar] [CrossRef]

- Lee, C.K. Dynamic performance of ground-source heat pumps fitted with frequency inverters for part-load control. Appl. Energy 2010, 87, 3507–3513. [Google Scholar] [CrossRef]

- Yu, Z.; Haghighat, F.; Fung, B.C.M.; Zhou, L. A novel methodology for knowledge discovery through mining associations between building operational data. Energy Build. 2012, 47, 430–440. [Google Scholar] [CrossRef]

- Ahmed, A.; Korres, N.E.; Ploennigs, J.; Elhadi, H.; Menzel, K. Mining building performance data for energy-efficient operation. Adv. Eng. Inform. 2011, 25, 341–354. [Google Scholar] [CrossRef]

- Kim, H.; Stumpf, A.; Kim, W. Analysis of an energy efficient building design through data mining approach. Autom. Constr. 2011, 20, 37–43. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, C.; Zhang, Y.; Wang, Z.; Li, J. A review of data mining technologies in building energy systems: Load prediction, pattern identification, fault detection and diagnosis. Energy Built Environ. 2020, 1, 149–164. [Google Scholar] [CrossRef]

- Ma, R.; Yu, N. A New Route for Energy Efficiency Diagnosis and Potential Analysis of Energy Consumption from Air-Conditioning System. In Proceedings of the 14th International Conference for Enhanced Building Operations (ICEBO2014), Beijing, China, 14–17 September 2014. [Google Scholar]

- Du, Z.; Fan, B.; Jin, X.; Chi, J. Fault detection and diagnosis for buildings and HVAC systems using combined neural networks and subtractive clustering analysis. Build. Environ. 2014, 73, 1–11. [Google Scholar] [CrossRef]

- Du, Z.; Jin, X.; Yang, Y. Fault diagnosis for temperature, flow rate and pressure sensors in VAV systems using wavelet neural network. Appl. Energy 2009, 86, 1624–1631. [Google Scholar] [CrossRef]

- Lee, W.-Y.; House, J.M.; Kyong, N.-H. Subsystem level fault diagnosis of a building’s air-handling unit using general regression neural networks. Appl. Energy 2004, 77, 153–170. [Google Scholar] [CrossRef]

- Chen, Y.; Hao, X.; Zhang, G.; Wang, S. Flow meter fault isolation in building central chilling systems using wavelet analysis. Energy Convers. Manag. 2006, 47, 1700–1710. [Google Scholar] [CrossRef]

- Yang, X.; Du, Z.; Jin, X.; Fan, B.; Guo, Y.; Yang, Y. Wavelet Packet and Neural Network Methods for Fixed Bias Fault Diagnosis for Air Handling Unit Sensors. In Proceedings of the 6th International Symposium on Heating, Ventilating and Air Conditioning, ISHVAC 2009, Nanjing, China, 6–9 November 2009. [Google Scholar]

- Wang, S.; Cui, J. Sensor-fault detection, diagnosis and estimation for centrifugal chiller systems using principal-component analysis method. Appl. Energy 2005, 82, 197–213. [Google Scholar] [CrossRef]

- Jin, X.; Du, Z. Fault tolerant control of outdoor air and AHU supply air temperature in VAV air conditioning systems using PCA method. Appl. Eng. 2006, 26, 1226–1237. [Google Scholar] [CrossRef]

- Du, Z.; Jin, X.; Yang, Y. Wavelet Neural Network-Based Fault Diagnosis in Air-Handling Units. HvacR Res. 2008, 14, 959–973. [Google Scholar] [CrossRef]

- Zhu, Y.; Jin, X.; Du, Z. Fault diagnosis for sensors in air handling unit based on neural network pre-processed by wavelet and fractal. Energy Build. 2012, 44, 7–16. [Google Scholar] [CrossRef]

- Idowu, S.; Saguna, S.; Ahlund, C. Applied machine learning: Forecasting heat load in district heating system. Energy Build. 2016, 133, 478–488. [Google Scholar] [CrossRef]

- Zhao, D.; Zhong, M.; Zhang, X.; Su, X. Energy consumption predicting model of VRV (Variable refrigerant volume) system in office buildings based on data mining. Energy 2016, 102, 660–668. [Google Scholar] [CrossRef]

- Liu, J.; Wang, J.; Li, G.; Chen, H.; Shen, L.; Xing, L. Evaluation of the energy performance of variable refrigerant flow systems using dynamic energy benchmarks based on data mining techniques. Appl. Energy 2017, 208, 522–539. [Google Scholar] [CrossRef]

- Li, G.; Hu, Y.; Chen, H.; Li, H.; Hu, M.; Guo, Y.; Liu, J.; Sun, S.; Sun, M. Data partitioning and association mining for identifying VRF energy consumption patterns under various part loads and refrigerant charge conditions. Appl. Energy 2017, 185, 846–861. [Google Scholar] [CrossRef]

- Brown, C.E. Applied Multivariate Statistics in Geohydrology and Related Sciences; Springer: Berlin/Heidelberg, Germany, 1998; ISBN 978-3-642-80330-7. [Google Scholar]

- Groeneveld, R.A.; Meeden, G. Measuring Skewness and Kurtosis. Statistics 1984, 33, 391–399. [Google Scholar] [CrossRef]

- Joanes, D.N.; Gill, C.A. Comparing measures of sample skewness and kurtosis. J. R. Stat. Soc. Ser. D Stat. 1998, 47, 183–189. [Google Scholar] [CrossRef]

- Guyon, I.; Elisseeff, A. An introduction to variable and feature selection. J. Mach. Learn. Res. 2003, 3, 1157–1182. [Google Scholar]

- Newton, R.R.; Rudestam, K.E. Your Statistical Consultant: Answers to Your Data Analysis Questions; SAGE Publications, Ltd.: London, UK, 2013; ISBN 9781412997591. [Google Scholar]

- Lewis-Beck, M.; Bryman, A.; Futing Liao, T. The SAGE Encyclopedia of Social Science Research Methods; Sage Publications, Inc.: Thousand Oaks, CA, USA, 2004; ISBN 9780761923633. [Google Scholar]

- Ma, R. The study of Energy Efficiency Diagnosis Methodology for Air-Conditioning Systems with the Actual Operating Data. Ph.D. Thesis, Southwest Jiaotong University, Chengdu, China, 2014. [Google Scholar]

| Equipment No. | Erange | Emean | Esd | Evar | Cs | Ck | Emedian | Emode | Cv | Cm |

|---|---|---|---|---|---|---|---|---|---|---|

| ChWP-1 | 12.80 | 7.45 | 3.93 | 15.47 | −0.03 | −1.21 | 7.20 | 6.90 | 0.53 | 0.49 |

| ChWP-2 | 13.10 | 7.72 | 4.37 | 19.12 | −0.07 | −1.37 | 7.50 | 13.50 | 0.57 | 0.48 |

| ChWP-3 | 25.90 | 19.97 | 8.23 | 67.80 | −0.99 | −0.45 | 24.60 | 26.30 | 0.41 | 0.10 |

| CWP-1 | 25.20 | 19.69 | 7.14 | 50.91 | −1.00 | −0.55 | 24.20 | 24.30 | 0.36 | 0.10 |

| CWP-2 | 12.60 | 9.70 | 3.58 | 12.84 | −1.15 | −0.13 | 11.80 | 12.00 | 0.37 | 0.12 |

| CWP-3 | 36.50 | 28.12 | 10.64 | 113.23 | −1.01 | −0.55 | 35.00 | 35.00 | 0.38 | 0.10 |

| GWP-1 | 10.80 | 6.37 | 3.02 | 9.15 | −0.14 | −1.61 | 6.70 | 9.50 | 0.47 | 0.44 |

| GWP-2 | 34.40 | 18.26 | 9.56 | 91.41 | 0.03 | −1.49 | 17.95 | 26.40 | 0.52 | 0.53 |

| GWP-3 | 44.00 | 33.64 | 11.02 | 121.38 | −1.25 | 0.16 | 40.30 | 40.70 | 0.33 | 0.14 |

| Ch-1 | 258.00 | 216.08 | 71.66 | 5135.15 | −1.19 | −0.09 | 255.70 | 264.50 | 0.33 | 0.07 |

| Ch-2 | 259.80 | 193.17 | 86.76 | 7527.56 | −0.76 | −1.09 | 249.60 | 258.50 | 0.45 | 0.09 |

| AHU-1 | 14.10 | 7.74 | 3.58 | 12.80 | −0.12 | −1.35 | 8.50 | 10.80 | 0.46 | 0.45 |

| AHU-2 | 14.90 | 7.11 | 1.78 | 3.17 | −1.70 | 4.50 | 7.30 | 7.00 | 0.25 | 0.55 |

| AHU-3 | 7.50 | 4.44 | 2.23 | 4.95 | 0.06 | −1.65 | 3.90 | 2.00 | 0.50 | 0.52 |

| AHU-4 | 7.30 | 2.97 | 1.73 | 2.99 | 1.60 | 1.15 | 2.20 | 2.20 | 0.58 | 0.74 |

| AHU-5 | 8.80 | 6.26 | 1.47 | 2.17 | −2.60 | 6.79 | 6.60 | 6.50 | 0.24 | 0.30 |

| Rank | Numerical Characteristic | Effectiveness 1 | (1 − p) Value |

|---|---|---|---|

| 1 | Cm | Effective | 1.000 |

| 2 | Emedian | Effective | 0.963 |

| 3 | Emean | Effective | 0.959 |

| 4 | Emode | Effective | 0.959 |

| 5 | Erange | Effective | 0.952 |

| 6 | Esd | Effective | 0.950 |

| 7 | Evar | Marginal | 0.904 |

| 8 | Cv | Ineffective | 0.872 |

| 9 | Cs | Ineffective | 0.864 |

| 10 | Ck | Ineffective | 0.485 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, R.; Wang, X.; Shan, M.; Yu, N.; Yang, S. Recognition of Variable-Speed Equipment in an Air-Conditioning System Using Numerical Analysis of Energy-Consumption Data. Energies 2020, 13, 4975. https://doi.org/10.3390/en13184975

Ma R, Wang X, Shan M, Yu N, Yang S. Recognition of Variable-Speed Equipment in an Air-Conditioning System Using Numerical Analysis of Energy-Consumption Data. Energies. 2020; 13(18):4975. https://doi.org/10.3390/en13184975

Chicago/Turabian StyleMa, Rongjiang, Xianlin Wang, Ming Shan, Nanyang Yu, and Shen Yang. 2020. "Recognition of Variable-Speed Equipment in an Air-Conditioning System Using Numerical Analysis of Energy-Consumption Data" Energies 13, no. 18: 4975. https://doi.org/10.3390/en13184975

APA StyleMa, R., Wang, X., Shan, M., Yu, N., & Yang, S. (2020). Recognition of Variable-Speed Equipment in an Air-Conditioning System Using Numerical Analysis of Energy-Consumption Data. Energies, 13(18), 4975. https://doi.org/10.3390/en13184975