Review of Key Performance Indicators for Process Monitoring in the Mining Industry

Abstract

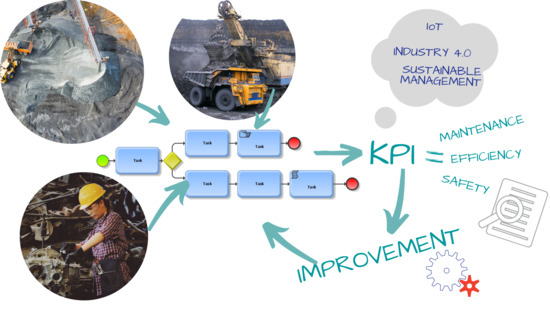

:1. Introduction

2. Materials and Methods

2.1. Process Monitoring and Control

2.2. Systematic Literature Review

- RQ1:

- What are the main areas of the application of KPIs in an organisation?

- RQ2:

- What are the most commonly used KPIs for data-based process optimisation in the mining industry?

- For the WoS searching for “mining”, mineral”, “processing”, the results are 32 articles;

- For the WOL searching for “key performance indicator” in keywords and “mining industry”, there were 26 articles.

3. Results

3.1. SLR Results

- Human resources: compensation cost, % of participants in communication training, % of training courses matching company requirements, consistent development of leadership skills, and the strengthening of the manager’s role as a coach and a mentor (leadership index) [20].

- Finance: value added per employee, value added in relation to cost, turnover per employee, investment per employee, value added in relation to investments, and the share of investments to the total costs [18].

- Operational: availability, utilisation, cycle time, flow time, corrective maintenance ratio, mean time to failure, mean time to repair, overall equipment effectiveness (OEE), production effectiveness, production process ratio, quality, % of available man hours used in proactive work, the number of work order requests, % of scheduled man hours over the total available man hours, the number of unplanned maintenance interventions, unscheduled maintenance downtime, health and environment incidents, and the number of unplanned maintenance interventions [31,32].

3.2. Classification and Definition of Mining KPIs for Process Monitoring

3.3. Discussion of the Presented Concept

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhou, C.; Damiano, N.; Whisner, B.; Reyes, M. Industrial Internet of Things (IIoT) applications in underground coal mines. Min. Eng. 2017, 69, 50–56. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lin, B.; Wu, W.; Song, M. Industry 4.0: Driving factors and impacts on firm’s performance: An empirical study on China’s manufacturing industry. Ann. Oper. Res. 2019. [Google Scholar] [CrossRef]

- Xu, L.D.; Xu, E.L.; Li, L. Industry 4.0: State of the art and future trends. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar] [CrossRef] [Green Version]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Pereira, A.C.; Romero, F. A review of the meanings and the implications of the Industry 4.0 concept. Proc. Manuf. 2017, 13, 1206–1214. [Google Scholar] [CrossRef]

- Alcácer, V.; Cruz-Machado, V. Scanning the Industry 4.0: A Literature Review on Technologies for Manufacturing Systems. Eng. Sci. Technol. Int. J. 2019, 22, 899–919. [Google Scholar] [CrossRef]

- Bertayeva, K.; Panaedova, G.; Natocheeva, N.; Kulagovskaya, T.; Belyanchikova, T. Industry 4.0 in the mining industry: Global trends and innovative development. E3S Web Conf. 2019, 135. [Google Scholar] [CrossRef]

- Lööw, J.; Abrahamsson, L.; Johansson, J. Mining 4.0—The Impact of New Technology from a Work Place Perspective. Min. Metall. Explor. 2019, 36, 701–707. [Google Scholar] [CrossRef] [Green Version]

- Badawy, M.; El-Aziz, A.A.A.; Idress, A.M.; Hefny, H.; Hossam, S. A survey on exploring key performance indicators. Future Comput. Inf. J. 2016, 1, 47–52. [Google Scholar] [CrossRef]

- Ralston, J.; Reid, D.; Hargrave, C.; Hainsworth, D. Sensing for advancing mining automation capability: A review of underground automation technology development. Int. J. Min. Sci. Technol. 2014, 24, 305–310. [Google Scholar] [CrossRef]

- Sganzerla, C.; Seixas, C.; Conti, A. Disruptive Innovation in Digital Mining. Proc. Eng. 2016, 138, 64–71. [Google Scholar] [CrossRef] [Green Version]

- Singh, A.; Kumar, D.; Hötzel, J. IoT Based information and communication system for enhancing underground mines safety and productivity: Genesis, taxonomy and open issues. Ad. Hoc. Netw. 2018, 78, 115–129. [Google Scholar] [CrossRef]

- Gautham, B.P.; Reddy, S.; Runkana, V. Future of Mining, Mineral Processing and Metal Extraction Industry. Trans. Indian Inst. Met. 2019, 72, 2159–2177. [Google Scholar] [CrossRef]

- Skrzypkowski, K. The influence of room and pillar method geometry on the deposit utilization rate and rock bolt load. Energies 2019, 12, 4770. [Google Scholar] [CrossRef] [Green Version]

- Torkko, M.; Katajavuori, N.; Linna, A.; Juppo, A.M. The utilisation of quality KPIs in the pharmaceutical industry. J. Pharm. Innov. 2014, 9, 175–182. [Google Scholar] [CrossRef]

- Lu, D.; Asian, S.; Ertek, G.; Sevinc, M. Mind the perception gap An integrative performance management framework for service supply chains. Int. J. Phys. Distrib. Logist. Manag. 2019, 49, 33–51. [Google Scholar] [CrossRef]

- Torbacki, W.; Kijewska, K. Identifying Key Performance Indicators to be used in Logistics 4.0 and Industry 4.0 for the needs of sustainable municipal logistics by means of the DEMATEL method. In Proceedings of the 3rd International Conference Green Cities—Green Logistics For Greener Cities, Szczecin, Poland, 13–14 September 2018; Iwan, S., Thompson, R.G., Kijewska, K., Eds.; Elsevier Science Bv.: Amsterdam, The Netherlands, 2019; Volume 39, pp. 534–543. [Google Scholar]

- Hedvičáková, M.; Král, M. Benefits of KPIS For Industry Sector Evaluation: The Case Study From The Czech Republic. E+M Ekon. Manag. 2019, 22, 97–113. [Google Scholar] [CrossRef]

- Zámečník, R. The Qualitative Indicators in Human Resource Accounting. Mark. Manag. Innov. 2016, 4, 325–341. [Google Scholar]

- Gabčanová, I. Human Resources Key Performance Indicators. J. Compet. 2012, 4, 117–128. [Google Scholar] [CrossRef] [Green Version]

- Voronov, A.; Voronov, Y.; Voronov, A.; Demirel, N. Operation Quality Indicators for Shovel-Truck Systems at Open-Pit Coal Mines. In Proceedings of the IV International Innovative Mining Symposium, Kemerovo, Russia, 14–16 October 2019; EDP Sciences: Les Ulis, France, 2019; Volume 105. [Google Scholar]

- Bhadani, K.; Asbjornsson, G.; Hulthen, E.; Evertsson, M. Development and implementation of key performance indicators for aggregate production using dynamic simulation. Miner. Eng. 2020, 145. [Google Scholar] [CrossRef]

- Voronov, Y.; Voronov, A.; Voronov, A. Quality Criterion of the Loading and Transport System Operation at Open-Pit Mines. In Proceedings of the IV International Innovative Mining Symposium, Kemerovo, Russia, 14–16 October 2019; EDP Sciences: Les Ulis, France, 2019; Volume 105. [Google Scholar]

- Fisseler, D.; Kemény, Z.; Reiners, R. Monitoring and Control Framework for Business Processes in Ubiquitous Environments. In Proceedings of the 2016 Intl IEEE Conferences on Ubiquitous Intelligence Computing, Advanced and Trusted Computing, Scalable Computing and Communications, Cloud and Big Data Computing, Internet of People, and Smart World Congress (UIC/ATC/ScalCom/CBDCom/IoP/SmartWorld), Toulouse, France, 18–21 July 2016; pp. 863–868. [Google Scholar]

- Mardonova, M.; Choi, Y. Review of Wearable Device Technology and Its Applications to the Mining Industry. Energies 2018, 11, 547. [Google Scholar] [CrossRef] [Green Version]

- Skrzypkowski, K.; Korzeniowski, W.; Zagórski, K.; Zagórska, A. Adjustment of the yielding system of mechanical rock bolts for room and pillar mining method in stratified rock mass. Energies 2020, 13, 2082. [Google Scholar] [CrossRef] [Green Version]

- Aksu, U.; Schunselaar, D.M.M.; Reijers, H.A. Automated Prediction of Relevant Key Performance Indicators for Organisations. In Business Information Systems, PTI; Abramowicz, W., Corchuelo, R., Eds.; Springer-Verlag: Berlin/Heidelberger, Germany, 2019; Volume 353, pp. 283–299. [Google Scholar]

- Sathananthan, S. Data valuation considering knowledge transformation, process models and data models. In Proceedings of the 2018 12th International Conference on Research Challenges In Information Science (RCIS), New York, NY, USA, 29–31 May 2018. [Google Scholar]

- Kaganski, S.; Majak, J.; Karjust, K.; Toompalu, S. Implementation of Key Performance Indicators Selection Model as Part of the Enterprise Analysis Model. In Proceedings of the Manufacturing Systems 4.0, The 50th CIRP Conference on Manufacturing Systems, Taichung City, Taiwan, 3–5 May 2017; Tseng, M.M., Tsai, H.Y., Wang, Y., Eds.; Elsevier Science Bv.: Amsterdam, The Netherlands, 2017; Volume 63, pp. 283–288. [Google Scholar]

- Grozdanovic, M.; Savic, S.; Marjanovic, D. Assessment of the key factors for ergonomic design of management information systems in coal mines. Int. J. Min. Reclam. Environ. 2015, 29, 96–111. [Google Scholar] [CrossRef]

- Alkan, B.; Bullock, S. Assessing operational complexity of manufacturing systems based on algorithmic complexity of key performance indicator time-series. J. Oper. Res. Soc. 2020, 1–15. [Google Scholar] [CrossRef]

- Aditya, P.; Kumar, U.; Galar, D.; Stenström, C. Performance measurement and management for maintenance: A literature review. J. Qual. Maint. Eng. 2015, 21, 2–33. [Google Scholar]

- Visser, W.F. A Blueprint for Performance-Driven Operations Management. Min. Metall. Explor. 2020, 37, 823–831. [Google Scholar] [CrossRef]

- Bouffard, S.C. Benefits realised and lessons learned from modeling the production capacity of the Jansen Potash Project. Miner. Process. Extr. Metall. Rev. 2020, 41, 50–58. [Google Scholar] [CrossRef]

- Navarra, A.; Alvarez, M.; Rojas, K.; Menzies, A.; Pax, R.; Waters, K. Concentrator operational modes in response to geological variation. Miner. Eng. 2019, 134, 356–364. [Google Scholar] [CrossRef]

- Otto, T.J.; Musingwini, C. A spatial mine-to-plan compliance approach to improve alignment of short- and long-term mine planning at open pit mines. J. South. Afr. Inst. Min. Metall. 2019, 119, 253–259. [Google Scholar] [CrossRef] [Green Version]

- Jena, M.C.; Mishra, S.K.; Moharana, H.S. Application of Industry 4.0 to enhance sustainable manufacturing. Environ. Prog. Sust. Energy 2020, 39, 1–11. [Google Scholar] [CrossRef]

- Viveros Gunckel, P.; Kristjanpoller, F.; López-Campos, M.; Crespo Márquez, A.; Pascual, R. Graphical analysis for overall effectiveness management: A graphical method to support operation and maintenance performance assessment. Qual. Reliab. Eng. Int. 2018, 34, 1615–1632. [Google Scholar] [CrossRef]

- Pasch, O.; Uludag, S. Optimization of the load-and-haul operation at an opencast colliery. J. South. Afr. Inst. Min. Metall. 2018, 118, 449–456. [Google Scholar] [CrossRef]

- Olkiewicz, M.; Wolniak, R.; Ostapko, B. The Analysis of Dependencies Between Extraction And Resource Consumption in 2008–2014 on the Example of Glisno Gravel Pit. Arch. Min. Sci. 2018, 63, 801–812. [Google Scholar] [CrossRef]

- Li, C.; Runge, K.; Shi, F.; Farrokhpay, S. Effect of froth rheology on froth and flotation performance. Miner. Eng. 2018, 115, 4–12. [Google Scholar] [CrossRef]

- Bezminabadi, S.N.; Ramezanzadeh, A.; Jalali, S.-M.E.; Tokhmechi, B.; Roustaei, A. Effect of Rock Properties on Rop Modeling Using Statistical and Intelligent Methods: A Case Study of an Oil Well in Southwest of Iran. Arch. Min. Sci. 2017, 62, 131–144. [Google Scholar] [CrossRef] [Green Version]

- Sebutsoe, T.C.; Musingwini, C. Characterising a mining production system for decision-making purposes in a platinum mine. J. South. Afr. Inst. Min. Metall. 2017, 117, 199–206. [Google Scholar] [CrossRef] [Green Version]

- Bester, M.; Russell, T.; van Heerden, J.; Carey, R. Reconciliation of the mining value chain—Mine to design as a critical enabler for optimal and safe extraction of the mineral reserve. J. South. Afr. Inst. Min. Metall. 2016, 116, 407–411. [Google Scholar] [CrossRef]

- Fourie, H. Improvement in the overall efficiency of mining equipment: A case study. J. South. Afr. Inst. Min. Metall. 2016, 116, 275–281. [Google Scholar] [CrossRef]

- Petit, P.J. Business optimisation for platinum mining projects and operations. J. South. Afr. Inst. Min. Metall. 2016, 116, 123–130. [Google Scholar] [CrossRef] [Green Version]

- Zaruba Natalyi, A.; Egorova Natalyi, N. Lean Governance as a Condition for the Creation of Intellectual Coal Industry. In Proceedings of the 8th Russian-Chinese Symposium Coal In The 21st Century: Mining, Processing, Safety, Kemerovo, Russia, 10–12 October 2016; Tailakov, O.V., Ed.; Atlantis Press: Paris, France, 2016; Volume 92, pp. 39–44. [Google Scholar]

- Nikulin, C.; Ulloa, A.; Carmona, C.; Creixell, W. A Computer-Aided Application For Modeling And Monitoring Operational And Maintenance Information In Mining Trucks. Arch. Min. Sci. 2016, 61, 695–708. [Google Scholar] [CrossRef] [Green Version]

- Prakash, A.; Murthy, V.M.S.R.; Singh, K.B. A new rock cuttability index for predicting key performance indicators of surface miners. Int. J. Rock Mech. Min. Sci. 2015, 77, 339–347. [Google Scholar] [CrossRef]

- Segopolo, P.R. Optimization of shuttle car utilisation at an underground coal mine. J. South. Afr. Inst. Min. Metall. 2015, 115, 285–296. [Google Scholar] [CrossRef]

- Czaplicka-Kolarz, K.; Burchart-Korol, D.; Turek, M.; Borkowski, W. Model of Eco-Efficiency Assessment of Mining Production Processes. Arch. Min. Sci. 2015, 60, 477–486. [Google Scholar] [CrossRef]

- Dauber, C.; Bendrat, N. Key performance indicators—A tool to assess ICT applications in underground coal mines. J. South. Afr. Inst. Min. Metall. 2014, 114, 1017–1022. [Google Scholar]

- Schoevaerts, B.; Balg, C.; Brown, S.; Van Zyl, C. Fast, safe, and fully mechanised installation of high-tensile chain-link mesh for underground support. J. South. Afr. Inst. Min. Metall. 2012, 112, 127–133. [Google Scholar]

- Tan, P. Modeling and control of copper loss in smelting slag. JOM 2011, 63, 51–57. [Google Scholar] [CrossRef]

- Mkhwanazi, D. Optimizing LHD utilisation. J. South. Afr. Inst. Min. Metall. 2011, 111, 273–280. [Google Scholar]

- Marais, C.; Aldrich, C. The estimation of platinum flotation grade from froth image features by using artificial neural networks. J. South. Afr. Inst. Min. Metall. 2011, 111, 81–85. [Google Scholar]

- BHP Sustainability Report. 2019. Available online: https://www.bhp.com/-/media/documents/investors/annual-reports/2019/bhpsustainabilityreport2019.pdf (accessed on 26 June 2020).

- Rio Tinto. Sustainability Reporting. Available online: https://www.riotinto.com/sustainability/sustainability-reporting (accessed on 25 June 2020).

- Glencore. Sustainability Reporting Highlights 2019. Available online: https://www.glencore.com/dam:jcr/c7f6c5fc-b275-4e12-9448-de5302805781/2019-Glencore-Sustainability-Highlights--.pdf (accessed on 22 June 2020).

- Vale. Sustainability Report 2019. Available online: http://www.vale.com/EN/investors/information-market/annual-reports/sustainability-reports/Sustainability%20Reports/Relatorio_sustentabilidade_vale_2019_alta_en.pdf (accessed on 29 June 2020).

- Anglo American. Sustainability Report. 2019. Available online: https://www.angloamerican.com/~/media/Files/A/Anglo-American-Group/PLC/investors/annual-reporting/2020/aa-sustainability-report-2019-v1.pdf (accessed on 23 June 2020).

- Fortescue Metal Group Ltd. Annual Report FY19. Available online: https://www.fmgl.com.au/docs/default-source/annual-reporting-suite/fy19-annual-report.pdf (accessed on 29 June 2020).

- Fresnillo PLC Annual Report and Accounts. Available online: http://www.fresnilloplc.com/media/451923/fres-33085-annual-report-2019-web.pdf (accessed on 23 June 2020).

- Newmont. Sustainability Report Performance Data. 2019. Available online: https://s24.q4cdn.com/382246808/files/doc_downloads/2019/sustainability/Newmont-2019-sustainability-report-ESG-tables.pdf (accessed on 26 June 2020).

- Boliden Annual and Sustainability Report 2019. A Sustainable Future with Metals. 2019. Available online: https://vp217.alertir.com/afw/files/press/boliden/202003107199-1.pdf (accessed on 22 June 2020).

- First Quantum Minerals Environment, Safety and Social Data Report. 2019. Available online: https://s24.q4cdn.com/821689673/files/doc_downloads/environmental-health-and-safety/2019-Environment-Safety-Social-Data-Report-FINAL.pdf (accessed on 29 June 2020).

- Lumley, G.; McKee, M. Mining for Efficiency; PricewaterhouseCoopers: London, UK, 2014. [Google Scholar]

- Dougall, A.W.; Mmola, T.M. Identification of key performance areas in the southern African surface mining delivery environment. J. South. Afr. Inst. Min. Metall. 2015, 115, 1001–1006. [Google Scholar] [CrossRef]

- Korski, J.; Tobór-Osadnik, K.; Wyganowska, M. Mining machines effectiveness and OEE Indicator. IOP Conf. Ser. Mater. Sci. Eng. 2017, 268. [Google Scholar] [CrossRef]

- Johnson, R.B.; Onwuegbuzie, A.J. Toward a Definition of Mixed Methods Research. J. Mix. Methods Res. 2007, 1, 112–133. [Google Scholar] [CrossRef]

| Author (s) | Year | Field of Application | Examples of KPIs Provided by Article | KPI Types Used |

|---|---|---|---|---|

| [33] | 2020 | Mining and mineral processing | Yes | Indicators related to a mine’s organisation. |

| [34] | 2020 | Potash | Yes | Degree of blockage or degree of starvation. |

| [22] | 2020 | Rock raw materials | Yes | Measurement of performance in an aggregate production process—simulation in real time. |

| [35] | 2019 | Geometallurgy | No | x |

| [36] | 2019 | Iron ore | Yes | Mining process planning—NPV (net present value) and LOM (life of mine). |

| [21] | 2019 | Coal | Yes | Quality indicator set. |

| [23] | 2019 | Minerals | Yes | Indicators related to loading and transport systems. |

| [37] | 2019 | Cement plant | Yes | Energy consumption, carbon footprint, specific water consumption, effectiveness. |

| [38] | 2018 | Mining industry | Yes | Effectiveness, maintenance, and operations management indicators. |

| [39] | 2018 | Coal | Yes | Productivity improvement (e.g., bucket fill factor, loading conditions, cycle time). |

| [40] | 2018 | Gravel | Yes | Employees’ working time, time of running machines, fuel consumption, and electricity consumption. |

| [41] | 2018 | Mineral | Yes | Key flotation performance indicators: froth height above the recovery and silica recovery. |

| [42] | 2017 | Rock in oil well | Yes | Rate of penetration. |

| [43] | 2017 | Platinum | Yes | Production (e.g., face length mined, achieved blasts, development to mill). |

| [44] | 2016 | Rock | No | x |

| [45] | 2016 | Platinum | Yes | Improvement in the overall efficiency of mining equipment at levels of availability, utilisation, productivity, and quality. |

| [46] | 2016 | Platinum | Yes | Financial. |

| [47] | 2016 | Coal | No | x |

| [48] | 2016 | Copper | No | x |

| [49] | 2015 | Coal | Yes | Predicting the performance of surface miner production. |

| [50] | 2015 | Coal hauling | Yes | Optimisation of shuttle car utilisation (e.g., analysing the away time and safety). |

| [30] | 2015 | Coal | Yes | Ergonomic. |

| [51] | 2015 | Coal | Yes | Environmental and economic. |

| [52] | 2014 | Coal | Yes | Transport (e.g., time to repair, time to reach a person). |

| [53] | 2012 | Hard rock | No | x |

| [54] | 2011 | Copper | Yes | Production (e.g., maximising settle time, no slag skimming when tap hole is open to the vessel). |

| [55] | 2011 | Load haul dump machinery | Yes | Machine availability and utilisation. |

| [56] | 2011 | Platinum flotation grade | No | x |

| Mining Companies | BHP Billiton | Rio Tinto | Glencore | Vale | Anglo American | Fortescue Metal | Fresnillo | Newmont | Boliden | First Quantum Minerals | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Main Groups of KPIs | |||||||||||

| Business ethics and transparency | x | x | |||||||||

| Community relationships and development | x | x | x | x | x | ||||||

| Economic performance | x | x | x | x | x | x | x | ||||

| Environment | x | x | x | x | x | x | x | x | x | x | |

| Equal opportunities | x | ||||||||||

| Health and safety | x | x | x | x | x | x | x | x | x | x | |

| People/employees | x | x | x | x | x | ||||||

| Production | x | x | |||||||||

| Recovery of degraded areas | x | ||||||||||

| Society | x | x | x | ||||||||

| Socio-political performance | x | ||||||||||

| Field | Exemplary KPIs |

|---|---|

| Maintenance | Average bucket weight, average fuel use per machine, average number of loads per hour/day/week/month, average loading time, average swing time, average number of dumps per hour/day/week/month, dump time, total minutes lost per shift due to breaks, average payload, overall equipment effectiveness (OEE). |

| Financial | Cash operating costs per unit produced, lifting costs, unit variable costs, utilisation. |

| Temporal | Change time (time between cycles), empty travel time, lost time incident frequency rate, cycle distance, loaded travel time, tons of ore feed, cycle time, loaded stop time, tons per load, tons per hour, empty stop time. |

| Safety | Fatality frequency rate, incident rate (accidents, etc.) per hour. |

| Physical characteristic | Degree of purity and physical characteristics, raw material substitution rate (percentage), dilution of ore, reserve and resource replacement, the efficiency of metallurgical recovery, fuel consumption (e.g., litres/hour), waste volume, waste per ton, waste recycling (e.g., tons per time unit). |

| Engine | Transmission | Hydraulic Systems | Tires and Suspensions | Exhaust Aftertreatment |

|---|---|---|---|---|

| Engine speed | Retarder oil temperature | Oil pressure | Pressure | Filter regeneration |

| Torque | Retarder oil pressure | Oil temperature | Temperature | Exhaust temperatures |

| Coolant temperature | Shaft gear | Power supply | Strain | AdBlue consumption |

| Oil temperature | Oil level | Gas mass flow rate | ||

| Oil pressure | ||||

| Engine fuel rate | ||||

| Throttle |

| Decision-Makers | Superintendent | Shift Supervisor | Operator | Maintenance Manager | |

|---|---|---|---|---|---|

| KPIs | |||||

| Technical KPIs | |||||

| Fuel/energy consumption | x | x | x | ||

| Payload | x | x | x | ||

| Temperatures | x | x | |||

| Pressures | x | x | |||

| Engine load and speed | x | x | |||

| Errors and warnings | x | x | x | ||

| Hydraulic systems | x | ||||

| Tires and suspensions | x | ||||

| Exhaust after-treatment | x | ||||

| Temporal KPIs | |||||

| Operating and idle time | x | x | x | x | |

| Cycle duration | x | x | x | ||

| Loading and dumping times | x | x | |||

| Queuing and spotting times | x | x | |||

| Relocation times | x | x | |||

| Downtimes | x | x | x | ||

| Maintenance durations | x | x | x | x | |

| Spatial KPIs | |||||

| Geolocation of machine | x | x | x | ||

| Cycle distance | x | x | |||

| Loaded/empty travel distance | x | ||||

| Travel distance at beginning/end of shift | x | x | |||

| Slope angle and inclination | x | x | |||

| Safety KPIs | |||||

| Lost Time Injuries (LTI) | x | x | |||

| Lost Time Injury Frequency Rate (LTIFR) | x | x | |||

| Frequency of refresher training | x | x | x | x | |

| Planned routine safety checks versus completed routine safety checks | x | x | x | ||

| Percentage reduction in exposure hours to hazardous materials/activities | x | x | x | x | |

| Worker compensation costs | x | x | |||

| Incident rate (accidents, etc.) per x hours | x | x | |||

| Maintenance KPIs | |||||

| Number of equipment failures per day/week/month/year) | x | x | x | x | |

| Total minutes lost per shift due to breaks | x | x | x | x | |

| Mean time between failures (MTBF) | x | x | x | x | |

| Maintenance man-hours (MMH) | x | x | x | ||

| Mean time between shutdowns (MTBS) | x | x | |||

| Mean time to restore/repair (MTTR) | x | x | x | x | |

| Mean downtime (MDT) | x | x | x | x | |

| Maintenance ratio (MR = maintenance man-hours/equipment operating hours) | x | x | x | ||

| Availability | x | x | x | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gackowiec, P.; Podobińska-Staniec, M.; Brzychczy, E.; Kühlbach, C.; Özver, T. Review of Key Performance Indicators for Process Monitoring in the Mining Industry. Energies 2020, 13, 5169. https://doi.org/10.3390/en13195169

Gackowiec P, Podobińska-Staniec M, Brzychczy E, Kühlbach C, Özver T. Review of Key Performance Indicators for Process Monitoring in the Mining Industry. Energies. 2020; 13(19):5169. https://doi.org/10.3390/en13195169

Chicago/Turabian StyleGackowiec, Paulina, Marta Podobińska-Staniec, Edyta Brzychczy, Christopher Kühlbach, and Toyga Özver. 2020. "Review of Key Performance Indicators for Process Monitoring in the Mining Industry" Energies 13, no. 19: 5169. https://doi.org/10.3390/en13195169

APA StyleGackowiec, P., Podobińska-Staniec, M., Brzychczy, E., Kühlbach, C., & Özver, T. (2020). Review of Key Performance Indicators for Process Monitoring in the Mining Industry. Energies, 13(19), 5169. https://doi.org/10.3390/en13195169