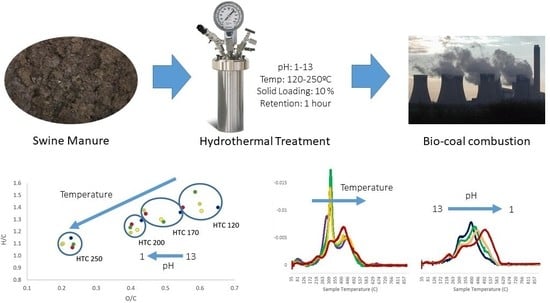

The Influence of pH on the Combustion Properties of Bio-Coal Following Hydrothermal Treatment of Swine Manure

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Hydrothermal Processing

2.3. Analysis

2.3.1. Inorganic Analysis

2.3.2. Organic Analysis and Determination of Combustion Properties

2.3.3. Prediction of Slagging and Fouling Propensity

3. Results

3.1. Influence of pH on Bio-Coal Composition

3.2. Influence of pH on Fuel Inorganic Chemistry

3.3. Influence of pH on Fuel Combustion Chemistry

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Szogi, A.A.; Vanotti, M.B.; Ro, K.S. Methods for Treatment of Animal Manures to Reduce Nutrient Pollution Prior to Soil Application. Curr. Pollut. Rep. 2015, 1, 47–56. [Google Scholar] [CrossRef]

- Heilmann, S.M.; Molde, J.S.; Timler, J.G.; Wood, B.M.; Mikula, A.L.; Vozhdayev, G.V.; Colosky, E.C.; Spokas, K.A.; Valentas, K.J. Phosphorus Reclamation through Hydrothermal Carbonization of Animal Manures. Environ. Sci. Technol. 2014, 48, 10323–10329. [Google Scholar] [CrossRef]

- Funke, A.; Ziegler, F. Hydrothermal carbonization of biomass: A summary and discussion of chemical mechanisms for process engineering. Biofuels Bioprod. Biorefining 2010, 4, 160–177. [Google Scholar] [CrossRef]

- Heilmann, S.M.; Davis, H.T.; Jader, L.R.; Lefebvre, P.A.; Sadowsky, M.J.; Schendel, F.J.; von Keitz, M.G.; Valentas, K.J. Hydrothermal carbonization of microalgae. Biomass Bioenergy 2010, 34, 875–882. [Google Scholar] [CrossRef]

- Heilmann, S.M.; Jader, L.R.; Sadowsky, M.J.; Schendel, F.J.; von Keitz, M.G.; Valentas, K.J. Hydrothermal carbonization of distiller’s grains. Biomass Bioenergy 2011, 35, 2526–2533. [Google Scholar] [CrossRef]

- Ekpo, U.; Ross, A.B.; Camargo-Valero, M.A.; Williams, P.T. A comparison of product yields and inorganic content in process streams following thermal hydrolysis and hydrothermal processing of microalgae, manure and digestate. Bioresour. Technol. 2016, 200, 951–960. [Google Scholar] [CrossRef]

- Dai, L.; Tan, F.; Wu, B.; He, M.; Wang, W.; Tang, X.; Hu, Q.; Zhang, M. Immobilization of phosphorus in cow manure during hydrothermal carbonization. J. Environ. Manag. 2015, 157, 49–53. [Google Scholar] [CrossRef] [PubMed]

- Ekpo, U.; Ross, A.B.; Camargo-Valero, M.A.; Fletcher, L.A. Influence of pH on hydrothermal treatment of swine manure: Impact on extraction of nitrogen and phosphorus in process water. Bioresour. Technol. 2016, 214, 637–644. [Google Scholar] [CrossRef] [PubMed]

- Titirici, M.-M.; Thomas, A.; Antonietti, M. Back in the black: hydrothermal carbonization of plant material as an efficient chemical process to treat the CO 2 problem? New J. Chem. 2007, 31, 787–789. [Google Scholar] [CrossRef]

- Hu, B.; Yu, S.-H.; Wang, K.; Liu, L.; Xu, X.-W. Functional carbonaceous materials from hydrothermal carbonization of biomass: an effective chemical process. Dalton Trans. 2008, 5414–5423. [Google Scholar] [CrossRef] [PubMed]

- Lu, X.; Zhang, Y.; Angelidaki, I. Optimization of H 2 SO 4-catalyzed hydrothermal pretreatment of rapeseed straw for bioconversion to ethanol: focusing on pretreatment at high solids content. Bioresour. Technol. 2009, 100, 3048–3053. [Google Scholar] [CrossRef]

- Demir-Cakan, R.; Baccile, N.; Antonietti, M.; Titirici, M.-M. Carboxylate-rich carbonaceous materials via one-step hydrothermal carbonization of glucose in the presence of acrylic acid. Chem. Mater. 2009, 21, 484–490. [Google Scholar] [CrossRef]

- Lynam, J.G.; Coronella, C.J.; Yan, W.; Reza, M.T.; Vasquez, V.R. Acetic acid and lithium chloride effects on hydrothermal carbonization of lignocellulosic biomass. Bioresour. Technol. 2011, 102, 6192–6199. [Google Scholar] [CrossRef] [PubMed]

- Reza, M.T.; Rottler, E.; Herklotz, L.; Wirth, B. Hydrothermal carbonization (HTC) of wheat straw: Influence of feedwater pH prepared by acetic acid and potassium hydroxide. Bioresour. Technol. 2015, 182, 336–344. [Google Scholar] [CrossRef] [PubMed]

- Ghanim, B.M.; Kwapinski, W.; Leahy, J.J. Hydrothermal carbonisation of poultry litter: Effects of initial pH on yields and chemical properties of hydrochars. Bioresour. Technol. 2017, 238, 78–85. [Google Scholar] [CrossRef] [PubMed]

- Koppejan, J.; Van Loo, S. The Handbook of Biomass Combustion and Co-Firing; Earthscan: London, UK, 2012. [Google Scholar]

- Riedl, R.; Dahl, J.; Obernberger, I.; Narodoslawsky, M. Corrosion in fire tube boilers of biomass combustion plants. In Proceedings of the China International Corrosion Control Conference, Beijing, China, 9–13 October 1999. [Google Scholar]

- Volpe, M.; Goldfarb, J.L.; Fiori, L. Hydrothermal carbonization of Opuntia ficus-indica cladodes: Role of process parameters on hydrochar properties. Bioresour. Technol. 2018, 247, 310–318. [Google Scholar] [CrossRef] [PubMed]

- Mäkelä, M.; Kwong, C.W.; Broström, M.; Yoshikawa, K. Hydrothermal treatment of grape marc for solid fuel applications. Energy Convers. Manag. 2017, 145, 371–377. [Google Scholar] [CrossRef]

- Lane, D.J.; Truong, E.; Larizza, F.; Chiew, P.; de Nys, R.; van Eyk, P.J. Effect of Hydrothermal Carbonization on the Combustion and Gasification Behavior of Agricultural Residues and Macroalgae: Devolatilization Characteristics and Char Reactivity. Energy Fuels 2017. [Google Scholar] [CrossRef]

- PetroviĿ, J.; PerišiĿ, N.; MaksimoviĿ, J.D.; MaksimoviĿ, V.; KragoviĿ, M.; StojanoviĿ, M.; LauševiĿ, M.; MihajloviĿ, M. Hydrothermal conversion of grape pomace: Detailed characterization of obtained hydrochar and liquid phase. J. Anal. Appl. Pyrolysis 2016, 118, 267–277. [Google Scholar] [CrossRef]

- Bach, Q.-V.; Tran, K.-Q.; Skreiberg, Ø. Accelerating wet torrefaction rate and ash removal by carbon dioxide addition. Fuel Process. Technol. 2015, 140, 297–303. [Google Scholar] [CrossRef]

- Benavente, V.; Calabuig, E.; Fullana, A. Upgrading of moist agro-industrial wastes by hydrothermal carbonization. J. Anal. Appl. Pyrolysis 2014, 113, 89–98. [Google Scholar] [CrossRef] [Green Version]

- Broch, A.; Jena, U.; Hoekman, S.; Langford, J. Analysis of Solid and Aqueous Phase Products from Hydrothermal Carbonization of Whole and Lipid-Extracted Algae. Energies 2013, 7, 62. [Google Scholar] [CrossRef] [Green Version]

- Reza, M.T.; Lynam, J.G.; Uddin, M.H.; Coronella, C.J. Hydrothermal carbonization: Fate of inorganics. Biomass Bioenergy 2013, 49, 86–94. [Google Scholar] [CrossRef]

- Smith, A.M.; Singh, S.; Ross, A.B. Fate of inorganic material during hydrothermal carbonisation of biomass: Influence of feedstock on combustion behaviour of hydrochar. Fuel 2016, 169, 135–145. [Google Scholar] [CrossRef]

- Mäkelä, M.; Yoshikawa, K. Ash behavior during hydrothermal treatment for solid fuel applications. Part 2: Effects of treatment conditions on industrial waste biomass. Energy Convers. Manag. 2016, 121, 409–414. [Google Scholar] [CrossRef]

- Smith, A.M.; Ross, A.B. Production of bio-coal, bio-methane and fertilizer from seaweed via hydrothermal carbonisation. Algal Res. 2016, 16, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Smith, A.M.; Whittaker, C.; Shield, I.; Ross, A.B. The potential for production of high quality bio-coal from early harvested Miscanthus by hydrothermal carbonisation. Fuel 2018, 220, 546–557. [Google Scholar] [CrossRef]

- Smith, A.M.; Ross, A.B. The Influence of Residence Time during Hydrothermal Carbonisation of Miscanthus on Bio-Coal Combustion Chemistry. Energies 2019, 12, 523. [Google Scholar] [CrossRef] [Green Version]

- Grimm, A.; Skoglund, N.; Boström, D.; Ohman, M. Bed agglomeration characteristics in fluidized quartz bed combustion of phosphorus-rich biomass fuels. Energy Fuels 2011, 25, 937–947. [Google Scholar] [CrossRef]

- Lindström, E.; Sandström, M.; Boström, D.; Öhman, M. Slagging Characteristics during Combustion of Cereal Grains Rich in Phosphorus. Energy Fuels 2007, 21, 710–717. [Google Scholar] [CrossRef]

- Thy, P.; Jenkins, B.M.; Grundvig, S.; Shiraki, R.; Lesher, C.E. High temperature elemental losses and mineralogical changes in common biomass ashes. Fuel 2006, 85, 783–795. [Google Scholar] [CrossRef]

- Thy, P.; Lesher, C.E.; Jenkins, B.M. Experimental determination of high-temperature elemental losses from biomass slag. Fuel 2000, 79, 693–700. [Google Scholar] [CrossRef]

- Jenkins, B.; Baxter, L.; Miles, T. Combustion properties of biomass. Fuel Process. Technol. 1998, 54, 17–46. [Google Scholar] [CrossRef]

- Bapat, D.; Kulkarni, S.; Bhandarkar, V. Design and Operating Experience on Fluidized Bed Boiler Burning Biomass Fuels with High Alkali Ash; American Society of Mechanical Engineers: New York, NY, USA, 1997. [Google Scholar]

- Antal, M.J.; Mok, W.S.L.; Richards, G.N. Mechanism of formation of 5-(hydroxymethyl)-2-furaldehyde from d-fructose and sucrose. Carbohydr. Res. 1990, 199, 91–109. [Google Scholar] [CrossRef]

- Jin, F.; Zhou, Z.; Moriya, T.; Kishida, H.; Higashijima, H.; Enomoto, H. Controlling hydrothermal reaction pathways to improve acetic acid production from carbohydrate biomass. Environ. Sci. Technol. 2005, 39, 1893–1902. [Google Scholar] [CrossRef]

- Smith, K.L.; Smoot, L.D.; Fletcher, T.H.; Pugmire, R.J. The Structure and Reaction Processes of Coal; Springer Science & Business Media: New York, NY, USA, 2013. [Google Scholar]

- Garrote, G.; Domínguez, H.; Parajó, J.C. Hydrothermal processing of lignocellulosic materials. Holz als Roh-und Werkst. 1999, 57, 191–202. [Google Scholar] [CrossRef]

- Sevilla, M.; Fuertes, A.B. Chemical and Structural Properties of Carbonaceous Products Obtained by Hydrothermal Carbonization of Saccharides. Chem. Eur. J. 2009, 15, 4195–4203. [Google Scholar] [CrossRef]

- Kei-ichi, S.; Yoshihisa, I.; Hitoshi, I. Catalytic Activity of Lanthanide(III) Ions for the Dehydration of Hexose to 5-Hydroxymethyl-2-furaldehyde in Water. Bull. Chem. Soc. Jpn. 2001, 74, 1145–1150. [Google Scholar] [CrossRef]

- Patil, S.K.R.; Lund, C.R.F. Formation and Growth of Humins via Aldol Addition and Condensation during Acid-Catalyzed Conversion of 5-Hydroxymethylfurfural. Energy Fuels 2011, 25, 4745–4755. [Google Scholar] [CrossRef]

- Baccile, N.; Antonietti, M.; Titirici, M.-M. One-Step Hydrothermal Synthesis of Nitrogen-Doped Nanocarbons: Albumine Directing the Carbonization of Glucose. ChemSusChem 2010, 3, 246–253. [Google Scholar] [CrossRef] [Green Version]

- Yu, L.; Falco, C.; Weber, J.; White, R.J.; Howe, J.Y.; Titirici, M.-M. Carbohydrate-Derived Hydrothermal Carbons: A Thorough Characterization Study. Langmuir 2012, 28, 12373–12383. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.-H.; Ye, S.-C.; Sheen, H.-K. Hydrothermal carbonization of sugarcane bagasse via wet torrefaction in association with microwave heating. Bioresour. Technol. 2012, 118, 195–203. [Google Scholar] [CrossRef] [PubMed]

- Wohlgemuth, S.-A.; Vilela, F.; Titirici, M.-M.; Antonietti, M. A one-pot hydrothermal synthesis of tunable dual heteroatom-doped carbon microspheres. Green Chem. 2012, 14, 741–749. [Google Scholar] [CrossRef]

- Marschner, H.; Marschner, P. Marschner’s Mineral Nutrition of Higher Plants; Academic Press: Cambridge, MA, USA, 2012. [Google Scholar]

- Korbee, R.; Kiel, J.; Zevenhoven, M.; Skrifvars, B.; Jensen, P.; Frandsen, F. Investigation of biomass inorganic matter by advanced fuel analysis and conversion experiments. In Proceedings of the Power Production in the 21st Century: Impacts of Fuel Quality and Operations; United Engineering Foundation Advanced Combustion Engineering Research Center: Snowbird, UT, USA, 2001. [Google Scholar]

- Jin, Y.-S.; Jiang, T.; Yang, Y.-B.; Li, Q.; Li, G.-H.; Guo, Y.-F. Removal of phosphorus from iron ores by chemical leaching. J. Cent. South Univ. Technol. 2006, 13, 673–677. [Google Scholar] [CrossRef]

- Miller, B.G.; Tillman, D.A. Combustion Engineering Issues for Solid Fuel Systems; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Tillman, D.A.; Duong, D.N.B.; Harding, N.S. Chapter 4—Blending Coal with Biomass: Cofiring Biomass with Coal. In Solid Fuel Blending; Tillman, D.A., Duong, D.N.B., Harding, N.S., Eds.; Butterworth-Heinemann: Boston, MA, USA, 2012; pp. 125–200. [Google Scholar] [CrossRef]

- Dahlquist, E. Technologies for Converting Biomass to Useful Energy, 1st ed.; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Zheng, C. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 2007, 86, 1781–1788. [Google Scholar] [CrossRef]

- Peterson, A.A.; Vogel, F.; Lachance, R.P.; Fröling, M.; Antal, M.J., Jr.; Tester, J.W. Thermochemical biofuel production in hydrothermal media: A review of sub-and supercritical water technologies. Energy Environ. Sci. 2008, 1, 32–65. [Google Scholar] [CrossRef]

- Su, S.; Pohl, J.H.; Holcombe, D.; Hart, J.A. Techniques to determine ignition, flame stability and burnout of blended coals in p.f. power station boilers. Prog. Energy Combust. Sci. 2001, 27, 75–98. [Google Scholar] [CrossRef]

- Williams, A.; Jones, J.; Ma, L.; Pourkashanian, M. Pollutants from the combustion of solid biomass fuels. Prog. Energy Combust. Sci. 2012, 38, 113–137. [Google Scholar] [CrossRef]

- Yarin, L.P.; Hetsroni, G.; Mosyak, A. Combustion of Two-Phase Reactive Media; Springer Science & Business Media: Heidelberg, Germany, 2013. [Google Scholar]

- Saddawi, A.; Jones, J.M.; Williams, A. Influence of alkali metals on the kinetics of the thermal decomposition of biomass. Fuel Process. Technol. 2012, 104, 189–197. [Google Scholar] [CrossRef]

- Jones, J.M.; Darvell, L.I.; Pourkashanian, M.; Williams, A. The Role of Metals in Biomass Char Combustion. In Proceedings of the European Combustion Meeting, Louvain-la-Neuve, Belgium, 3–6 April 2005. [Google Scholar]

- Nowakowski, D.J.; Jones, J.M.; Brydson, R.M.D.; Ross, A.B. Potassium catalysis in the pyrolysis behaviour of short rotation willow coppice. Fuel 2007, 86, 2389–2402. [Google Scholar] [CrossRef]

- Huang, H.Y.; Yang, R.T. Catalyzed Carbon–NO Reaction Studied by Scanning Tunneling Microscopy and ab Initio Molecular Orbital Calculations. J. Catal. 1999, 185, 286–296. [Google Scholar] [CrossRef]

- Backreedy, R.I.; Jones, J.M.; Pourkashanian, M.; Williams, A. Burn-out of pulverised coal and biomass chars. Fuel 2003, 82, 2097–2105. [Google Scholar] [CrossRef]

- Kannan, M.P.; Richards, G.N. Gasification of biomass chars in carbon dioxide: dependence of gasification rate on the indigenous metal content. Fuel 1990, 69, 747–753. [Google Scholar] [CrossRef]

- Stojanowska, G.; Jones, J. Influence of added calcium on thermal decomposition of biomass, lignite and their blends. Arch. Combust. 2006, 26, 91. [Google Scholar]

- Backreedy, R.I.; Jones, J.M.; Pourkashanian, M.; Williams, A. Modeling the reaction of oxygen with coal and biomass chars. Proc. Combust. Inst. 2002, 29, 415–421. [Google Scholar] [CrossRef]

- Skrifvars, B.-J.; Laurén, T.; Hupa, M.; Korbee, R.; Ljung, P. Ash behaviour in a pulverized wood fired boiler—A case study. Fuel 2004, 83, 1371–1379. [Google Scholar] [CrossRef]

- Miles, T.R.; Miles, T., Jr.; Baxter, L.; Bryers, R.; Jenkins, B.; Oden, L. Alkali Deposits Found in Biomass Power Plants: A preliminary Investigation of Their Extent and Nature; National Renewable Energy Lab.: Golden, CO, USA; Miles Thomas R.: Portland, OR, USA; Sandia National Labs.: Livermore, CA, USA; Foster Wheeler Development Corp.: Livingston, NJ, USA; California University: Davis, CA, USA; Bureau of Mines, Albany Research Center: Albany, OR, USA, 1995; Volume 1. [Google Scholar]

- Wang, L.; Hustad, J.E.; Skreiberg, Ø.; Skjevrak, G.; Grønli, M. A Critical Review on Additives to Reduce Ash Related Operation Problems in Biomass Combustion Applications. Energy Procedia 2012, 20, 20–29. [Google Scholar] [CrossRef] [Green Version]

- Dahlin, R.S.; Vann Bush, P.; Snyder, T.R. Fundamental Mechanisms in Flue-Gas Conditioning. Topical Report No. 1, Literature Review and Assembly of Theories on the Interactions of Ash and FGD Sorbents; Southern Research Inst.: Birmingham, AL, USA, 1992. [Google Scholar]

- Parker, K.R. Applied Electrostatic Precipitation; Springer Science & Business Media: Dordrecht, The Netherlands, 2012. [Google Scholar]

- Shanthakumar, S.; Singh, D.N.; Phadke, R.C. Flue gas conditioning for reducing suspended particulate matter from thermal power stations. Prog. Energy Combust. Sci. 2008, 34, 685–695. [Google Scholar] [CrossRef]

| Slagging/Fouling Index | Expression | Limit | |

|---|---|---|---|

| Alkali Index (AI) | AI < 0.17, safe combustion AI > 0.17 < 0.34, probable slagging and fouling AI > 0.34, almost certain slagging and fouling [35] | Equation (1) | |

| Bed Agglomeration Index (BAI) | BAI < 0.15, bed agglomeration likely [36] | Equation (2) | |

| Acid Base Ratio (R) | R < 0.5, low slagging risk [36] | Equation (3) |

| Sample Name | Dry Basis | ||||||

|---|---|---|---|---|---|---|---|

| Yield (%) | C (wt.%) | H (wt.%) | N (wt.%) | S (wt.%) | O (wt.%) | Ash (wt.%) | |

| Unprocessed Pig Manure | n/a | 44.0 ± 0.5 | 5.1 ± 0.1 | 2.9 ± 0.1 | 0.2 ± 0.0 | 35.7 ± 0.7 | 12.6 |

| Sodium Hydroxide 120 °C | 84 | 42.7 ± 0.3 | 5.0 ± 0.0 | 2.4 ± 0.0 | 0.1 ± 0.0 | 37.1 ± 0.5 | 12.6 |

| Sodium Hydroxide 170 °C | 64 | 45.0 ± 0.2 | 5.1 ± 0.1 | 2.1 ± 0.0 | 0.1 ± 0.0 | 32.6 ± 0.9 | 15.2 |

| Sodium Hydroxide 200 °C | 59 | 48.4 ± 0.2 | 5.2 ± 0.1 | 2.4 ± 0.0 | 0.2 ± 0.0 | 27.8 ± 0.0 | 16.0 |

| Sodium Hydroxide 250 °C | 41 | 49.8 ± 0.0 | 4.8 ± 0.0 | 2.5 ± 0.0 | 0.3 ± 0.0 | 15.0 ± 0.1 | 27.6 |

| Water 120 °C | 86 | 45.4 ± 0.5 | 5.8 ± 0.4 | 2.4 ± 0.1 | 0.1 ± 0.0 | 35.5 ± 1.0 | 10.7 |

| Water 170 °C | 62 | 47.3 ± 0.3 | 5.0 ± 0.0 | 2.3 ± 0.1 | 0.2 ± 0.0 | 31.2 ± 0.4 | 14.0 |

| Water 200 °C | 59 | 50.8 ± 0.3 | 5.2 ± 0.0 | 2.4 ± 0.0 | 0.2 ± 0.0 | 27.0 ± 0.1 | 14.3 |

| Water 250 °C | 43 | 53.5 ± 3.4 | 4.9 ± 0.4 | 2.8 ± 0.2 | 0.3 ± 0.0 | 16.7 ± 0.3 | 21.9 |

| Acetic Acid 120 °C | 83 | 45.0 ± 0.2 | 5.1 ± 0.0 | 2.6 ± 0.1 | 0.1 ± 0.0 | 36.2 ± 0.4 | 11.0 |

| Acetic Acid 170 °C | 61 | 47.9 ± 0.7 | 5.2 ± 0.1 | 2.5 ± 0.1 | 0.1 ± 0.0 | 31.1 ± 0.6 | 13.0 |

| Acetic Acid 200 °C | 59 | 50.1 ± 0.8 | 5.1 ± 0.1 | 2.3 ± 0.1 | 0.1 ± 0.0 | 27.9 ± 1.9 | 14.5 |

| Acetic Acid 250 °C | 44 | 56.6 ± 0.6 | 5.2 ± 0.1 | 2.9 ± 0.0 | 0.2 ± 0.0 | 15.4 ± 0.1 | 19.7 |

| Formic Acid 120 °C | 83 | 45.0 ± 1.1 | 5.4 ± 0.2 | 2.5 ± 0.1 | 0.2 ± 0.0 | 35.9 ± 1.4 | 11.0 |

| Formic Acid 170 °C | 61 | 49.8 ± 0.1 | 5.7 ± 0.2 | 2.6 ± 0.0 | 0.2 ± 0.0 | 29.0 ± 0.9 | 12.7 |

| Formic Acid 200 °C | 58 | 50.8 ± 0.2 | 5.0 ± 0.1 | 2.3 ± 0.1 | 0.2 ± 0.0 | 27.1 ± 0.3 | 14.6 |

| Formic Acid 250 °C | 44 | 56.0 ± 1.4 | 5.1 ± 0.1 | 2.9 ± 0.1 | 0.3 ± 0.0 | 14.9 ± 0.3 | 20.8 |

| Sulphuric Acid 120 °C | 75 | 47.9 ± 0.5 | 5.6 ± 0.0 | 2.2 ± 0.0 | 1.0 ± 0.0 | 35.2 ± 2.3 | 8.1 |

| Sulphuric Acid 170 °C | 58 | 50.5 ± 0.6 | 5.7 ± 0.0 | 2.4 ± 0.1 | 1.7 ± 0.1 | 29.8 ± 0.7 | 10.0 |

| Sulphuric Acid 200 °C | 57 | 52.4 ± 0.2 | 5.5 ± 0.0 | 2.2 ± 0.0 | 1.7 ± 0.0 | 28.1 ± 0.2 | 10.1 |

| Sulphuric Acid 250 °C | 47 | 56.4 ± 0.7 | 5.0 ± 0.1 | 2.7 ± 0.0 | 3.4 ± 0.0 | 17.3 ± 0.3 | 15.1 |

| Sample Name | Dry Ash Free Basis | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Yield (%) | C (wt.%) | H (wt.%) | N (wt.%) | S (wt.%) | O (wt.%) | H/C | O/C | Volatile Matter (%) | Fixed Matter (%) | |

| Unprocessed Pig Manure | n/a | 50.1 | 5.8 | 3.3 | 0.2 | 40.6 | 1.39 | 0.61 | 74 | 26 |

| Sodium Hydroxide 120 °C | 84 | 48.9 | 5.7 | 2.8 | 0.2 | 42.5 | 1.40 | 0.65 | 80 | 20 |

| Sodium Hydroxide 170 °C | 62 | 53.0 | 6.0 | 2.4 | 0.1 | 38.4 | 1.36 | 0.54 | 80 | 20 |

| Sodium Hydroxide 200 °C | 57 | 57.7 | 6.2 | 2.8 | 0.2 | 33.1 | 1.29 | 0.43 | 77 | 23 |

| Sodium Hydroxide 250 °C | 34 | 68.8 | 6.6 | 3.4 | 0.4 | 20.8 | 1.15 | 0.23 | 68 | 32 |

| Water 120 °C | 88 | 50.9 | 6.5 | 2.7 | 0.2 | 39.7 | 1.53 | 0.59 | 82 | 18 |

| Water 170 °C | 61 | 54.9 | 5.9 | 2.7 | 0.3 | 36.2 | 1.28 | 0.49 | 78 | 22 |

| Water 200 °C | 58 | 59.3 | 6.1 | 2.8 | 0.3 | 31.5 | 1.24 | 0.40 | 76 | 24 |

| Water 250 °C | 38 | 68.5 | 6.2 | 3.6 | 0.4 | 21.3 | 1.09 | 0.23 | 67 | 33 |

| Acetic Acid 120 °C | 85 | 50.5 | 5.8 | 2.9 | 0.2 | 40.7 | 1.37 | 0.60 | 80 | 20 |

| Acetic Acid 170 °C | 61 | 55.1 | 6.0 | 2.9 | 0.2 | 35.8 | 1.30 | 0.49 | 79 | 21 |

| Acetic Acid 200 °C | 58 | 58.6 | 5.9 | 2.7 | 0.2 | 32.7 | 1.21 | 0.42 | 75 | 25 |

| Acetic Acid 250 °C | 40 | 70.5 | 6.5 | 3.7 | 0.3 | 19.1 | 1.10 | 0.20 | 67 | 33 |

| Formic Acid 120 °C | 85 | 50.6 | 6.0 | 2.8 | 0.2 | 40.4 | 1.43 | 0.60 | 81 | 19 |

| Formic Acid 170 °C | 61 | 57.0 | 6.5 | 3.0 | 0.2 | 33.2 | 1.38 | 0.44 | 79 | 21 |

| Formic Acid 200 °C | 57 | 59.5 | 5.9 | 2.6 | 0.2 | 31.7 | 1.19 | 0.40 | 75 | 25 |

| Formic Acid 250 °C | 40 | 70.7 | 6.5 | 3.6 | 0.3 | 18.9 | 1.10 | 0.20 | 68 | 32 |

| Sulphuric Acid 120 °C | 79 | 52.1 | 6.1 | 2.4 | 1.1 | 38.3 | 1.40 | 0.55 | 83 | 17 |

| Sulphuric Acid 170 °C | 60 | 56.1 | 6.3 | 2.6 | 1.9 | 33.1 | 1.35 | 0.44 | 83 | 17 |

| Sulphuric Acid 200 °C | 59 | 58.3 | 6.1 | 2.4 | 1.9 | 31.3 | 1.26 | 0.40 | 76 | 24 |

| Sulphuric Acid 250 °C | 46 | 66.4 | 5.9 | 3.2 | 4.0 | 20.4 | 1.07 | 0.23 | 66 | 34 |

| Sample Name | mg/kg Fuel (db) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Na | K | Mg | Ca | Al | Si | P | Mn | Fe | Cu | Zn | Sr | |

| Unprocessed Pig Manure | 1426 | 12,100 | 9395 | 27,035 | 434 | 3654 | 15,197 | 314 | 1090 | 140 | 634 | 367 |

| Sodium Hydroxide 120 °C | 2933 | 4126 | 9869 | 30,212 | 413 | 3447 | 15,431 | 445 | 1278 | 153 | 604 | 39 |

| Sodium Hydroxide 170 °C | 2020 | 2927 | 10,002 | 41,385 | 620 | 4067 | 19,254 | 633 | 1712 | 230 | 864 | 61 |

| Sodium Hydroxide 200 °C | 1121 | 1371 | 7056 | 45,915 | 715 | 3324 | 24,748 | 531 | 1797 | 254 | 963 | 51 |

| Sodium Hydroxide 250 °C | 404 | 577 | 17,221 | 74,240 | 1174 | 10,311 | 41,254 | 819 | 3177 | 394 | 1771 | 93 |

| Water 120 °C | 193 | 1493 | 6232 | 31,645 | 546 | 3710 | 13,139 | 411 | 1464 | 195 | 701 | 45 |

| Water 170 °C | 92 | 1043 | 5388 | 41,790 | 674 | 3249 | 21,806 | 599 | 1632 | 227 | 788 | 61 |

| Water 200 °C | 156 | 411 | 6544 | 38,053 | 660 | 3203 | 25,178 | 452 | 1224 | 197 | 657 | 40 |

| Water 250 °C | n/d | 392 | 10,323 | 61,727 | 1008 | 4533 | 36,468 | 766 | 2287 | 380 | 1444 | 80 |

| Acetic Acid 120 °C | 199 | 1920 | 4201 | 30,840 | 572 | 4709 | 15,020 | 433 | 1447 | 220 | 701 | 45 |

| Acetic Acid 170 °C | 37 | 469 | 4201 | 38,345 | 783 | 3699 | 20,876 | 499 | 1527 | 262 | 758 | 45 |

| Acetic Acid 200 °C | 105 | 425 | 4596 | 43,490 | 721 | 3321 | 23,494 | 573 | 1555 | 271 | 853 | 55 |

| Acetic Acid 250 °C | 53 | 397 | 7123 | 57,455 | 941 | 3504 | 34,106 | 590 | 2252 | 324 | 1489 | 71 |

| Formic Acid 120 °C | 114 | 1048 | 3685 | 30,815 | 576 | 5344 | 15,808 | 403 | 1523 | 208 | 653 | 42 |

| Formic Acid 170 °C | 85 | 644 | 3624 | 37,304 | 750 | 3995 | 20,297 | 462 | 1336 | 234 | 642 | 48 |

| Formic Acid 200 °C | 125 | 508 | 4542 | 43,529 | 809 | 3646 | 24,236 | 500 | 1411 | 286 | 803 | 55 |

| Formic Acid 250 °C | 161 | 743 | 8307 | 60,023 | 1023 | 4893 | 34,543 | 901 | 2528 | 317 | 1516 | 89 |

| Sulphuric Acid 120 °C | 171 | 1312 | 1490 | 19,342 | 609 | 5182 | 2566 | 56 | 518 | 195 | 234 | 27 |

| Sulphuric Acid 170 °C | 160 | 1252 | 1170 | 25,280 | 670 | 4559 | 1728 | n/d | 593 | 222 | 226 | 28 |

| Sulphuric Acid 200 °C | 125 | 1213 | 2152 | 24,507 | 709 | 4287 | 3815 | 138 | 734 | 203 | 281 | 32 |

| Sulphuric Acid 250 °C | 28 | 406 | 4083 | 34,688 | 877 | 3472 | 6670 | 414 | 1295 | 336 | 923 | 55 |

| Sample Name | Dry Basis | |||||

|---|---|---|---|---|---|---|

| HHV (MJ/kg) | Volatile Matter (%) | Fixed Matter (%) | AI | BAI | ||

| Unprocessed Pig Manure | 15.8 | 64.8 | 22.6 | 1.17 | 0.08 | 8.54 |

| Sodium Hydroxide 120 °C | 14.9 | 70.9 | 18.1 | 0.86 | 0.14 | 9.05 |

| Sodium Hydroxide 170 °C | 16.7 | 67.9 | 16.7 | 0.54 | 0.27 | 8.76 |

| Sodium Hydroxide 200 °C | 18.9 | 62.8 | 18.8 | 0.25 | 0.55 | 9.91 |

| Sodium Hydroxide 250 °C | 21.0 | 48.3 | 22.4 | 0.09 | 2.55 | 5.76 |

| Water 120 °C | 17.3 | 76.9 | 16.9 | 0.13 | 0.90 | 6.63 |

| Water 170 °C | 17.6 | 68.3 | 18.9 | 0.09 | 1.55 | 8.73 |

| Water 200 °C | 19.8 | 65.7 | 20.3 | 0.05 | 1.92 | 8.31 |

| Water 250 °C | 22.1 | 54.0 | 27.0 | 0.02 | 6.92 | 9.32 |

| Acetic Acid 120 °C | 16.1 | 69.9 | 17.1 | 0.18 | 0.73 | 4.97 |

| Acetic Acid 170 °C | 18.1 | 67.3 | 17.8 | 0.04 | 3.29 | 6.81 |

| Acetic Acid 200 °C | 19.2 | 63.2 | 21.0 | 0.04 | 2.80 | 8.52 |

| Acetic Acid 250 °C | 23.8 | 53.4 | 26.2 | 0.03 | 5.19 | 10.44 |

| Formic Acid 120 °C | 16.5 | 73.5 | 16.9 | 0.10 | 1.39 | 4.27 |

| Formic Acid 170 °C | 19.8 | 69.3 | 18.1 | 0.05 | 1.90 | 6.19 |

| Formic Acid 200 °C | 19.6 | 63.4 | 21.1 | 0.05 | 2.12 | 7.72 |

| Formic Acid 250 °C | 23.6 | 55.4 | 25.8 | 0.06 | 2.72 | 8.35 |

| Sulphuric Acid 120 °C | 17.9 | 77.7 | 16.4 | 0.11 | 0.36 | 2.66 |

| Sulphuric Acid 170 °C | 19.8 | 74.3 | 14.8 | 0.10 | 0.44 | 3.67 |

| Sulphuric Acid 200 °C | 20.6 | 66.7 | 20.9 | 0.09 | 0.58 | 3.91 |

| Sulphuric Acid 250 °C | 23.2 | 56.3 | 28.7 | 0.02 | 3.28 | 6.41 |

| Sample Name | Ash Transition Temperature (°C) | |||

|---|---|---|---|---|

| Shrinkage | Deformation | Hemisphere | Flow | |

| Unprocessed | 1260 ± 0 | 1320 ± 0 | 1380 ± 0 | 1500 ± 0 |

| Sodium Hydroxide 120 °C | 1140 ± 0 | 1510 ± 0 | 1560 ± 10 | >1570 |

| Sodium Hydroxide 170 °C | 1330 ± 0 | 1460 ± 20 | 1500 ± 10 | >1570 |

| Sodium Hydroxide 200 °C | 1040 ± 0 | 1380 ± 10 | 1420 ± 0 | 1530 ± 0 |

| Sodium Hydroxide 250 °C | 1100 ± 0 | 1290 ± 0 | 1300 ± 0 | 1360 ± 0 |

| Water 120 °C | 1070 ± 0 | 1440 ± 0 | 1480 ± 0 | 1520 ± 0 |

| Water 170 °C | 1120 ± 0 | 1340 ± 0 | 1360 ± 0 | 1490 ± 0 |

| Water 200 °C | 1000 ± 0 | 1340 ± 0 | 1370 ± 0 | 1430 ± 0 |

| Water 250 °C | 1040 ± 0 | 1300 ± 0 | 1350 ± 0 | 1410 ± 0 |

| Acetic Acid 120 °C | 1100 ± 0 | 1290 ± 0 | 1330 ± 0 | 1370 ± 0 |

| Acetic Acid 170 °C | 1100 ± 0 | 134 ± 00 | 1370 ± 0 | 1410 ± 0 |

| Acetic Acid 200 °C | 1160 ± 0 | 1310 ± 0 | 1370 ± 0 | 1410 ± 0 |

| Acetic Acid 250 °C | 1000 ± 0 | 1310 ± 0 | 1370 ± 0 | 1420 ± 0 |

| Formic Acid 120 °C | 970 ± 0 | 1320 ± 0 | 1360 ± 0 | 1400 ± 0 |

| Formic Acid 170 °C | 1080 ± 0 | 1350 ± 0 | 1380 ± 0 | 1420 ± 0 |

| Formic Acid 200 °C | 1040 ± 0 | 1370 ± 0 | 1400 ± 0 | 1440 ± 0 |

| Formic Acid 250 °C | 1270 ± 0 | 1320 ± 0 | 1360 ± 0 | 1410 ± 0 |

| Sulphuric Acid 120 °C | 960 ± 0 | 1400 ± 80 | 1460 ± 60 | 1520 ± 20 |

| Sulphuric Acid 170 °C | 990 ± 0 | 129 ± 00 | 1545 ± 5 | 1560 ± 0 |

| Sulphuric Acid 200 °C | 880 ± 0 | 1340 ± 0 | 1350 ± 0 | 1390 ± 0 |

| Sulphuric Acid 250 °C | 1010 ± 0 | >1570 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Smith, A.M.; Ekpo, U.; Ross, A.B. The Influence of pH on the Combustion Properties of Bio-Coal Following Hydrothermal Treatment of Swine Manure. Energies 2020, 13, 331. https://doi.org/10.3390/en13020331

Smith AM, Ekpo U, Ross AB. The Influence of pH on the Combustion Properties of Bio-Coal Following Hydrothermal Treatment of Swine Manure. Energies. 2020; 13(2):331. https://doi.org/10.3390/en13020331

Chicago/Turabian StyleSmith, Aidan Mark, Ugochinyere Ekpo, and Andrew Barry Ross. 2020. "The Influence of pH on the Combustion Properties of Bio-Coal Following Hydrothermal Treatment of Swine Manure" Energies 13, no. 2: 331. https://doi.org/10.3390/en13020331

APA StyleSmith, A. M., Ekpo, U., & Ross, A. B. (2020). The Influence of pH on the Combustion Properties of Bio-Coal Following Hydrothermal Treatment of Swine Manure. Energies, 13(2), 331. https://doi.org/10.3390/en13020331