Design and 3D CFD Static Performance Study of a Two-Blade IceWind Turbine

Abstract

:1. Introduction

2. Physical Model

3. Numerical Model

3.1. Domain Dimensions

3.2. Boundary Conditions

3.3. Domain Meshing

3.4. Turbulence Modeling Approach

4. Savonius Turbine

5. Results

6. Comparison with Previous Work

7. Conclusions

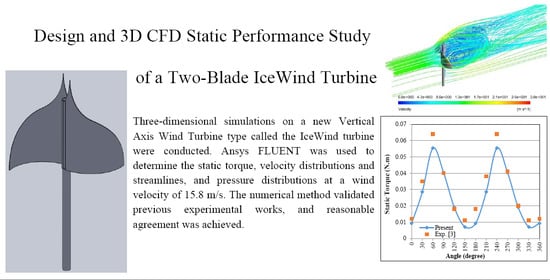

- The comparison between the IceWind and Savonius turbines showed similar flow patterns. However, the IceWind turbine was found to be slightly better than the Savonius wind turbine with the same swept area. Although the IceWind turbine is not simple to manufacture, its shape has a better look and performance.

- The air flow velocity distribution of the IceWind turbine led to the maximal velocity and a larger wake area.

- The air flow velocity streamlines demonstrated that vortices behind the IceWind rotor are three-dimensional.

- The air flow pressure distributions showed that positive pressure appears on the turbine side facing the air. On the opposite side, the pressure is negative.

- The numerical method validated previous experimental works, and reasonable agreement was achieved.

Author Contributions

Funding

Conflicts of Interest

References

- IceWind Turbine Site. Available online: http://icewind.is/en/ (accessed on 27 November 2019).

- Aymane, E. Savonius Vertical Wind Turbine: Design, Simulation, and Physical Testing. Master’s Thesis, School of Science and Engineering, Alakhawayn University, Ifrane, Morocco, 2017. [Google Scholar]

- Afify, R.S. Experimental Studies of an IceWind Turbine. Int. J. Appl. Eng. Res. 2019, 14, 3633–3645. [Google Scholar]

- Sarma, N.K.; Biswas, A.; Misra, R.D. Experimental and computational evaluation of Savonius hydrokinetic turbine for low velocity condition with comparison to Savonius wind turbine at the same input power. Energy Convers. Manag. 2014, 83, 88–98. [Google Scholar] [CrossRef]

- Nasef, M.H.; El-Askary, W.A.; AbdEL-hamid, A.A.; Gad, H.E. Evaluation of Savonius rotor performance: Static and dynamic studies. J. Wind Eng. Ind. Aerodyn. 2013, 123, 1–11. [Google Scholar] [CrossRef]

- Kacprzak, K.; Liskiewicz, G.; Sobczak, K. Numerical investigation of conventional and modified Savonius wind turbines. Renew. Energy 2013, 60, 578–585. [Google Scholar] [CrossRef]

- Dobrev, I.; Massouh, F. CFD and PIV investigation of unsteady flow through Savonius wind turbine. Energy Procedia 2011, 6, 711–720. [Google Scholar] [CrossRef] [Green Version]

- McTavish, S.; Feszty, D.; Sankar, T. Steady and rotating computational fluid dynamics simulations of a novel vertical axis wind turbine for small-scale power generation. Renew. Energy 2012, 41, 171–179. [Google Scholar] [CrossRef]

- Fluent, A. 12.0 Theory Guide; Ansys Inc.: Canonsburg, PA, USA, 2009. [Google Scholar]

- Marsh, P.; Ranmuthugala, D.; Penesis, I.; Thomas, G. Three-dimensional numerical simulations of straight-bladed vertical axis tidal turbines investigating power output, torque ripple and mounting forces. Renew. Energy 2015, 83, 67–77. [Google Scholar] [CrossRef] [Green Version]

- McNaughton, J.; Billard, F.; Revell, A. Turbulence modelling of low Reynolds number flow effects around a vertical axis turbine at a range of tip-speed ratios. J. Fluids Struct. 2014, 47, 124–138. [Google Scholar] [CrossRef]

- Wilcox, D.C. Turbulence Modeling for CFD, 2nd ed.; DCW Industries: La Canada Flintridge, CA, USA, 1998; ISBN 0-9636051-5-1. [Google Scholar]

- Blazek, J. Computational Fluid Dynamics: Principles and Applications, 1st ed.; Elsevier Science Ltd.: Oxford, UK, 2001; ISBN 0080430090. [Google Scholar]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef] [Green Version]

- Chong, W.; Fazlizan, A.; Poh, S.; Pan, K.; Hew, W.; Hsiao, F. The design, simulation and testing of an urban vertical axis wind turbine with the Omni-direction-guide-vane. Appl. Energy 2013, 112, 601–609. [Google Scholar] [CrossRef]

- Nobile, R.; Vahdati, M.; Barlow, J.F.; Mewburn-Crook, A. Unsteady flow simulation of a vertical axis augmented wind turbine: A two-dimensional study. J. Wind Eng. Ind. Aerodyn. 2014, 125, 168–179. [Google Scholar] [CrossRef] [Green Version]

- Lim, Y.; Chong, W.; Hsiao, F. Performance investigation and optimization of a vertical axis wind turbine with the Omni-direction-guide-vane. Procedia Eng. 2013, 67, 59–69. [Google Scholar] [CrossRef] [Green Version]

- Danao, L.A.; Edwards, J.; Eboibi, O.; Howell, R. A numerical investigation into the influence of unsteady wind on the performance and aerodynamics of a vertical axis wind turbine. Appl. Energy 2014, 116, 111–124. [Google Scholar] [CrossRef] [Green Version]

- Mohamed, M.H.; Ali, A.M.; Hafiz, A.A. CFD analysis for H-rotor Darrieus turbine as a low speed wind energy converter. Eng. Sci. Technol. 2015, 18, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Almohammadi, K.M.; Ingham, D.B.; Ma, L.; Pourkashan, M. Computational fluid dynamics (CFD) mesh independency techniques for a straight blade vertical axis wind turbine. Energy 2013, 58, 483–493. [Google Scholar] [CrossRef]

- Fujisawa, N.; Gotoh, F. Visualization study of the flow in and around a Savonius rotor. Exp. Fluids 1992, 12, 407–412. [Google Scholar] [CrossRef]

- Fujisawa, N. On the torque mechanism of Savonius rotors. J. Wind Eng. Ind. Aerodyn. 1992, 40, 277–292. [Google Scholar] [CrossRef]

- Fujisawa, N.; Gotoh, F. Pressure measurements and flow visualization study of a Savonius rotor. J. Wind Eng. Ind. Aerodyn. 1992, 39, 51–60. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

| Boundary Location | Boundary Condition |

|---|---|

| Inlet (Left) | Velocity inlet |

| Outlet (Right) | Pressure outlet |

| Top | Wall |

| Sides | Wall |

| bottom | Wall |

| Turbine’s surfaces | Wall |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mansour, H.; Afify, R. Design and 3D CFD Static Performance Study of a Two-Blade IceWind Turbine. Energies 2020, 13, 5356. https://doi.org/10.3390/en13205356

Mansour H, Afify R. Design and 3D CFD Static Performance Study of a Two-Blade IceWind Turbine. Energies. 2020; 13(20):5356. https://doi.org/10.3390/en13205356

Chicago/Turabian StyleMansour, Hamdy, and Rola Afify. 2020. "Design and 3D CFD Static Performance Study of a Two-Blade IceWind Turbine" Energies 13, no. 20: 5356. https://doi.org/10.3390/en13205356

APA StyleMansour, H., & Afify, R. (2020). Design and 3D CFD Static Performance Study of a Two-Blade IceWind Turbine. Energies, 13(20), 5356. https://doi.org/10.3390/en13205356