Environmental Impacts of Charging Concepts for Battery Electric Vehicles: A Comparison of On-Board and Off-Board Charging Systems Based on a Life Cycle Assessment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Technological Systems

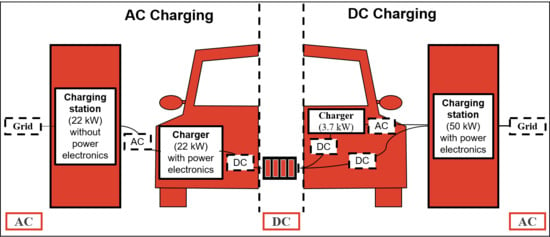

- In our AC system, all electric vehicles have an OBC to charge the battery with a power up to 22 kW. Any publicly accessible charging point provides a charging capacity of 22 kW. For charging at home, a 3.7 kW charging point (AC) is available. Charging with 3.7 kW requires no additional power electronics.

- In our DC system, each electric vehicle is equipped with an OBC with 3.7 kW charging power that allows for charging at home (AC). Additionally, all electric vehicles can be charged with an OfBC with 50 kW charging power at publicly accessible charging points (DC).

2.2. Scenarios

- In the first scenario (S), the innovation and imitation coefficients of the Bass model are adopted from [24]. Although [24] data are based on data of global sales of hybrid Toyota vehicles, they are considered to be sufficiently good estimates. The values for the vehicle stock, the number of new registrations, and the number of retired passenger cars are taken from [25]. For a near future distribution, a vehicle stock of 170,000 vehicles is estimated, which seems to be reasonable (136,617 electric vehicles on 1 January 2020 in Germany [26]).

- The second scenario (M) is based on data by [27,28], who state the objective that road traffic in Germany should be climate-neutral by 2050. One possibility of how this aim might be reached is to regulate the registration of new cars so that solely BEVs can be registered. For our estimation, we assume that as of 2040, only BEVs can be newly registered, which leads to a vehicle stock of about 220,000 BEVs in the near future. Comparable values can be estimated when calculating innovation and imitation coefficients based on the vehicle stock [25] and the new vehicle registrations of electric vehicles [29].

- The third scenario (L) is based on the aim of one million electric vehicles in 2020 [30]. According to [31] and the actual vehicle stock [26], this target is not realistically achievable for 2020, but experts assume that the million level could be reached in 2022 [31]. With the assumptions made for the market volume, we consider this limit as an intermediate target. We further assume that the vehicle stock is increasing exponentially up to that limit, resulting in a vehicle stock of 310,000 BEVs in the near future. Table 2 shows the vehicle stocks in the three scenarios presented.

2.3. Life Cycle Assessment (LCA): Scope and Goal Definition, Life Cycle Inventory (LCI), and Life Cycle Impact Assessment (LCIA)

2.3.1. Goal and Scope

2.3.2. Life Cycle Inventory (LCI)

Production of Components

- Filter

- AC-DC converter

- DC-DC converter

- Printed circuit board (PCB), driver board, logic board and busbars

- Enclosure of electronic components and heatsink.

- Charging infrastructure

Transport and Use Phase

2.3.3. Life Cycle Impact Assessment (LCIA)

3. Results

3.1. Results and Interpretation of the Life Cycle Impact Assessment (LCIA)

3.1.1. Component-Based Results

- Power electronics

- Charging infrastructure (CIS)

3.1.2. System-Based Results

- Chargers

- Charging infrastructure (CIS)

- Charging infrastructure, chargers, transport, and use phase

3.1.3. Scenario-Based Results

3.1.4. Sensitivity Analyses

3.2. Economic Analysis

4. Conclusions and Outlook

Author Contributions

Funding

Conflicts of Interest

Appendix A. Background Information to Section 2.2

Appendix B. Background Information for the Life Cycle Inventory (LCI)

- Filter

- AC-DC Converter

- DC-DC Converter

- Printed circuit board (PCB), driver board, logic board, and busbars

- Enclosure of electronic components and heatsink

- Charging infrastructure (CIS)

| Energy Source | Percentage Share [%] |

|---|---|

| Coal | 43.51 |

| Nuclear | 25.05 |

| Natural gas | 9.32 |

| Wind power | 4.03 |

| Hydropower | 3.32 |

| oil | 1.47 |

| Hydropower, pumped storage | 1.06 |

| biomass | 0.57 |

| biogas | 0.49 |

| photovoltaic | 0.09 |

| Other | 11.08 |

| Impact Category | AC System | DC System | ||||

|---|---|---|---|---|---|---|

| Scenario S | Scenario M | Scenario L | Scenario S | Scenario M | Scenario L | |

| WD | 4.97 ∙ 106 | 6.43 ∙ 106 | 8.80 ∙ 106 | 4.14 ∙ 106 | 5.36 ∙ 106 | 7.34 ∙ 106 |

| ULO | 8.44 ∙ 106 | 1.09 ∙ 107 | 1.49 ∙ 107 | 5.45 ∙ 106 | 7.05 ∙ 106 | 9.65 ∙ 106 |

| TET | 6.79 ∙ 104 | 8.79 ∙ 104 | 1.20 ∙ 105 | 4.43 ∙ 104 | 5.73 ∙ 104 | 7.84 ∙ 104 |

| TA | 4.52 ∙ 106 | 5.86 ∙ 106 | 8.02 ∙ 106 | 3.31 ∙ 106 | 4.28 ∙ 106 | 5.86 ∙ 106 |

| POF | 2.23 ∙ 106 | 2.88 ∙ 106 | 3.94 ∙ 106 | 1.16 ∙ 106 | 1.50 ∙ 106 | 2.05 ∙ 106 |

| PMF | 1.46 ∙ 106 | 1.89 ∙ 106 | 2.59 ∙ 106 | 8.65 ∙ 105 | 1.12 ∙ 106 | 1.53 ∙ 106 |

| OD | 5.20 ∙ 101 | 6.73 ∙ 101 | 9.22 ∙ 101 | 3.84 ∙ 101 | 4.97 ∙ 101 | 6.81 ∙ 101 |

| NLT | 8.04 ∙ 104 | 1.04 ∙ 105 | 1.43 ∙ 105 | 4.44 ∙ 104 | 5.75 ∙ 104 | 7.87 ∙ 104 |

| MRD | 2.89 ∙ 108 | 3.74 ∙ 108 | 5.12 ∙ 108 | 9.22 ∙ 107 | 1.19 ∙ 108 | 1.63 ∙ 108 |

| ME | 8.42 ∙ 105 | 1.09 ∙ 106 | 1.49 ∙ 106 | 6.06 ∙ 105 | 7.84 ∙ 105 | 1.07 ∙ 106 |

| MET | 4.36 ∙ 107 | 5.64 ∙ 107 | 7.73 ∙ 107 | 3.59 ∙ 107 | 4.64 ∙ 107 | 6.35 ∙ 107 |

| IR | 1.78 ∙ 108 | 2.31 ∙ 108 | 3.16 ∙ 108 | 1.59 ∙ 108 | 2.06 ∙ 108 | 2.82 ∙ 108 |

| HT | 1.20 ∙ 109 | 1.55 ∙ 109 | 2.13 ∙ 109 | 8.22 ∙ 108 | 1.06 ∙ 109 | 1.46 ∙ 109 |

| FE | 1.31 ∙ 106 | 1.70 ∙ 106 | 2.33 ∙ 106 | 1.08 ∙ 106 | 1.40 ∙ 106 | 1.91 ∙ 106 |

| FET | 4.66 ∙ 107 | 6.03 ∙ 107 | 8.25 ∙ 107 | 3.91 ∙ 107 | 5.05 ∙ 107 | 6.92 ∙ 107 |

| FD | 2.67 ∙ 108 | 3.46 ∙ 108 | 4.74 ∙ 108 | 2.14 ∙ 108 | 2.77 ∙ 108 | 3.79 ∙ 108 |

| CC | 9.97 ∙ 108 | 1.29 ∙ 109 | 1.77 ∙ 109 | 8.02 ∙ 108 | 1.04 ∙ 109 | 1.42 ∙ 109 |

| ALO | 5.93 ∙ 107 | 7.67 ∙ 107 | 1.05 ∙ 108 | 5.03 ∙ 107 | 6.52 ∙ 107 | 8.92 ∙ 107 |

Appendix C. Detailed Results on Component Level

| Impact Category | AC-DC Converter | Filter | DC-DC Converter | PCB | Driver Board | Logic Board | Busbars |

|---|---|---|---|---|---|---|---|

| WD | 6.92 ∙ 10−10 | 2.71 ∙ 10−9 | 1.07 ∙ 10−9 | 9.21 ∙ 10−11 | 6.48 ∙ 10−10 | 5.58 ∙ 10−10 | 1.59 ∙ 10−11 |

| ULO | 2.12 ∙ 10−9 | 1.12 ∙ 10−8 | 3.29 ∙ 10−9 | 2.18 ∙ 10−10 | 2.40 ∙ 10−9 | 2.08 ∙ 10−9 | 4.44 ∙ 10−11 |

| TET | 2.20 ∙ 10−11 | 6.51 ∙ 10−11 | 3.95 ∙ 10−11 | 6.83 ∙ 10−12 | 2.63 ∙ 10−11 | 1.63 ∙ 10−11 | 1.19 ∙ 10−12 |

| TA | 1.10 ∙ 10−9 | 4.26 ∙ 10−9 | 1.86 ∙ 10−9 | 8.32 ∙ 10−11 | 5.77 ∙ 10−10 | 4.46 ∙ 10−10 | 5.21 ∙ 10−11 |

| POF | 8.54 ∙ 10−10 | 4.72 ∙ 10−9 | 1.25 ∙ 10−9 | 5.18 ∙ 10−11 | 3.59 ∙ 10−10 | 3.11 ∙ 10−10 | 1.07 ∙ 10−11 |

| PMF | 5.00 ∙ 10−10 | 2.24 ∙ 10−9 | 8.09 ∙ 10−10 | 3.98 ∙ 10−11 | 2.75 ∙ 10−10 | 2.19 ∙ 10−10 | 1.52 ∙ 10−11 |

| OD | 6.89 ∙ 10−15 | 6.12 ∙ 10−14 | 1.00 ∙ 10−14 | 1.19 ∙ 10−15 | 8.52 ∙ 10−15 | 8.35 ∙ 10−15 | 4.34 ∙ 10−17 |

| NLT | 2.34 ∙ 10−11 | 1.63 ∙ 10−10 | 3.36 ∙ 10−11 | 2.20 ∙ 10−12 | 1.64 ∙ 10−11 | 1.36 ∙ 10−11 | 2.05 ∙ 10−13 |

| MRD | 1.04 ∙ 10−7 | 9.36 ∙ 10−7 | 2.81 ∙ 10−7 | 7.64 ∙ 10−9 | 7.19 ∙ 10−8 | 5.54 ∙ 10−8 | 4.36 ∙ 10−9 |

| ME | 1.89 ∙ 10−10 | 8.76 ∙ 10−10 | 3.00 ∙ 10−10 | 1.71 ∙ 10−11 | 1.27 ∙ 10−10 | 1.14 ∙ 10−10 | 4.54 ∙ 10−12 |

| MET | 6.58 ∙ 10−9 | 2.18 ∙ 10−8 | 1.22 ∙ 10−8 | 5.29 ∙ 10−10 | 7.33 ∙ 10−9 | 8.14 ∙ 10−9 | 3.88 ∙ 10−10 |

| IR | 1.65 ∙ 10−8 | 7.99 ∙ 10−8 | 2.40 ∙ 10−8 | 1.72 ∙ 10−9 | 1.03 ∙ 10−8 | 9.12 ∙ 10−9 | 6.74 ∙ 10−11 |

| HT | 3.50 ∙ 10−7 | 9.26 ∙ 10−7 | 6.61 ∙ 10−7 | 2.50 ∙ 10−8 | 3.79 ∙ 10−7 | 4.25 ∙ 10−7 | 2.33 ∙ 10−8 |

| FE | 1.99 ∙ 10−10 | 6.30 ∙ 10−10 | 3.56 ∙ 10−10 | 1.65 ∙ 10−11 | 2.35 ∙ 10−10 | 2.67 ∙ 10−10 | 1.05 ∙ 10−11 |

| FET | 6.40 ∙ 10−9 | 1.99 ∙ 10−8 | 1.17 ∙ 10−8 | 4.80 ∙ 10−10 | 7.52 ∙ 10−9 | 8.62 ∙ 10−9 | 3.63 ∙ 10−10 |

| FD | 3.92 ∙ 10−8 | 2.18 ∙ 10−7 | 5.62 ∙ 10−8 | 3.73 ∙ 10−9 | 2.38 ∙ 10−8 | 2.13 ∙ 10−8 | 1.99 ∙ 10−10 |

| CC | 1.43 ∙ 10−7 | 7.77 ∙ 10−7 | 2.06 ∙ 10−7 | 1.37 ∙ 10−8 | 8.65 ∙ 10−8 | 7.75 ∙ 10−8 | 7.88 ∙ 10−10 |

| ALO | 7.80 ∙ 10−9 | 4.03 ∙ 10−8 | 1.11 ∙ 10−8 | 4.44 ∙ 10−10 | 3.02 ∙ 10−9 | 2.42 ∙ 10−9 | 7.86 ∙ 10−11 |

| Impact Category | AC System | DC System | Δ Absolute 1 | Δ Relative 1 |

|---|---|---|---|---|

| WD | 3.25 ∙ 10−5 | 3.13 ∙ 10−5 | 1.14 ∙ 10−6 | 3.50% |

| ULO | 1.13 ∙ 10−4 | 1.17 ∙ 10−4 | −3.86 ∙ 10−6 | −3.41% |

| TET | 2.74 ∙ 10−6 | 2.51 ∙ 10−6 | 2.34 ∙ 10−7 | 8.54% |

| TA | 9.74 ∙ 10−5 | 8.87 ∙ 10−5 | 8.69 ∙ 10−6 | 8.92% |

| POF | 2.70 ∙ 10−5 | 2.73 ∙ 10−5 | −2.79 ∙ 10−7 | −1.03% |

| PMF | 3.47 ∙ 10−5 | 3.55 ∙ 10−5 | −7.55 ∙ 10−7 | −2.18% |

| OD | 1.74 ∙ 10−10 | 2.13 ∙ 10−10 | −3.92 ∙ 10−11 | −22.54% |

| NLT | 5.53 ∙ 10−7 | 5.78 ∙ 10−7 | −2.55 ∙ 10−8 | −4.61% |

| MRD | 1.14 ∙ 10−2 | 1.17 ∙ 10−2 | −3.27 ∙ 10−4 | −2.86% |

| ME | 1.12 ∙ 10−5 | 1.08 ∙ 10−5 | 4.04 ∙ 10−7 | 3.61% |

| MET | 9.32 ∙ 10−4 | 8.85 ∙ 10−4 | 4.67 ∙ 10−5 | 5.01% |

| IR | 2.25 ∙ 10−4 | 2.67 ∙ 10−4 | −4.26 ∙ 10−5 | −18.99% |

| HT | 5.17 ∙ 10−2 | 4.48 ∙ 10−2 | 7.00 ∙ 10−3 | 13.52% |

| FE | 2.35 ∙ 10−5 | 2.05 ∙ 10−5 | 3.01 ∙ 10−6 | 12.81% |

| FET | 8.73 ∙ 10−4 | 8.33 ∙ 10−4 | 3.98 ∙ 10−5 | 4.56% |

| FD | 8.99 ∙ 10−4 | 1.06 ∙ 10−3 | −1.59 ∙ 10−4 | −17.66% |

| CC | 3.05 ∙ 10−3 | 3.79 ∙ 10−3 | −7.39 ∙ 10−4 | −24.22% |

| ALO | 2.51 ∙ 10−4 | 2.77 ∙ 10−4 | −2.55 ∙ 10−5 | −10.13% |

References

- Yilmaz, M.; Krein, P.T. Review of Battery Charger Topologies, Charging Power Levels, and Infrastructure for Plug-In Electric and Hybrid Vehicles. IEEE Trans. Power Electron. 2013, 28, 2151–2169. [Google Scholar] [CrossRef]

- Zeit Online. Forscher Warnen Vor Einer Heißzeit. 2018. Available online: https://www.zeit.de/wissen/umwelt/2018-08/klimaerwaermung-heisszeit-kippelemente-studie-klimaforschung (accessed on 10 August 2020).

- Umweltbundesamt. Beobachteter Klimawandel. 2013. Available online: https://www.umweltbundesamt.de/themen/klima-energie/klimawandel/beobachteter-klimawandel (accessed on 10 August 2020).

- Stern, N. The Economics of Climate Change: The Stern Review; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar] [CrossRef] [Green Version]

- Breidenich, C.; Magraw, D.; Rowley, A.; Rubin, J.W. The Kyoto protocol to the United Nations framework convention on climate change. Am. J. Int. Law 1998, 92, 315–331. [Google Scholar] [CrossRef]

- Agreement, P. The Paris Agreement. In Proceedings of the Parties to the United Nations Framework Convention on Climate Change, Paris, France, 30 November–12 December 2015. [Google Scholar]

- Umweltbundesamt. Trendtabellen Treibhausgase 1990–2018 (Stand: EU-Submission). 2020. Available online: https://www.umweltbundesamt.de/dokument/trendtabellen-treibhausgase-1990-2018-stand-eu (accessed on 5 December 2020).

- Umweltbundesamt. Emissionsdaten. 2020. Available online: https://www.umweltbundesamt.de/themen/verkehr-laerm/emissionsdaten#verkehrsmittelvergleich_personenverkehr (accessed on 10 August 2020).

- Eisenkopf, A.; Fricke, H.; Friedrich, M.; Haasis, H.-D.; Knieps, G.; Knorr, A. Nach der Klimakonferenz in Paris: Wird eine neue Klimastrategie für den Verkehr benötigt? Z. Verk. 2016, 87. [Google Scholar]

- Hawkins, T.R.; Singh, B.; Majeau-Bettez, G.; Strømman, A.H. Comparative Environmental Life Cycle Assessment of Conventional and Electric Vehicles. J. Ind. Ecol. 2012, 17, 53–64. [Google Scholar] [CrossRef]

- International Energy Agency. Global EV Outlook 2017; International Energy Agency: Paris, France, 2017. [Google Scholar] [CrossRef]

- Nykvist, B.; Nilsson, M. Rapidly falling costs of battery packs for electric vehicles. Nat. Clim. Chang. 2015, 5, 329–332. [Google Scholar] [CrossRef]

- Faria, R.; Moura, P.; Delgado, J.; De Almeida, A.T. A sustainability assessment of electric vehicles as a personal mobility system. Energy Convers. Manag. 2012, 61, 19–30. [Google Scholar] [CrossRef]

- Elektromobilität, N.P. Fortschrittsbericht 2018—Markthochlaufphase; Nationale Plattform Elektromobilität (NPE): Berlin, Germany, 2018. [Google Scholar]

- Musavi, F.; Edington, M.; Eberle, W.; Dunford, W.G. Evaluation and Efficiency Comparison of Front End AC-DC Plug-in Hybrid Charger Topologies. IEEE Trans. Smart Grid 2012, 3, 413–421. [Google Scholar] [CrossRef]

- Nordelöf, A.; Messagie, M.; Tillman, A.-M.; Söderman, M.L.; Van Mierlo, J. Environmental impacts of hybrid, plug-in hybrid, and battery electric vehicles—What can we learn from life cycle assessment? Int. J. Life Cycle Assess. 2014, 19, 1866–1890. [Google Scholar] [CrossRef] [Green Version]

- Tintelecan, A.; Dobra, A.C.; Marțiș, C. Literature Review—Electric Vehicles Life Cycle Assessment. In Proceedings of the 2020 ELEKTRO, Taormina, Italy, 23 March 2020; pp. 1–6. [Google Scholar]

- Faria, R.; Marques, P.; Moura, P.; Freire, F.; Delgado, J.; De Almeida, A.T. Impact of the electricity mix and use profile in the life-cycle assessment of electric vehicles. Renew. Sustain. Energy Rev. 2013, 24, 271–287. [Google Scholar] [CrossRef]

- Zhang, Z.; Sun, X.; Ding, N.; Yang, J. Life cycle environmental assessment of charging infrastructure for electric vehicles in China. J. Clean. Prod. 2019, 227, 932–941. [Google Scholar] [CrossRef]

- Lucas, A.; Silva, C.A.; Neto, R.C. Life cycle analysis of energy supply infrastructure for conventional and electric vehicles. Energy Policy 2012, 41, 537–547. [Google Scholar] [CrossRef]

- Nansai, K.; Tohno, S.; Kono, M.; Kasahara, M.; Moriguchi, Y. Life-cycle analysis of charging infrastructure for electric vehicles. Appl. Energy 2001, 70, 251–265. [Google Scholar] [CrossRef]

- Traut, E.; Hendrickson, C.; Klampfl, E.; Liu, Y.; Michalek, J.J. Optimal design and allocation of electrified vehicles and dedicated charging infrastructure for minimum life cycle greenhouse gas emissions and cost. Energy Policy 2012, 51, 524–534. [Google Scholar] [CrossRef]

- Bass, F.M. A New Product Growth for Model Consumer Durables. Manag. Sci. 1969, 15, 215–227. [Google Scholar] [CrossRef]

- Massiani, J.; Gohs, A. The choice of Bass model coefficients to forecast diffusion for innovative products: An empirical investigation for new automotive technologies. Res. Transp. Econ. 2015, 50, 17–28. [Google Scholar] [CrossRef] [Green Version]

- Kraftfahrt-Bundesamt (KBA)–Federal Motor Transport Authority. Bestand an Pkw in den Jahren 2009 bis 2018 nach Ausgewählten Kraftstoffarten. 2018. Available online: www.kba.de/DE/Statistik/Fahrzeuge/Bestand/Umwelt/b_umwelt_z.html?nn=663524 (accessed on 15 December 2018).

- Kraftfahrt-Bundesamt (KBA)–Federal Motor Transport Authority. Bestand an Personenkraftwagen am 1. Januar 2020 nach Bundesländern und Ausgewählten Kraftstoffarten Absolut. 2020. Available online: https://www.kba.de/DE/Statistik/Fahrzeuge/Bestand/Umwelt/fz_b_umwelt_archiv/2020/2020_b_umwelt_dusl.html?nn=2601598 (accessed on 6 August 2020).

- Bergk, F.; Biemann, K.; Heidt, C.; Knörr, W.; Lambrecht, U.; Schmidt, T. Klimaschutzbeitrag des Verkehrs Bis 2050. Available online: https://www.umweltbundesamt.de/sites/default/files/medien/1410/publikationen/texte_56_2016_klimaschutzbeitrag_des_verkehrs_2050_getagged.pdf (accessed on 5 December 2020).

- Umweltbundesamt. Klimabilanz 2017: Emissionen Gehen Leicht Zurück. 2018. Available online: https://www.umweltbundesamt.de/presse/pressemitteilungen/klimabilanz-2017-emissionen-gehen-leicht-zurueck (accessed on 6 August 2020).

- Kraftfahrt-Bundesamt (KBA)–Federal Motor Transport Authority. Neuzulassungen von Pkw in den Jahren 2008 bis 2017 nach Ausgewählten Kraftstoffarten. 2018. Available online: https://www.kba.de/DE/Statistik/Fahrzeuge/Neuzulassungen/Umwelt/n_umwelt_z.htmlnn=652326 (accessed on 15 December 2018).

- Bundesregierung. Regierungsprogramm Elektromobilität; Publ. Bundesregierung: Berlin, Germany, 2011. [Google Scholar]

- Nationale Plattform Elektromobilität (NPE). Die Ziele. 2020. Available online: http://nationale-plattform-elektromobilitaet.de/hintergrund/die-ziele/ (accessed on 6 August 2020).

- Kraftfahrt-Bundesamt (KBA)–Federal Motor Transport Authority. Bestand am 01. Januar 2018 nach Segmenten. 2018. Available online: https://www.kba.de/DE/Statistik/Fahrzeuge/Bestand/Segmente/segmente_node.html (accessed on 15 May 2018).

- Kompetenzzentrum Elektromobilität NRW. Data Sheet: Hyundai Kona Elektro (100 kW). 2018. Available online: https://www.elektromobilitaet.nrw.de/fileadmin/Daten/Download_Dokumente/Fahrzeuge/Hyundai_Kona_Elektro__100_kW_.pdf (accessed on 10 January 2020).

- Kompetenzzentrum Elektromobilität NRW. Data Sheet: Jaguar I-PACE. 2018. Available online: https://www.elektromobilitaet.nrw.de/fileadmin/Daten/Download_Dokumente/Fahrzeuge/Jaguar_I-PACE.pdf (accessed on 10 January 2020).

- Kompetenzzentrum Elektromobilität NRW. Data Sheet: Nissan Leaf. 2018. Available online: https://www.elektromobilitaet.nrw.de/fileadmin/Daten/Download_Dokumente/Fahrzeuge/Nissan_Leaf.pdf (accessed on 10 January 2020).

- Kompetenzzentrum Elektromobilität NRW. Data Sheet: Hyundai Kona Elektro (150 kW). 2018. Available online: https://www.elektromobilitaet.nrw.de/fileadmin/Daten/Download_Dokumente/Fahrzeuge/Hyundai_Kona_Elektro__150_kW_.pdf (accessed on 10 January 2020).

- Kompetenzzentrum Elektromobilität NRW. Data Sheet: VW e-Golf. 2018. Available online: https://www.elektromobilitaet.nrw.de/fileadmin/Daten/Download_Dokumente/Fahrzeuge//VW_e-Golf.pdf (accessed on 10 January 2020).

- Kompetenzzentrum Elektromobilität NRW. Data Sheet: Opel Ampera-e. 2018. Available online: https://www.elektromobilitaet.nrw.de/fileadmin/Daten/Download_Dokumente/Fahrzeuge/Opel_Ampera-e.pdf (accessed on 10 October 2018).

- Kompetenzzentrum Elektromobilität NRW. Data Sheet: Renault Zoe, Z.E. 2018. Available online: https://www.elektromobilitaet.nrw.de/fileadmin/Daten/Download_Dokumente/Fahrzeuge/Renault_Zoe_Z.E..pdf (accessed on 10 October 2018).

- Kompetenzzentrum Elektromobilität NRW. Data Sheet: Tesla Model S 100D. 2018. Available online: https://www.elektromobilitaet.nrw.de/fileadmin/Daten/Download_Dokumente/Fahrzeuge/Tesla_Model_S_100D.pdf (accessed on 10 October 2018).

- Kompetenzzentrum Elektromobilität NRW. Data Sheet: Tesla Model X 100D. 2018. Available online: https://www.elektromobilitaet.nrw.de/fileadmin/Daten/Download_Dokumente/Fahrzeuge/Tesla_Model_X_100D.pdf (accessed on 10 January 2020).

- Kraftfahrt-Bundesamt (KBA)–Federal Motor Transport Authority. Erneut mehr Gesamtkilometer bei Geringerer Jahresfahrleistung je Fahrzeug. 2018. Available online: https://www.kba.de/DE/Statistik/Kraftverkehr/VerkehrKilometer/2017_vk_kurzbericht_pdf.pdf?__blob=publicationFile&v=14 (accessed on 3 June 2018).

- Kang, J.E.; Recker, W. An activity-based assessment of the potential impacts of plug-in hybrid electric vehicles on energy and emissions using 1-day travel data. Transp. Res. Part D Transp. Environ. 2009, 14, 541–556. [Google Scholar] [CrossRef]

- Robinson, A.; Blythe, P.; Bell, M.; Hübner, Y.; Hill, G. Analysis of electric vehicle driver recharging demand profiles and subsequent impacts on the carbon content of electric vehicle trips. Energy Policy 2013, 61, 337–348. [Google Scholar] [CrossRef] [Green Version]

- Siegrist, A.; Schnabl, P.; Burkhart, S.; de Haan, P.; Bianchetti, R. Elektromobilität: Studie Ladeinfrastruktur Region Basel. Available online: https://docplayer.org/8358125-Elektromobilitaet-studie-ladeinfrastruktur-region-basel.html (accessed on 5 December 2020).

- Nationale Plattform Elektromobilität. Vision und Roadmap der Nationalen Plattform Elektromobilität. Gem. Geschäftsst. Elektromobilität Bundesreg 2013, 27. Available online: http://nationale-plattform-elektromobilitaet.de/fileadmin/user_upload/Redaktion/1379668151_de_2122747422.pdf (accessed on 5 December 2020).

- Christensen, L.; Nørrelund, A.V.; Olsen, A. Travel behaviour of potential Electric Vehicle drivers. The need for changing A contribution to the Edison project. In Proceedings of the European Transport Conference 2010, Glasgow, UK, 11–13 October 2010. [Google Scholar]

- EAFO. Country Detail Electricity. 2019. Available online: https://www.eafo.eu/electric-vehicle-charging-infrastructure (accessed on 6 August 2020).

- Lucas, A.; Prettico, G.; Flammini, M.G.; Kotsakis, E.; Fulli, G.; Masera, M. Indicator-Based Methodology for Assessing EV Charging Infrastructure Using Exploratory Data Analysis. Energies 2018, 11, 1869. [Google Scholar] [CrossRef] [Green Version]

- Ladesäulen-Bestand in Deutschland für Dreimal so Viele Elektroautos Ausreichend. Available online: https://www.emobilserver.de/nachrichten/energie-ladetechnik/1131-ladesäulen-bestand-in-deutschland-für-dreimal-so-viele-elektroautos-ausreichend.html (accessed on 6 August 2020).

- ABB. Terra 184 Infographic. 2020. Available online: https://search.abb.com/library/Download.aspx?DocumentID=9AKK107680A8808&LanguageCode=en&DocumentPartId=&Action=Launch (accessed on 7 August 2020).

- Sheet NLG664—On Board Fast Charger. Available online: https://www.brusa.biz/fileadmin/template/Support-Center/Datenbl%C3%A4tter/BRUSA_DB_EN_NLG664.pdf (accessed on 5 December 2020).

- EVTEC AG. Data: Move&Charge 3in1. 2020. Available online: https://www.evtec.ch/en/products/move_and_charge/ (accessed on 7 August 2020).

- Stercom Power Solutions GmbH: Feel the Power. Available online: https://stercom.de/_media//PDFs/Deutsch/OBC_D1.7.pdf (accessed on 5 December 2020).

- Bundesnetzagentur. Ladesäulenkarte. 2020. Available online: https://www.bundesnetzagentur.de/DE/Sachgebiete/ElektrizitaetundGas/Unternehmen_Institutionen/HandelundVertrieb/Ladesaeulenkarte/Ladesaeulenkarte_node.html (accessed on 5 August 2020).

- McManus, M.C.; Taylor, C.M. The changing nature of life cycle assessment. Biomass Bioenergy 2015, 82, 13–26. [Google Scholar] [CrossRef] [Green Version]

- International Organization for Standardization. ISO 14040: Environmental Management—Life Cycle Assessment; Principles and Framework; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- International Organization for Standardization. ISO 14044: Environmental Management—Life Cycle Assessment; Requirements and Guidelines; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B.P. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Green Delta. 2020. OpenLCA. Available online: http://www.openlca.org/ (accessed on 5 December 2020).

- Schroeder, A.; Traber, T. The economics of fast charging infrastructure for electric vehicles. Energy Policy 2012, 43, 136–144. [Google Scholar] [CrossRef]

- Stella, K.; Wollersheim, O.; Fichtner, W.; Jochem, P.; Schücking, M.; Nastold, M. Über 300.000 Kilometer unter Strom: Physikalisch-Technische, Ökonomische, Ökologische und Sozialwissenschaftliche Begleitforschung des Schaufensterprojektes RheinMobil: Grenzüberschreitende, Perspektivisch Wirtschaftliche Elektrische Pendler-und Dienstwagenverkehre im Deutsch-Französischen Kontext: Schaufenster Elektromobilität-eine Initiative der Bundesregierung: LivingLab BWe Mobil; Karlsruher Institut für Technologie (KIT): Karlsruhe, Germany, 2015. [Google Scholar]

- Shiau, C.S.N.; Samaras, C.; Hauffe, R.; Michalek, J.J. Impact of battery weight and charging patterns on the economic and environmental benefits of plug-in hybrid vehicles. Energy Policy 2009. [Google Scholar] [CrossRef]

- ABB. Global Product Portfolio-Smarter Mobility. 2019. Available online: https://new.abb.com/about/our-businesses/electrification/e-mobilitysolutions (accessed on 5 December 2020).

- Evtec. Data Sheet: Espresso&Charge. 2018. Available online: https://www.evtec.ch/en/products/espressoandcharge-usp/ (accessed on 7 August 2020).

- Mortimer, B.; Olk, C.; Roy, G.K.; Tarnate, W.R.; Doncker, R.W.; Monti, A. Fast-Charging Technologies, Topologies and Standards 2.0; E.ON Energy Research Center Series: Aachen, Germany, 2019; Volume 11. [Google Scholar]

- Schmenger, J.; Zeltner, S.; Kramer, R.; Endres, S.; Marz, M. A 3.7 kW on-board charger based on modular circuit design. In Proceedings of the IECON 2015—41st Annual Conference of the IEEE Industrial Electronics Society, Yokohama, Japan, 9–12 November 2015; pp. 001382–001387. [Google Scholar]

- Schmenger, J.; Endres, S.; Zeltner, S.; März, M. A 22 kW on-board charger for automotive applications based on a modular design. In Proceedings of the 2014 IEEE Conference on Energy Conversion (CENCON), Johor Bahru, Malaysia, 13–14 October 2014; pp. 1–6. [Google Scholar]

- Schmenger, J.; Kramer, R.; Marz, M. Active hybrid common mode filter for a highly integrated on-board charger for automotive applications. In Proceedings of the 2015 IEEE 13th Brazilian Power Electronics Conference and 1st Southern Power Electronics Conference (COBEP/SPEC), Santos, Brazil, 29 November–2 December 2015; pp. 1–7. [Google Scholar]

- Hultin, A.; Wolgers, J. Integration of Fast Charger Stations. Master’s Thesis, Chalmers University of Technology, Göteborg, Sweden, 2017. [Google Scholar]

- Liserre, M.; Blaabjerg, F.; Hansen, S. Design and Control of an LCL-Filter-Based Three-Phase Active Rectifier. IEEE Trans. Ind. Appl. 2005, 41, 1281–1291. [Google Scholar] [CrossRef]

- Reznik, A.; Simoes, M.G.; Al-Durra, A.; Muyeen, S.M. LCL Filter design and performance analysis for grid-interconnected systems. IEEE Trans. Ind. Appl. 2014. [Google Scholar] [CrossRef]

- Beres, R.N.; Wang, X.; Liserre, M.; Blaabjerg, F.; Bak, C.L. A Review of Passive Power Filters for Three-Phase Grid-Connected Voltage-Source Converters. IEEE J. Emerg. Sel. Top. Power Electron. 2016, 4, 54–69. [Google Scholar] [CrossRef] [Green Version]

- Plaßmann, W.; Schulz, D. Handbuch Elektrotechnik, 6th ed.; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Reznik, A.; Simões, M.G.; Al-Durra, A.; Muyeen, S.M. LCL filter design and performance analysis for small wind turbine systems. In Proceedings of the 2012 IEEE Power Electronics and Machines in Wind Applications, Denver, CO, USA, 16–18 July 2012; pp. 1–7. [Google Scholar]

- Fastron Group. Data Sheet: TLC/10A. 2016. Available online: http://fastrongroup.com/toroid-line-chokes/tlc10a (accessed on 5 December 2020).

- ICAR. Data Sheet: Power Electronics Capacitors: MKP Series. 2011. Available online: https://www.icar.com/wp-content/uploads/2018/05/MKP-Icar-Capacitors.pdf (accessed on 5 December 2020).

- Infineon. Data Sheet IPW60R045CP. 2013. Available online: https://www.mouser.es/datasheet/2/196/Infineon-IPW60R045CP-DS-v02_02-en-1227462.pdf (accessed on 5 December 2020).

- Infineon. Data Sheet IDW40G65C5B. 2015. Available online: https://www.infineon.com/dgdl/Infineon-IDW40G65C5B-DS-v02_00-EN.pdf?fileId=5546d4624e24005f014e451799b149e1 (accessed on 5 December 2020).

- Murata Manufacturing Co. Ltd. Data KC355WD72J474MH01#. 2020. Available online: https://www.murata.com/en-eu/products/productdetail?partno=KC355WD72J474MH01%23 (accessed on 7 August 2020).

- TDK. Epcos Data Book 2013: Ferrites and Accessories. 2013. Available online: https://www.tdk-electronics.tdk.com/download/519704/069c210d0363d7b4682d9ff22c2ba503/ferrites-and-accessories-db-130501.pdf (accessed on 5 December 2020).

- Chae, H.J.; Kim, W.Y.; Yun, S.Y.; Jeong, Y.S.; Lee, J.Y.; Moon, H.T. 3.3kW on board charger for electric vehicle. In Proceedings of the 8th International Conference on Power Electronics—ECCE, Jeju, Korea, 30 May–3 June 2011. [Google Scholar]

- Lai, J.S.; Miwa, H.; Lai, W.H.; Tseng, N.H.; Lee, C.S.; Lin, C.H. A high-efficiency on-board charger utilitzing a hybrid LLC and phase-shift DC-DC converter. In Proceedings of the 2014 International Conference on Intelligent Green Building and Smart Grid, IGBSG, Taipei, Taiwan, 23–25 April 2014. [Google Scholar]

- Infineon. Data Sheet IPW65R045C7. 2013. Available online: https://www.infineon.com/dgdl/Infineon-IPW65R045C7-DS-v02_01 (accessed on 5 December 2020).

- Elgström, T.; Nordgren, L. Evaluation and Design of High Frequency Transformers for on Board Charging Applications. Master’s Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2016. [Google Scholar]

- TDK Electronics AG. Data Sheet: Ferrite Cores for Switching Power Supplies: Large PQ Series. 2016. Available online: https://product.tdk.com/info/en/catalog/datasheets/ferrite_mz_sw_large_pq_en.pdf (accessed on 5 December 2020).

- Nordelöf, A.; Alatalo, M. A scalable life cycle inventory of an automotive power electronic inverter unit—Part I: Design and composition. Int. J. Life Cycle Assess. 2019, 24, 78–92. [Google Scholar] [CrossRef] [Green Version]

- Laminated Bus Bar Solutions—Mersen. Available online: https://ep-us.mersen.com/sites/mersen_us/files/2018-12/Laminated-Busbar-Solutions.pdf (accessed on 5 December 2020).

- Fraunhofer Institute for Integrated Systems and Device Technology IISB. 3.7 kW Battery Charger for Automotive Applications. 2014. Available online: https://www.iisb.fraunhofer.de/content/dam/iisb2014/en/Documents/Research-Areas/vehicle_electronics/FraunhoferIISB_ProductSheet_FE_3k7W-Onboard-Battery-Charger_www.pdf (accessed on 5 December 2020).

- Conrad Electronics International GmbH & CoKG. Data: Universal Enclosures. 2020. Available online: https://www.conrad.com/o/universal-enclosures-0203042 (accessed on 7 August 2020).

- Star Charge. 180 kW Super DC Charger_DC Series. 2018. Available online: http://en.starcharge.com/show.asp?id=37 (accessed on 7 August 2020).

- ESL. Ladekabel Elektroauto. 2020. Available online: https://esl-emobility.com/de/ladekabel-elektroauto.html (accessed on 20 November 2018).

- Lapp Group. Data Sheet: ÖLFLEX® CHARGE. 2020. Available online: https://lappaustria.lappgroup.com/produkte/katalog-e-shop/anschluss-und-steuerleitungen/besondere-anwendungen/emobility/oelflex-charge.html (accessed on 5 December 2020).

- Phoenix Contact. Data Sheet: DC Charging Cable–EV-T2M4CC-DC60A-2,5M16ESBK00-1623043. 2020. Available online: https://www.phoenixcontact.com/online/portal/pi?uri=pxc-oc-itemdetail:pid=1623043&library=pien&tab=1 (accessed on 5 December 2020).

- Lapp Group. Data Sheet: ÖLFLEX® SERVO 2YSLCY-JB. 2020. Available online: https://products.lappgroup.com/online-catalogue/power-and-control-cables/servo-applications/pvc-sheath/oelflex-servo-2yslcy-jb.html (accessed on 5 December 2020).

- Walther-Werke Ferdinand Walther GmbH. Data Sheet: E41X01A249B0. 2017. Available online: https://www.walther-werke.de/pdf/datasheets/PD_E41X01A249B0_DE.pdf (accessed on 5 December 2020).

- Schrack Technik GmbH. Data: I-CHARGE Public. 2020. Available online: https://www.schrack.at/know-how/alternativenergie/elektromobilitaet/i-charge-stromtankstellen/i-charge-public/ (accessed on 7 August 2020).

- Elektrohandel Wandelt GmbH. Data: Mennekes 1311510SW Ladestation Basic 22. 2020. Available online: https://www.elektro-wandelt.de/Mennekes-1311510SW-Ladestation-Basic-22.html (accessed on 7 August 2020).

- Elektrohandel Wandelt GmbH. Data: Mennekes 1319610SW Ladestation Smart 22 SW. 2020. Available online: https://www.elektro-wandelt.de/Mennekes-1319610SW-Ladestation-Smart-22-SW.html (accessed on 7 August 2020).

- Circocontrol, S.A. Data Sheet: Serie eStreet (AC). Available online: https://circontrol.de/wp-content/uploads/saule-estreet-datasheet.pdf (accessed on 5 December 2020).

- Data: Alfen Twin. 2020. Available online: https://alfen.com/de/icu-twin (accessed on 7 August 2020).

- ABL SURSUM. Data Sheet: Ladesäule eMC2. 2018. Available online: https://www.ablmobility.de/global/downloads/datenblaetter/emc2/eMC2_DE/2P4445.pdf?m=1597417459& (accessed on 5 December 2020).

- ABL SURSUM. Data Sheet: LADESÄULE eMC3. 2019. Available online: https://www.ablmobility.de/global/downloads/anleitungen/emc3/eMC3_UM_IM_DE.pdf?m=1602138773& (accessed on 5 December 2020).

- Compleo Charging Solutions GmbH. Data Sheet: Compleo Advanced. Available online: https://www.compleo-cs.com/fileadmin/user_upload/ladestationen/datenblaetter_advanced_digital.pdf (accessed on 5 December 2020).

- EBG Group. Data Sheet: CITO BM2 500. Available online: https://pub-mediabox-storage.rxweb-prd.com/exhibitor/document/e2c22e9f-8306-4880-836f-6e42a889b7ae (accessed on 5 December 2020).

- Charge-ON GmbH. Data Sheet: Ladestation Pro. Available online: https://www.eon-drive.de/content/dam/eon-emobility-de/Playground/PDFs/Datasheets/Pro_Datenblatt.pdf (accessed on 5 December 2020).

- Walther-Werke Ferdinand Walther GmbH. Data: Charging Station Evolution 350 Key with Two Charging Points Type 2 up to 22kW and Basis Monitoring. Available online: https://www.walther-werke.de/nc/products-page/filter/ctrl/product/action/show/partno/e21901ae0910-14/?tx_waltherwerkeproducts_productfilter%5Bebene%5D=2&tx_waltherwerkeproducts_productfilter%5Bebene2%5D=13&tx_waltherwerkeproducts_productfilter%5Bebene3%5D (accessed on 7 August 2020).

- PC Electric GmbH. Data Sheet: Ladesäule LS4. Available online: https://oxomi.com/p/3000237/catalog/10163042 (accessed on 5 December 2020).

- Castellan, A.G. Data: Empfang-Ladestation. Available online: https://www.castellan-ag.de/details/empfang-ladestation.html (accessed on 7 August 2020).

- Swarco Traffic Systems GmbH. Data Sheet: Evolt Public 7″. 2017. Available online: https://www.swarco.com/sites/default/files/public/downloads/2018-10/01_2017%20SWARCO%20EVOLT%20Public%207%20Final.pdf (accessed on 5 December 2020).

- Delta Electronics (Netherlands) B.V. Data Sheet: 150 kW Ultra-Fast Charger. 2019. Available online: https://emobility.delta-emea.com/downloads/Brochure%20-%20UFC%20Ultra%20Fast%20Charger%20V7%20EN%202019-10-07.pdf.pdf (accessed on 5 December 2020).

- ABB Inc. Data Sheet: Terra 53 Multi-Standard DC Charging Station. 2014. Available online: https://new.abb.com/ev-charging/de/produkte/ladestationen-pkws/terra-schnelllades%c3%a4ulen/terra-54-cjg (accessed on 5 December 2020).

- Petrotec Group. Data Sheet: PFAST MULTI. 2014. Available online: https://www.petrotec.com/media/33069/modibp-fast-multi-05_2014.pdf (accessed on 5 December 2020).

- Borken-Kleefeld, J.; Weidema, B.P. Global default data for freight transport per product group. Manuscr. Spec. Ecoinvent 2013, 3. [Google Scholar]

- Frischknecht, R.; Tuchschmid, M.; Emmenegger, M.F.; Bauer, C.; Dones, R. Strommix. Sachbilanzen von Energiesystemen: Grundlagen Für Den Ökologischen Vergleich von Energiesystemen und den Einbezug von Energiesystemen in Ökobilanzen für Die Schweiz; Dones, R., Ed.; Paul Scherrer Institut, Villigen & Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2007; ISBN 3-905594-38-2. [Google Scholar]

- Koj, J.C.; Wulf, C.; Zapp, P. Environmental impacts of power-to-X systems-A review of technological and methodological choices in Life Cycle Assessments. Renew. Sustain. Energy Rev. 2019, 112, 865–879. [Google Scholar] [CrossRef]

- Rosenbaum, R.K. Selection of Impact Categories, Category Indicators and Characterization Models in Goal and Scope Definition. In Goal and Scope Definition in Life Cycle Assessment; Springer: Berlin/Heidelberg, Germany, 2017; pp. 63–122. [Google Scholar]

- Huijbregts, M.; Steinmann, Z.J.N.; Elshout, P.M.F.M.; Stam, G.; Verones, F.; Vieira, M.D.M. ReCiPe 2016. Natl. Inst. Public Health Environ. 2016, 194. [Google Scholar] [CrossRef]

- Hauschild, M.Z.; Rosenbaum, R.K.; Olsen, S. Life Cycle Assessment; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Jolliet, O.; Müller-Wenk, R.; Bare, J.; Brent, A.; Goedkoop, M.; Heijungs, R. The LCIA midpoint-damage framework of the UNEP/SETAC life cycle initiative. Int. J. Life Cycle Assess. 2004, 9, 394. [Google Scholar] [CrossRef] [Green Version]

- Bare, J.C.; Hofstetter, P.; Pennington, D.W.; De Haes, H.A.U. Midpoints versus endpoints: The sacrifices and benefits. Int. J. Life Cycle Assess. 2000, 5, 319. [Google Scholar] [CrossRef] [Green Version]

- Elektromobilität, N.P. Ladeinfrastruktur für Elektrofahrzeuge in Deutschland: Statusbericht und Handlungsempfehlungen; Nationale Plattform Elektromobilität (NPE): Berlin, Germany, 2015. [Google Scholar]

- Funke, S.Á. Techno-Ökonomische Gesamtbewertung Heterogener Maßnahmen zur Verlängerung der Tagesreichweite von Batterieelektrischen Fahrzeugen. Ph.D. Thesis, Universität Kassel, Kassel, Germany, 2018. [Google Scholar]

- Mathieu, G. Design of an On-Board Charger for Plug-In Hybrid Electrical Vehicle (PHEV). Master’s Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2009. [Google Scholar]

- Hischier, R.; Classen, M.; Lehmann, M.; Scharnhorst, W. Life Cycle Inventories of Electric and Electronic Equipment: Production, Use and Disposal; Final Report Ecoinvent Data v2.0; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2007. [Google Scholar] [CrossRef]

- Austerlitz Electronic GmbH. Data Sheet: Heatsinks. 2018. Available online: http://austerlitz-electronic.de/katalog/Austerlitz_Katalog-13_DE-EN.pdf (accessed on 5 December 2020).

- MENNEKES Elektrotechnik GmbH & Co. KG. Data Sheet: Basic 3,7, Basic 11, Basic 22, Basic S 22. 2013. Available online: https://datatransfer.chargeupyourday.de/Graphics/XPic9/00039836_0.pdf (accessed on 5 December 2020).

- Klaus Faber, A.G. Data Sheet: Power Cable NYY-J/-O. 2020. Available online: https://www.faberkabel.de/upload/files/downloads/204/2017_faber_katalog.pdf (accessed on 5 December 2020).

- Charge-ON GmbH. Data Sheet: E.ON Ladestation Fast. Available online: https://www.eon-drive.de/content/dam/eon-emobility-de/Playground/PDFs/Datasheets/Fast_Datenblatt.pdf (accessed on 5 December 2020).

- Fine Tubes Ltd. Data Sheet: Stainless Steel Alloys 304/304L. 2018. Available online: https://www.finetubes.co.uk/-/media/ametekfinetubes/files/downloads/alloy%20data%20sheets/stainless%20steel%20-%20alloys%20304%20and%20304l.pdf?utm_source=&utm_medium=undefined (accessed on 5 December 2020).

- Classen, M.; Althaus, H.-J.; Blaser, S.; Tuchschmid, M.; Jungbluth, N.; Doka, G. Life Cycle Inventories of Metals; Final Report Ecoinvent Data v2.1 No.10; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2009. [Google Scholar]

| AC System | DC System | ||||

|---|---|---|---|---|---|

| 22 kW OBC | 22 kW CIS | 50 kW OfBC | 50 kW CIS | 3.7 kW OBC | |

| Number of BEVs | x | − | − | − | x |

| Amount of charging infrastructure 1 | − | x | x | x | − |

| Scenario S | Scenario M | Scenario L | ||

|---|---|---|---|---|

| Vehicle stock | 170,000 | 220,000 | 310,000 | |

| Number of public charging points | AC system | 14,579 | 18,867 | 25,827 |

| DC system | 6415 | 8302 | 11,364 | |

| Number of public charging stations | AC system | 7290 | 9434 | 12,914 |

| DC system | 3207 | 4151 | 5682 |

| Component | Manufacturer | Notation | Ref. | Number of Components | ||

|---|---|---|---|---|---|---|

| 3.7 kW | 22 kW 1 | 50 kW 1 | ||||

| Coil (mains side) | Fastron Group | TLC/10A-100M-00 | [76] | 2 | 4 | 8 |

| Coil (inverter side) | Fastron Group | TLC/10A-471M-00 | [76] | 2 | 4 | − |

| Coil (inverter side) | Fastron Group | TLC/10A-331M-00 | [76] | − | − | 8 |

| Capacitor | ICAR | MKP-B1X-8-48 | [77] | 2 | 4 | 6 |

| Component | Manufacturer | Notation | Ref. | Number of Components | ||

|---|---|---|---|---|---|---|

| 3.7 kW | 22 kW 1 | 50 kW 1 | ||||

| MOSFET | Infineon | IPW60R045CP | [78] | 2 | 2 | 4 |

| Diode | Infineon | IDW40G65C5B | [79] | 6 | 6 | 12 |

| Capacitor | Murata | KC355WD72J474MH01# | [80] | 2 | 2 | 4 |

| Coil | Epcos | EELP 58 Core | [81] | 2 | 2 | 4 |

| Component | Manufacturer | Notation | Ref. | Number of Components | ||

|---|---|---|---|---|---|---|

| 3.7 kW | 22 kW 1 | 50 kW 1 | ||||

| MOSFET | Infineon | IPW65R045C7 | [84] | 4 | 8 | 20 |

| Diode | Infineon | IDW40G65C5B | [79] | 4 | 8 | 20 |

| Capacitor | Murata | KC355WD72J474MH01# | [80] | 2 | 4 | 10 |

| Coil | Epcos | EELP 64 Core | [81] | 1 | 2 | 5 |

| Unit | Charging Power in Kw | |||

|---|---|---|---|---|

| 22 | 50 | |||

| Dimensions | Height | m | 1.5 | 2 |

| Width | m | 0.4 | 0.85 | |

| Depth | m | 0.24 | 1 | |

| Impact Category | Abbreviation | Unit |

|---|---|---|

| Water depletion | WD | m3 |

| Urban land occupation | ULO | m2a |

| Terrestrial ecotoxicity | TET | kg 1,4-DCB-eq. |

| Terrestrial acidification | TA | kg SO2-eq. |

| Photochemical oxidant formation | POF | kg NMVOC |

| Particulate matter formation | PMF | kg PM10-eq. |

| Ozone depletion | OD | kg CFC-11-eq. |

| Natural land transformation | NLT | m2 |

| Mineral resource depletion | MRD | kg Fe-eq. |

| Marine eutrophication | ME | kg N-eq. |

| Marine ecotoxicity | MET | kg 1,4-DCB-eq. |

| Ionizing radiation | IR | kg U235-eq. |

| Human toxicity | HT | kg 1,4-DCB-eq. |

| Freshwater eutrophication | FE | kg P-eq. |

| Freshwater ecotoxicity | FET | kg 1,4-DCB-eq. |

| Fossil resource depletion | FD | kg oil-eq. |

| Climate change | CC | kg CO2-eq. |

| Agricultural land occupation | ALO | m2a |

| Impact Category | Absolute Reductions | ||

|---|---|---|---|

| Scenario S | Scenario M | Scenario L | |

| CC | |||

| HT | |||

| MRD | |||

| NLT | |||

| POF | |||

| Parameter | Original Value | Interval | Iterations | Impact On |

|---|---|---|---|---|

| Emission intensity of the production of power electronics | 100% | [80%;120%] | 20 | Production |

| Degree of utilization | 10% | [5%;25%] | 20 | Production |

| Efficiency | 90% | [80%;100%] | 20 | Production and use phase |

| Ratio of charging at home/non-public charging | 70% | [60%;80%] | 20 | Production and use phase |

| Parameter | Unit | System | |

|---|---|---|---|

| Charging power | kW | 22 | 50 |

| Charging points (for each charging station) | Pieces | 2 | 2 |

| Hardware | EUR | 2500 | 3000 |

| Grid connection cost | EUR | 2000 | 10,000 |

| Permission and planning | EUR | 1000 | 3000 |

| Montage, construction cost and signage | EUR | 2000 | 7000 |

| Total investment cost | EUR | 7500 | 50,000 |

| Current cost | EUR/a | 750 | 3000 |

| Interest rate | % | 5 | 5 |

| Life span | a | 10 | 10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kabus, M.; Nolting, L.; Mortimer, B.J.; Koj, J.C.; Kuckshinrichs, W.; De Doncker, R.W.; Praktiknjo, A. Environmental Impacts of Charging Concepts for Battery Electric Vehicles: A Comparison of On-Board and Off-Board Charging Systems Based on a Life Cycle Assessment. Energies 2020, 13, 6508. https://doi.org/10.3390/en13246508

Kabus M, Nolting L, Mortimer BJ, Koj JC, Kuckshinrichs W, De Doncker RW, Praktiknjo A. Environmental Impacts of Charging Concepts for Battery Electric Vehicles: A Comparison of On-Board and Off-Board Charging Systems Based on a Life Cycle Assessment. Energies. 2020; 13(24):6508. https://doi.org/10.3390/en13246508

Chicago/Turabian StyleKabus, Mona, Lars Nolting, Benedict J. Mortimer, Jan C. Koj, Wilhelm Kuckshinrichs, Rik W. De Doncker, and Aaron Praktiknjo. 2020. "Environmental Impacts of Charging Concepts for Battery Electric Vehicles: A Comparison of On-Board and Off-Board Charging Systems Based on a Life Cycle Assessment" Energies 13, no. 24: 6508. https://doi.org/10.3390/en13246508

APA StyleKabus, M., Nolting, L., Mortimer, B. J., Koj, J. C., Kuckshinrichs, W., De Doncker, R. W., & Praktiknjo, A. (2020). Environmental Impacts of Charging Concepts for Battery Electric Vehicles: A Comparison of On-Board and Off-Board Charging Systems Based on a Life Cycle Assessment. Energies, 13(24), 6508. https://doi.org/10.3390/en13246508