Optimization of Pump Turbine Closing Operation to Minimize Water Hammer and Pulsating Pressures During Load Rejection

Abstract

:1. Introduction

2. Hydraulic Transient Simulation with Pulsating Pressure Estimation

2.1. Pipeline System Model

2.2. Pump Turbine Model

2.3. Ball Valve Model

2.4. Estimating Dynamic Pulsating Pressures

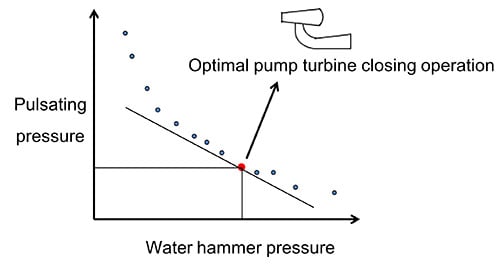

3. Formulations for Optimization of Pump Turbine Closing Process

3.1. Closing Strategies

3.2. Objective Functions

3.3. Constraints

3.4. Evolutionary Algorithms

4. Results and Discussion

4.1. System Specification of the PSP and Field Tests

4.2. Case 1: Single-Objective Optimization of Single Load Rejection Scenario

4.3. Case 2: Single-Objective Optimization of Two Load Rejection Scenarios

4.4. Case 3: Multi-Objective Optimization of Two Load Rejection Scenarios

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Rehman, S.; Al-Hadhrami, L.M.; Alam, M.M. Pumped hydro energy storage system: A technological review. Renew. Sust. Energy Rev. 2015, 44, 5865–5898. [Google Scholar] [CrossRef]

- Mitchell, C. Momentum is increasing towards a flexible electricity system based on renewables. Nat. Energy 2016, 1, 15030. [Google Scholar] [CrossRef]

- Chazarra, M.; Pérez-Díaz, J.I.; García-González, J.; Praus, R. Economic viability of pumped-storage power plants participating in the secondary regulation service. Appl. Energy 2018, 216, 224–233. [Google Scholar] [CrossRef]

- Cavazzini, G.; Covi, A.; Pavesi, G.; Ardizzon, G. Analysis of the unstable behavior of a pump-turbine in turbine mode: Fluid-dynamical and spectral characterization of the S-shape characteristic. J. Fluids Eng. Trans. ASME 2015, 138, 021105. [Google Scholar] [CrossRef]

- Zeng, W.; Yang, J.; Guo, W. Runaway instability of pump-turbines in S-shaped regions considering water compressibility. J. Fluids Eng. Trans. ASME 2015, 137, 051401. [Google Scholar] [CrossRef]

- Wang, Z.; Zhu, B.; Wang, X.; Qin, D. Pressure Fluctuations in the S-Shaped Region of a Reversible Pump-Turbine. Energies 2017, 10, 96. [Google Scholar] [CrossRef] [Green Version]

- Zuo, Z.; Fan, H.; Liu, S.; Wu, Y. S-shaped characteristics on the performance curves of pump-turbines in turbine mode—A review. Renew. Sust. Energy Rev. 2016, 60, 836–851. [Google Scholar] [CrossRef]

- Tanaka, H. Vibration Behavior and Dynamic Stress of Runners of Very High Head Reversible Pump-turbines. Int. J. Fluid Mach. Syst. 2011, 4, 289–306. [Google Scholar] [CrossRef]

- Vakil, A.; Firoozabadi, B. Investigation of Valve-Closing Law on the Maximum Head Rise of a Hydropower Plant. Sci. Iran. Trans. B Mech. Eng. 2009, 16, 2222–2228. [Google Scholar]

- Zhang, C.; Yang, J. Study on Linkage Closing Rule between Ball Valve and Guide Vane in High Head Pumped Storage Power Station. Water Resour. Power 2011, 29, 128–131. [Google Scholar]

- Zeng, W.; Yang, J.; Hu, J.; Yang, J. Guide-Vane Closing Schemes for Pump-Turbines Based on Transient Characteristics in S-shaped Region. J. Fluids Eng. 2016, 138, 051302. [Google Scholar] [CrossRef]

- Zhao, Z.; Yang, J.; Yang, W.; Hu, J.; Chen, M. A coordinated optimization framework for flexible operation of pumped storage hydropower system: Nonlinear modeling, strategy optimization and decision making. Energy Convers. Manag. 2019, 194, 75–93. [Google Scholar] [CrossRef]

- Zhou, J.; Wu, Y.; Xu, Y.; Zheng, Y. Research on optimization method of pumped-storage units guide vane closing law. J. Huazhong Univ. Sci. Technol. (Nat. Sci. Ed.) 2017, 45, 123–127. [Google Scholar]

- Zhou, J.; Xu, Y.; Zheng, Y.; Zhang, Y. Optimization of guide vane closing schemes of pumped storage hydro unit using an enhanced multi-objective gravitational search algorithm. Energies 2017, 10, 911. [Google Scholar] [CrossRef]

- Lai, X.; Li, C.; Zhou, J.; Zhang, N. Multi-objective optimization of the closure law of guide vanes for pumped storage units. Renew. Energy 2019, 139, 302–312. [Google Scholar] [CrossRef]

- Xia, L.; Cheng, Y.; Cai, F. Pressure Pulsation Characteristics of a Model Pump-turbine Operating in the S-shaped Region: CFD Simulations. Int. J. Fluid Mach. Syst. 2017, 10, 2872–2895. [Google Scholar] [CrossRef] [Green Version]

- Hu, J.; Yang, J.; Zeng, W.; Yang, J. Transient Pressure Analysis of a Prototype Pump Turbine: Field Tests and Simulation. J. Fluids Eng. 2018, 140, 071102. [Google Scholar] [CrossRef]

- Yang, J.; Yang, J.; Wang, C.; Bao, H. Simulation of pressure fluctuation of a pump turbine in load rejection. J. Hyroelectr. Eng. 2014, 33, 2862–2894. [Google Scholar]

- Chaudhry, M.H. Applied Hydraulic Transients; Springer: New York, NY, USA, 2014. [Google Scholar]

- Li, X.; Tang, X.; Shi, X.; Chen, H.; Li, C. Load rejection transient with joint closing law of ball-valve and guide vane for two units in pumped storage power station. J. Hydroinf. 2017, 20, 3013–3015. [Google Scholar] [CrossRef] [Green Version]

- Journal of Fluids EngineeringWylie, E.B.; Streeter, V.L.; Suo, L. Fluid Transients in Systems; Prentice-Hall: Englewood Cliffs, NJ, USA, 1993. [Google Scholar]

- Karney, B.W.; Ghidaoui, M.S. Flexible discretization algorithm for fixed-grid MOC in pipelines. J. Hydraul. Eng. 1997, 123, 1004–1011. [Google Scholar] [CrossRef]

- Zhou, J.; Zhao, Z.; Zhang, C.; Li, C.; Xu, Y. A real-time accurate model and its predictive fuzzy PID controller for pumped storage unit via error compensation. Energies 2017, 11, 35. [Google Scholar] [CrossRef] [Green Version]

- Hu, W.; Wu, B.; Ling, H. An Automatic Method for Contour Interpolation in Map Design. Available online: http://en.cnki.com.cn/Article_en/CJFDTotal-JSJX200008010.htm (accessed on 23 February 2020).

- Mousavi, S.J.; Shourian, M. Capacity optimization of hydropower storage projects using particle swarm optimization algorithm. J. Hydroinf. 2009, 12, 2752–2791. [Google Scholar] [CrossRef]

- Fu, W.; Tan, J.; Zhang, X.; Chen, T.; Wang, K. Blind Parameter Identification of MAR Model and Mutation Hybrid GWO-SCA Optimized SVM for Fault Diagnosis of Rotating Machinery. Complexity 2019, 2019, 17. [Google Scholar] [CrossRef]

- Li, F.-F.; Qiu, J. Incorporating ecological adaptation in a multi-objective optimization for the Three Gorges Reservoir. J. Hydroinf. 2015, 18, 5645–5678. [Google Scholar] [CrossRef]

- Meniconi, S.; Brunone, B.; Mazzetti, E.; Laucelli, D.B.; Borta, G. Hydraulic characterization and transient response of pressure reducing valves: Laboratory experiments. J. Hydroinf. 2017, 19, 798–810. [Google Scholar] [CrossRef]

- Boeringer, D.W.; Werner, D.H. Particle swarm optimization versus genetic algorithms for phased array synthesis. IEEE Trans. Antennas Propag. 2004, 52, 7717–7779. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 1821–1897. [Google Scholar] [CrossRef] [Green Version]

| Upstream Reservoir Water Level (m) | Downstream Reservoir Water Level (m) | Runner inlet Diameter (m) | Rated Head (m) | Rated Flow (m3/s) | Rated Speed (r/min) | Rated Load (MW) |

|---|---|---|---|---|---|---|

| 751.57 | 223.54 | 3.86 | 532.74 | 62.75 | 500 | 300 |

| Index | Requirement |

|---|---|

| Maximum pressure at the spiral case | 820 m |

| Minimum pressure at the draft tube | 12.0 m |

| Maximum relative speed rise | 45% |

| Maximum water level of the upstream surge tank | 770.00 m |

| Minimum water level of the upstream surge tank | 700.00 m |

| Maximum water level of the downstream surge tank | 245.00 m |

| Minimum water level of the downstream surge tank | 180.00 m |

| Maximum Relative Rotational Speed | Maximum Total Pressure at the Spiral Case (m) | Minimum Total Pressure at the Draft Tube (m) | |

|---|---|---|---|

| Measured | 132% | 739.1 | 49.1 |

| Predicted | 129% | 733.3 | 51.6 |

| Absolute error | 3% | 5.8 | 2.5 |

| Subcases | GVCS | BVCS |

|---|---|---|

| Subcase 1.1 | Two-stage | Not closed |

| Subcase 1.2 | Three-stage | Not closed |

| Subcase 1.3 | Two-stage | Two-stage |

| Subcase 1.4 | Three-stage | Two-stage |

| Scheme | Two-Stage | Three-Stage | ||||

|---|---|---|---|---|---|---|

| 1 | 630.3 | 99.7 | 0.5 | 625.7 | 91.5 | 0.5000 |

| 3 | 641.9 | 97.8 | 0.4928 | 632.4 | 90.8 | 0.4975 |

| 5 | 657.7 | 96.0 | 0.4667 | 641.9 | 89.4 | 0.5015 |

| 7 | 668.1 | 95.1 | 0.4438 | 647.9 | 88.8 | 0.4969 |

| 9 | 672.2 | 93.9 | 0.4528 | 663.1 | 87.4 | 0.4835 |

| 11 | 675.9 | 88.4 | 0.5452 | 663.4 | 87.4 | 0.4829 |

| 13 | 683.1 | 86.6 | 0.5516 | 664.0 | 87.3 | 0.4823 |

| 15 | 685.3 | 86.3 | 0.5495 | 664.1 | 87.3 | 0.4824 |

| 17 | 688.8 | 85.7 | 0.5482 | 669.2 | 86.7 | 0.4810 |

| 19 | 691.2 | 85.1 | 0.5500 | 669.3 | 86.7 | 0.4809 |

| 21 | 691.8 | 85.0 | 0.5507 | 670.0 | 86.6 | 0.4804 |

| 23 | 692.1 | 84.8 | 0.5525 | 670.2 | 86.6 | 0.4812 |

| 25 | 692.6 | 84.7 | 0.5530 | 670.8 | 86.5 | 0.4815 |

| 27 | 693.2 | 84.5 | 0.5547 | 674.1 | 86.2 | 0.4785 |

| 29 | 695.9 | 84.0 | 0.5532 | 678.8 | 85.5 | 0.4819 |

| 31 | 697.0 | 83.8 | 0.5525 | 685.7 | 84.2 | 0.4921 |

| 33 | 698.6 | 83.6 | 0.5513 | 696.5 | 81.8 | 0.5221 |

| 35 | 703.8 | 82.3 | 0.5558 | 699.0 | 81.0 | 0.5367 |

| 37 | 708.6 | 81.2 | 0.5588 | 703.7 | 79.8 | 0.5518 |

| 39 | 712.7 | 80.1 | 0.5650 | 710.7 | 78.0 | 0.5787 |

| 41 | 719.2 | 78.1 | 0.5784 | 714.7 | 76.5 | 0.6060 |

| 43 | 725.8 | 76.7 | 0.5822 | 720.3 | 75.2 | 0.6211 |

| 44 | 728.7 | 75.3 | 0.5970 | 725.7 | 74.8 | 0.6140 |

| 46 | 735.8 | 74.3 | 0.5902 | 736.3 | 74.0 | 0.5987 |

| 48 | 749.1 | 74.3 | 0.5388 | 758.9 | 73.5 | 0.5353 |

| 50 | 760.0 | 74.1 | 0.5000 | 769.4 | 73.4 | 0.5000 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, J.; Zeng, W.; Zhao, Z.; Yang, J.; Yang, J. Optimization of Pump Turbine Closing Operation to Minimize Water Hammer and Pulsating Pressures During Load Rejection. Energies 2020, 13, 1000. https://doi.org/10.3390/en13041000

Ye J, Zeng W, Zhao Z, Yang J, Yang J. Optimization of Pump Turbine Closing Operation to Minimize Water Hammer and Pulsating Pressures During Load Rejection. Energies. 2020; 13(4):1000. https://doi.org/10.3390/en13041000

Chicago/Turabian StyleYe, Jiawei, Wei Zeng, Zhigao Zhao, Jiebin Yang, and Jiandong Yang. 2020. "Optimization of Pump Turbine Closing Operation to Minimize Water Hammer and Pulsating Pressures During Load Rejection" Energies 13, no. 4: 1000. https://doi.org/10.3390/en13041000

APA StyleYe, J., Zeng, W., Zhao, Z., Yang, J., & Yang, J. (2020). Optimization of Pump Turbine Closing Operation to Minimize Water Hammer and Pulsating Pressures During Load Rejection. Energies, 13(4), 1000. https://doi.org/10.3390/en13041000