3.1. Eco-Indicator 99

Table 2 presents the results of characterizing the environmental consequences occurring in the life cycle of selected components of the 1 megawatt photovoltaic power plant. Impacts are presented in the 11 categories of impact characteristic of the Eco-indicator 99 method. Two impact models were distinguished: the first one was the life cycle, including landfill disposal as a form of post-disposal management, while the second one was recycling. For all adverse effects in the area of human health, all tested groups showed the highest negative impact on the category of inorganic compounds causing respiratory diseases (e.g., life cycle of photovoltaic panels with landfill: 0.22 DALY; inverter life cycle with storage: 0.14 DALY). The largest quantity is formed at the stage of production of materials and elements, and the maximum share is characterized by sulfur dioxide and nitrogen oxides. These compounds are poisonous to humans and animals and have a harmful effect on plants. Sulfur dioxide is a by-product of burning fossil fuels, which, for example, contributes to atmospheric pollution (smog). In turn, nitrogen oxide is a compound with high biological activity and easily penetrates biological membranes. It is also created, among other things, as a result of burning fossil fuels and industrial processes that can cause smog. For categories affecting environmental deterioration, the ecotoxic compounds category was the most important, for which the maximum level of harmful impact was recorded for photovoltaic panels deposited in landfill: 137,741 PAF·m

2/a. Ecotoxic compounds are substances which, due to their origin, chemical, biological or other properties, constitute or may pose a direct or delayed threat to humans, animals and plants. In the life cycle of a photovoltaic power plant, the largest amount arises from the storage of materials and components at the landfill. A particular threat is copper ion emissions, which in addition to reducing the quality of the environment, can contribute to the formation of diseases of the nervous and digestive systems in humans (for example: mental disorders or liver damage). In the area of processes affecting the depletion of raw material resources, the highest level of harmful impact was recorded in the raw materials category for the life cycle of electrical installations with post-consumer use in the form of landfill (322,646 MJ), and in the fossil fuels category for the life cycle of photovoltaic panels placed in landfill after use (400,584 MJ). The largest amount of fossil fuels is consumed during the plastics and materials plant production phase. The most processes with the highest energy demand include, for e.g., the production of PV cells. Burning of conventional fuels is associated with many hazardous emissions to the atmosphere, water and soil, which are the causes of, for examplem, diseases, increasing the greenhouse effect, ozone layer depletion or increased smog and acid rain. In most of the categories considered, there is a positive impact of the use of recycling processes, to reduce the harmful impact of particular groups of components of the analyzed photovoltaic power plant.

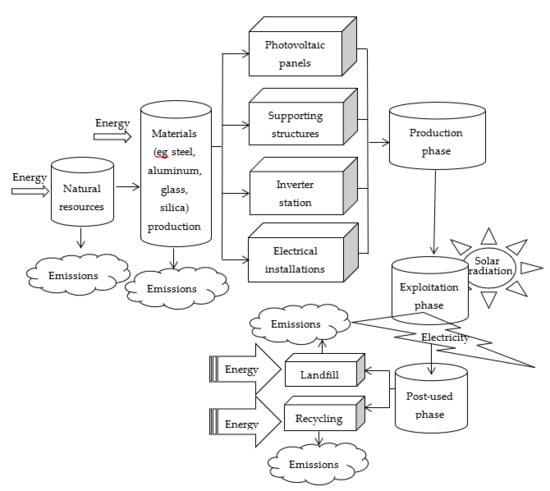

The results of grouping and weighting the environmental after-effects of the existence of selected groups of 1 MW photovoltaic power plants are summarized in

Table 3. For the life cycle of photovoltaic panels deposited in landfill, the highest level of harmful impact was recorded in terms of: fossil fuel extraction (9534 Pt), inorganic compounds causing respiratory diseases (5729 Pt), mining of minerals (1621 Pt) and carcinogenic compounds (1822 Pt). Silicon cell production processes are associated with a huge demand for energy, which in the case of the analyzed power station is about 5 million MJ. This energy is most often obtained from non-renewable sources, which causes many negative impacts in relation to human and animal health, and a reduction in the quality of the environment. Another problem is the excessive exploitation of raw material deposits, including silver, used in the electrical contacts of the cells, whose extraction causes the most negative consequences in comparison to other substances and chemical compounds used in the production of PV cells. For the life cycle of supporting structures, including post-use disposal, the categories were: ecotoxic compounds (832 Pt), carcinogenic compounds (827 Pt), and fossil fuel extraction (606 Pt). Supporting structures were made mainly of galvanized steel. The galvanizing process of steel poses a threat to health and the environment. In thermal processes, smoke and zinc vapors (especially particles smaller than 1 µm) can, for example, get into the respiratory system, causing many diseases. In the life cycle of the inverter station including landfill disposal, the highest levels of negative impact were reported in terms of: inorganic compounds causing respiratory disease (3725 Pt), and fossil fuel extraction (1887 Pt). In the cycle of existence of an electrical installation, which after ending its life cycle will be deposited in landfill, the most negative influence on the environment was attributed to mineral extraction (7679 Pt) and inorganic compounds causing respiratory diseases (1327 Pt). An important element found in both inverter station and electrical installation are electrical cables and wires. The main raw material for their production is copper, the extraction and processing of which is associated with very high energy inputs, obtained from conventional sources. As a consequence, many harmful compounds are emitted into the environment, and the resources of raw materials and fuels are depleted. The application of recycling would reduce the harmful impact on the environment of all analyzed groups of photovoltaic elements.

The highest total level of harmful impact on the environment is the life cycle of photovoltaic panels ending in landfill storage (22,029 Pt), but in this case, the use of recycling processes significantly reduces their negative impact on the environment. The key reason for this is the abovementioned very high energy demand in the production of PV cells. Reuse of cells recovered in the recycling process is associated with large savings in both energy and materials (e.g., elimination of significant material losses arising during cutting silicon rollers). The lowest total damaging effect was found in the supporting structures (1089 and 3197 Pt) (

Figure 4).

The highest level of harmful impact on the environment of 1 MW photovoltaic power plant was observed at the manufacturing stage. The largest category of harmful effects was characterized by the categories of fossil fuel extraction and minerals, while the smallest – compounds causing the increase of the ozone hole. The largest share in the negative impact on the environment was characterized by the production processes of PV panels, which are part of the photovoltaic power plant with the highest demand for energy and materials. The lowest level of negative impact was the exploitation stage (32 Pt total). By comparing the received forms of post-use management, the most negative influence on the environment is the landfill. Carcinogenic compounds and ecotoxic compounds can be classified as the most potent adverse effects. The use of recycling processes would reduce the impact of the life cycle in most of the impact categories analyzed. The fossil fuel mining processes and emissions of inorganic compounds affecting respiratory diseases would be most positively affected (

Figure 5).

Post-use disposal of photovoltaic power plant components could be the most important source of oncogenic factors contributing to the development of cancer by mutation of genetic material. The highest level of harmful emissions was recorded for cadmium ions (2547 Pt). Cadmium is an element that easily concentrates in air, water and soil and quickly moves in the soil–plant–human trophic chain. Due to easy absorption and bioaccumulation in living organisms and toxic influence, it is one of the most serious threats to the natural environment and man. For this reason, it is important to minimize the storage of materials and components of solar power plants in landfills. The production phase also has a significant impact on the carcinogenic emissions—538 Pt total—and the highest share of arsenic: 363 Pt. The use of recycling would reduce the harmful impact of carcinogens by a total of 824 Pt, mainly in the range of arsenic (-514 Pt) (

Table 4).

The production stage is distinguished by the highest level of negative impact in organic compounds causing respiratory diseases, altogether 11 Pt, especially in the emissions of non-methane volatile organic compounds (10 Pt). NMVOC is a group of organic compounds that occur as by-products in many industrial processes and are a source of environmental pollution, including, for example: acetone (paints, protective covers, sealants), aliphatic hydrocarbons (paints, glues, sealants, combustion processes), aromatic hydrocarbons (paints, glues, combustion processes), polycyclic aromatic hydrocarbons (paints, polymeric materials, incomplete combustion processes, e.g., car exhaust gas) or chlorine-containing compounds (varnishes, solvents). During storage of the power plant components in landfill, biogenic methane may be the greatest risk: 1 Pt. Recycling processes would reduce the damaging impact of the total lifetime by 17 Pt, including non-methane volatile organic compounds by 16 Pt (

Table 5).

The highest level of harmful impact on the environment of respiratory organisms caused by respiratory diseases occurring during the 1 MW photovoltaic power plant cycle was recorded for the production stage–10,837 Pt in total. The highest share was in sulfur dioxide (3194 Pt) and nitrogen oxide (3091 Pt). Recycling would allow a total reduction of harmful effects of 7423 Pt, mainly in the sulfur oxide (-3274 Pt) and particulates in total (-2521 Pt). A key negative health role is played by atmospheric aerosols or particulate matter (PM). They are drops or solid particles of natural or anthropogenic origin (impurities). PM 2.5 (particle size 2.5 µm or smaller) is the most harmful because prolonged exposure to it results in a reduction in life expectancy, while short-term exposure to high concentrations causes an increase in deaths from respiratory and circulatory diseases and increases the risk of emergencies that require hospitalization (for example: worsening of asthma, decreased lung function), because dust enters the blood directly through the lungs. Atmospheric aerosols also contribute to smog (

Table 6).

The highest level of emissions of substances causing climate change is the production of materials, and components, which results in a total of 2049 Pt, mainly composed of carbon dioxide (891 Pt). Over the past two centuries there has been a marked acceleration of climate change. The basic factor shaping the speed of these changes is the emission of carbon dioxide and other greenhouse gases, which arise, for example: during the exploitation of fossil fuels, used in the life cycle of a photovoltaic power plant most often for obtaining electricity for various processes, including the energy most intensive—PV cell production. Landfill disposal can result in total negative emissions of 292 Pt, primarily biogenic methane (201 Pt). Recycling, as a form of post-use management, would allow the reduction of dangerous emissions by a total of 2685 Pt, mainly in carbon dioxide (-1947 Pt) (

Table 7).

Radioactive compounds are characterized by possessing nuclear nuclei with radioactive decay, most commonly associated with alpha particle emission, beta particles, and gamma radiation. The highest number of such elements in the 1 MW photovoltaic power plant cycle was noted for the production phase (total 28 Pt). It is associated with the processes of extracting mineral resources and fossil fuels, during which there are not only emissions of dust and gases containing many harmful substances (e.g., sulfur and nitrogen oxides, chlorine, fluorine, heavy metals), but also radioactive elements such as uranium, thorium, and potassium, and their breakdown products, for example: radium and radon. In this case, these are mainly radon isotopes—

222Ra (21 Pt)—and carbon—

14C (7 Pt) (

Table 8).

The ozone hole is a phenomenon of a decrease in the concentration of ozone (O

3) in the stratosphere, resulting in a decrease in the level of absorption of ultraviolet radiation reaching the Earth from the Sun. It is, therefore, a threat to living organisms. During the processes of producing materials, and components of the plant under investigation, harmful substances causing the ozone hole to increase in total 2 Pt are formed, mainly bromotrifluoromethane (1,5 Pt). Halon 1301 may have a toxic effect on the central nervous system and other bodily functions (

Table 9).

Comparing all phases of the life cycle, particularly high levels of harmful impact of waste disposal in the form of waste landfills are visible in the category of ecotoxic compounds (a total of 1503 Pt). The most significant level of negative emissions was copper ions (1200 Pt). The high level of emissions of ecotoxic substances is also characterized by the production phase (total 837 Pt), which consists mainly of the harmful effects of nickel (280 Pt) and zinc (263 Pt). Recycling could significantly reduce emissions by a total of -397 Pt, primarily in terms of minimizing the negative impact of nickel (-212 Pt). Nickel is used in the manufacture of many materials and components of a photovoltaic power plant, ranging from steel elements to resistors. The main source of nickel in the environment is the combustion of conventional fuels (especially coal and oil), as well as steel production and electroplating processes. The absorption of nickel into the body is primarily through the respiratory system. Nickel tends to accumulate in the lungs. With wind and rain, it gets into soil and groundwater. It is also one of the components of smog (

Table 10).

Acidification of the environment is a phenomenon of progressive decrease in the pH value of its individual components. It can be caused by anthropopressure, for example: by emissions of air pollutants (e.g., SO

2, NO

x, NH

3) as a result of combustion of conventional fuels. Eutrophication, on the other hand, consists of enriching the environment with biophilic elements, mainly phosphorus, which causes an excessive increase in their trophic (biological productivity). Materials and elements of a 1 megawatt photovoltaic power plant can be distinguished primarily by nitrogen oxide (596 Pt) and sulfur dioxide (182 Pt). The total negative impact of the production stage is 975 Pt. Recycling processes would minimize harmful emissions by a total of 502 Pt, including 314 Pt for nitrogen oxide and 187 for sulfur oxide (

Table 11).

The highest level of negative impact of land use category was characterized by the production stage (total of 1551 Pt), including primarily the processes related to the transformation to mineral extraction site (338 Pt). A significantly lower level of adverse impact is the potential for landfill disposal—a total of 35 Pt. Extraction of mineral resources is an area of economic activity with one of the highest harmful impacts on human health and the quality of the environment. It is associated with environmental destruction, especially serious in the case of open pit mines. It is characterized by the consumption of huge amounts of water, often causing shortages, and at the same time results in the contamination of surface and groundwater, as well as a reduction in their level by up to several meters (

Table 12).

Economic development entails an increase in demand for various types of natural resources, resulting in the depletion of non-renewable resources. Although their deposits are limited, their exploitation continues to grow. The stage of production of 1 megawatt photovoltaic power plant, characterized by the highest value of harmful influence in the mineral mining sector, is the production phase (total 9453 Pt), mainly in the field of tin mining (6610 Pt) and copper (2230 Pt). Due to its physical and chemical properties, tin is very important for industry. Its use in the metallurgical industry is the largest. In addition, this element is used for solders alloys. Tin is also used to coat other metals, e.g., steel, with a thin anti-corrosive layer. Recycling would minimize the pervasive effects analyzed, a total of 1889 Pt, mainly in the field of bauxite mining (-1835 Pt) (

Table 13).

The highest level of harmful impacts in the category of fossil fuel extraction processes is characterized by a production phase (total of 12,159 Pt), which consists primarily of processes related to extraction of natural gas (5509 Pt) and crude oil (2366 Pt). This is connected to the high energy demand of production processes, in particular PV cells. Recycling as a form of post-disposal management would reduce several adverse effects by a total of 10,095 Pt, mainly in the oil-related processes (-7794 Pt). However, landfill disposal would result in an increase in the unfavorable impact on the life cycle of the tested power plant by 137 Pt (

Table 14).

3.5. Other Energy Sources

Using the databases available in the SimaPro software and calculations made previously for a 1 MW photovoltaic power plant, a comparison was made of the environmental impact of the processes of obtaining electricity from photovoltaics with selected, commonly used conventional energy sources and with the structure of the mixed energy characteristic of Poland, mainly based on hard and brown coal (approximately 80%).

The analyzed photovoltaic power station, during its 20-year life cycle, is able to produce about 20,000 MWh of electricity, which value was taken as a reference value. The degree of impact on the surroundings resulting from the combustion of an amount of hard coal, brown coal, and heating oil necessary to obtain the same amount of electricity was analyzed. In addition, an analogous analysis was carried out when 20,000 MWh of energy was obtained in Poland.

Table 15 summarizes the results of the characterization of the environmental after-effects arising from the generation of 20,000 MWh of electricity from the selected energy sources. The highest level of harmful impact of the analyzed energy sources is visible in the area of emissions of compounds having a negative impact on the quality of the environment (category: ecotoxic compounds, compounds causing acidification/eutrophication, land use) and in processes related to the depletion of raw material resources (categories: mineral extraction, extraction of fossil fuels). This is characteristic of energy extraction processes, especially from conventional sources.

The results of grouping and weighting environmental consequences arising as a result of generating 20,000 MWh of electricity from selected energy sources are presented in

Table 16. The highest value of harmful impact on the environment was noted in the following categories: inorganic compounds causing respiratory diseases (from 3437 to 357,703 Pt), compounds that cause climate change (from 2351 to 163,556 Pt), and the extraction of fossil fuels (from 2198 to 246,591 Pt).

The highest total level of harmful impact on the environment was from the production of 20,000 MWh of electricity was determined to be from hard coal (709,17 Pt) and brown coal (633,445 Pt). A high degree of negative impact on the environment was also noted for the Polish energy mix (683,220 Pt), due to the fact that it is mainly based on the burning of brown and hard coal. Obtaining energy from solar radiation possessed the lowest level of adverse impact on the environment, with this type of installation exerting an impact from 13,997 (recycling) to 42,492 Pt (storage) throughout its entire life cycle, depending on the form of post-use management. Despite some expenditure of energy and materials in the production and post-use management phase, the use of a renewable energy source, i.e., photovoltaics, causes the least negative environmental consequences compared to conventional energy sources (

Figure 9).

Additionally, the amount of greenhouse gas emissions resulting from the production of 20,000 MWh of electricity was analyzed from the same energy sources using the IPCC method. The highest level of GHG emissions was found when obtaining energy from natural gas (29,989 Mg CO

2 eq), hard coal (22,872 Mg CO

2 eq), and brown coal (22,241 Mg CO

2 eq). In the case of photovoltaic power plants, the emission level was the lowest and amounted to about 400 Mg CO

2 eq. The obtained results confirm that photovoltaic power plants can be a source of energy enabling the reduction of greenhouse gas emissions, and hence are one of the ways of reducing the greenhouse effect (

Figure 10).

As a result of these considerations it was found that the total highest level of harmful impact on the environment is the life cycle of post-consumer photovoltaic panels when stored in landfill (22,029 Pt). The largest amount of greenhouse gases generated during the post-consumer life cycle of photovoltaic panels is from storage in landfill (269,099 kg CO2 eq). The greatest amount of energy absorbed during the life cycle of photovoltaic panels is from the use of this form of storage—nearly 5 million MJ. The use of recycling processes reduces the energy consumption of all groups of components of the power plant in question. Silver, nickel, copper, PA 6, lead, and cadmium are among the materials with the most harmful influence on the environment.

An additional element of the analysis was the comparison of the environmental impact of the processes of obtaining electricity from photovoltaics with selected, most commonly used conventional energy sources and with the structure of the mixed energy characteristic of Poland, which is mainly based on hard and brown coal (approximately 80%). The highest level of harmful impact of the analyzed energy sources is visible in the area of compound emissions: ecotoxic (2,671,933 PAF·m2/a brown coal), compounds causing acidification/eutrophication (335,746 PAF·m2/a hard coal), land use (192,997 PAF·m2/a hard coal) and within processes related to the depletion of raw material resources includes: mineral extraction (398,914 MJ PV power plant (landfill)), and extraction of fossil fuels (10,360,976 MJ heating oil).