A Building Life-Cycle Embodied Performance Index—The Relationship between Embodied Energy, Embodied Carbon and Environmental Impact

Abstract

:1. Introduction

2. Background and Terminology

2.1. Embodied Carbon

2.2. Embodied Energy

2.3. Embodied Environmental Impact

2.4. Current Status of Research

3. Method and Materials

3.1. Life-Cycle Embodied Performance (LCEP)

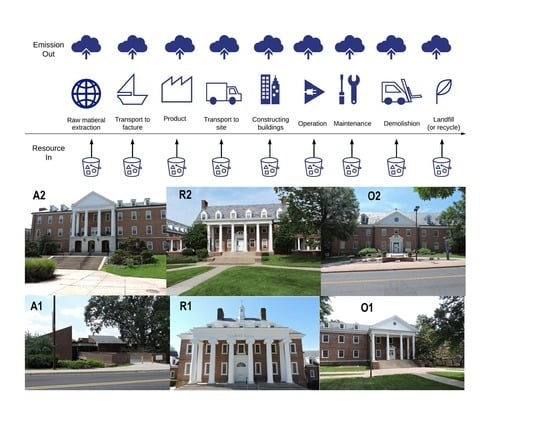

3.2. Case Project Specification

3.3. Data Collection

- Original construction documents and renovation documents (if any), provided by facility managers.

- Field measurements by the research team.

- Existing data on material quantities and embodied carbon dioxide are extracted and gathered from literature.

- New LCI data on new materials is obtained through leading practitioners, from major AEC companies, working with authors.

- The open-source Inventory of Carbon and Energy database from the University of Bath was published in 2008. (It is currently the most frequently used embodied carbon database in this industry, due to its comprehensive summary of the best available embodied carbon data [37]).

3.4. System, Boundaries, Building Models and Software

3.5. Statistical Analyses

4. Analysis Findings

4.1. Correlation between Embodied Energy and Embodied Carbon

4.2. Correlation between Environmental Impact and LCEP

4.3. Building Components and Materials’ Contribution

5. Discussion and Conclusions

- Ozone depletion potential may be usable as an indicator to predict the value of LCEP

- Using LCEE and LCEC independently from each other can lead to incomplete assessments

- Regardless of the large variation in the performance of different building types, building exterior assemblies, particularly exterior walls, are a common significant factor influencing embodied energy and embodied carbon.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| LCEC | life-cycle embodied carbon |

| LCECC | life-cycle embodied carbon coefficient |

| LCECI | life-cycle embodied carbon intensity |

| LCEE | life-cycle embodied energy |

| LCEEI | life-cycle embodied energy intensity |

| LCEEC | life-cycle embodied energy coefficient |

| EC | embodied carbon |

| IEC | initial embodied carbon |

| REC | recurring embodied carbon |

| DEC | demolition embodied carbon |

| REC | recycled embodied carbon |

| EEC | embodied energy coefficients |

| AP | acidification potential |

| OD | ozone depletion potential |

| SF | smog formation potential |

| EP | eutrophication potential |

References

- Gustavsson, L.; Joelsson, A.; Sathre, R. Life cycle primary energy use and carbon emission of an eight-storey wood-framed apartment building. Energy Build. 2010, 42, 230–242. [Google Scholar] [CrossRef]

- Chastas, P.; Theodosiou, T.; Bikas, D. Embodied energy in residential buildings-towards the nearly zero energy building: A literature review. Build. Environ. 2016, 105, 267–282. [Google Scholar] [CrossRef]

- Hu, M. The Embodied Impact of Existing Building Stock. In Toward Sustainability Through Digital Technologies and Practices in the Eurasian Region; IGI Global: Hershey, PA, USA, 2020; pp. 1–31. [Google Scholar]

- Dixit, M.; Fernandez-Solis, J.L.; Lavy, S.; Culp, C.H. Need for an embodied energy measurement protocol for buildings: A review paper. Renew. Sustain. Energy Rev. 2012, 16, 3730–3743. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Barreneche, C.; Miró, L.; Morera, J.M.; Bartolí, E.; Fernandez, A.I. Low carbon and low embodied energy materials in buildings: A review. Renew. Sustain. Energy Rev. 2013, 23, 536–542. [Google Scholar] [CrossRef]

- Optis, M.; Wild, P. Inadequate documentation in published life cycle energy reports on buildings. Int. J. Life Cycle Assess. 2010, 15, 644–651. [Google Scholar] [CrossRef]

- Kneifel, J.; O’Rear, E.; Webb, D.; O’Fallon, C. An Exploration of the Relationship between Improvements in Energy Efficiency and Life-Cycle Energy and Carbon Emissions using the BIRDS Low-Energy Residential Database. Energy Build. 2017, 160, 19–33. [Google Scholar] [CrossRef]

- De Wolf, C.; Pomponi, F.; Moncaster, A.M. Measuring embodied carbon dioxide equivalent of buildings: A review and critique of current industry practice. Energy Build. 2017, 140, 68–80. [Google Scholar] [CrossRef]

- Hendriks, C.; Worrell, E.; Price, L.; Martin, N.; Meida, L.O.; De Jager, D.; Riemer, P. Emission reduction of greenhouse gases from the cement industry. In Greenhouse Gas Control Technologies 4; Elsevier: Amsterdam, The Netherlands, 1999; pp. 939–944. [Google Scholar]

- British Standard Institutions (BSI). BS EN 15978 Sustainability of Construction Works Assessment of Environmental Perforamnce of Buildings—Calculation Method; British Standards Institution: London, UK, 2011. [Google Scholar]

- Hu, M. Life-cycle environmental assessment of energy-retrofit strategies on a campus scale. Build. Res. Inf. 2019, 4, 1–22. [Google Scholar] [CrossRef]

- Athena Sustainable Materials Institute. About Whole-Building LCA and Embodied Carbon. Available online: http://www.athenasmi.org/resources/publications/ (accessed on 20 January 2020).

- Andrew, A. Embodied Energy Coefficients of Building Materials; Centre for Building Performance Research, Victoria University of Wellington: Kelburn, New Zealand, 1996. [Google Scholar]

- Dias, W.; Pooliyadda, S. Quality based energy contents and carbon coefficients for building materials: A systems approach. Energy 2004, 29, 561–580. [Google Scholar] [CrossRef]

- Zeebe, R.E.; Zachos, J.C.; Caldeira, K.; Tyrrell, T. OCEANS: Carbon Emissions and Acidification. Science 2008, 321, 51–52. [Google Scholar] [CrossRef]

- Azari, R.; Garshasbi, S.; Amini, P.; Rashed-Ali, H.; Mohammadi, Y.; Najafabadi, R.A. Multi-objective optimization of building envelope design for life cycle environmental performance. Energy Build. 2016, 126, 524–534. [Google Scholar] [CrossRef]

- Scheuer, C.; A Keoleian, G.; Reppe, P. Life cycle energy and environmental performance of a new university building: Modeling challenges and design implications. Energy Build. 2003, 35, 1049–1064. [Google Scholar] [CrossRef]

- Bina, R.; Upma, S.; Chuhan, A.K.; Diwakar, S.; Raaz, M. Photochemical Smog Pollution and Its Mitigation Measures. J. Adv. Sci. Res. 2011, 2, 28–33. [Google Scholar]

- Energy Education. Smog. Available online: https://energyeducation.ca/encyclopedia/Smog (accessed on 6 April 2020).

- Kim, T.-H.; Chae, C.U. Environmental Impact Analysis of Acidification and Eutrophication Due to Emissions from the Production of Concrete. Sustainability 2016, 8, 578. [Google Scholar] [CrossRef] [Green Version]

- Hill, C.A.S.; Dibdiaková, J. The environmental impact of wood compared to other building materials. Int. Wood Prod. J. 2016, 7, 215–219. [Google Scholar] [CrossRef]

- Buchanan, A.H.; Honey, B.G. Energy and carbon dioxide implications of building construction. Energy Build. 1994, 20, 205–217. [Google Scholar] [CrossRef]

- Debnath, A.; Singh, S.; Singh, Y. Comparative assessment of energy requirements for different types of residential buildings in India. Energy Build. 1995, 23, 141–146. [Google Scholar] [CrossRef]

- Suzuki, M.; Oka, T.; Okada, K. The estimation of energy consumption and CO2 emission due to housing construction in Japan. Energy Build. 1995, 22, 165–169. [Google Scholar] [CrossRef]

- Winther, B.; Hestnes, A. Solar Versus Green: The Analysis of a Norwegian Row House. Sol. Energy 1999, 66, 387–393. [Google Scholar] [CrossRef]

- Keoleian, G.A.; Blanchard, S.; Reppe, P. Life-Cycle Energy, Costs, and Strategies for Improving a Single-Family House. J. Ind. Ecol. 2000, 4, 135–156. [Google Scholar] [CrossRef]

- Mithraratne, N.; Vale, B. Life cycle analysis model for New Zealand houses. Build. Environ. 2004, 39, 483–492. [Google Scholar] [CrossRef]

- Ralph, H.; Opray, L.; Grant, T. Integrating Life Cycle Assessment into housing environmental performance assessment. In Proceedings of the 5th Australian Conference on Life Cycle Assessment: Achieving Business Benefits from Managing Life Cycle Impacts, Melbourne, Australia, 22–24 November 2006. [Google Scholar]

- Casals, X.G. Analysis of building energy regulation and certification in Europe: Their role, limitations and differences. Energy Build. 2006, 38, 381–392. [Google Scholar] [CrossRef]

- Thormark, C. The effect of material choice on the total energy need and recycling potential of a building. Build. Environ. 2006, 41, 1019–1026. [Google Scholar] [CrossRef]

- Szalay, Z. What is missing from the concept of the new European Building Directive? Build. Environ. 2007, 42, 1761–1769. [Google Scholar] [CrossRef]

- Citherlet, S.; Defaux, T. Energy and environmental comparison of three variants of a family house during its whole life span. Build. Environ. 2007, 42, 591–598. [Google Scholar] [CrossRef]

- Lucchi, E.; Tabak, M.; Troi, A. The “Cost Optimality” Approach for the Internal Insulation of Historic Buildings. Energy Procedia 2017, 133, 412–423. [Google Scholar] [CrossRef]

- Bogdan, A.; Kouloumpi, I.; Thomsen, K.E.; Aggerholm, S.; Enseling, A.; Loga, T.; Witczak, K. Implementing the cost-optimal methodology in EU countries: Lessons learned from three case studies. Energy Procedia 2015, 78, 2022–2027. [Google Scholar]

- Andra, B.; Kašs, K.; Edīte, K.; Gatis, Ž.; Agris, K.; Dagnija, B.; Armands, G.; Reinis, P.; Marika, R.; Lelde, T.; et al. Robust Internal Thermal Insulation of Historic Buildings-State of the art on historic building insulation materials and retrofit strategies. Lirias 2019, 21, 1–87. [Google Scholar]

- Akkurt, G.; Aste, N.; Borderon, J.; Buda, A.; Calzolari, M.; Chung, D.; Costanzo, V.; Del Pero, C.; Evola, G.; Huerto-Cardenas, H.; et al. Dynamic thermal and hygrometric simulation of historical buildings: Critical factors and possible solutions. Renew. Sustain. Energy Rev. 2020, 118, 109509. [Google Scholar] [CrossRef]

- Pomponi, F.; Moncaster, A.M. Scrutinising embodied carbon in buildings: The next performance gap made manifest. Renew. Sustain. Energy Rev. 2018, 81, 2431–2442. [Google Scholar] [CrossRef] [Green Version]

- Pielke, R.A., Sr. Climate Vulnerability: Understanding and Addressing Threats to Essential Resources; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Stephan, A.; Muñoz, S.; Healey, G.; Alcorn, J. Analysing material and embodied environmental flows of an Australian university—Towards a more circular economy. Resour. Conserv. Recycl. 2020, 155, 104632. [Google Scholar] [CrossRef]

- Stephan, A.; Crawford, R.H.; De Myttenaere, K. Multi-scale life cycle energy analysis of a low-density suburban neighbourhood in Melbourne, Australia. Build. Environ. 2013, 68, 35–49. [Google Scholar] [CrossRef] [Green Version]

- Ripa, M.; Fiorentino, G.; Vacca, V.; Ulgiati, S. The relevance of site-specific data in Life Cycle Assessment (LCA). The case of the municipal solid waste management in the metropolitan city of Naples (Italy). J. Clean. Prod. 2017, 142, 445–460. [Google Scholar] [CrossRef]

- Crawford, R.H.; Stephan, A.; Prideaux, F. A comprehensive database of environmental flow coefficients for construction materials: Closing the loop in environmental design. In Proceedings of the 53rd International Conference of the Architectural Science Association 2019: Revisiting the Role of Architecture for ’Surviving’ Development, Roorkee, India, 28–30 November 2019. [Google Scholar]

| Study | Building Type | Country | Yr | LCEEI (MJ/m2/yr) | Construction Types | LCECI (kgCO2e/m2/yr) | Life Span of Building | LCEP (kgCO2eq)/MJ | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Buchananand Honey [22] | COR | New Zealand | 1994 | 76–1300 | Wood | 100–1000 | 25 | 0.7–1.32 |

| 2 | Debnath et al [23] | COR | India | 1995 | 82–100 | Load bearing – Reinforced Concrete | N/A | *50 ** | N/A |

| COR | 74–84 | ||||||||

| COR | 62–86 | ||||||||

| 3 | Suzuki et al [24] | COR (multi-family) | Japan | 1995 | 216–270 | Steel Reinforced Concrete | 850 | *37 *** | 3.15–3.94 |

| COR (single-family) | 100 | Wood | 250 | *30 | 2.5 | ||||

| COR (single-family) | 122 | Lightweight Steel | 400 | *37 | 3.28 | ||||

| 4 | Winther and Hestnes [25] | COR | Norway | 1999 | 36–40.1 | Timber | N/A | 50 | N/A |

| LER | 49.4 | 50 | |||||||

| Super insulated | 88.48 | 50 | |||||||

| 5 | Keoleian et al (2000) [26] | COR | USA | 2000 | 126 | N/A | 32 | 50 | 0.25 |

| LER | 145 | 89 | 50 | 0.61 | |||||

| 6 | Mithraratene and Vale [27] | LER | New Zealand | 2004 | 44.25 | Light timber | N/A | 100 | N/A |

| Super insulated | 50.41 | 100 | |||||||

| 7 | Horne et al. [28] | LER | Australia | 2006 | 41–57 | N/A | N/A | 50 | N/A |

| 8 | Casals [29] | COR | Spain | 2006 | N/A | N/A | 30 | N/A | |

| LER | 30 | ||||||||

| 9 | Thormark [30] | LER | Sweden | 2006 | 60.3–96.2 | Timber | N/A | 50 | N/A |

| 10 | Szalay [31] | COR | Hungary | 2007 | 71 | N/A | N/A | 50 | N/A |

| LER | 227–243 | 50 | |||||||

| 11 | Citherlet and Defaux [32] | COR | Switzerland | 2007 | 108 | N/A | 50 | ||

| LER | 105–113 | 50 |

| Building # | Building Function | Floor Area (Sq.m) | Floor # | Yr of Construction | Yr of Renovations |

|---|---|---|---|---|---|

| A1 (A) | Academic | 7,015 | 2 | 1972 | - |

| A2 (C) | Academic | 2,256 | 4 | 1957 | 2011 |

| O1 (L) | Officea | 4,218 | 4 | 1969 | - |

| O2 (H) | Office | 5,585 | 4 | 1964 | 2004 |

| R1 (W) | Residential | 982 | 4 | 1948 | 1984 |

| R2 () | Residential | 2768 | 4 | 1955 | 2010 |

| Building Components | A1 | A2 |

|---|---|---|

| Foundation | Concrete spread footing | Concrete spread footing |

| Exterior wall | 10 cm brick masonry supported by 20 cm concrete masonry block | 10 cm brick masonry supported by 20 cm concrete masonry block |

| Exterior window | Steel window frames with single paned glass, no coating. PVC window frame double-glazed no coating air | Wood window frames with single paned glass, no coating. |

| Exterior door | Aluminum frame, single pane, sliding and swing door | Wood frame, single panel, swing door |

| Interior wall | Concrete masonry block and brick masonry wall | 10 cm concrete masonry block |

| Partition wall | 3 5/8” metal stud wall with 1 layer of 5/8” gypsum board on either exterior side | 10 cm mtl stud wall with with 1 layer of 5/8” gypsum board on either exterior side, 8cm batt insulation inside |

| Floor | Concrete | Asphalt tile on concrete floor |

| Columns | Concrete | Concrete |

| Roof | Concrete roof support, built up roofing and reflecting aggregate surface with 1” rigid insulation | Flat seam metal roof on 3” gypsum roof tile Slate roof on 3” gypsum roof tile |

| Beams | Concrete | Concrete |

| O1 (L) | O1 (H) | |

| Foundation | Concrete spread footing @ 2500 psi supporting a 12 cm (5 inch) concrete slab | Concrete spread footing |

| Exterior wall | 10 cm (4 inch) Brick masonry, supported by 20 cm (8 inch) concrete masonry block, with 5cm (2 inch) rigid insulation | 10 cm (4 inch) brick masonry supported by 25 cm (10 inch) concrete masonry block, no insulation |

| Exterior window | Wood window frames with single paned glass, no coating | Wood window frames with double-glazed glass |

| Interior wall | 10 cm (4 inch) Brick masonry wall with 1 cm (1/2 inch) gypsum wall board | 10 cm (4 inch) metal stud with gypsum board on both sides |

| Partition wall | 10 cm (4 inch) concrete masonry block, painted | 20 cm (8 inch) concrete masonry block, with gypsum board on one side; 10 cm (4 inch) Wood stud with plywood boards on both side |

| Floor | 15 cm (6 inch) concrete one-way joists floor with #4 continuous steel rebar, pan width of 36 cm (14 inch) | 15 cm (6 inch) concrete one-way joists floor over reinforced concrete slab |

| Columns | 20 cm (8 inch) concrete column @ 3000 psi | 20 cm (8 inch) concrete column @ 3000 psi |

| Roof | (2 × 4 inch) wood rafters supported by (1/4 inch) slate tile with (3/4 inch) plywood underneath, 10 cm (4 inch) batt insulation inbetween rafters | 5 × 10 cm (2 × 4 inch) wood rafters supported by (1/4 inch) slate tile with (3/4 inch) plywood underneath, 10 cm (4 inch) batt insulation inbetween rafters |

| Beams | Concrete joist beam @ 3000 psi | concrete joist beam @ 3000 psi |

| R1 | R1 | |

| Foundation | 30 × 76 cm Concrete spread footing | Concrete spread footing |

| Exterior wall | 10 cm (4 inch) brick masonry supported by 20 cm (8 inch) concrete masonry block, no insulation | 10 cm (4 inch) Brick masonry supported by 10 cm (4 inch) concrete masonry block, without air gap, without insulation |

| Exterior window | Metal window frames with single paned glass, no coating | |

| Interior wall | 10 cm (4 inch) metal stud with gypsum board on both sides | 10 cm (4 inch) concrete block |

| Partition wall | 20 cm (8 inch) concrete masonry block, with Gypsum board one side | 10 cm (4 inch) Wood stud with plywood board on both side |

| Floor | - | - |

| Columns | 20 × 20 cm (8 inch) concrete columns @ 3000 psi | 35 × 35 cm (14 inch) concrete columns @ 3000 psi |

| Roof | (2 × 4 inch) Wood rafters supported (1/4 inch) slate tile with (3/4 inch) plywood underneath, 10 cm (4 inch) batt insulation in-between rafters | Built-up light weight concrete roof over reinforced concrete slab |

| Beams | Concrete @ 3000 psi | Concrete @ 3000 psi |

| Building Number | LCEEC (MJ/kg/yr) | LCEEI (kgCO2eq/kg/yr) | LCECC (MJ/m2/yr) | LCECI (kgCO2eq /m2 /yr) | LCEP(/kgCO2eq /MJ /yr) |

|---|---|---|---|---|---|

| A1 | 1.84 | 2324.87 | 0.19 | 245.07 | 0.105 |

| A2 | 4.53 | 12,614.20 | 0.37 | 1042.97 | 0.083 |

| O1 | 2.15 | 3746.88 | 0.22 | 374.39 | 0.100 |

| O2 | 3.87 | 5518.85 | 0.38 | 535.42 | 0.097 |

| R1 | 3.90 | 10,876.95 | 0.38 | 1053.81 | 0.097 |

| R2 | 2.49 | 3619.27 | 0.27 | 392.08 | 0.108 |

| Category | R-Squared | Adjusted R-Squared | Significance F | p-Value | Significance |

|---|---|---|---|---|---|

| AP | 0.161 | −0.049 | 0.431 | 0.431 | No |

| OD | 0.877 | 0.846 | 0.006 | 0.006 | Yes |

| SF | 0.214 | 0.017 | 0.356 | 0.356 | No |

| EP | 0.387 | 0.234 | 0.187 | 0.187 | No |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, M. A Building Life-Cycle Embodied Performance Index—The Relationship between Embodied Energy, Embodied Carbon and Environmental Impact. Energies 2020, 13, 1905. https://doi.org/10.3390/en13081905

Hu M. A Building Life-Cycle Embodied Performance Index—The Relationship between Embodied Energy, Embodied Carbon and Environmental Impact. Energies. 2020; 13(8):1905. https://doi.org/10.3390/en13081905

Chicago/Turabian StyleHu, Ming. 2020. "A Building Life-Cycle Embodied Performance Index—The Relationship between Embodied Energy, Embodied Carbon and Environmental Impact" Energies 13, no. 8: 1905. https://doi.org/10.3390/en13081905

APA StyleHu, M. (2020). A Building Life-Cycle Embodied Performance Index—The Relationship between Embodied Energy, Embodied Carbon and Environmental Impact. Energies, 13(8), 1905. https://doi.org/10.3390/en13081905