A Study of Temperature-Dependent Hysteresis Curves for a Magnetocaloric Composite Based on La(Fe, Mn, Si)13-H Type Alloys

Abstract

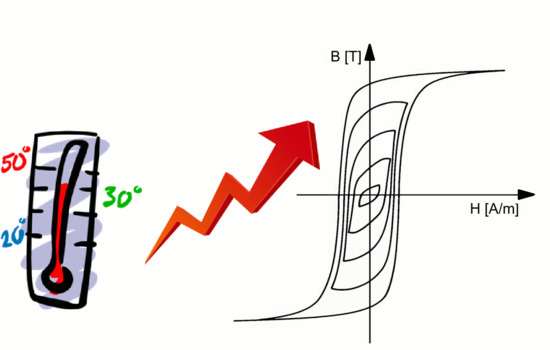

:1. Introduction

2. Materials and Methods

- conventional cooling systems based on vapor-compression cycles of chlorofluorocarbons, hydrochlorofluorocarbons and hydrofluorocarbons are inefficient (theoretical efficiency of Carnot’s cycle does not exceed 40%) and may contribute to environmental burden (depletion of the ozone layer); on the other hand, MCE refrigeration systems can attain 60% efficiency and are environment-friendly;

3. Modeling

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ewing, J.A.X. Experimental researches in magnetism. Philos. Trans. R. Soc. Lond. 1885, 176, 523–640. [Google Scholar]

- Bertotti, G. Hysteresis in Magnetism, 1st ed.; Elsevier/Academic Press: San Diego, CA, USA, 1998. [Google Scholar]

- Liu, C.; Chau, K.T. Electromagnetic Design of a New Electrically Controlled Magnetic Variable-Speed Gearing Machine. Energies 2014, 7, 1539–1554. [Google Scholar] [CrossRef] [Green Version]

- Chen, W.; Ma, J.; Huang, X.; Fang, Y.-T. Predicting Iron Losses in Laminated Steel with Given Non-Sinusoidal Waveforms of Flux Density. Energies 2015, 8, 13726–13740. [Google Scholar] [CrossRef] [Green Version]

- Gallicchio, G.; Palmieri, M.; Di Nardo, M.; Monopoli, V.G. Fast Torque Computation of Hysteresis Motors and Clutches Using Magneto-static Finite Element Simulation. Energies 2019, 12, 3311. [Google Scholar] [CrossRef] [Green Version]

- Takacs, J. A phenomenological mathematical model of hysteresis. COMPEL Int. J. Comput. Math. Electr. Electron. Eng. 2001, 20, 1002–1015. [Google Scholar] [CrossRef]

- Preisach, F. Über die magnetische Nachwirkung. Z. Phys. 1935, 94, 277–302. [Google Scholar] [CrossRef]

- Mayergoyz, I.D. Mathematical Models of Hysteresis and Their Applications; Elsevier: Amsterdam, The Netherlands, 2003. [Google Scholar]

- Jiles, D.; Atherton, D. Theory of ferromagnetic hysteresis. J. Magn. Magn. Mater. 1986, 61, 48–60. [Google Scholar] [CrossRef]

- Cardelli, E. Advances in Magnetic Hysteresis Modeling; Elsevier BV: Amsterdam, The Netherlands, 2015; Volume 24, pp. 323–409. [Google Scholar]

- Chwastek, K. A dynamic extension to the Takács model. Phys. B Condens. Matter 2010, 405, 3800–3802. [Google Scholar] [CrossRef]

- Jastrzębski, R.; Jakubas, A.; Chwastek, K. A Comparison of Two Phenomenological Descriptions of Magnetization Curves Based on T(x) Model. Acta Phys. Pol. A 2019, 136, 720–723. [Google Scholar] [CrossRef]

- Raghunathan, A.; Melikhov, Y.; Snyder, J.E.; Jiles, D.C. Theoretical Model of Temperature Dependence of Hysteresis Based on Mean Field Theory. IEEE Trans. Magn. 2010, 46, 1507–1510. [Google Scholar] [CrossRef]

- Sutor, A.; Rupitsch, S.J.; Bi, S.; Lerch, R. A modified Preisach hysteresis operator for the modeling of temperature dependent magnetic material behavior. J. Appl. Phys. 2011, 109, 7. [Google Scholar] [CrossRef] [Green Version]

- Górecki, K.; Rogalska, M.; Zarȩbski, J.; Detka, K. Modelling Characteristics of Ferromagnetic Cores with the Influence of Temperature. J. Physics: Conf. Ser. 2014, 494, 012016. [Google Scholar] [CrossRef] [Green Version]

- Gozdur, R.; Gębara, P.; Chwastek, K. Modeling hysteresis curves of La(FeCoSi)13 compound near the transition point with the GRUCAD model. Open Phys. 2018, 16, 266–270. [Google Scholar] [CrossRef]

- Longhitano, M.R.; Sixdenier, F.; Scorretti, R.; Krähenbühl, L.; Geuzaine, C. Temperature-dependent hysteresis model for soft magnetic materials. COMPEL Int. J. Comput. Math. Electr. Electron. Eng. 2019, 38, 1595–1613. [Google Scholar] [CrossRef]

- Górecki, K.; Detka, K. Influence of Power Losses in the Inductor Core on Characteristics of Selected DC–DC Converters. Energies 2019, 12, 1991. [Google Scholar] [CrossRef] [Green Version]

- McKeehan, L.W.; Bozorth, R.M. Hysteresis Losses and the Area of the Hysteresis Loop. Phys. Rev. 1934, 46, 526–527. [Google Scholar] [CrossRef]

- Almanza, M.; Kedous-Lebouc, A.; Yonnet, J.-P.; Legait, U.; Roudaut, J. Magnetic refrigeration: Recent developments and alternative configurations. Eur. Phys. J. Appl. Phys. 2015, 71, 10903. [Google Scholar] [CrossRef]

- Basso, V.; Bertotti, G.; LoBue, M.; Sasso, C. Theoretical approach to the magnetocaloric effect with hysteresis. J. Magn. Magn. Mater. 2005, 290, 654–657. [Google Scholar] [CrossRef]

- Basso, V.; Sasso, C.; Bertotti, G.; LoBue, M. Effect of material hysteresis in magnetic refrigeration cycles. Int. J. Refrig. 2006, 29, 1358–1365. [Google Scholar] [CrossRef]

- Von Moos, L.; Bahl, C.R.H.; Nielsen, K.K.; Engelbrecht, K. The influence of hysteresis on the determination of the magnetocaloric effect in Gd 5 Si 2 Ge 2. J. Phys. D: Appl. Phys. 2014, 48, 25005. [Google Scholar] [CrossRef]

- Raghunathan, A.; Melikhov, Y.; Snyder, J.E.; Jiles, D.C. Modeling of two-phase magnetic materials based on the Jiles-Atherton theory. J. Magn. Magn. Mater. 2012, 324, 20–22. [Google Scholar] [CrossRef]

- Frydrych, P.; Nowicki, M. Two phase magnetic material modelling using two dimensional extended Preisach model. J. Electr. Eng. 2018, 69, 464–466. [Google Scholar] [CrossRef] [Green Version]

- Takacs, J.; Mészáros, I. Separation of magnetic phases in alloys. Phys. B Condens. Matter 2008, 403, 3137–3140. [Google Scholar] [CrossRef]

- Gozdur, R.; Gębara, P.; Chwastek, K. The effect of temperature on magnetization curves near Curie point in LaFeCoSi. Acta Phys. Pol. A 2020, in press. [Google Scholar]

- Govindappa, P.; Trevizoli, P.V.; Campbell, O.; Niknia, I.; Christiaanse, T.V.; Teyber, R.; Misra, S.; Schwind, M.A.; Van Asten, D.; Zhang, L.; et al. Experimental investigation of MnFeP1−xAsxmultilayer active magnetic regenerators. J. Phys. D Appl. Phys. 2017, 50, 315001. [Google Scholar] [CrossRef]

- Christiaanse, T.V.; Trevizoli, P.; Misra, S.; Carroll, C.; Van Asten, D.; Zhang, L.; Teyber, R.; Govindappa, P.; Niknia, I.; Rowe, A.M. Experimental study of 2-layer regenerators using Mn–Fe–Si–P materials. J. Phys. D Appl. Phys. 2018, 51, 105002. [Google Scholar] [CrossRef]

- Shen, H.; Luo, L.; Xing, D.; Jiang, S.; Liu, J.; Huang, Y.; Guo, S.; Sun, H.; Liu, Y.; Sun, J.; et al. The Magnetocaloric Composite Designed by Multi-Gd-Al-Co Microwires with Close Performances. Phys. Status Solidi 2019, 216, 1900090. [Google Scholar] [CrossRef]

- Zimm, C.; Jastrab, A.; Sternberg, A.; Pecharsky, V.; Gschneidner, K.; Osborne, M.; Anderson, I. Description and Performance of a Near-Room Temperature Magnetic Refrigerator. Adv. Cryog. Eng. 1998, 43, 1759–1766. [Google Scholar]

- Tishin, A.M.; Spichkin, Y. The Magnetocaloric Effect and Its Applications; Informa UK Limited: London, UK, 2003. [Google Scholar]

- Gschneidner, K.; Pecharsky, V. Thirty years of near room temperature magnetic cooling: Where we are today and future prospects. Int. J. Refrig. 2008, 31, 945–961. [Google Scholar] [CrossRef] [Green Version]

- Gutfleisch, O.; Willard, M.A.; Brueck, E.; Chen, C.H.; Sankar, S.G.; Liu, J.P. ChemInform Abstract: Magnetic Materials and Devices for the 21st Century: Stronger, Lighter, and More Energy Efficient. Chemin 2011, 42. [Google Scholar] [CrossRef]

- Franco, V.; Blázquez, J.; Ingale, B.; Conde, A. The Magnetocaloric Effect and Magnetic Refrigeration Near Room Temperature: Materials and Models. Annu. Rev. Mater. Res. 2012, 42, 305–342. [Google Scholar] [CrossRef] [Green Version]

- Gómez, J.R.; Garcia, R.F.; Catoira, A.D.M.; Gómez, M.R. Magnetocaloric effect: A review of the thermodynamic cycles in magnetic refrigeration. Renew. Sustain. Energy Rev. 2013, 17, 74–82. [Google Scholar] [CrossRef]

- Balli, M.; Jandl, S.; Fournier, P.; Kedous-Lebouc, A. Advanced materials for magnetic cooling: Fundamentals and practical aspects. Appl. Phys. Rev. 2017, 4, 021305. [Google Scholar] [CrossRef]

- Krautz, M.; Beyer, M.; Jäschke, C.; Schinke, L.; Waske, A.; Seifert, J. A Magnetocaloric Booster Unit for Energy-Efficient Air-Conditioning. Crystals 2019, 9, 76. [Google Scholar] [CrossRef] [Green Version]

- Kagathara, J.; Wieland, S.; Gärtner, E.; Uhlenwinkel, V.; Steinbacher, M. Heat Treatment and Formation of Magnetocaloric 1:13 Phase in LaFe11.4Si1.2Co0.4 Processed by Laser Beam Melting. Materials 2020, 13, 773. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Barcza, A.; Katter, M.; Zellmann, V.; Russek, S.; Jacobs, S.; Zimm, C. Stability and Magnetocaloric Properties of Sintered La(Fe, Mn, Si)_{13}H_{z} Alloys. IEEE Trans. Magn. 2011, 47, 3391–3394. [Google Scholar] [CrossRef]

- Gozdur, R.; Lebioda, M.; Bernacki, Ł. Power Losses in LaFexCoySi1.1Intermetallics near the Magnetic Phase Transition. Acta Phys. Pol. A 2015, 128, 98–103. [Google Scholar] [CrossRef]

- Moses, A.J.; Ling, P.C.Y. Dimensional factors affecting magnetic properties of wound cores. Phys. Scr. 1989, 40, 249–251. [Google Scholar] [CrossRef]

- Grimmond, W.; Moses, A.; Ling, P. Geometrical factors affecting magnetic properties of wound toroidal cores. IEEE Trans. Magn. 1989, 25, 2686–2693. [Google Scholar] [CrossRef]

- Koprivica, B.; Milovanović, A.; Djekić, M. Effects of wound toroidal core dimensional and geometrical parameters on measured magnetic properties of electrical steel. Serbian J. Electr. Eng. 2013, 10, 459–471. [Google Scholar] [CrossRef] [Green Version]

- Nakata, T.; Takahashi, N.; Fujiwara, K.; Nakano, M.; Ogura, Y. Accurate measurement method of magnetization curve using ring specimen. J. Magn. Magn. Mater. 1992, 112, 71–73. [Google Scholar] [CrossRef]

- Nakata, T.; Takahashi, N.; Fujiwara, K.; Nakano, M.; Ogura, Y.; Matsubara, K. An improved method for determining the DC magnetization curve using a ring specimen. IEEE Trans. Magn. 1992, 28, 2456–2458. [Google Scholar] [CrossRef]

- Tutkun, N.; Moses, A. Effects of geometrical factors on iron loss increase in wound toroidal cores energized by pulse width modulated voltage sources. J. Magn. Magn. Mater. 2004, 281, 110–114. [Google Scholar] [CrossRef]

- Gębara, P.; Pawlik, P. Broadening of temperature working range in magnetocaloric La(Fe,Co,Si)13- based multicomposite. J. Magn. Magn. Mater. 2017, 442, 145–151. [Google Scholar] [CrossRef]

- Gębara, P.; Díaz-García, Á.; Yan Law, J.; Franco, V. Magnetocaloric response of binary Gd-Pd and ternary Gd-(Mn,Pd) alloys. J. Magn. Magn. Mater. 2020, 500, 166175. [Google Scholar] [CrossRef]

- Gębara, P.; Pawlik, P.; Kulej, E.; Wysłocki, J.J.; Pawlik, K.; Przybył, A. The evolution of microstructure in annealed LaFeSi-type alloys. Opt. Appl. 2009, 39, 761–764. [Google Scholar]

| Tc (K) | Fe | La | Si | Mn |

|---|---|---|---|---|

| 318K | 78.9 | 16.0 | 4.1 | 0.9 |

| 313K | 76.6 | 18.4 | 4.0 | 1.0 |

| 298K | 77.5 | 16.6 | 4.1 | 1.8 |

| Source of Uncertainty | Instrumentation /Method | Intrinsic Error | Assumed Distribution | Relative Uncertainty |

|---|---|---|---|---|

| Voltage , | DAQ card NI-PCI-4462, Range ±1 V | 5.81 mV | uniform | 0.30 % |

| Voltage | DAQ card NI-PCI-4462, Range ±3.16 V | 15.1 mV | uniform | 2.38 % |

| Resistance RSHUNT | Keysight 3458 A Range 10 Ω | 0.12 mΩ | uniform | 0.01 % |

| Frequency f | Keysight 3458 A Range 40 Hz | 0.005 Hz | triangular | 0.05% |

| Temperature | LTC2983 | 0.25 deg | uniform | 1.0% |

| Core Type | Temperature | |Jr| | |Hc| | Hm | Jm | Ps |

|---|---|---|---|---|---|---|

| (K ) | (T) | (A/m) | (A/m) | (T) | (mW/kg) | |

| Composite | 293.8 | 0.1751 | 296.0 | 2998.2 | 0.6152 | 62.99 |

| Tc = 298 K | 293.8 | 0.0732 | 222.0 | 3000.5 | 0.4332 | 34.16 |

| Tc = 313 K | 293.8 | 0.2046 | 291.7 | 3000.5 | 0.7028 | 68.98 |

| Tc = 318 K | 293.8 | 0.2311 | 304.2 | 3002.4 | 0.7804 | 86.70 |

| Tc = 298 K | 298.0 | 0.0039 | 204.1 | 2999.2 | 0.0524 | 3.26 |

| Tc = 313 K | 313.0 | 0.0110 | 288.8 | 3000.0 | 0.0837 | 7.95 |

| Tc = 318 K | 318.0 | 0.0471 | 211.3 | 3000.8 | 0.2867 | 25.68 |

| Composite | 298.0 | 0.1340 | 293.7 | 2997.1 | 0.4427 | 46.83 |

| Composite | 313.0 | 0.0450 | 269.1 | 2999.6 | 0.1894 | 18.68 |

| Composite | 318.0 | 0.0086 | 319.1 | 3003.9 | 0.0557 | 6.167 |

| T (K) | a, (A/m) | Hc, (A/m) | Ms (A/m) | |

|---|---|---|---|---|

| 293.85 | sample with TC = 298 K | 1948.9 | 192.0 | 1.12 × 105 |

| - | sample with TC = 313 K | 1184.6 | 286.4 | 5.31 × 105 |

| - | sample with TC = 318 K | 1188.6 | 299.5 | 5.92 × 105 |

| 307.65 | sample with TC = 298 K | 3569.3 | 201.9 | 3.84 × 105 |

| - | sample with TC = 313 K | 1383.5 | 231.9 | 3.95 × 105 |

| - | sample with TC = 318 K | 1330.4 | 260.7 | 5.24 × 105 |

| 329.65 | sample with TC = 298 K | 3857.2 | 185.0 | 3.80 × 104 |

| - | sample with TC = 313 K | 2839.5 | 325.5 | 4.98 × 105 |

| - | sample with TC = 318 K | 1182.2 | 417.4 | 1.98 × 105 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gozdur, R.; Gębara, P.; Chwastek, K. A Study of Temperature-Dependent Hysteresis Curves for a Magnetocaloric Composite Based on La(Fe, Mn, Si)13-H Type Alloys. Energies 2020, 13, 1491. https://doi.org/10.3390/en13061491

Gozdur R, Gębara P, Chwastek K. A Study of Temperature-Dependent Hysteresis Curves for a Magnetocaloric Composite Based on La(Fe, Mn, Si)13-H Type Alloys. Energies. 2020; 13(6):1491. https://doi.org/10.3390/en13061491

Chicago/Turabian StyleGozdur, Roman, Piotr Gębara, and Krzysztof Chwastek. 2020. "A Study of Temperature-Dependent Hysteresis Curves for a Magnetocaloric Composite Based on La(Fe, Mn, Si)13-H Type Alloys" Energies 13, no. 6: 1491. https://doi.org/10.3390/en13061491

APA StyleGozdur, R., Gębara, P., & Chwastek, K. (2020). A Study of Temperature-Dependent Hysteresis Curves for a Magnetocaloric Composite Based on La(Fe, Mn, Si)13-H Type Alloys. Energies, 13(6), 1491. https://doi.org/10.3390/en13061491