Life Cycle Assessment of a Commercially Available Organic Rankine Cycle Unit Coupled with a Biomass Boiler

Abstract

:1. Introduction

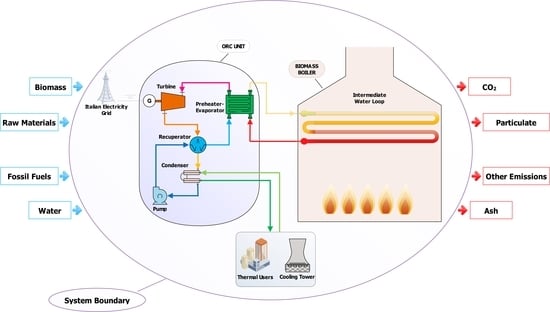

2. Case Study and Model Settings

3. Materials and Methods

- Plant working in full electric mode for 6000 h/year. This operating condition corresponds to a production during the entire life of the plant of 13,500 MWh.

- Plant running in CHP mode for 3000 h/year while, for the remainder 3000 h/year, it works in full electric mode. Note that, this is a regular working condition for plants serving residential users, as in the under-investigation case. It corresponds to an electricity production during the entire life of the plant of 11,160 MWh, and a heat production of 33,750 MWh.

- IPCC 2013 GWP100y [56], developed by the IPCC with a unique focus on the greenhouse effect. In this work, the analysis refers to the factors over 100 years, which quantify the medium-term effects of emissions.

- ReCiPe 2016, whose primary goal is transforming the long list of inventory results into a small number of significant indicators [57] but sufficient to describe the total effects of the process under examination on the environment. Here, the Hierarchical Perspective (H) is used, as suggested in [52], with “European” standardization and “medium” weighing set. Both Midpoint and Endpoint Indicators are computed.

- Cumulative Energy Demand, a method with a unique focus on the energy demand [58].

- Greenhouse Gas protocol [59], developed by the World Resources Institute and the World Business Council for Sustainable Development, with a unique focus on the carbon footprint. It considers also biogenic and untaken emissions.

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| 1.4-DCB | 1.4-DICHLOROBENZENE |

| CFC11 | Trichlorofluoromethane |

| CHP | Combined Heat and Power |

| CO2 | Carbon Dioxide |

| Cu | Copper |

| eq | equivalent |

| EU | European Union |

| g | gramme |

| GHG | Green House Gases |

| GT | Gas Turbine |

| GWP | Global Warming Potential |

| HCF | hydrocarbons fluid |

| ICE | Internal Combustion Engine |

| kBq Co-60eq | kilobecquerels of cobalt-60 equivalents |

| kg | kilogramme |

| LCA | Life Cycle Assessment |

| N | Nitrogen |

| NOx | Nitrogen Oxide |

| ODP | Ozone Depletion Potential |

| ORC | Organic Rankine Cycle |

| P | Phosphorus |

| PM | Particulate Matter |

| RES | Renewable Energy Sources |

| SO2 | Sulphur Dioxide |

| SRC | Steam Rankine Cycle |

| WHRU | Waste Heat Recovery Unit |

References

- BP. BP Statistical Review of World Energy 2018; BP: London, UK, 2018. [Google Scholar]

- International Energy Agency. World Energy Outlook 2018 Summary; Technical report; International Energy Agency: Paris, France, 2018. [Google Scholar] [CrossRef]

- International Renewable Energy Agency (IRENA). Global Energy Transformation: A Roadmap to 2050; International Renewable Energy Agency: Abu Dhabi, UAE, 2018. [Google Scholar] [CrossRef]

- European Parliament and Council of the European Union. Directive 2009/28/EC of the European Parliament and of the Council of 23 April 2009 on the Promotion of the Use of Energy from Renewable sources and Amending and Subsequently Repealing Directives 2001/77/EC and 2003/30/EC; European Commission: Brussels, Belgium, 2009. [Google Scholar]

- European Council. 2030 Framework for Climate and Energy Policies; European Commission: Brussels, Belgium, 2014. [Google Scholar]

- European Council. EU Roadmap 2050; European Commission: Brussels, Belgium, 2010. [Google Scholar]

- Stoppato, A.; Benato, A.; Mirandola, A. Assessment of stresses and residual life of plant components in view of life-time extension of power plants. In Proceedings of the 25th International Conference on Efficiency, Cost, Optimization, Simulations and Environmental Impact of Energy Systems (ECOS 2012), Perugia, Italy, 26–29 June 2012. [Google Scholar]

- Benato, A.; Stoppato, A.; Bracco, S. Combined cycle power plants: A comparison between two different dynamic models to evaluate transient behaviour and residual life. Energy Convers. Manag. 2014, 87, 1269–1280. [Google Scholar] [CrossRef]

- Benato, A.; Stoppato, A.; Mirandola, A. Dynamic behaviour analysis of a three pressure level heat recovery steam generator during transient operation. Energy 2015, 90, 1595–1605. [Google Scholar] [CrossRef]

- Benato, A.; Stoppato, A. Pumped Thermal Electricity Storage: A technology overview. Therm. Sci. Eng. Prog. 2018, 6, 301–315. [Google Scholar] [CrossRef]

- Benato, A.; Stoppato, A. Energy and cost analysis of an Air Cycle used as prime mover of a Thermal Electricity Storage. J. Energy Storage 2018, 17, 29–46. [Google Scholar] [CrossRef]

- Benato, A.; Stoppato, A. Integrated Thermal Electricity Storage System: Energetic and cost performance. Energy Convers. Manag. 2019, 197, 111833. [Google Scholar] [CrossRef]

- Benato, A.; Stoppato, A. Energy and Cost Analysis of a New Packed Bed Pumped Thermal Electricity Storage Unit. J. Energy Resour. Technol. Trans. ASME 2018. [Google Scholar] [CrossRef]

- Benato, A.; Stoppato, A. Heat transfer fluid and material selection for an innovative Pumped Thermal Electricity Storage system. Energy 2018, 147, 155–168. [Google Scholar] [CrossRef]

- Park, H.; Baldick, R. Integration of compressed air energy storage systems co-located with wind resources in the ERCOT transmission system. Int. J. Electr. Power Energy Syst. 2017, 90, 181–189. [Google Scholar] [CrossRef]

- Benato, A. Performance and cost evaluation of an innovative Pumped Thermal Electricity Storage power system. Energy 2017, 138, 419–436. [Google Scholar] [CrossRef]

- Benato, A.; Stoppato, A.; Mirandola, A. State-of-the-art and future development of sensible heat thermal electricity storage systems. Int. J. Heat Technol. 2017, 35, S244–S251. [Google Scholar] [CrossRef]

- WBA. Global Bioenergy Statistics 2018; Technical Report; WBA: West Bromwich, UK, 2018. [Google Scholar]

- Pereira, R.G.; Oliveira, C.D.; Oliveira, J.L.; Oliveira, P.C.P.; Fellows, C.E.; Piamba, O.E. Exhaust emissions and electric energy generation in a stationary engine using blends of diesel and soybean biodiesel. Renew. Energy 2007. [Google Scholar] [CrossRef]

- Benato, A.; Macor, A. Italian Biogas Plants: Trend, Subsidies, Cost, Biogas Composition and Engine Emissions. Energies 2019, 12, 979. [Google Scholar] [CrossRef] [Green Version]

- Chiaramonti, D.; Rizzo, A.M.; Spadi, A.; Prussi, M.; Riccio, G.; Martelli, F. Exhaust emissions from liquid fuel micro gas turbine fed with diesel oil, biodiesel and vegetable oil. Appl. Energy 2013. [Google Scholar] [CrossRef]

- Benato, A.; Macor, A.; Rossetti, A. Biogas Engine Emissions: Standards and On-Site Measurements. Energy Procedia 2017, 126, 398–405. [Google Scholar] [CrossRef]

- Nikpey Somehsaraei, H.; Mansouri Majoumerd, M.; Breuhaus, P.; Assadi, M. Performance analysis of a biogas-fueled micro gas turbine using a validated thermodynamic model. Appl. Therm. Eng. 2014. [Google Scholar] [CrossRef]

- Benato, A.; Macor, A. Biogas Engine Waste Heat Recovery Using Organic Rankine Cycle. Energies 2017, 10, 327. [Google Scholar] [CrossRef]

- Macor, A.; Benato, A. Experimental Measurements and Damage Assessment on Human Health. Energies 2020, 13, 1044. [Google Scholar] [CrossRef] [Green Version]

- Vélez, F.; Segovia, J.J.; Martin, M.C.; Antolin, G.; Chejne, F.; Quijano, A. A technical, economical and market review of organic Rankine cycles for the conversion of low-grade heat for power generation. Renew. Sustain. Energy Rev. 2012, 16, 4175–4189. [Google Scholar] [CrossRef]

- Benato, A.; Stoppato, A.; Mirandola, A. Renewable Energy Conversion and Waste Heat Recovery Using Organic Rankine Cycles. In Renewable Energy Systems; Kale, S.A., Ed.; Nova Science Publishers: Hauppauge, NY, USA, 2016; Chapter 11. [Google Scholar]

- Bianchi, M.; De Pascale, A. Bottoming cycles for electric energy generation: Parametric investigation of available and innovative solutions for the exploitation of low and medium temperature heat sources. Appl. Energy 2011, 88, 1500–1509. [Google Scholar] [CrossRef]

- Pezzuolo, A.; Benato, A.; Stoppato, A.; Mirandola, A. The ORC-PD: A versatile tool for fluid selection and Organic Rankine Cycle unit design. Energy 2016, 102, 605–620. [Google Scholar] [CrossRef]

- Benato, A. Improving the efficiency of a cataphoresis oven with a cogenerative organic Rankine cycle unit. Therm. Sci. Eng. Prog. 2018, 5, 182–194. [Google Scholar] [CrossRef]

- Pezzuolo, A.; Benato, A.; Stoppato, A.; Mirandola, A. Recovering gas turbine high-temperature exhaust heat using organic Rankine cycle with mixture as working fluid. In Proceedings of the 29th International Conference on Efficiency, Cost, Optimization, Simulations and Environmental Impact of Energy Systems (ECOS 2016), Portoroz, Slovenia, 19–26 June 2016. [Google Scholar]

- Campana, F.; Bianchi, M.; Branchini, L.; De Pascale, A.; Petto, A.; Baresi, M.; Fermi, A.; Rossetti, N.; Vescovo, R. ORC waste heat recovery in European energy intensive industries: Energy and GHG savings. Energy Convers. Manag. 2013, 76, 244–252. [Google Scholar] [CrossRef]

- Branchini, L.; De Pascale, A.; Peretto, A. Systematic comparison of {ORC} configurations by means of comprehensive performance indexes. Appl. Therm. Eng. 2013, 61, 129–140. [Google Scholar] [CrossRef]

- Cavazzini, G.; Bari, S.; Pavesi, G.; Ardizzon, G. A multi-fluid PSO-based algorithm for the search of the best performance of sub-critical Organic Rankine Cycles. Energy 2017. [Google Scholar] [CrossRef]

- Benato, A.; Cavazzini, G.; Bari, S.; Ardizzon, G. ORC pump efficiency estimation and real behaviour under different working fluids. In Proceedings of the 32nd International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems (ECOS 2019), Wrocław, Poland, 23–28 June 2019. [Google Scholar]

- Ancona, M.A.; Bianchi, M.; Branchini, L.; De Pascale, A.; Melino, F.; Orlandini, V.; Ottaviano, S.; Peretto, A.; Pinelli, M.; Spina, P.R.; et al. A Micro-ORC Energy System: Preliminary Performance and Test Bench Development. Energy Procedia 2016. [Google Scholar] [CrossRef]

- Ancona, M.A.; Bianchi, M.; Branchini, L.; Pascale, A.; Melino, F.; Ottaviano, S.; Peretto, A.; Scarponi, L.B. Heat recovery from a liquefied natural gas production process by means of an organic rankine cycle. In Proceedings of the ASME Turbo Expo, Lillestrøm, Norway, 11 June 2018. [Google Scholar] [CrossRef]

- ISO. 14040: Environmental Management–Life Cycle Assessment—Principles and Framework; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Stougie, L.; Tsalidis, G.A.; van der Kooi, H.J.; Korevaar, G. Environmental and exergetic sustainability assessment of power generation from biomass. Renew. Energy 2018. [Google Scholar] [CrossRef]

- Walsh, C.; Thornley, P. The environmental impact and economic feasibility of introducing an organic Rankine cycle to recover low grade heat during the production of metallurgical coke. J. Clean. Prod. 2012. [Google Scholar] [CrossRef]

- Liu, C.; He, C.; Gao, H.; Xie, H.; Li, Y.; Wu, S.; Xu, J. The environmental impact of organic Rankine cycle for waste heat recovery through life-cycle assessment. Energy 2013. [Google Scholar] [CrossRef]

- Heberle, F.; Schifflechner, C.; Brüggemann, D. Life cycle assessment of Organic Rankine Cycles for geothermal power generation considering low-GWP working fluids. Geothermics 2016. [Google Scholar] [CrossRef]

- Lin, Y.P.; Wang, W.H.; Pan, S.Y.; Ho, C.C.; Hou, C.J.; Chiang, P.C. Environmental impacts and benefits of organic Rankine cycle power generation technology and wood pellet fuel exemplified by electric arc furnace steel industry. Appl. Energy 2016. [Google Scholar] [CrossRef]

- Uusitalo, A.; Uusitalo, V.; Grönman, A.; Luoranen, M.; Jaatinen-Värri, A. Greenhouse gas reduction potential by producing electricity from biogas engine waste heat using organic Rankine cycle. J. Clean. Prod. 2016. [Google Scholar] [CrossRef]

- Sedpho, S.; Sampattagul, S.; Chaiyat, N.; Gheewala, S.H. Conventional and exergetic life cycle assessment of organic rankine cycle implementation to municipal waste management: The case study of Mae Hong Son (Thailand). Int. J. Life Cycle Assess. 2017. [Google Scholar] [CrossRef]

- Monteleone, B.; Chiesa, M.; Marzuoli, R.; Verma, V.K.; Schwarz, M.; Carlon, E.; Schmidl, C.; Ballarin Denti, A. Life cycle analysis of small scale pellet boilers characterized by high efficiency and low emissions. Appl. Energy 2015. [Google Scholar] [CrossRef]

- Singh, P.; Gundimeda, H.; Stucki, M. Environmental footprint of cooking fuels: A life cycle assessment of ten fuel sources used in Indian households. Int. J. Life Cycle Assess. 2014. [Google Scholar] [CrossRef]

- Boschiero, M.; Kelderer, M.; Schmitt, A.O.; Andreotti, C.; Zerbe, S. Influence of agricultural residues interpretation and allocation procedures on the environmental performance of bioelectricity production—A case study on woodchips from apple orchards. Appl. Energy 2015. [Google Scholar] [CrossRef]

- Stoppato, A. Life cycle assessment of photovoltaic electricity generation. Energy 2008. [Google Scholar] [CrossRef]

- Fantinato, D.; Stoppato, A.; Benato, A. LCA analysis of a low-energy residential building. In Proceedings of the 32nd International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems (ECOS 2019), Wrocław, Poland, 23–28 June 2019; pp. 3153–3165. [Google Scholar]

- Toscani, A.; Stoppato, A.; Benato, A. LCA of a concert: Evaluation of the Carbon footprint and of Cumulative energy demand. In Proceedings of the 32nd International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems (ECOS 2019), Wrocław, Poland, 23–28 June 2019; pp. 3203–3213. [Google Scholar]

- Préconsultants. SimaPro 9.0. Available online: https://simapro.com/ (accessed on 8 April 2020).

- Laleman, R.; Albrecht, J.; Dewulf, J. Life cycle analysis to estimate the environmental impact of residential photovoltaic systems in regions with a low solar irradiation. Renew. Sustain. Energy Rev. 2011, 15, 267–281. [Google Scholar] [CrossRef]

- Hung, T.C.; Wang, S.K.; Kuo, C.H.; Pei, B.S.; Tsai, K.F. A study of organic working fluids on system efficiency of an ORC using low-grade energy sources. Energy 2010. [Google Scholar] [CrossRef]

- Qiu, G.; Shao, Y.; Li, J.; Liu, H.; Riffat, S.B. Experimental investigation of a biomass-fired {ORC}-based micro-{CHP} for domestic applications. Fuel 2012, 96, 374–382. [Google Scholar] [CrossRef] [Green Version]

- IPCC. Revised Supplementary Methods and Good Practice Guidance Arising from the Kyoto Protocol, Intergovernmental Panel on Climate Change; Technical Report; IPCC: Geneva, Switzerland, 2013. [Google Scholar]

- Huijbregts, M.; Steinmann, Z.J.N.; Elshout, P.M.F.M.; Stam, G.; Verones, F.; Vieira, M.D.M.; Zijp, M.; van Zelm, R. ReCiPe 2016; National Institute for Public Health and the Environment: Bilthoven, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Frischknecht, R.; Wyss, F.; Büsser Knöpfel, S.; Lützkendorf, T.; Balouktsi, M. Cumulative energy demand in LCA: The energy harvested approach. Int. J. Life Cycle Assess. 2015. [Google Scholar] [CrossRef]

- Schmitz, S.; Dawson, B.; Spannagle, M.; Thomson, F.; Koch, J.; Eaton, R. The Greenhouse Gas Protocol—A Corporate Accounting and Reporting Standard; Revised, Ed.; The GHG Protocol Corporate Accounting and Reporting Standard; World Resources Institute and World Business Council for Sustainable Development: Washington, DC, USA, 2001. [Google Scholar]

- Istituto Superiore per la Protezione e la Ricerca Ambientale. Fattori di emissione per la produzione ed il consumo di energia elettrica in Italia (Emission Factors for Production and Consumption of electricity). Technical Report; 2019. Available online: http://www.sinanet.isprambiente.it/it/sia-ispra/serie-storiche-emissioni/ (accessed on 8 April 2020).

- Stougie, L.; Giustozzi, N.; van der Kooi, H.; Stoppato, A. Environmental, economic and exergetic sustainability assessment of power generation from fossil and renewable energy sources. Int. J. Energy Res. 2018. [Google Scholar] [CrossRef]

| Parameters | Unit | Full Electric Mode | CHP Mode |

|---|---|---|---|

| Input thermal power | kW | 1100 | |

| Inlet temperature of the heat transfer fluid (water) | C | ≥160 | |

| Outlet temperature of the heat transfer fluid (water) | C | 140 | |

| Heat transfer fluid (water) mass flow rate | kg/s | 13.14 | |

| Electric power | kW | 150 | 98 |

| Electric efficiency | % | 13.6 | 8.6 |

| Output thermal power | kW | 940 | 1000 |

| Inlet temperature of water for thermal use | C | 26 | 60 |

| Outlet temperature of water for thermal use | C | 36 | 80 |

| Water mass flow rate | kg/s | 22.46 | 11.95 |

| Components | Characteristics |

|---|---|

| Pre-heater | Counter-flow brazed plate heat exchanger |

| Evaporator | Counter-flow brazed plate heat exchanger |

| Turbine | Radial turbine with fixed nozzles |

| Electric generator | Brushless synchronous generator with permanent magnets |

| Regenerative heat exchanger | Counter-flow brazed plate heat exchanger |

| Condenser | Counter-flow brazed plate heat exchanger |

| Pump | Centrifugal machine |

| Material | Unit | Weight |

|---|---|---|

| Steel | kg | 5320 |

| Brass | kg | 25 |

| Pig iron | kg | 150 |

| Copper | kg | 510 |

| Aluminium alloy | kg | 2 |

| Permanent magnets | kg | 4.32 |

| Impact Category | Unit | Total |

|---|---|---|

| Global warming | kg CO2,eq | 0.085283 |

| Stratospheric ozone depletion | kg CFC11eq | 5.53 |

| Ionizing radiation | kBq Co-60eq | 0.001301 |

| Ozone formation. Human health | kg NOx,eq | 0.001811 |

| Fine particulate matter formation | kg PM2.5eq | 0.000439 |

| Ozone formation. Terrestrial ecosystems | kg NOx,eq | 0.00184 |

| Terrestrial acidification | kg SO2,eq | 0.001447 |

| Freshwater eutrophication | kg Peq | 5.83 |

| Marine eutrophication | kg Neq | 8.33 |

| Terrestrial ecotoxicity | kg 1.4-DCB | 1.68345 |

| Freshwater ecotoxicity | kg 1.4-DCB | 0.007768 |

| Marine ecotoxicity | kg 1.4-DCB | 0.01133 |

| Human carcinogenic toxicity | kg 1.4-DCB | 0.002995 |

| Human non-carcinogenic toxicity | kg 1.4-DCB | 0.510964 |

| Land use | m2a cropeq | 0.87156 |

| Mineral resource scarcity | kg Cueq | 0.000275 |

| Fossil resource scarcity | kg oileq | 0.015262 |

| Water consumption | m3 | 0.009958 |

| Impact Category | g CO2,eq |

|---|---|

| Fossil | 73.2 |

| Biogenic | 1910 |

| from land transformation | 0.89 |

| CO2 uptake | 1900 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stoppato, A.; Benato, A. Life Cycle Assessment of a Commercially Available Organic Rankine Cycle Unit Coupled with a Biomass Boiler. Energies 2020, 13, 1835. https://doi.org/10.3390/en13071835

Stoppato A, Benato A. Life Cycle Assessment of a Commercially Available Organic Rankine Cycle Unit Coupled with a Biomass Boiler. Energies. 2020; 13(7):1835. https://doi.org/10.3390/en13071835

Chicago/Turabian StyleStoppato, Anna, and Alberto Benato. 2020. "Life Cycle Assessment of a Commercially Available Organic Rankine Cycle Unit Coupled with a Biomass Boiler" Energies 13, no. 7: 1835. https://doi.org/10.3390/en13071835

APA StyleStoppato, A., & Benato, A. (2020). Life Cycle Assessment of a Commercially Available Organic Rankine Cycle Unit Coupled with a Biomass Boiler. Energies, 13(7), 1835. https://doi.org/10.3390/en13071835