Air Conditioning Energy Saving from Cloud-Based Artificial Intelligence: Case Study of a Split-Type Air Conditioner

Abstract

:1. Introduction

2. VSD Applied to Split-Type Air Conditioners

2.1. Energy Efficiency Study Case and Baseline

2.2. Proportional-Integral-Differential Control

2.3. Control Model

- Rapidly decrease the indoor temperature, and this control goal decreases TI(t) to equal Tset in 25 min.

- Stably control the indoor temperature, with the control goal stabilizing to TI(t) in the range of Tset °C for an unlimited amount of time.

3. Cloud-Based AI Development

- After the introduction of AI, the time required to reduce indoor temperature and maintain a stable temperature range unchanged.

- After the introduction of AI, the energy consumption reduced from the aforementioned PID control.

3.1. Review of AI Techniques

- AI applied to HVAC control and not to diagnosis, prediction, or forecasting.

- Containing actual quantization data and energy saving percentages reported after AI technique implementation.

- Fully reported implementation control structure.

3.2. Energy Efficiency Improvement Methodology #1: Fuzzy + PID Control

3.3. Energy Efficiency Improvement Methodology #2: MPC

3.4. Additional hardware

4. Experimental Setup

4.1. Energy Efficiency Measurement

4.1.1. EER

4.1.2. CSPF

4.2. Environmental Control Chamber Test

5. Results and Discussions

6. Conclusions

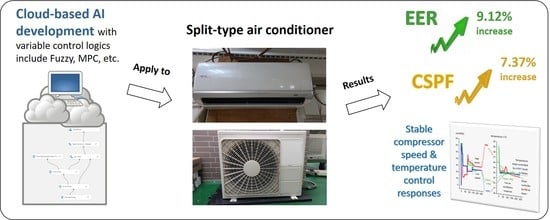

- MPC was the most effective methodology for improving the energy efficiency of air conditioners. In the study case, a split-type air conditioner equipped with a VSD and PID control had an EER value of 5.7. By using MPC, the cloud-based AI could increase the EER value to 6.22. Up to 9.12% energy efficiency improvement was achieved.

- Dynamic control responses were tested under four weather conditions, including late spring, early summer, hot summer, and early autumn. In the late spring with low outside temperatures, the cloud-based AI maintained a compressor speed 24.12% lower than that of the original PID control in the air conditioner. In the hot summer, the cloud-based AI maintained a speed 9.8% lower than originally and achieved high energy efficiency.

- Compared with a high-efficiency motor, heat exchanger, and VSD applications on air conditioners, the cloud-based AI was the most cost effective way to improve energy efficiency. It only cost 1 USD to achieve a 0.58% improvement in energy efficiency. This was 5–8 times less expensive than the other three methods. For other energy improving methodologies applied to air conditioners, the cost–benefit ratios all had gentle curves; thus, more cost must be invested to improve energy efficiency. Only AI introduction could increase cost–benefit ratios and considerably improve energy efficiency without considerable cost.

- The cloud-based AI used the MPC to extract the control case in the database with SI. The demanded rotational speed was directly inputted to the compressor, and the error feedback control of the PID control was replaced. Thus, indoor temperature control could achieve in stable periods.

- According to climate conditions, cloud-based AI could provide linear outputs related to ΔT between indoor and outdoor environments, and had linear changes. Thus, heat transmitted from outdoor to indoor environments was minimized.

- The cloud-based AI could allow mobile phones to collect indoor statuses to estimate heat gain. In addition, the control model could be controlled precisely, such as the parameters shown in Equation (3).

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| AC | air conditioning |

| AI | artificial intelligence |

| ANN | artificial neural network |

| COP | coefficient of performance |

| CSPF | cooling season power factor |

| heat coefficient | |

| DMS | decision making system |

| control error | |

| EER | energy efficiency ratio |

| GA | genetic algorithm |

| GS | global similarity |

| h | hour |

| HVAC | heating, ventilation and air conditioning |

| IEA | international energy agency |

| IR | infra-red |

| cost function of temperature control | |

| evaluation function of the control system | |

| kW | kilo-watt |

| KP | proportional coefficient |

| KI | integral coefficient |

| KD | differential coefficient |

| m | thermal mass in an indoor environment |

| MAS | multi-agent system |

| min | minute |

| ML | machine learning |

| MPC | model-based predictive control |

| PID | proportional-integral-differential |

| air conditioning cooling capacity | |

| occupants’ heat gain | |

| R(t) | compressor rotational speed |

| Rth | thermal resistance between indoor and outdoor environments |

| RMB | Chinese Yuan |

| RNN | recurrent neural network |

| RBR | rule-based reasoning |

| RT | refrigeration ton |

| SDK | software developing kits |

| SI | similarity index |

| SNN | spiking neural network |

| SP | set point |

| SPopm | optimized set point |

| sensor output prediction of the next stage | |

| indoor air temperature varied with time | |

| constant outdoor air temperature | |

| desired temperature set | |

| USD | united states dollar |

| VSD | variable speed drive |

| VRF | variable refrigerant flow |

| and | experience parameters for sensor value prediction |

| pheromone intensity | |

| weighting coefficients |

References

- Available online: https://www.iea.org/news/air-conditioning-use-emerges-as-one-of-the-key-drivers-of-global-electricity-demand-growth (accessed on 1 November 2019).

- Karali, N.; Shah, N.; Park, W.Y.; Khanna, N.; Ding, C.; Lin, J.; Zhou, N. Improving the energy efficiency of room air conditioners in China: Costs and benefits. Appl. Energy 2020, 258, 114023. [Google Scholar] [CrossRef]

- Schibuola, L.; Scarpa, M.; Tambani, C. Variable speed drive (VSD) technology applied to HVAC systems Cooling systems Variable speed drive (VSD) technology applied to HVAC for energy saving : An experimental investigation for energy saving : An experimental inves. Energy Procedia 2018, 148, 806–813. [Google Scholar] [CrossRef]

- Wang, S.; Jin, X. Model-based optimal control of VAV air-conditioning system using genetic algorithm. Build. Environ. 2000, 35, 471–487. [Google Scholar] [CrossRef]

- Salakij, S.; Yu, N.; Paolucci, S.; Antsaklis, P. Model-Based Predictive Control for building energy management. I: Energy modeling and optimal control. Energy Build. 2016, 133, 345–358. [Google Scholar] [CrossRef]

- Mena, R.; Rodríguez, F.; Castilla, M.; Arahal, M.R. A prediction model based on neural networks for the energy consumption of a bioclimatic building. Energy Build. 2014, 82, 142–155. [Google Scholar] [CrossRef]

- Salsbury, T.; Mhaskar, P.; Qin, S.J. Predictive control methods to improve energy efficiency and reduce demand in buildings. Comput. Chem. Eng. 2013, 51, 77–85. [Google Scholar] [CrossRef]

- Arabali, A.; Ghofrani, M.; Etezadi-Amoli, M.; Fadali, M.S.; Baghzouz, Y. Genetic-algorithm-based optimization approach for energy management. IEEE Trans. Power Deliv. 2013, 28, 162–170. [Google Scholar] [CrossRef]

- Ferreira, P.M.; Silva, S.M.; Ruano, A.E. Model based predictive control of HVAC systems for human thermal comfort and energy consumption minimisation. IFAC Proc. Vol. 2012, 45, 236–241. [Google Scholar] [CrossRef]

- Huang, H.; Chen, L.; Mohammadzaheri, M.; Hu, E. A new zone temperature predictive modeling for energy saving in buildings. Procedia Eng. 2012, 49, 142–151. [Google Scholar] [CrossRef] [Green Version]

- Huang, G.; Wang, S.; Xu, X. A robust model predictive control strategy for improving the control performance of air-conditioning systems. Energy Convers. Manag. 2009, 50, 2650–2658. [Google Scholar] [CrossRef]

- Kolokotsa, D. Comparison of the performance of fuzzy controllers for the management of the indoor environment. Build. Environ. 2003, 38, 1439–1450. [Google Scholar] [CrossRef]

- Moon, J.W.; Jung, S.K.; Kim, Y.; Han, S.H. Comparative study of artificial intelligence-based building thermal control methods—Application of fuzzy, adaptive neuro-fuzzy inference system, and artificial neural network. Appl. Therm. Eng. 2011, 31, 2422–2429. [Google Scholar] [CrossRef]

- Jahedi, G.; Ardehali, M.M. Genetic algorithm-based fuzzy-pid control methodologies for enhancement of energy efficiency of a dynamic energy system. Energy Convers. Manag. 2011, 52, 725–732. [Google Scholar] [CrossRef]

- Yucelen, T. A PID type fuzzy logic controller: Design, performance evaluation and applications with PLCs on long deadtime systems. IFAC Proc. Vol. 2006, 39, 17–22. [Google Scholar] [CrossRef]

- Kolokotsa, D.; Saridakis, G.; Pouliezos, A.; Stavrakakis, G.S. Design and installation of an advanced EIB TM fuzzy indoor comfort controller using Matlab TM. Energy Build. 2006, 38, 1084–1092. [Google Scholar] [CrossRef]

- Chaudhuri, T.; Soh, Y.C.; Li, H.; Xie, L. A feedforward neural network based indoor-climate control framework for thermal comfort and energy saving in buildings. Appl. Energy 2019, 248, 44–53. [Google Scholar] [CrossRef]

- Čongradac, V.; Kulić, F. Recognition of the importance of using artificial neural networks and genetic algorithms to optimize chiller operation. Energy Build. 2012, 47, 651–658. [Google Scholar] [CrossRef]

- Yuce, B.; Rezgui, Y.; Mourshed, M. ANN-GA smart appliance scheduling for optimized energy management in the domestic sector. Energy Build. 2016, 111, 311–325. [Google Scholar] [CrossRef]

- Moon, J.W. Comparative performance analysis of the artificial-intelligence-based thermal control algorithms for the double-skin building. Appl. Therm. Eng. 2015, 91, 334–344. [Google Scholar] [CrossRef]

- Jafarinejad, T.; Erfani, A.; Fathi, A.; Shafii, M.B. Bi-level energy-efficient occupancy profile optimization integrated with demand-driven control strategy: University building energy saving. Sustain. Cities Soc. 2019, 48, 101539. [Google Scholar] [CrossRef]

- Li, M.H.; Ren, Q.C. Optimization for the chilled water system of HVAC systems in an intelligent building. In Proceedings of the 2010 International Conference on Computational and Information Sciences, Chengdu, China, 17–19 December 2010; pp. 889–891. [Google Scholar]

- Sakawa, M.; Matsui, T. Heat load prediction in district heating and cooling systems through recurrent neural networks. Int. J. Oper. Res. 2015, 23, 284. [Google Scholar] [CrossRef]

- Mihalakakou, G.; Santamouris, M.; Tsangrassoulis, A. On the energy consumption in residential buildings. Energy Build. 2002, 34, 727–736. [Google Scholar] [CrossRef]

- Petri, I.; Li, H.; Rezgui, Y.; Yang, C.; Yuce, B.; Jayan, B. A modular optimization model for reducing energy consumption in large scale building facilities. Renew. Sustain. Energy Rev. 2014, 38, 990–1002. [Google Scholar] [CrossRef]

- Gao, L.; Wang, S.; Li, J.; Li, H. Application of the extended theory of planned behavior to understand individual’s energy saving behavior in workplaces. Resour. Conserv. Recycl. 2017, 127, 107–113. [Google Scholar] [CrossRef]

- Ortega, J.L.G.; Han, L.; Whittacker, N.; Bowring, N. A machine-learning based approach to model user occupancy and activity patterns for energy saving in buildings. In Proceedings of the 2015 Science and Information Conference, SAI 2015, London, UK, 28–30 July 2015; pp. 474–482. [Google Scholar]

- Nguyen, T.A.; Aiello, M. Energy intelligent buildings based on user activity: A survey. Energy Build. 2013, 56, 244–257. [Google Scholar] [CrossRef] [Green Version]

- Karjalainen, S. Should it be automatic or manual—The occupant’s perspective on the design of domestic control systems. Energy Build. 2013, 65, 119–126. [Google Scholar] [CrossRef]

- Kim, H.; Lee, S.K.; Kim, H.; Kim, H. Implementing home energy management system with UPnP and mobile applications. Comput. Commun. 2012, 36, 51–62. [Google Scholar] [CrossRef]

- Intille, S.S. Designing a home of the future. IEEE Pervasive Comput. 2002, 1, 76–82. [Google Scholar] [CrossRef] [Green Version]

- Byun, J.; Kim, Y.; Hwang, Z.; Park, S. An intelligent cloud-based energy management system using machine to machine communications in future energy environments. In Proceedings of the 2012 IEEE International Conference on Consumer Electronics (ICCE), Las Vegas, NV, USA, 13–16 January 2012; pp. 664–665. [Google Scholar]

- Kim, J.; Cho, W.H.; Jeong, Y.; Song, O. Intelligent energy management system for smart offices. In Proceedings of the 2012 IEEE International Conference on Consumer Electronics (ICCE), Las Vegas, NV, USA, 13–16 January 2012; pp. 668–669. [Google Scholar]

- Byun, J.; Hong, I.; Park, S. Intelligent cloud home energy management system using household appliance priority based scheduling based on prediction of renewable energy capability. IEEE Trans. Consum. Electron. 2012, 58, 1194–1201. [Google Scholar] [CrossRef]

- Gonzalez-Vidal, A.; Ramallo-Gonzalez, A.P.; Skarmeta, A. Empirical study of massive set-point behavioral data: Towards a cloud-based artificial intelligence that democratizes thermostats. In Proceedings of the 2018 IEEE International Conference on Smart Computing (SMARTCOMP), Taormina, Italy, 18–20 June 2018; pp. 211–218. [Google Scholar]

- Ciabattoni, L.; Ippoliti, G.; Benini, A.; Longhi, S.; Pirro, M. Design of a home energy management system by online neural networks. In Proceedings of the IFAC Proceedings Volumes (IFAC-PapersOnline), IFAC, Caen, France, 3–5 July 2013; pp. 677–682. [Google Scholar]

- Javed, A.; Larijani, H.; Wixted, A. Improving Energy Consumption of a Commercial Building with IoT and Machine Learning. IT Prof. 2018, 20, 30–38. [Google Scholar] [CrossRef] [Green Version]

- Dalamagkidis, K.; Kolokotsa, D.; Kalaitzakis, K.; Stavrakakis, G.S. Reinforcement learning for energy conservation and comfort in buildings. Build. Environ. 2007, 42, 2686–2698. [Google Scholar] [CrossRef]

- Lara-rosano, F.; Valverde, N.K. Knowledge-based systems for energy conservation programs. Expert Syst. Appl. 1998, 14, 25–35. [Google Scholar] [CrossRef]

- Kofler, M.J.; Kastner, W. A knowledge base for energy-efficient smart homes. In Proceedings of the 2010 IEEE International Energy Conference, Manama, Bahrain, 18–22 December 2010; pp. 85–90. [Google Scholar]

- DiSanto, K.G.; DiSanto, S.G.; Monaro, R.M.; Saidel, M.A. Active demand side management for households in smart grids using optimization and artificial intelligence. Meas. J. Int. Meas. Confed. 2018, 115, 152–161. [Google Scholar] [CrossRef]

- Jahedi, G.; Ardehali, M.M. Wavelet based artificial neural network applied for energy efficiency enhancement of decoupled HVAC system. Energy Convers. Manag. 2012, 54, 47–56. [Google Scholar] [CrossRef]

- Stavropoulos, T.G.; Kontopoulos, E.; Bassiliades, N.; Argyriou, J.; Bikakis, A.; Vrakas, D.; Vlahavas, I. Rule-based approaches for energy savings in an ambient intelligence environment. Pervasive Mob. Comput. 2015, 19, 1–23. [Google Scholar] [CrossRef]

- Yang, R.; Wang, L. Development of multi-agent system for building energy and comfort management based on occupant behaviors. Energy Build. 2013, 56, 1–7. [Google Scholar] [CrossRef]

- Wim, Z.; Timilehin, L.; Kennedy, A. Towards multi-agent systems in building automation and control for improved occupant comfort and energy efficiency—State of the art, challenges. In Proceedings of the 2013 Fourth International Conference on Intelligent Systems Design and Engineering Applications, Zhangjiajie, China, 6–7 November 2013; pp. 718–722. [Google Scholar]

- Klein, L.; Kwak, J.Y.; Kavulya, G.; Jazizadeh, F.; Becerik-Gerber, B.; Varakantham, P.; Tambe, M. Coordinating occupant behavior for building energy and comfort management using multi-agent systems. Autom. Constr. 2012, 22, 525–536. [Google Scholar] [CrossRef]

- Hadjiski, M.; Sgurev, V.; Boishina, V. Multi agent intelligent control of centralized HVAC systems. In Proceedings of the IFAC Proceedings Volumes (IFAC-PapersOnline), IFAC, Bansko, Bulgaria, 2–5 October 2006; pp. 195–200. [Google Scholar]

| AI Techniques | References | Effects |

|---|---|---|

| Genetic algorithm and model-based predictive control for the air conditioning system | [4,5,6,7,8,9,10,11,12] | Max energy saving up to 39.8% |

| Fuzzy + proportional-integral-differential controller for the air conditioning system | [12,13,14,15,16] | Max 36.8% |

| Neural networks (NNs) including artificial, spiking, and recurrent NNs for thermal comfort control and energy saving in the air conditioning system | [17,18,19,20,21,22,23,24] | Max 36.5% |

| Distributed AI for understanding users’ behavior in working spaces | [25,26,27,28,29,30,31] | Max 34.9% |

| Cloud-based AI for intelligent control | [32,33,34,35,36] | Max 22.5% |

| Improved energy consumption by the Internet of Things and machine learning/reinforcement learning/deep learning | [37,38] | Max 20% |

| Knowledge-based system for HVAC control | [39,40] | Max 20% |

| Decision-making system for household energy saving and HVAC control | [41,42] | Max 10% |

| Rule-based reasoning for the optimized scheduling control of a chiller | [43] | Max 4% |

| Multi-agent system in the end control device | [44,45,46,47] | Max 1.1% |

| Parameter | Range |

|---|---|

| Cooling capacity | 2.5–12 kW |

| Heating capacity | 3–13.5 kW |

| Air volume flow rate | 300–2500 m3/h |

| Static pressure | −50 to 450 Pa |

| Differential pressure | 0–1000 Pa |

| Pressure measurement accuracy | ±0.5 Pa |

| Pressure control accuracy | ±2 Pa |

| Indoor dry-bulb temperature | 5–45 °C |

| Indoor humidity | 35–93% |

| Outdoor dry-bulb temperature | −20 to 60 °C |

| Outdoor humidity | 25–90% |

| Indoor/outdoor temperature measurement accuracy | ±0.1 °C |

| Indoor/outdoor temperature control accuracy | ±0.2 °C |

| Indoor/outdoor humidity measurement accuracy | ±0.2 °C (WB) |

| Indoor/outdoor humidity control accuracy | ±0.5 °C (WB) |

| Standard uncertainty of energy efficiency measurement | ±0.15% |

| Parameter | Range |

|---|---|

| Cooling capacity | 1.05–10.47 kW |

| Heating capacity | 1.05–10.47 kW |

| Indoor dry-bulb temperature | 5–45 °C |

| Indoor humidity | 40–80% |

| Outdoor dry-bulb temperature | 5–60 °C |

| Outdoor humidity | 25–90% |

| Indoor/outdoor temperature measurement accuracy | ±1 °C |

| Indoor/outdoor temperature control accuracy | ±2 °C |

| Dimensions | 5 × 3 × 2.6 m3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, D.; Tsai, F.-P. Air Conditioning Energy Saving from Cloud-Based Artificial Intelligence: Case Study of a Split-Type Air Conditioner. Energies 2020, 13, 2001. https://doi.org/10.3390/en13082001

Lee D, Tsai F-P. Air Conditioning Energy Saving from Cloud-Based Artificial Intelligence: Case Study of a Split-Type Air Conditioner. Energies. 2020; 13(8):2001. https://doi.org/10.3390/en13082001

Chicago/Turabian StyleLee, Dasheng, and Fu-Po Tsai. 2020. "Air Conditioning Energy Saving from Cloud-Based Artificial Intelligence: Case Study of a Split-Type Air Conditioner" Energies 13, no. 8: 2001. https://doi.org/10.3390/en13082001

APA StyleLee, D., & Tsai, F. -P. (2020). Air Conditioning Energy Saving from Cloud-Based Artificial Intelligence: Case Study of a Split-Type Air Conditioner. Energies, 13(8), 2001. https://doi.org/10.3390/en13082001