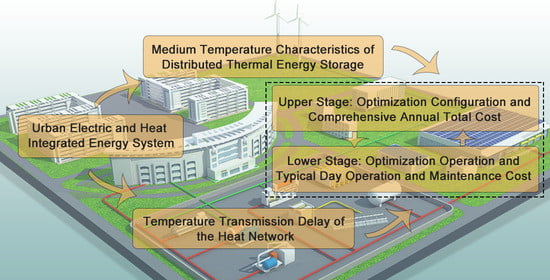

Distributed Thermal Energy Storage Configuration of an Urban Electric and Heat Integrated Energy System Considering Medium Temperature Characteristics

Abstract

:1. Introduction

2. Medium Temperature Characteristics of Distributed Thermal Energy Storage Models

2.1. Water Thermal Energy Storage

2.2. Electric Heater Phase Change Thermal Energy Storage

3. Urban Electric and Heat Integrated Energy System Models

3.1. Electric Heat Coupling Device

3.2. Wind Power

3.3. Power Plant

3.4. Temperature Transmission Delay Characteristics of the Heat Network

3.5. Electric Power Grid

4. Two-Stage Optimal Configuration Model of DTES Considering Economy

4.1. Upper Stage: Optimization of DTES Configuration Considering Comprehensive Annual Total Cost

4.2. Lower Stage: Optimization of the UEHIES Considering Typical Day Operation and Maintenance Cost

4.3. Solution Method

- Step 1:

- Read and initialize the data, and enter the upper stage;

- Step 2:

- An immune cell population representing configuration information is generated by an immune transfer strategy;

- Step 3:

- Proceed to the lower stage, optimize the variable according to the configuration information in Step 2, determine the typical daily operation and maintenance cost, and deliver the information to the upper stage;

- Step 4:

- Return to the upper stage, calculate the comprehensive annual total cost, and judge whether the algorithm converges or not. If it converges, enter Step 5; if it does not, extract the dominant immune cells to form an antigen combination, correct the parameters of immune transmission and cross mutation, and return to Step 2;

- Step 5:

- Output the results and generate the best configuration scheme.

5. Case Study

5.1. Medium Temperature Characteristics

5.1.1. Influence of Temperature Transmission Delay Characteristics of the Heat Network on Configuration Scheme

- The annual operation and maintenance cost of the scenario with TTD-HN (S4), compared with the scenario without TTD-HN (S3), is reduced by CNY 21.49 million—a decrease of 3.54%;

- The configuration heat capacity and HEX capacity of S4 compared with S3 is greatly reduced, and the annual investment cost is reduced by ¥8.709 million, or 59.4%. At the same time, the heat node selection of S4 is completely different from S3.

- During the night period, the state points of the two CHP units in S4 are closer to point B (CHP1: (150, 145.8); CHP2: (65, 30)) than those in S3, which provides more space for wind power utilization and reduces fuel consumption. Taking 1:00 as an example, the electric power of CHP1 in S4 is 163.8 MW, and the fuel consumption is 89.7 tons of standard coal per hour, which is 122.5 MW and 26.5 tons/h lower than S3. The electric power of CHP2 is 30.0 MW, and the fuel consumption is 18,900 m3 of natural gas per hour, which is 17.0 MW and 23,100 m3/h lower than S3. According to the statistics, the annual operating and maintenance cost of CHP1 and CHP2 units at night are reduced by ¥12.619 million and ¥1.816 million.

- During the day period, although the operation cost of CHP1 increases in S4, the efficiency improves. The average efficiency of CHP1 is increased from 4.610 MWh/tons (heat generation: 1.760 MWh/tons + electric generation: 2.850 MWh/tons) in S3 to 4.722 MWh/tons (heat generation: 1.905 MWh/tons + electric generation: 2.817 MWh/tons). In this period, the electricity generation of CHP1 increases by 53.9 MWh and the heat generation increases by 322.1 MWh, while the annual operating cost increases by ¥4.158 million, or 33% of the cost reduction during the night. CHP2 mainly undertakes peak heat load regulation at night, and its daytime operation state points are basically unchanged.

5.1.2. Influence of Medium Temperature Characteristics of Distributed Thermal Energy Storage on the Configuration Scheme

5.2. Distributed Thermal Energy Storage Types

- S6: Only EH-PHTES is equipped;

- S7: WTES and EH-PHTES are configured together.

- In the three scenarios, H4, H18, and H19 are selected to configure DTES because of their large restriction of the regulation ability of the heat network. In scenarios S6 and S7, the H22–E25 node is selected to configure EH-PHTES, because H22–E25 is the closest electricity and heat load coupling node to the wind farm. Configuring EH-PHTES here can make use of the wind power nearby;

- Compared with S5, the annual operating and maintenance cost of S6 decreases by ¥1.499 million, the annual investment cost increases by ¥2.011 million, and the annual total cost is ¥0.512 million greater. Compared with S5, the annual operating and maintenance cost of S7 is reduced by ¥1.041 million, the annual investment cost is increased by ¥0.534 million, and the annual total cost is reduced by ¥0.506 million.

- In S5, the costs of CHP1 and CHP2 units, TPG units and DTES are the lowest among the three scenarios, and the total cost is reduced by ¥0.801 million and ¥0.217 million, respectively, compared with S6 and S7. This is because WTES can not only discharge in the night period but also charge in the day period, which has the strongest effect on improving the regulation ability of the heat network. Additionally, EH-PHTES can only discharge to the heat network, so the regulation ability of the heat network is limited;

- The wind curtailment penalty cost in S6 is the lowest in three scenarios, at ¥2.298 million and ¥1.041 million lower than that in S5 and S7. This is because EH-PHTES can directly use wind power for heating, which is more conducive to wind power consumption;

- In the S7 configuration scheme, three nodes (H4, H18, H19) with a severe restriction on the improvement of the heat network regulation ability are selected to configure WTES, and the node (H22–E25) with the most direct use of wind power is selected to configure EH-PHTES. The advantages of the two types of DTES are fully reflected to optimize the operation cost, and the investment cost is not excessively high. Thus, the comprehensive annual total cost is the lowest of the three scenarios.

5.3. Heat Load Types

- S8: The commercial heat load is set at the head nodes H4, H5, H18, and H19;

- S9: The commercial heat load is set at the end nodes H14, H16, H27, and H28.

5.4. Wind Power Capacity

- S10: The capacity of wind power is set to 100 MW;

- S11: The capacity of wind power is set to 300 MW.

- With the wind power capacity of S10, S7, and S11 increasing in turn, the wind power utilization gradually increases and the annual operation and maintenance cost of the units gradually decreases; however, at the same time, the wind curtailment penalty cost increases. This is because in the day period, wind farms and CHP and TPG units share the power load supply and give priority to clean and cheap wind power output. With the increase of wind power capacity, the wind power generation and utilization quantity increase, the power outputs of CHP and TPG units decrease, fuel consumption decreases, and the annual operation and maintenance cost decreases. However, at night, there is insufficient utilization space for wind power. With the increase in capacity, the wind curtailment power increases and the annual cost of the wind curtailment penalty increases.

- With the increase of wind power capacity, the amount of EH-PHTES, the heat and HEX capacity, and the rated power of EH increase. This is because the increase of wind curtailment power is more conducive to the EH-PHTES system realizing its potential to use nearby wind power. In order to make more use of wind power, the number of EH-PHTES systems and the capacity of each component are required to increase continuously to improve the wind power utilization. However, this also causes an increase in the investment cost.

5.5. Centralized Thermal Energy Storage

6. Conclusions

- (1)

- Considering TTD-HN, the heat network can be effectively utilized, the heat capacity and HEX capacity can be reduced, and the investment cost can be reduced. At the same time, considering MTC-DTES can avoid the waste of configuration heat capacity and reduce the actual operation and maintenance costs;

- (2)

- Compared with the centralized configuration, the heat and HEX capacity of DTES is significantly decreased, the thermal energy storage investment cost is reduced, and the economic factors of the system are improved;

- (3)

- WTES has a stronger effect on improving the regulation ability of the heat network and EH-PHTES is more conducive to improving the wind power utilization. The capacity of wind power is a major factor when determining the configuration scheme of EH-PHTES;

- (4)

- Different types and distributions of heat load directly affect the temperature of HES, resulting in the change of the location and number of nodes that severely restrict the regulating ability of the heat network, thus changing the configuration nodes and investment cost of DTES.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Superscripts: | |||

| Combined heat and power plant | Electric heater phase change thermal energy storage | ||

| Water thermal energy storage | Heat network | ||

| Thermal power generation | Heat exchange station | ||

| Heat source station | Heat exchanger | ||

| Operation and maintenance | Electric heater | ||

| Wind power | Water thermal energy storage | ||

| Distributed thermal energy storage | Discharge heat power | ||

| Charge heat power | |||

| Subscripts: | |||

| / | Node number | / | Supply/return pipe |

| Time interval number | / | Maximum/minimum value | |

| Path number between HSS and HES | Upper value | ||

| Corner point number of CHP | Lower value | ||

| 1/2 | Primary/secondary heat network | Investment | |

| Variables: | |||

| Mass flow of the heat network into HEX, kg/s | Mass flow of WTES pipe, kg/s | ||

| Mass flow of the primary heat network into HEX in node i at time t, kg/s | Mass flow of HES connected to the primary heat network in node i, kg/s | ||

| Mass flow of the secondary heat network into HEX in node i at time t, kg/s | Mass flow of HES connected to the secondary heat network in node i, kg/s | ||

| Mass flow of EH-PHTES circulating pipes, kg/s | Mass flow of HSS connected to the primary heat network in node i, kg/s | ||

| Heat power of the heat network, MW | Heat power of HEX, MW | ||

| Heat power of WTES, MW | Heat power of EH-PHTES, MW | ||

| Heat charging power of WTES in node i at time t, MW | Heat charging power of EH-PHTES in node i at time t, MW | ||

| Heat discharging power of WTES in node i at time t, MW | Heat discharging power of EH-PHTES in node i at time t, MW | ||

| Temperature of the heat network transfer medium in HEX inlet, °C | Temperature of the heat network transfer medium in HEX outlet, °C | ||

| Temperature of WTES upper zone, °C | Temperature of WTES lower zone, °C | ||

| Temperature of HES supply pipe connected to the primary heat network, °C | Temperature of WTES water tank average value in node i, °C | ||

| Temperature of HES supply pipe connected to the primary heat network in node i at time t, °C | Temperature of HES return pipe connected to the secondary heat network in node i at time t, °C | ||

| Phase transition temperature of EH-PHTES, °C | Designed temperature of HES, °C | ||

| Temperature of HSS supply pipe in node i, °C | Temperature of HSS return pipe in node i, °C | ||

| Temperature of ambient, °C | Indoor temperature, °C | ||

| Temperature difference at HEX outlet, °C | Temperature difference at HEX inlet, °C | ||

| Capacity of WTES HEX connected to the primary heat network, MW/°C | The actual heat transfer capacity of HEX, MW/°C | ||

| Capacity of EH-PHTES HEX connected to the secondary heat network, MW/°C | Maximum of WTES HEX configuration capacity, MW/°C | ||

| Capacity of WTES HEX connected to the secondary heat network, MW/°C | Maximum of EH-PHTES HEX configuration capacity, MW/°C | ||

| Thermal resistance of WTES connected to the primary heat network in node i at time t, °C/MW | The number n EH-PHTES configuration node | ||

| Thermal resistance of EH-PHTES connected to the secondary heat network in node i at time t, °C/MW | The number n WTES configuration node | ||

| Thermal resistance of WTES connected to the secondary heat network in node i at time t, °C/MW | Set of WTES configuration nodes | ||

| Set of EH-PHTES configuration nodes. | Set of WTES alternative configuration nodes | ||

| Set of EH-PHTES alternative configuration nodes. | Set of CHP units | ||

| Set of TPG units | Set of wind farms | ||

| Set of DTES | Set of typical day numbers | ||

| Set of pipes that the path passes through | Set of time interval number | ||

| Set of pipes/nodes that the path passes through | Set of paths from node i to node j | ||

| Maximum of EH-PHTES configuration capacity, MWh | Maximum of WTES configuration capacity, MWh | ||

| Minimum of WTES heat quantity in node i, MWh | Maximum of WTES heat quantity in node i, MWh | ||

| Minimum of EH-PHTES heat quantity in node i, MWh | Maximum of EH-PHTES heat quantity in node i, MWh | ||

| Heat capacity of WTES tank in node i, MWh | Quantity of heat in WTES in node i at time t, MWh | ||

| Heat capacity of EH-PHTES storage tank in node i, MWh | Quantity of heat in EH-PHTES in node i at time t, MWh | ||

| Heat power of CHP, MW | Electric power of CHP, MW | ||

| Heat power of CHP at corner point k, MW | Electric power of CHP at corner point k, MW | ||

| Set of corner point k | Set of CHP in node i | ||

| Heat load of HES in node i at time t, MW | Electric active power in node i at time t, MW | ||

| Electric reactive power in node i at time t, MW | Electric active load, MW | ||

| Rated power of EH, MW | Maximum ramping power, MW/h | ||

| Maximum rated power of EH, MW | Electric power of EH in node i at time t, MW | ||

| Predicted wind power in node i at time t, MW | Real wind power in node i at time t, MW | ||

| Wind curtailment power in node i at time t, MW | Wind power capacity, MW | ||

| Electric reactive load, MVar | Annual investment cost, ¥ | ||

| Comprehensive annual total cost, ¥ | Investment cost of WTES in node i, ¥ | ||

| Annual operation and maintenance cost, ¥ | Operation cost of CHP at time t, ¥ | ||

| Investment cost of EH-PHTES in node i, ¥ | Wind curtailment cost at time t, ¥ | ||

| Operation cost of TPG at time t, ¥ | Node voltage, p.u. | ||

| Operation and maintenance cost of DTES at time t, ¥ | Speed of wind farm in node i at time t, m/s | ||

| Parameters: | |||

| Real part of node admittance matrix | Imaginary part of node admittance matrix | ||

| Real part of node admittance matrix without grounding branches | Imaginary part of node admittance matrix without grounding branches | ||

| Combination coefficients of CHP | Temperature transfer coefficient | ||

| Temperature loss coefficient of pipe | Temperature distribution coefficient of node | ||

| Time delay of path , h | Radiator coefficient of thermal users | ||

| The fuel consumption of TPG, t/MWh | Dispatch time interval, h | ||

| Discount rate, % | Design service life, year | ||

| Number of general days represented by typical day in a year, day | Electric to thermal efficiency of EH, % | ||

| The initial time interval | The final time interval | ||

| Specific heat capacity of heat medium, kJ/(kg·°C) | Price of fuel, ¥/t | ||

| Medium density, kg/m3 | Price of heat quantity capacity, ¥/MWh | ||

| Price of wind curtailment, ¥/MWh | Price of CHP unit at corner point k, ¥/h | ||

| Maintenance price of equipment heat power, ¥/MWh | Price of EH capacity, ¥/MW | ||

| Maintenance price of equipment electric power, ¥/MWh | Price of heat exchanger, ¥/(MW/°C) | ||

| Latent heat of phase change material, kWh/kg | Volume of phase change material, m3 | ||

| Liquid ratio of PHTES, % | Volume of WTES water tank, m3 | ||

| Cut-in speed of wind generator, m/s | Cut-out speed of wind generator, m/s | ||

| Rated speed of wind generator, m/s | Rounded-up value of | ||

| Rounded-down value of | |||

Appendix A

| Node | Type | HL(MW) | Delay(h) | m(kg/s) | Node | Type | HL(MW) | Delay(h) | m(kg/s) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 3 | 0.00 | 15 | 1 | 0.00 | ||||

| 2 | 1 | 0.00 | 16 | 1 | 8.05 | 6.459 | 47.92 | ||

| 3 | 1 | 0.00 | 17 | 1 | 0.00 | ||||

| 4 | 1 | 17.20 | 1.060 | 102.38 | 18 | 1 | 8.84 | 1.032 | 52.62 |

| 5 | 1 | 5.51 | 1.742 | 32.80 | 19 | 1 | 12.39 | 1.425 | 73.75 |

| 6 | 1 | 14.61 | 2.683 | 86.96 | 20 | 1 | 19.92 | 1.641 | 118.57 |

| 7 | 1 | 20.22 | 2.820 | 120.36 | 21 | 1 | 27.57 | 1.978 | 164.11 |

| 8 | 1 | 12.42 | 2.960 | 73.93 | 22 | 1 | 34.16 | 2.374 | 203.33 |

| 9 | 1 | 10.55 | 3.532 | 62.80 | 23 | 1 | 28.44 | 3.049 | 169.29 |

| 10 | 1 | 0.00 | 24 | 1 | 11.23 | 3.873 | 66.85 | ||

| 11 | 1 | 9.68 | 4.222 | 57.63 | 25 | 1 | 16.93 | 4.612 | 100.77 |

| 12 | 1 | 7.63 | 4.373 | 45.42 | 26 | 1 | 10.40 | 5.544 | 61.90 |

| 13 | 1 | 8.97 | 4.672 | 53.39 | 27 | 1 | 8.41 | 5.986 | 50.06 |

| 14 | 1 | 6.48 | 4.908 | 38.57 | 28 | 1 | 21.44 | 6.540 | 127.62 |

| No | F_No | T_No | Length (m) | Diameter (m) | m (kg/s) | Conductivity (W/(m·°C) | Roughness (m) |

|---|---|---|---|---|---|---|---|

| 1 | 1 | 2 | 1000 | 1 | 1911.018 | 0.2 | 0.005 |

| 2 | 2 | 3 | 2264.5 | 1 | 722.149 | 0.2 | 0.005 |

| 3 | 3 | 4 | 865 | 1 | 722.149 | 0.2 | 0.005 |

| 4 | 4 | 5 | 1939 | 1 | 619.768 | 0.2 | 0.005 |

| 5 | 5 | 6 | 2531 | 1 | 586.970 | 0.2 | 0.005 |

| 6 | 6 | 7 | 315 | 1 | 500.006 | 0.2 | 0.005 |

| 7 | 7 | 8 | 300 | 0.9 | 379.649 | 0.2 | 0.005 |

| 8 | 8 | 9 | 990 | 0.9 | 305.720 | 0.2 | 0.005 |

| 9 | 9 | 10 | 689 | 0.9 | 242.923 | 0.2 | 0.005 |

| 10 | 10 | 11 | 259 | 0.9 | 242.923 | 0.2 | 0.005 |

| 11 | 11 | 12 | 200 | 0.8 | 185.298 | 0.2 | 0.005 |

| 12 | 12 | 13 | 300 | 0.8 | 139.881 | 0.2 | 0.005 |

| 13 | 13 | 14 | 260 | 0.6 | 86.488 | 0.2 | 0.005 |

| 14 | 14 | 15 | 402 | 0.6 | 47.917 | 0.2 | 0.005 |

| 15 | 15 | 16 | 1600 | 0.35 | 47.917 | 0.2 | 0.005 |

| 16 | 2 | 17 | 2500 | 1 | 1188.869 | 0.2 | 0.005 |

| 17 | 17 | 18 | 2500 | 1 | 1188.869 | 0.2 | 0.005 |

| 18 | 18 | 19 | 2050 | 1 | 1136.250 | 0.2 | 0.005 |

| 19 | 19 | 20 | 1050 | 1 | 1062.500 | 0.2 | 0.005 |

| 20 | 20 | 21 | 1800 | 0.9 | 943.929 | 0.2 | 0.005 |

| 21 | 21 | 22 | 1750 | 0.9 | 779.821 | 0.2 | 0.005 |

| 22 | 22 | 23 | 2200 | 0.9 | 576.488 | 0.2 | 0.005 |

| 23 | 23 | 24 | 1900 | 0.9 | 407.202 | 0.2 | 0.005 |

| 24 | 24 | 25 | 1800 | 0.8 | 340.357 | 0.2 | 0.005 |

| 25 | 25 | 26 | 1600 | 0.8 | 239.583 | 0.2 | 0.005 |

| 26 | 26 | 27 | 1000 | 0.6 | 177.679 | 0.2 | 0.005 |

| 27 | 27 | 28 | 900 | 0.6 | 127.619 | 0.2 | 0.005 |

| Corner Points | (MW) | (MW) | (tons/h) | (CNY/h) | |

| CHP1 | A | 0 | 180 | 55.8 | 27,900 |

| B | 150 | 145.8 | 85.78 | 42,891 | |

| C | 270 | 387 | 137.98 | 68,985 | |

| D | 0 | 450 | 135 | 67,500 | |

| Corner Points | (MW) | (MW) | (m3/h) | (CNY/h) | |

| CHP1 | A | 0 | 40 | 13,333 | 34,667 |

| B | 65 | 30 | 18,889 | 49,111 | |

| C | 125 | 85 | 42,000 | 109,200 | |

| D | 0 | 100 | 25,000 | 65,000 |

| 0.35 | |||||

| 0.08 | |||||

| 95 °C | 65 °C | 20 years | |||

| 60 °C | ¥1,000,000 | 4.2 | |||

| ¥150,000 | ¥15,000,000 | 20 °C | |||

| ¥15,000,000 | ¥1,500,000 | 100% | |||

| ¥20 | ¥20 | / | 75 °C/40 °C | ||

| 160 MWh | 50 MWh | / | 80 °C/60 °C | ||

| 2.0 MW/°C | 2.0 MW/°C | / | 120 °C/95 °C | ||

| 2.0 MW/°C | 50 MW |

| Heat Node | 4 | 5 | 6 | 7 | 8 | 9 | 11 | 12 | 13 | 14 | 16 |

| Electric Node | 1 | 1 | 22 | 21 | 30 | 30 | 19 | 19 | 29 | 28 | 27 |

| Heat Node | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 |

| Electric Node | 3 | 8 | 7 | 25 | 25 | 24 | 24 | 13 | 14 | 15 | 17 |

Appendix B

References

- Abbott, D. Keeping the energy debate clean: How do we supply the world’s energy needs? Proc. IEEE 2010, 98, 42–66. [Google Scholar] [CrossRef]

- Kober, T.; Schiffer, H.-W.; Densing, M.; Panos, E. Global energy perspectives to 2060—WEC’s World Energy Scenarios 2019. Energy Strat. Rev. 2020, 31, 100523. [Google Scholar] [CrossRef]

- GWEC. Global Wind Report 2019. Available online: https://gwec.net/docs/global-wind-report-2019/ (accessed on 1 September 2020).

- Wu, J.; Yan, J.; Jia, H.; Hatziargyriou, N.; Djilali, N.; Sun, H. Integrated Energy Systems. Appl. Energy 2016, 167, 155–157. [Google Scholar] [CrossRef]

- Mancarella, P. MES (multi-energy systems): An overview of concepts and evaluation models. Energy 2014, 65, 1–17. [Google Scholar] [CrossRef]

- Li, G. Sensible heat thermal storage energy and exergy performance evaluations. Renew. Sustain. Energy Rev. 2016, 53, 897–923. [Google Scholar] [CrossRef]

- Kousksou, T.; Jamil, A.; El Rhafiki, T.; Zeraouli, Y. Paraffin wax mixtures as phase change materials. Sol. Energy Mater. Sol. Cells 2010, 94, 2158–2165. [Google Scholar] [CrossRef]

- Alva, G.; Lin, Y.; Fang, G. An overview of thermal energy storage systems. Energy 2018, 144, 341–378. [Google Scholar] [CrossRef]

- Vandermeulen, A.; Van Der Heijde, B.; Helsen, L. Controlling district heating and cooling networks to unlock flexibility: A review. Energy 2018, 151, 103–115. [Google Scholar] [CrossRef]

- Schuchardt, G.K. Integration of decentralized thermal storages within District Heating (DH) Networks. Environ. Clim. Technol. 2016, 18, 5–16. [Google Scholar] [CrossRef] [Green Version]

- Jebamalai, J.M.; Marlein, K.; Laverge, J. Influence of centralized and distributed thermal energy storage on district heating network design. Energy 2020, 202, 117689. [Google Scholar] [CrossRef]

- Victoria, M.; Zhu, K.; Brown, T.; Andresen, G.B.; Greiner, M. The role of storage technologies throughout the decarbonisation of the sector-coupled European energy system. Energy Convers. Manag. 2019, 201, 111977. [Google Scholar] [CrossRef] [Green Version]

- Good, N.; Mancarella, P. Flexibility in multi-energy communities with electrical and thermal storage: A stochastic, robust approach for multi-service demand response. IEEE Trans. Smart Grid 2017, 10, 503–513. [Google Scholar] [CrossRef]

- Patteeuw, D.; Bruninx, K.; Arteconi, A.; Delarue, E.; D’haeseleer, W.; Helsen, L. Integrated modeling of active demand re-sponse with electric heating systems coupled to thermal energy storage systems. Appl. Energy 2015, 151, 306–319. [Google Scholar] [CrossRef] [Green Version]

- Good, N.; Karangelos, E.; Navarro-Espinosa, A.; Mancarella, P. Optimization under uncertainty of thermal storage-based flexible demand response with quantification of residential users’ discomfort. IEEE Trans. Smart Grid 2015, 6, 2333–2342. [Google Scholar] [CrossRef]

- Marguerite, C.; Andresen, G.B.; Dahl, M. Multi-criteria analysis of storages integration and operation solutions into the dis-trict heating network of Aarhus—A simulation case study. Energy 2018, 158, 81–88. [Google Scholar] [CrossRef]

- Dincer, I.; Ezan, M.A. Thermal energy storage applications. In Heat Storage: A Unique Solution for Energy Systems; Springer: Cham, Switzerland, 2018; pp. 85–135. [Google Scholar]

- Zhang, L.; Xiong, X.; Hu, J. Operation of a Microgrid System with Distributed Energy Resources and Storage. Lect. Notes Elect. Eng. 2015, 313, 495–502. [Google Scholar]

- Kong, X.; Bai, L.; Hu, Q.; Li, F.; Wang, C. Day-ahead optimal scheduling method for grid-connected microgrid based on energy storage control strategy. J. Mod. Power Syst. Clean Energy 2016, 4, 648–658. [Google Scholar] [CrossRef] [Green Version]

- Guillén-Lambea, S.; Carvalho, M.; Delgado, M.; Lazaro, A. Sustainable enhancement of district heating and cooling configurations by combining thermal energy storage and life cycle assessment. Clean Technol. Environ. Policy 2021, 23, 857–867. [Google Scholar] [CrossRef]

- Thomson, A.; Claudio, G. The Technical and Economic Feasibility of Utilising Phase Change Materials for Thermal Storage in District Heating Networks. Energy Proc. 2019, 159, 442–447. [Google Scholar] [CrossRef]

- Xin-Rui, L.; Fu-Jia, Z.; Qiu-Ye, S.; Peng, J. Location and Capacity Selection Method for Electric Thermal Storage Heating Equip-ment Connected to Distribution Network Considering Load Characteristics and Power Quality Management. Appl. Sci. 2020, 10, 2666. [Google Scholar]

- Guo, Y.; Wang, C.; Shi, Y.; Guo, C.; Shang, J.; Yang, X. Comprehensive optimization configuration of electric and thermal cloud energy storage in regional integrated energy system. Power Syst. Technol. 2020, 44, 1611–1623. [Google Scholar]

- Li, Z.; Wu, W.; Shahidehpour, M.; Wang, J.; Zhang, B. Combined heat and power dispatch considering pipeline energy storage of district heating network. IEEE Trans. Sustain. Energy 2016, 7, 12–22. [Google Scholar] [CrossRef]

- Cheng, H.; Wu, J.; Luo, Z.; Zhou, F.; Liu, X.; Lu, T. Optimal Planning of Multi-Energy System Considering Thermal Storage Capacity of Heating Network and Heat Load. IEEE Access 2019, 7, 13364–13372. [Google Scholar] [CrossRef]

- Li, Z.; Wu, W.; Wang, J.; Zhang, B.; Zheng, T. Transmission-Constrained Unit Commitment Considering Combined Electricity and District Heating Networks. IEEE Trans. Sustain. Energy 2016, 7, 480–492. [Google Scholar] [CrossRef]

- Zhao, B.; Zhang, X.; Ni, C.; Mu, Y.; Wang, M.; Meng, X. Optimal Scheduling Method for Electrical-Thermal Integrated Energy System Considering Heat Storage Characteristics of Heating Network. In Proceedings of the 2019 IEEE Innovative Smart Grid Technologies—Asia (ISGT Asia), Chengdu, China, 24 October 2019; p. 19093752. [Google Scholar] [CrossRef]

- Guo, Z.-Y.; Zhu, H.-Y.; Liang, X.-G. Entransy—A physical quantity describing heat transfer ability. Int. J. Heat Mass Transf. 2007, 50, 2545–2556. [Google Scholar] [CrossRef]

- Chen, Q.; Liang, X.-G.; Guo, Z.-Y. Entransy theory for the optimization of heat transfer—A review and update. Int. J. Heat Mass Transf. 2013, 63, 65–81. [Google Scholar] [CrossRef]

- Shen, Y.; Zhang, H.; Xu, H.; Yu, P.; Bai, T. Maximum heat transfer capacity of high temperature heat pipe with triangular grooved wick. J. Cent. South Univ. 2015, 22, 386–391. [Google Scholar] [CrossRef]

- Miha, B.; Bojan, G.; Iztok, G.; Ivan, B. Dynamic behaviour of a plate heat exchanger: Influence of temperature disturbances and flow configurations. Int. J. Heat Mass Transf. 2020, 163, 120439. [Google Scholar]

- Al-Dawery, S.K.; Alrahawi, A.M.; Al-Zobai, K.M. Dynamic modeling and control of plate heat exchanger. Int. J. Heat Mass Transf. 2012, 55, 6873–6880. [Google Scholar] [CrossRef]

- Wang, Y.; You, S.; Zheng, W.; Zhang, H.; Zheng, X.; Miao, Q. State space model and robust control of plate heat exchanger for dynamic performance improvement. Appl. Therm. Eng. 2018, 128, 1588–1604. [Google Scholar] [CrossRef]

- Chenhui, L.; Wenchuan, W.; Bin, W.; Mohammad, S.; Boming, Z. Joint Commitment of Generation Units and Heat Exchange Stations for Combined Heat and Power Systems. IEEE Trans. Sustain. Energy 2019, 11, 1118–1127. [Google Scholar]

- Zhao, C.; Lu, W.; Tian, Y. Heat transfer enhancement for thermal energy storage using metal foams embedded within phase change materials (PCMs). Sol. Energy 2010, 84, 1402–1412. [Google Scholar] [CrossRef] [Green Version]

- Inaba, H.; Kim, M.; Horibe, A. Melting Heat Transfer Characteristics of Microencapsulated Phase Change Material Slurries with Plural Microcapsules Having Different Diameters. J. Heat Transf. 2004, 126, 558–565. [Google Scholar] [CrossRef]

- Wang, L.; Su, J.; Ren, L. Preparation of thermal energy storage microcapsule by phase change. Polym. Mater. Sci. Eng. 2005, 21, 276–279. [Google Scholar]

- Lu, Q.; Hu, B.; Wang, H.; Zhang, N.; Liu, L. Heat-supply of thermal power plant in wind-heat conflict. Electr. Power. Autom. Equip. 2017, 37, 236–244. [Google Scholar]

- Danish Energy Agency. Technology Data for Energy Plants. Available online: https://ens.dk/sites/ens.dk/files/Statistik/technology_data_catalogue_for_el_and_dh_-_0009.pdf (accessed on 12 November 2020).

- Zheng, J.; Zhou, Z.; Zhao, J.; Wang, J. Integrated heat and power dispatch truly utilizing thermal inertia of district heating network for wind power integration. Appl. Energy 2018, 211, 865–874. [Google Scholar] [CrossRef]

- Lahdelma, R.; Hakonen, H. An efficient linear programming algorithm for combined heat and power production. Eur. J. Oper. Res. 2003, 148, 141–151. [Google Scholar] [CrossRef]

- Davide, A.; Francesco, C.; Ludovico, T. Wind Turbine Power Curve Upgrades. Energies 2018, 11, 1300. [Google Scholar]

- Cheon, J.; Kim, J.; Lee, J.; Lee, K.; Choi, Y. Development of Hardware-in-the-Loop-Simulation Testbed for Pitch Control System Performance Test. Energies 2019, 12, 2031. [Google Scholar] [CrossRef] [Green Version]

- Hassan, A.; Han, P.; Steven, R.W.; Beni, S. Cost–Benefit Analysis of HELE and Subcritical Coal-Fired Electricity Generation Technologies in Southeast Asia. Sustainability 2021, 13, 1591. [Google Scholar]

- Catalina, H.M.; Maria, T.C.G.; Alois, S.; Alvaro, L. Comparison between Concentrated Solar Power and Gas-Based Gener-ation in Terms of Economic and Flexibility-Related Aspects in Chile. Energies 2021, 14, 1063. [Google Scholar]

- Oleksii, E.; Vitalii, Z. Usage of biomass CHP for balancing of power grid in Ukraine. E3S Web Conf. In Proceedings of the 8th International Conference on Thermal Equipment, Renewable Energy and Rural Development, Targoviste, Romania, 20 August 2019; p. 02005. [Google Scholar] [CrossRef]

- Wei, W.; Shi, Y.; Hou, K.; Guo, L.; Wang, L.; Jia, H.; Wu, J.; Tong, C. Coordinated Flexibility Scheduling for Urban Integrated Heat and Power Systems by Considering the Temperature Dynamics of Heating Network. Energies 2020, 13, 3273. [Google Scholar] [CrossRef]

- Wang, D.; Zhi, Y.-Q.; Jia, H.-J.; Hou, K.; Zhang, S.-X.; Du, W.; Wang, X.-D.; Fan, M.-H. Optimal scheduling strategy of district integrated heat and power system with wind power and multiple energy stations considering thermal inertia of buildings under different heating regulation modes. Appl. Energy 2019, 240, 341–358. [Google Scholar] [CrossRef]

- Rafalskaya, T.A. Investigating the possibility of using low-temperature heat supply with the central qualitative regulation. Therm. Eng. 2019, 66, 858–867. [Google Scholar] [CrossRef]

- Dongli, Y.; Jun, C.; Congwei, T.; Zhilong, W.; Chen, L.; Hongfu, W. Optimal Energy Flow of Combined Electrical and Heating Multi-energy System Considering the Linear Network Constraints. Proc. CSEE 2019, 39, 1933–1944. [Google Scholar]

- Seyed, M.F.; Sajjad, A.G.B.G.; Seyed, H.H.; Mehrdad, A. Introducing a Novel DC Power Flow Method with Reactive Power Considerations. IEEE Trans. Power Syst. 2014, 30, 3012–3023. [Google Scholar]

- Mohammad, A.M.; Mohammad, H.; Kazem, Z.; Mehdi, A.; Behnam, M.-I.; Mousa, M.; Amjad, A.-M. A novel hybrid two-stage framework for flexible bidding strategy of reconfigurable micro-grid in day-ahead and real-time markets. Int. J. Electr. Power Energy Syst. 2020, 123, 106293. [Google Scholar]

- Yuanxing, X.; Qingshan, X.; Jun, Z.; Xiaodong, Y. Two-stage robust optimisation of user-side cloud energy storage configuration considering load fluctuation and energy storage loss. IET Gener. Transm. Distrib. 2020, 14, 3278–3287. [Google Scholar]

- Wang, C.; Yu, B.; Xiao, J.; Guo, L. Multi-scenario, multi-objective optimization of grid-parallel Microgrid. In Proceedings of the 2011 4th International Conference on Electric Utility Deregulation and Restructuring and Power Technologies (DRPT), Weihai, China, 6–9 July 2011. [Google Scholar] [CrossRef]

- MOHURD. Code for Urban Heating Supply Planning, 2nd ed.; China Architecture & Building Press: Beijing, China, 2015; pp. 12–51.

- Zhang, N. Properties Control and Heat Transfer Enhancement of Fatty Acids Phase Change Materials. Ph.D. Thesis, Southwest Jiaotong University, Chengdu, China, 2016. [Google Scholar]

- Zhang, N.; Yanping, Y.; Yaguang, Y.; Cao, X.; Yang, X. Effect of carbon nanotubes on the thermal behaviour of palmitic–stearic acid eutectic mixtures as phase change materials for energy storage. Sol. Energy 2014, 110, 64–70. [Google Scholar] [CrossRef]

- Chen, X.; Kang, C.; O’Malley, M.; Xia, Q.; Bai, J.; Liu, C.; Sun, R.; Wang, W.; Li, H. Increasing the Flexibility of Combined Heat and Power for Wind Power Integration in China: Modeling and Implications. IEEE Trans. Power Syst. 2015, 30, 1848–1857. [Google Scholar] [CrossRef]

| Scenarios | TTD-HN | WTES Configuration | MTC-DTES |

|---|---|---|---|

| S1 | No | No | -- |

| S2 | Yes | No | -- |

| S3 | No | Yes | No |

| S4 | Yes | Yes | No |

| S5 | Yes | Yes | Yes |

| Scenarios | Node | Annual Cost 1 | |||||

|---|---|---|---|---|---|---|---|

| S1 | -- | -- | -- | -- | 65,362.9 | -- | 65,362.9 |

| S2 | -- | -- | -- | -- | 59,873.3 | -- | 59,873.3 |

| S3 | H21 | 160 | 0.4 | 0.5 | 60,687.6 | 1466.7 | 62,154.2 |

| H22 | 160 | 0.5 | 0.6 | ||||

| H23 | 160 | 0.4 | 0.5 | ||||

| H28 | 120 | 0.3 | 0.4 | ||||

| S4 | H4 | 65 | 0.3 | 0.3 | 58,538.6 | 595.8 | 59,134.4 |

| H18 | 35 | 0.1 | 0.2 | ||||

| H19 | 40 | 0.2 | 0.2 | ||||

| H20 | 60 | 0.3 | 0.3 | ||||

| S5 | H4 | 55 | 0.4 | 0.2 | 58,707.3 | 542.4 | 59,249.7 |

| H18 | 25 | 0.2 | 0.1 | ||||

| H19 | 40 | 0.3 | 0.2 | ||||

| H20 | 45 | 0.3 | 0.2 | ||||

| Scenarios | CHP1 | CHP2 | TPG | Wind Curtailment | DTES |

|---|---|---|---|---|---|

| S3 | 25,769.3 | 15,823.5 | 16,664.0 | 2025.7 | 405.0 |

| S4 | 24,923.2 | 15,641.9 | 16,565.1 | 1272.7 | 135.7 |

| Reduction | 846.1 | 181.6 | 98.9 | 753.0 | 269.3 |

| Scenarios | |||

|---|---|---|---|

| S4 | 58,538.6 | 595.8 | 59,134.4 |

| NS4 | 58,763.6 | 595.8 | 59,359.4 |

| S5 | 58,707.3 | 542.4 | 59,249.7 |

| Scenarios | Node 1 | Annual Cost | |||||

|---|---|---|---|---|---|---|---|

| S5 | H4 | 55 | 0.4 | 0.2 | 58,707.3 | 542.4 | 59,249.7 |

| H18 | 25 | 0.2 | 0.1 | ||||

| H19 | 40 | 0.3 | 0.2 | ||||

| H20 | 45 | 0.3 | 0.2 | ||||

| S6 | H4–E1 | 8.0 | 3.0 | 0.2 | 58,557.4 | 743.5 | 59,300.9 |

| H18–E3 | 5.0 | 3.0 | 0.2 | ||||

| H19–E8 | 6.0 | 3.0 | 0.2 | ||||

| H22–E25 | 12.0 | 8.0 | 0.5 | ||||

| S7 | H4 | 30 | 0.2 | 0.1 | 58,603.2 | 595.8 | 59,199.1 |

| H18 | 25 | 0.2 | 0.1 | ||||

| H19 | 35 | 0.3 | 0.2 | ||||

| H22–E25 | 9.0 | 8.0 | 0.5 | ||||

| Sceneries | CHP1 | CHP2 | TPG | Wind Curtailment | DTES |

|---|---|---|---|---|---|

| S5 | 24,981.9 | 15,651.0 | 16,610.4 | 1352.2 | 111.7 |

| S6 | 24,997.0 | 15,687.4 | 16,622.1 | 1122.4 | 128.6 |

| S7 | 24,987.0 | 15,653.2 | 16,619.4 | 1226.5 | 117.1 |

| Scenarios | Node | Annual Cost | |||||

|---|---|---|---|---|---|---|---|

| S7 | H4 | 30 | 0.2 | 0.1 | 58,603.2 | 595.8 | 59,199.1 |

| H18 | 25 | 0.2 | 0.1 | ||||

| H19 | 35 | 0.3 | 0.2 | ||||

| H22–E25 | 9.0 | 8.0 | 0.5 | ||||

| S8 | H20 | 20 | 0.1 | 0.1 | 58,264.1 | 412.5 | 58,676.7 |

| H21 | 20 | 0.1 | 0.1 | ||||

| H22–E25 | 9.0 | 8.0 | 0.5 | ||||

| S9 | H14 | 15 | 0.1 | 0.1 | 59,503.9 | 420.1 | 59,924.0 |

| H16 | 20 | 0.1 | 0.1 | ||||

| H27 | 20 | 0.1 | 0.1 | ||||

| H28 | 80 | 0.5 | 0.3 | ||||

| Scenarios | Node | Wind | Annual Cost | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| S7 | H4 | 30 | 0.2 | 0.1 | 2618.9 | 521.7 | 1317.1 | 57,286.3 | 595.8 | 59,199.1 |

| H18 | 25 | 0.2 | 0.1 | |||||||

| H19 | 35 | 0.3 | 0.2 | |||||||

| H22–E25 | 9.0 | 8.0 | 0.5 | |||||||

| S10 | H4 | 30 | 0.3 | 0.1 | 1471.2 | 65.8 | 0 | 59,195.3 | 313.2 | 59,508.5 |

| H18 | 25 | 0.2 | 0.1 | |||||||

| H19 | 30 | 0.3 | 0.2 | |||||||

| S11 | H4 | 30 | 0.2 | 0.1 | 3358.2 | 968.3 | 2590.6 | 56,017.2 | 1209.5 | 59,817.3 |

| H18 | 25 | 0.2 | 0.1 | |||||||

| H22–E25 | 14 | 12 | 1.2 | |||||||

| H23–E24 | 14 | 12 | 1.3 | |||||||

| Scenarios | Node | Annual Cost | |||||

|---|---|---|---|---|---|---|---|

| S5 | H4 | 55 | 0.4 | 0.2 | 58,707.3 | 542.4 | 59,249.7 |

| H18 | 25 | 0.2 | 0.1 | ||||

| H19 | 40 | 0.3 | 0.2 | ||||

| H20 | 45 | 0.3 | 0.2 | ||||

| S12 | H1 | 295 | 2.2 | 1.5 | 58,726.2 | 1016.0 | 59,742.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, W.; Guo, Y.; Hou, K.; Yuan, K.; Song, Y.; Jia, H.; Sun, C. Distributed Thermal Energy Storage Configuration of an Urban Electric and Heat Integrated Energy System Considering Medium Temperature Characteristics. Energies 2021, 14, 2924. https://doi.org/10.3390/en14102924

Wei W, Guo Y, Hou K, Yuan K, Song Y, Jia H, Sun C. Distributed Thermal Energy Storage Configuration of an Urban Electric and Heat Integrated Energy System Considering Medium Temperature Characteristics. Energies. 2021; 14(10):2924. https://doi.org/10.3390/en14102924

Chicago/Turabian StyleWei, Wei, Yusong Guo, Kai Hou, Kai Yuan, Yi Song, Hongjie Jia, and Chongbo Sun. 2021. "Distributed Thermal Energy Storage Configuration of an Urban Electric and Heat Integrated Energy System Considering Medium Temperature Characteristics" Energies 14, no. 10: 2924. https://doi.org/10.3390/en14102924

APA StyleWei, W., Guo, Y., Hou, K., Yuan, K., Song, Y., Jia, H., & Sun, C. (2021). Distributed Thermal Energy Storage Configuration of an Urban Electric and Heat Integrated Energy System Considering Medium Temperature Characteristics. Energies, 14(10), 2924. https://doi.org/10.3390/en14102924