Environmental Impact Evaluation of Current Municipal Solid Waste Treatments in India Using Life Cycle Assessment

Abstract

:1. Introduction

2. Method and Materials

2.1. Waste Characterization

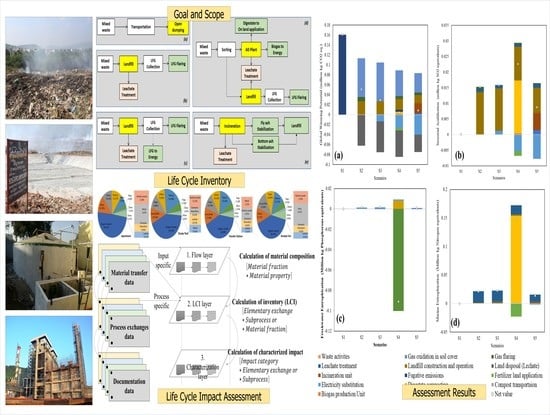

2.2. Scenarios Development for Waste Management Systems

2.2.1. Scenario (S1): Baseline Scenario: Unlined Landfill

2.2.2. Scenario (S2): Engineered Landfill without Energy Recovery

2.2.3. Scenario (S3): Engineered Landfill with Energy Recovery

2.2.4. Scenario (S4): Anaerobic Digestion of Food Waste and Residues Dumped in Engineered Landfill without Energy Recovery

2.2.5. Scenario (S5): Incineration with Energy Recovery and Residues Dumped in an Inert Landfill

2.3. Life Cycle Assessment

2.3.1. Goal and Scope Definition

2.3.2. Life Cycle Inventory Data

Landfill

Anaerobic Digestion and Compost Land Application

Incineration Unit

2.3.3. Life Cycle Impact Assessment

2.3.4. Uncertainty Analysis

2.3.5. Comparative Analysis of Scenarios

3. Results and Discussion

3.1. Physicochemical Characteristics of MSW

3.2. Life Cycle Impact Assessment Results

3.2.1. Global Warming Potential

3.2.2. Terrestrial Acidification

3.2.3. Fresh Water and Marine Eutrophication

3.2.4. Toxicity Potential

3.3. Sensitivity Analysis

3.4. Uncertainty Analysis

3.5. Comparison of Scenarios

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AD | Anaerobic digestion |

| ADP | Abiotic depletion potential |

| ADPE | Abiotic depletion |

| ADPF | Abiotic depletion (fossil fuels) |

| ASTM | American Society for Testing Materials |

| BLF | Bioreactor landfill |

| COL | Collection |

| COM | Composting |

| EASETECH | Environmental Assessment System for Environmental TECHnologies |

| EBM | Excel-based model |

| EP | Eutrophication potential |

| ETP | Ecotoxicity potential |

| FEW | Freshwater eutrophication |

| FWT | Fresh water ecotoxicity |

| GVMC | Greater Visakhapatnam Municipal Corporation |

| GWP | Global warming potential |

| HTP | Human toxicity potential |

| IC | Impact category |

| IM | Impact method |

| INC | Incineration |

| IPCC | Intergovernmental Panel on Climate Change |

| LCA | Life cycle assessment |

| LCI | Life cycle inventory |

| LCIA | Life cycle impact assessment |

| LF | Landfill |

| LFG | Landfill gas |

| LFGR | Landfill with gas collection |

| LFWGR | Landfill without gas collection |

| LPG | Liquified petroleum gas |

| LT | Leachate treatment |

| MAE | Marine aquatic ecotoxicity |

| MCS | Monte Carlo simulation |

| ME | Marine water eutrophication |

| MET | Marine ecotoxicity |

| MoHUA | Ministry of Housing and Urban Affairs |

| MRF | Material recycling facility |

| MSW | Municipal solid waste |

| OB | Open burning |

| OD | Open dumping |

| ODP | Ozone depletion potential |

| PM | Particulate matter |

| POCP | Photochemical ozone creation potential |

| PYR | Pyrolysis |

| RDF | Refuse-derived fuel |

| REC | Recycling |

| SW | Software tool |

| SWM | Solid waste management |

| TA | Terrestrial acidification |

| TE | Terrestrial ecotoxicity |

| TRANS | Transportation |

References

- Iyamu, H.O.; Anda, M.; Ho, G. A review of municipal solid waste management in the BRIC and high-income countries: A thematic framework for low-income countries. Habitat Int. 2020, 95, 102097. [Google Scholar] [CrossRef]

- Khandelwala, H.; Thallaa, A.K.; Kumar, S.; Kumar, R. Life cycle assessment of municipal solid waste management options for India. Bioresour. Technol. 2019, 288, 121515. [Google Scholar] [CrossRef]

- Cheela, V.R.S.; Dubey, B. Review of applications of systems engineering approaches in development of integrated solid waste management for a smart city. In Water Resources and Environmental Engineering II, 1st ed.; Rathinasamy, M., Chandramouli, S., Eds.; Springer: Singapore, 2019; pp. 159–177. [Google Scholar] [CrossRef]

- Cheela, V.R.S.; Shankar, U.; Dubey, B. Solid waste management: Policies, implementation and challenges. In Treatment and Disposal of Solid and Hazardous Wastes, 1st ed.; Debashish, D., Goel, S., Eds.; Springer: New Delhi, India, 2019; pp. 201–210. [Google Scholar]

- Kaur, R.R.; Luthra, A. Population growth, urbanization and electricity—Challenges and initiatives in the state of Punjab, India. Energy Strategy Rev. 2018, 21, 50–61. [Google Scholar] [CrossRef]

- Kumar, N.K.; Goel, S. Characterization of Municipal Solid Waste and a proposed management plan for Kharagpur, West Bengal, India. Resour. Conserv. Recycl. 2009, 53, 166–174. [Google Scholar] [CrossRef]

- Wielgosiński, G.; Czerwińska, J.; Szufa, S. Municipal Solid Waste Mass Balance as a Tool for Calculation of the Possibility of Implementing the Circular Economy Concept. Energies 2021, 14, 1811. [Google Scholar] [CrossRef]

- Kumar, S.; Smith, S.R.; Fowler, G.; Velis, C.; Kumar, S.J.; Arya, S.R.; Kumar, R.; Cheeseman, C. Challenges and opportunities associated with waste management in India. R. Soc. Open Sci. 2017, 4, 160764. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mandal, P.; Dubey, B.K.; Gupta, A.K. Review on landfill leachate treatment by electrochemical oxidation: Drawbacks, challenges and future scope. Waste Manag. 2017, 69, 250–273. [Google Scholar] [CrossRef]

- Mor, S.; Negi, P.; Ravindra, K. Assessment of groundwater pollution by landfills in India using leachate pollution index and estimation of error. Environ. Nanotechnol. Monit. Manag. 2018, 10, 467–476. [Google Scholar] [CrossRef]

- Agarwala, R.; Shuklaa, K.; Kumar, S.; Aggarwala, S.G.; Kawamura, K. Chemical composition of waste burning organic aerosols at landfill and urban sites in Delhi. Atmos. Pollut. Res. 2020, 11, 554–565. [Google Scholar] [CrossRef]

- Climate Links. Document on “Greenhouse Gas Emissions Factsheet: India”. United States Agency International Development. 2019. Available online: https://www.climatelinks.org/resources/greenhouse-gas-emissions-india (accessed on 13 February 2021).

- GMI (Global Methane Initiative). Document on “Global Methane Emissions and Mitigation Opportunities”. 2019. Available online: https://www.globalmethane.org/documents/gmi-mitigation-factsheet.pdf (accessed on 13 February 2021).

- Pahuja, N.; Pandey, N.; Mandak, K.; Bandyopadhyay, C. GHG Mitigation in India: An Overview of the Current Policy Landscape; World Resource Institute: Washington, DC, USA, 2014; pp. 1–32. Available online: https://www.wri.org/research/ghg-mitigation-india (accessed on 25 March 2021).

- Malmir, T.; Ranjbar, S.; Eicker, U. Improving Municipal Solid Waste Management Strategies of Montréal (Canada) Using Life Cycle Assessment and Optimization of Technology Options. Energies 2020, 13, 5701. [Google Scholar] [CrossRef]

- Saqib, N.U.; Sharma, H.B.; Baroutian, S.; Dubey, B.; Sarmah, A.K. Valorisation of food waste via hydrothermal carbonisation and technoeconomic feasibility assessment. Sci. Total Environ. 2019, 690, 261–276. [Google Scholar] [CrossRef]

- Clavreul, J.; Baumeister, H.; Christensen, T.H.; Damgaard, A. An environmental assessment system for environmental technologies. Environ. Model. Softw. 2014, 60, 18–30. [Google Scholar] [CrossRef] [Green Version]

- Soleymani Angili, T.; Grzesik, K.; Rödl, A.; Kaltschmitt, M. Life Cycle Assessment of Bioethanol Production: A Review of Feedstock, Technology and Methodology. Energies 2021, 14, 2939. [Google Scholar] [CrossRef]

- Yadav, P.; Samadder, S.R. Environmental impact assessment of municipal solid waste management options using life cycle assessment: A case study. Environ. Sci. Pollut. Res. 2018, 25, 838–854. [Google Scholar] [CrossRef]

- Laurent, A.; Bakas, I.; Clavreul, J.; Bernstad, A.; Niero, M.; Gentil, E.; Hauschild, M.Z.; Christensen, T.H. Review of LCA studies of solid waste management systems—Part I: Lessons learned and perspectives. Waste Manag. 2014, 34, 573–588. [Google Scholar] [CrossRef] [PubMed]

- Srivastava, A.K.; Nema, A.K. Life cycle assessment of integrated solid waste management system of Delhi. In Towards Life Cycle Sustainability Management; Finkbeiner, M., Ed.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 267–276. [Google Scholar] [CrossRef]

- Babu, G.L.S.; Lakshmikanthan, P.; Santhosh, L.G. Life cycle analysis of municipal solid waste (MSW) land disposal options in Bangalore city. In Proceedings of the Creating Infrastructure for a Sustainable World, International Conference on Sustainable Infrastructure, Long Beach, CA, USA, 6–8 November 2014; Hendrickson, C., Wallace, W.A., Eds.; ASCE: Reston, VA, USA, 2014. Available online: https://ascelibrary.org/doi/10.1061/9780784478745.075 (accessed on 25 March 2021).

- Sharma, B.K.; Chandel, M.K. Life cycle assessment of potential municipal solid waste management strategies for Mumbai, India. Waste Manag. Res. 2016, 35, 79–91. [Google Scholar] [CrossRef]

- Rana, R.; Ganguly, R.; Gupta, A.K. Life-cycle assessment of municipal solid-waste management strategies in Tricity region of India. J. Mater. Cycles Waste Manag. 2019, 21, 606–623. [Google Scholar] [CrossRef]

- Mehta, Y.D.; Shastri, Y.; Joseph, B. Economic analysis and life cycle impact assessment of municipal solid waste disposal: A case study of Mumbai, India. Waste Manag. Res. 2018, 36, 1177–1189. [Google Scholar] [CrossRef]

- Mali, S.T.; Patil, S.S.; Patil, D.Y. Life-cycle assessment of municipal solid waste management. Inst. Civ. Eng. Waste Resour. Manag. 2016, 169, 181–190. [Google Scholar] [CrossRef]

- Bohra, A.; Nema, A.K.; Ahluwalia, P. Global warming potential of waste management options: Case study of Delhi. Int. J. Environ. Technol. Manag. 2012, 15, 346–362. [Google Scholar]

- ASTM (American Society for Testing and Materials). D5231-92. In Standard Test Method for Determination of the Composition of Unprocessed Municipal Solid Waste; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Zhan, T.L.T.; Xu, X.B.; Chen, Y.M.; Ma, X.F.; Lan, J.W. Dependence of Gas Collection Efficiency on Leachate Level at Wet Municipal Solid Waste Landfills and Its Improvement Methods in China. J. Geotech. Geoenviron. Eng. 2015, 141, 1–11. [Google Scholar] [CrossRef]

- Barlaz, M.A.; Chanton, J.P.; Green, R.B. Controls on landfill gas collection efficiency: Instantaneous and lifetime performance. J. Air Waste Manag. Assoc. 2009, 59, 1399–1404. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Ni, Z.; Kong, X.; Liu, J. Greenhouse gas emissions from municipal solid waste with a high organic fraction under different management scenarios. J. Clean. Prod. 2017, 147, 451–457. [Google Scholar] [CrossRef]

- CPCB (Central Pollution Control Board). Selection Criteria for Waste Processing Technologies. 2016. Available online: https://cpcb.nic.in/uploads/MSW/SW_treatment_Technologies.pdf (accessed on 15 April 2021).

- IRG. Detailed Project Report on “Development of Municipal Solid Waste Processing & Disposal Facility for NOIDA and Greater Noida Gautam Buddha Nagar”. 2015. Available online: https://www.greaternoidaauthority.in/files/attachments/Annexure_B_DPR_Greater_Noida.pdf (accessed on 19 March 2021).

- International Standards Organization. ISO 14040. In Environmental Management—Life Cycle Assessment—Principles and Framework; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- International Standards Organization. ISO 14044. In Environmental Management—Life Cycle Assessments—Requirements and Guidelines; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Biswas, W.K. Life cycle assessment of seawater desalination in Western Australia. World Acad. Sci. Eng. Technol. 2009, 35, 369–375. [Google Scholar] [CrossRef]

- Frischknecht, R.; Althaus, H.J.; Bauer, C.; Doka, G.; Heck, T.; Jungbluth, N.; Kellenberger, D.; Nemecek, T. The environmental relevance of capital goods in life cycle assessments of products and services. Int. J. Life Cycle. Assess. 2007, 12, 7–17. [Google Scholar] [CrossRef]

- CPHEEO (Central Public Health and Environmental Engineering Organisation). Annexure on “Estimation of Landfill Capacity, Landfill Height, Landfill Area”. 2020. Available online: http://cpheeo.gov.in/upload/uploadfiles/files/annex17.pdf (accessed on 15 April 2021).

- Environmental Protection Agency (EPA). Report on “LFG Energy Project Development Handbook”. 2020. Available online: https://www.epa.gov/sites/production/files/2016-11/documents/pdh_full.pdf (accessed on 15 April 2021).

- Bassi, S.A.; Christensen, T.H.; Damgaard, A. Environmental performance of household waste management in Europe—An example of 7 countries. Waste Manag. 2017, 69, 545–557. [Google Scholar] [CrossRef] [Green Version]

- Bogner, J.E.; Chanton, J.P.; Blake, D.; Abichou, T.; Powelson, D. Effectiveness of Florida landfill biocover for reduction of CH4 and NMHC emissions. Environ. Sci. Technol. 2010, 44, 1197–1203. [Google Scholar] [CrossRef] [PubMed]

- Angelo, A.C.M.; Saraiva, A.B.; Clímaco, J.C.N.; EduardoInfante, C.; Valle, R. Life Cycle Assessment and Multi-criteria Decision Analysis: Selection of a strategy for domestic food waste management in Rio de Janeiro. J. Clean. Prod. 2017, 143, 744–756. [Google Scholar] [CrossRef]

- Database of Waste Management Technologies (DWMT). Article on “Dry AD Followed by Covered Windrows Composting”. 2014. Available online: http://www.epem.gr/waste-c-control/database/html/AD-01.htm (accessed on 18 March 2021).

- Turner, D.A.; Williams, I.D.; Kemp, S. Combined material flow analysis and life cycle assessment as a support tool for solid waste management decision making. J. Clean. Prod. 2016, 129, 234–248. [Google Scholar] [CrossRef] [Green Version]

- Sharma, B.K.; Chandel, M.K. Life cycle cost analysis of municipal solid waste management scenarios for Mumbai, India. Waste Manag. 2021, 124, 293–302. [Google Scholar] [CrossRef] [PubMed]

- Hoeve, M.; Bruun, S.; Jensen, L.S.; Christensen, T.H.; Scheutz, C. Life cycle assessment of garden waste management options including long-term emissions after land application. Waste Manag. 2019, 86, 54–66. [Google Scholar] [CrossRef]

- Ministry of Power (MOP). Report on “Power Sector at a Glance—All India”. 2021. Available online: https://powermin.gov.in/en/content/power-sector-glance-all-india (accessed on 24 April 2021).

- Delhi Electricity Regulatory Commission. Timarpura Incineration Plant, Delhi. 2015. Available online: http://www.derc.gov.in/ordersPetitions/orders/Misc/2007/Timarpur%20Waste%20management.pdf (accessed on 24 April 2021).

- Jain, P.; Powell, J.T.; Smith, J.L.; Townsend, T.G.; Tolaymat, T. Life-Cycle Inventory and Impact Evaluation of Mining Municipal Solid Waste Landfills. Environ. Sci. Technol. 2014, 48, 2920–2927. [Google Scholar] [CrossRef]

- Mistri, A.; Dhami, N.; Bhattacharyya, S.K.; Barai, S.K.V.; Mukherjee, A.; Biswas, W.K. Environmental implications of the use of bio-cement treated recycled aggregate in concrete. Resour. Conserv. Recycl. 2021, 167, 105436. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J. Report on “Priority Assessment of Toxic Substances in the Frame of LCA—Time Horizon Dependency in Toxicity Potentials Calculated with the Multi-Media Fate, Exposure and Effects Model USES-LCA. 2000. Available online: https://www.universiteitleiden.nl/binaries/content/assets/science/cml/publicaties_pdf/new-dutch-lca-guide/priority-assessment-of-toxic-substances-draft-report.pdf (accessed on 15 April 2021).

- Huijbregts, M.A.J. Report on “ReCiPe 2016 A Harmonized Life Cycle Impact Assessment Method at Midpoint and Endpoint Level Report I: Characterization”. 2016. Available online: https://www.rivm.nl/bibliotheek/rapporten/2016-0104.pdf (accessed on 24 April 2021).

- Goedkoop, M.; Oele, M.; Leijting, J.; Ponsioen, T.; Meijer, E. Introduction to LCA with SimaPro. 2013. Available online: https://pre-sustainability.com/files/2014/05/SimaPro8IntroductionToLCA.pdf (accessed on 24 April 2021).

- Clavreul, J.; Guyonnet, D.; Christensen, T.H. Quantifying uncertainty in LCA-modelling of waste management systems. Waste Manag. 2012, 32, 2482–2495. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hanandeh, A.E.; El-Zein, A. Life-cycle assessment of municipal solid waste management alternatives with consideration of uncertainty: SIWMS development and application. Waste Manag. 2010, 30, 902–911. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Seruga, P. The Municipal Solid Waste Management System with Anaerobic Digestion. Energies 2021, 14, 2067. [Google Scholar] [CrossRef]

- Rolewicz-Kalińska, A.; Lelicińska-Serafin, K.; Manczarski, P. The Circular Economy and Organic Fraction of Municipal Solid Waste Recycling Strategies. Energies 2020, 13, 4366. [Google Scholar] [CrossRef]

- Pavlas, M.; Dvořáček, J.; Pitschke, T.; Peche, R. Biowaste Treatment and Waste-To-Energy—Environmental Benefits. Energies 2020, 13, 1994. [Google Scholar] [CrossRef] [Green Version]

- Di Matteo, U.; Nastasi, B.; Albo, A.; Garcia, D.A. Energy Contribution of OFMSW (Organic Fraction of Municipal Solid Waste) to Energy-Environmental Sustainability in Urban Areas at Small Scale. Energies 2017, 10, 229. [Google Scholar] [CrossRef] [Green Version]

- Central Public Health and Environmental Engineering Organisation (CPHEEO). Manual on “Municipal Solid Waste Management Manual-Part II”. 2016. Available online: http://cpheeo.gov.in/upload/uploadfiles/files/Part2.pdf (accessed on 15 April 2021).

- Seruga, P.; Krzywonos, M.; Seruga, A.; Niedźwiecki, Ł.; Pawlak-Kruczek, H.; Urbanowska, A. Anaerobic Digestion Performance: Separate Collected vs. Mechanical Segregated Organic Fractions of Municipal Solid Waste as Feedstock. Energies 2020, 13, 3768. [Google Scholar] [CrossRef]

- National Research Council. Waste Incineration and Public Health; The National Academies Press: Washington, DC, USA, 2000.

- Kanhar, A.H.; Chen, S.; Wang, F. Incineration Fly Ash and Its Treatment to Possible Utilization: A Review. Energies 2020, 13, 6681. [Google Scholar] [CrossRef]

- Skrzypkowski, K.; Korzeniowski, W.; Młynarska, P. Binding capability of ashes and dusts from municipal solid waste incineration with salt brine and geotechnical parameters of the cemented samples. Arch. Min. Sci. 2018, 63, 903–918. [Google Scholar] [CrossRef]

- Korzeniowski, W.; Poborska-Młynarska, K.; Skrzypkowsk, K. The idea of the recovery of municipal solid waste incineration (MSWI) residues in Kłodawa salt mine S.A. By filling the excavations with self-solidifying mixtures. Arch. Min. Sci. 2018, 63, 553–565. [Google Scholar] [CrossRef]

| Functional Unit; Location | Software; Impact Method and Categories | Scenarios | Outcomes | Ref. |

|---|---|---|---|---|

| FU:1 Metric Ton; LO: Nagpur | SW: GaBi 8.0 IM: CML IC: GWP; TA; EP; ADP; HTP; POCP | S1: COM + LF S2: MRF + COM + LF S3: MRF + AD + LF S4: MRF + COM + AD + LF |

| [2] |

| FU:1 Metric Ton; LO: Dhanbad | SW: SimaPro 8.0 IM: CML IC: GWP, ODP; HTP; FWT; MAE; TE; POCP; TA; EP; ADPC; ADPF | S1: COL + TRANS S2: REC + OD + OB S3: COM + LFWGR S4: REC + COM + LFWG |

| [19] |

| FU: Daily generated waste LO: Delhi | ST: EBM IM: NM IC: GWP | S1: REC S2: COM S3: INC S4: LF |

| [21] |

| FU: 1 Metric Ton LO: Bangalore | ST: EBM IM: Eco-indicator; IPCC guideline IC: GWP; TA; POCP; EP | S1: OD S2: LFWGR S3: LFGR S4: BLF |

| [22] |

| FU:1 Metric Ton; LO: Mumbai | SW: GaBi 6.0 IM: IPCC guideline IC: GWP; TA; EP; HTP | S1: 31% BLF + 69% OD S2: 3.2% REC + 96:8% LF S3: 3.2% REC + 32% COM + 64.8% LF S4: 3.2% REC + 32% AD + 64.8% LF S5: 3.2% REC + 16% COM + 16% AD + 64.8% LF S6: 3.2% REC + 8%COM + 88.8% INC S7: 3.2% REC + 96.8%INC |

| [23] |

| FU: 1 Metric Ton LO: Chandigarh (C), Mohali (M), and Panchkula (P) | ST: SimaPro 8.3 IM: Eco-indicator IC: GWP; TA; EP; HTP | S1: OD (M and P); OD + RDF (C) S2: MRF + LF S3: MRF + COM + LF S4: MRF + COM + AD + LF S5: MRF + COM + INC |

| [24] |

| FU: 1 Metric Ton LO: Mumbai | ST: Open LCA 1.5 IM: ILCD 2011 IC: GWP; POP: HTP; FWT | S1: OD S2: LF S3: LF + LT S4: COM + LF |

| [25] |

| FU:1 Metric Ton; LO: Kolhapur | SW: SimaPro 7.0 IM: CML IC: GWP; ODP; TA; EP; ETP; HTP; POCP | S1: OD S2: COM S3: AD S4: PYR |

| [26] |

| FU: 1 Metric Ton LO: Delhi | ST: EBM IM: IPCC guidelines IC: GWP | S1. 9% COM + 91% OD S2. 22% COM + 78% LF S3. 10% COM + 12% RDF + 78% LF S4. 22% AD + 78% LF S5. 12% RDF + 10% AD + 78% LF S6. 100% LF S7. 33% AD + 67% LF S8. 18% AD + 15% RDF + 67% LF S9. 22% INC + 78% LF S10. 22% AD + 17% COM + 61% LF S11. 11% RDF + 11% COM + 11% AD + 67% LF S12. 16% RDF + 10% COM + 16% AD + 58% LF |

| [27] |

| Parameter | Value | Unit | Reference |

|---|---|---|---|

| Landfill | |||

| Diesel consumption | 2 | L t−1 | [22] |

| Methane generation | 55 | % | [39] |

| LFG Collection efficiency | 90 | % | [39] |

| LFG collected (Year 0–55) | 95 | % of generated | [40] |

| LFG collected (Year 55–100) | 0 | % of generated | [40] |

| LFG Top cover Oxidation | 36 | % CH4 | [41] |

| Anaerobic Digestion | |||

| Electricity (Pre-treatment) | 12.6 | kWh | [42] |

| Electricity (Reactor) | 14 | kWh | [43] |

| Methane emissions | 0.5% | % of CH4 | [43] |

| Transport of compost | 3 | L t−1 | [22] |

| Electricity recovery (biogas) | 35 | % | [23] |

| Land application | |||

| N2O-N emissions (direct) | 1.25 | % of N-tot | [42] |

| NH3-N emissions | 15 | % of N-tot | [42] |

| NO3−-N emissions | 20 | % of N-tot | [42] |

| Incoming N content | 4.85 | kg N-tot | [42] |

| Incoming P content | 0.65 | kg P-tot | [42] |

| Incoming K content | 1.48 | kg K-tot | [42] |

| Application of digestate | 20 | MJ/t digestate | [42] |

| Application of mineral fertilizers | 0.36 | MJ/kg N-tot | [42] |

| Incineration | |||

| Sodium hydroxide | 0.24 | kg | [44] |

| Hydrated Lime | 10 | kg | [44] |

| Activated Carbon | 0.25 | kg | [44] |

| Ammonia (NH3) | 0.5 | kg | [44] |

| Electricity Consumption | 0.27 | MWh | [43] |

| Impact Category | Unit |

|---|---|

| Global warming potential | kg CO2 equivalent |

| Terrestrial acidification | kg SO2 equivalent |

| Freshwater eutrophication | kg-phosphorus equivalent |

| Marine water eutrophication | kg-nitrogen equivalent |

| Human toxicity | kg 1,4-dichlorobenzene equivalent |

| Terrestrial ecotoxicity | kg 1,4-dichlorobenzene equivalent |

| Freshwater ecotoxicity | kg 1,4-dichlorobenzene equivalent |

| Marine ecotoxicity | kg 1,4-dichlorobenzene equivalent |

| Scenario (↓) | Mean | Standard Deviation | Variance |

|---|---|---|---|

| Impact Category | GWP | Unit: kg CO2 eq. | |

| S2 | 352.6 | 5.67 | 32.11 |

| S3 | 205.06 | 8.39 | 70.42 |

| S4 | 31.79 | 15.98 | 255.56 |

| S5 | 101.88 | 6.96 | 48.52 |

| Impact Category | TA | Unit: kg SO2 eq. | |

| S2 | 0.58 | 5.79 × 10−4 | 3.35 × 10−7 |

| S3 | 0.61 | 1.06 × 10−3 | 1.13 × 10−6 |

| S4 | 0.86 | 0.015 | 2.12 × 10−4 |

| S5 | 0.36 | 5.47 × 10−3 | 2.99 × 10−5 |

| Impact Category | FEW | Unit: kg-P eq. | |

| S2 | 2.98 × 10−4 | 2.57 × 10−6 | 6.6 × 10−12 |

| S3 | 2.91 × 10−4 | 2.35 × 10−6 | 5.56 × 10−12 |

| S4 | −1.7 × 10−2 | 8.38 × 10−4 | 7.03 × 10−7 |

| S5 | 2.04 × 10−4 | 1.64 × 10−6 | 2.68 × 10−12 |

| Impact Category | ME | Unit: kg-N eq. | |

| S2 | 0.16 | 1.28 × 10−3 | 1.66 × 10−6 |

| S3 | 0.17 | 1.18 × 10−3 | 1.41 × 10−6 |

| S4 | 1.09 | 4.45 × 10−2 | 1.98 × 10−3 |

| S5 | 0.11 | 8.06 × 10−4 | 6.51 × 10−6 |

| Impact Category | HTP | Unit: kg 1,4 DB eq. | |

| S2 | 3.03 | 8.89 × 10−3 | 7.91 × 10−5 |

| S3 | 2.41 | 1.61 × 10−2 | 2.47 × 10−4 |

| S4 | −163.57 | 7.99 | 63.85 |

| S5 | 0.74 | 3.81 × 10−2 | 1.45 × 10−3 |

| Impact Category | TE | Unit: kg 1,4 DB eq. | |

| S2 | 5.15 × 10−2 | 4.33 × 10−4 | 1.87 × 10−7 |

| S3 | 5.13 × 10−2 | 3.96 × 10−4 | 1.57 × 10−7 |

| S4 | 1.71 × 10−2 | 1.65 × 10−3 | 2.73 × 10−6 |

| S5 | 3.53 × 10−2 | 2.82 × 10−4 | 7.96 × 10−8 |

| Impact Category | FWT | Unit: kg 1,4 DB eq. | |

| S2 | 2.48 × 10−2 | 2.12 × 10−4 | 4.48 × 10−8 |

| S3 | 2.38 × 10−2 | 1.95 × 10−4 | 3.81 × 10−8 |

| S4 | −1.90 | 9.23 × 10−2 | 8.52 × 10−3 |

| S5 | 1.96 × 10−2 | 1.59 × 10−4 | 2.53 × 10−8 |

| Impact Category | MET | Unit: kg 1,4 DB eq. | |

| S2 | 3.85 × 10−2 | 1.81 × 10−4 | 3.27 × 10−8 |

| S3 | 2.94 × 10−2 | 2.84 × 10−4 | 8.05 × 10−8 |

| S4 | −9.34 × 10−2 | 6.33 × 10−3 | 4.01 × 10−5 |

| S5 | 2.96 × 10−2 | 2.65 × 10−4 | 7.03 × 10−8 |

| Scenario | GWP | TA | FEW | ME | HTP | TE | FWT | MET | MCS |

|---|---|---|---|---|---|---|---|---|---|

| S2 | 4 | 2 | 3 | 2 | 4 | 4 | 3 | 4 | 4 |

| S3 | 3 | 3 | 4 | 3 | 3 | 3 | 4 | 3 | 3 |

| S4 | 1 | 4 | 1 | 4 | 1 | 1 | 1 | 1 | 1 |

| S5 | 2 | 1 | 2 | 1 | 2 | 2 | 2 | 2 | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheela, V.R.S.; John, M.; Biswas, W.K.; Dubey, B. Environmental Impact Evaluation of Current Municipal Solid Waste Treatments in India Using Life Cycle Assessment. Energies 2021, 14, 3133. https://doi.org/10.3390/en14113133

Cheela VRS, John M, Biswas WK, Dubey B. Environmental Impact Evaluation of Current Municipal Solid Waste Treatments in India Using Life Cycle Assessment. Energies. 2021; 14(11):3133. https://doi.org/10.3390/en14113133

Chicago/Turabian StyleCheela, Venkata Ravi Sankar, Michele John, Wahidul K. Biswas, and Brajesh Dubey. 2021. "Environmental Impact Evaluation of Current Municipal Solid Waste Treatments in India Using Life Cycle Assessment" Energies 14, no. 11: 3133. https://doi.org/10.3390/en14113133

APA StyleCheela, V. R. S., John, M., Biswas, W. K., & Dubey, B. (2021). Environmental Impact Evaluation of Current Municipal Solid Waste Treatments in India Using Life Cycle Assessment. Energies, 14(11), 3133. https://doi.org/10.3390/en14113133