Heat Transfer Efficiency Prediction of Coal-Fired Power Plant Boiler Based on CEEMDAN-NAR Considering Ash Fouling

Abstract

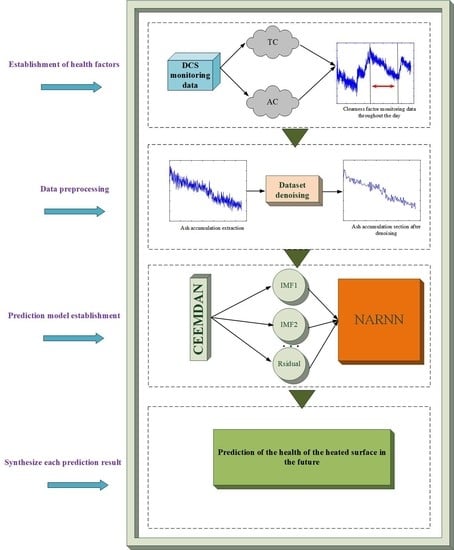

:1. Introduction

2. Problem Statement

2.1. Cleanliness Factor

2.2. Data Preprocessing

3. CEEMDAN

- Step 1:

- Connect all local extreme points in with cubic spline interpolation curves to form an upper and lower envelope and .

- Step 2:

- Mean curve of the envelope .

- Step 3:

- Recalculate the difference . If it does not meet the two sufficient conditions of the intrinsic mode function (IMF) component, replace with , and repeat steps 1 and 2 until meets the two conditions after iterations.

- Step 4:

- The IMF1 component is , and the corresponding remaining component is .

- Step 5:

- Repeat the above steps to decompose the residual component as the original sequence, and finally obtain IMF components and a residual component , where the residual component is a monotonic sequence or a constant sequence.

- Step 6:

- The final EMD decomposition formula is shown in Equation (16)

4. Dynamic Neural Network

4.1. Elman Neural Network

4.2. Nonlinear Autoregressive Neural Network

4.3. Network Structure Design

- Step 1:

- according to the ash accumulation data collected by DCS system under different working conditions, the average cleaning factor is obtained after processing the data, and the long sequence under different working conditions is tested to see whether it is a stationary sequence. ACF test or ADF test [37] unit root test is generally adopted.

- Step 2:

- after the stationary sequence is determined, all the sequences are detected by auto correlation, and partial correlation detection is carried out for all the sequences.

- Step 3:

- determine the input number or regression order according to Akaike information criterion.

5. Results and Discussions

5.1. Dataset Description

5.2. Case Analysis

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- China Electricity Council Statistics and Data Center. Available online: https://www.cec.org.cn/detail/index.html?0-285907 (accessed on 22 July 2020).

- Shi, Y.; Li, Q.; Wen, J.; Cui, F.; Pang, X.; Jia, J.; Zeng, J.; Wang, J. Soot Blowing Optimization for Frequency in Economizers to Improve Boiler Performance in Coal-Fired Power Plant. Energies 2019, 12, 2901. [Google Scholar] [CrossRef] [Green Version]

- Wen, J.; Shi, Y.; Pang, X.; Jia, J.; Zeng, J. Optimization of Boiler Soot Blowing Based on Hamilton-Jacobi-Bellman Equation. IEEE Access 2019, 7, 20850–20862. [Google Scholar] [CrossRef]

- Valero, A.; Cortes, C. Ash fouling in coal-fired utility boilers. Monitoring and optimization of on-load cleaning. Prog. Energy Combust. Sci. 1996, 22, 189–200. [Google Scholar] [CrossRef]

- Pattanayak, L.; Ayyagari, S.P.; Sahu, J.N. Optimization of Sootblowing frequency to improve boiler performance and reduce combustion pollution. Clean Technol. Environ. Policy 2015, 17, 1897–1906. [Google Scholar] [CrossRef]

- Li, Q.; Chen, X.; Shi, Y.; Zeng, J. Study on optimization of soot blowing based on monitoring model of coal-fired power station soot accumulation. In Proceedings of the 2018 Chinese Automation Congress (CAC), Xi’an, China, 30 November–2 December 2018; pp. 196–200. [Google Scholar]

- Zhou, H.; Zhang, H.; Li, L.; Zhou, B. Ash Deposit Shedding during Co-combustion of Coal and Rice Hull Using a Digital Image Technique in a Pilot-Scale Furnace. Energy Fuels 2013, 27, 7126–7137. [Google Scholar] [CrossRef]

- Tong, S.; Zhang, X.; Tong, Z.; Wu, Y.; Tang, N.; Zhong, W. Online Ash Fouling Prediction for Boiler Heating Surfaces based on Wavelet Analysis and Support Vector Regression. Energies 2020, 13, 59. [Google Scholar] [CrossRef] [Green Version]

- Peña, B.; Teruel, E.; Díez, L.I. Soft-computing models for soot-blowing optimization in coal-fired utility boilers. Appl. Soft Comput. 2011, 11, 1657–1688. [Google Scholar] [CrossRef]

- Perez, L.; Ladevie, B.; Tochon, P.; Batsale, J.C. A new transient thermal fouling probe for cross flow tubular heat exchangers. Int. J. Heat Mass Transf. 2009, 52, 407–414. [Google Scholar] [CrossRef] [Green Version]

- Mirek, P. Field testing of acoustic cleaning system working in 670mw(th) CFB boiler. Chem. Process Eng. 2013, 34, 283–291. [Google Scholar] [CrossRef]

- Shi, Y.; Wang, J.; Liu, Z. On-line monitoring of ash fouling and soot-blowing optimization for convective heat exchanger in coal-fired power plant boiler. Appl. Therm. Eng. 2015, 78, 39–50. [Google Scholar] [CrossRef]

- Jha, M.S.; Bressel, M.; Ould-Bouamama, B.; Dauphin-Tanguy, G. Dauphin-Tanguy, Particle filter-based hybrid prognostics of proton exchange membrane fuel cell in bond graph framework. Comput. Chem. Eng. 2016, 95, 216–230. [Google Scholar] [CrossRef]

- Wu, J.; Hu, K.; Cheng, Y.; Zhu, H.; Shao, X.; Wang, Y. Data-driven remaining useful life prediction via multiple sensor signals and deep long short-term memory neural network. ISA Trans. 2020, 97, 214–250. [Google Scholar] [CrossRef]

- Hu, Z.; Matovic, D. Heat flux monitoring in biomass-fired boilers: Possible areas of improvement. In Proceedings of the LASTED International Conference on Environmental Management and Engineering, Banff, AB, Canada, 6–8 July 2009; pp. 33–38. [Google Scholar]

- Zhang, S.; Shen, G.; An, L.; Li, G. Ash fouling monitoring based on acoustic pyrometry in boiler furnaces. Appl. Therm. Eng. 2015, 84, 74–81. [Google Scholar] [CrossRef]

- Harding, N.S.; O’Connor, D.C. Ash deposition impacts in the power industry. Fuel Process. Technol. 2007, 88, 1082–1093. [Google Scholar] [CrossRef]

- Jidong, L.; Dingpo, L.; Gang, L.; Kai, S. Research on fuzzy model for the soot blowing optimization in utility boilers. J. Huazhong Univ. Sci. Technol. 2005, 33, 35–37. [Google Scholar]

- Sivathanu, A.K.; Subramanian, S. Extended Kalman filter for fouling detection in thermal power plant reheater. Control Eng. Pract. 2018, 73, 91–99. [Google Scholar] [CrossRef]

- Zheng, S.; Zeng, X.; Qi, C.; Zhou, H. Mathematical modeling and experimental validation of ash deposition in a pulverized-coal boiler. Appl. Therm. Eng. 2017, 110, 720–729. [Google Scholar] [CrossRef]

- Peña, B.; Teruel, E.; Díez, L.I. Towards soot-blowing optimization in superheaters. Appl. Therm. Eng. 2013, 61, 737–746. [Google Scholar] [CrossRef]

- Kumari, S.A.; Srinivasan, S. Ash fouling monitoring and soot-blow optimization for reheater in thermal power plant. Appl. Therm. Eng. 2019, 149, 62–72. [Google Scholar] [CrossRef]

- Shi, Y.; Wen, J.; Cui, F.; Wang, J. An Optimization Study on Soot-Blowing of Air Preheaters in Coal-Fired Power Plant Boilers. Energies 2019, 12, 958. [Google Scholar] [CrossRef] [Green Version]

- Ma, Z.; Iman, F.; Lu, P.; Sears, R.; Kong, L.; Rokanuzzaman, A.S.; McCollor, D.P.; Benson, S.A. A comprehensive slagging and fouling prediction tool for coal-fired boilers and its validation/application. Fuel Process. Technol. 2007, 88, 1035–1043. [Google Scholar] [CrossRef]

- Shi, Y.; Wang, J. Ash fouling monitoring and key variables analysis for coal fired power plant boiler. Therm. Sci. 2015, 19, 253–265. [Google Scholar] [CrossRef]

- Li, Q.; Yan, P.; Liu, J.; Shi, Y.; Yu, D. Prediction of Pollution State of Heating Surface in Coal-Fired Utility Boilers. IEEE Access 2020, 8, 206132–206145. [Google Scholar] [CrossRef]

- Li, M.; Shi, Y.; Cui, F.; Wen, J.; Zeng, J. Research on Gray Prediction of Heated Surface Combining Empirical Mode Decomposition and Long Short-term Memory Network. In Proceedings of the 2020 16th International Conference on Control, Automation, Robotics and Vision (ICARCV), Shenzhen, China, 13–15 December 2020. [Google Scholar]

- Romeo, L.M.; Gareta, R. Neural network for evaluating boiler behaviour. Appl. Therm. Eng. 2006, 26, 1530–1536. [Google Scholar] [CrossRef]

- Teruel, E.; Cortes, C.; Diez, L.I.; Arauzo, I. Monitoring and prediction of fouling in coal-fired utility boilers using neural networks. Chem. Eng. Sci. 2005, 60, 5035–5048. [Google Scholar] [CrossRef]

- Chen, Y.; Peng, G.; Zhu, Z.; Li, S. A novel deep learning method based on attention mechanism for bearing remaining useful life prediction. Appl. Soft Comput. 2020, 86, 11. [Google Scholar] [CrossRef]

- Bi, F.; Ma, T.; Wang, X. Development of a novel knock characteristic detection method for gasoline engines based on wavelet-denoising and EMD decomposition. Mech. Syst. Signal Process. 2019, 117, 517–536. [Google Scholar] [CrossRef]

- Wang, J.J.; Sun, X.; Cheng, Q.; Cui, Q. An innovative random forest-based nonlinear ensemble paradigm of improved feature extraction and deep learning for carbon price forecasting. Sci. Total Environ. 2021, 762, 13. [Google Scholar] [CrossRef]

- Romeo, L.M.; Gareta, R. Fouling control in biomass boilers. Biomass Bioenergy 2009, 33, 854–861. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, X.P.; Tang, H.M. An improved ELMAN neural network with piecewise weighted gradient for time series prediction. Neurocomputing 2019, 359, 199–208. [Google Scholar] [CrossRef]

- Yang, L.; Wang, F.; Zhang, J.J.; Ren, W.H. Remaining useful life prediction of ultrasonic motor based on Elman neural network with improved particle swarm optimization. Measurement 2019, 143, 27–38. [Google Scholar] [CrossRef]

- Yang, X.; Xue, Q.; Yang, X.; Yin, H.; Qu, Y.; Li, X.; Wu, J. A novel prediction model for the inbound passenger flow of urban rail transit. Inf. Sci. 2021, 566, 347–363. [Google Scholar] [CrossRef]

- Liang, B.X.; Hu, J.P.; Liu, C.; Hong, B. Data pre-processing and artificial neural networks for tidal level prediction at the Pearl River Estuary. J. Hydroinformatics 2021, 23, 368–382. [Google Scholar] [CrossRef]

- Büyükşahin, Ü.Ç.; Ertekin, Ş. Improving forecasting accuracy of time series data using a new ARIMA-ANN hybrid method and empirical mode decomposition. Neurocomputing 2019, 361, 151–163. [Google Scholar] [CrossRef] [Green Version]

| BECR | 300 MW |

| Fuel (coal) mass flow | 35.4 kg/s |

| Main steam mass flow | 909.6 t/h |

| Superheated steam pressure | 17.25 MPa |

| Superheated steam temperature | 540 °C |

| Reheated steam flow | 743.2 t/h |

| Reheated steam pressure | 3.18 MPa |

| Reheated steam temperature | 540 °C |

| Feed water temperature | 270 °C |

| Total air flow | 295 kg/s |

| Step | RMSE | |||||

|---|---|---|---|---|---|---|

| M1 | M2 | M3 | M4 | M5 | M6 | |

| 5 | 0.004080 | 0.006873 | 0.005526 | 0.008967 | 0.009080 | 0.01111 |

| 20 | 0.01013 | 0.01899 | 0.009810 | 0.009741 | 0.01188 | 0.01970 |

| Step | MAPE | |||||

|---|---|---|---|---|---|---|

| M1 | M2 | M3 | M4 | M5 | M6 | |

| 5 | 0.005006 | 0.008441 | 0.007091 | 0.01020 | 0.010722 | 0.010822 |

| 20 | 0.01238 | 0.02522 | 0.012194 | 0.01157 | 0.014459 | 0.026376 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, Y.; Li, M.; Wen, J.; Yang, Y.; Cui, F.; Zeng, J. Heat Transfer Efficiency Prediction of Coal-Fired Power Plant Boiler Based on CEEMDAN-NAR Considering Ash Fouling. Energies 2021, 14, 4000. https://doi.org/10.3390/en14134000

Shi Y, Li M, Wen J, Yang Y, Cui F, Zeng J. Heat Transfer Efficiency Prediction of Coal-Fired Power Plant Boiler Based on CEEMDAN-NAR Considering Ash Fouling. Energies. 2021; 14(13):4000. https://doi.org/10.3390/en14134000

Chicago/Turabian StyleShi, Yuanhao, Mengwei Li, Jie Wen, Yanru Yang, Fangshu Cui, and Jianchao Zeng. 2021. "Heat Transfer Efficiency Prediction of Coal-Fired Power Plant Boiler Based on CEEMDAN-NAR Considering Ash Fouling" Energies 14, no. 13: 4000. https://doi.org/10.3390/en14134000

APA StyleShi, Y., Li, M., Wen, J., Yang, Y., Cui, F., & Zeng, J. (2021). Heat Transfer Efficiency Prediction of Coal-Fired Power Plant Boiler Based on CEEMDAN-NAR Considering Ash Fouling. Energies, 14(13), 4000. https://doi.org/10.3390/en14134000