Verification and Validation of Large Eddy Simulation for Tip Clearance Vortex Cavitating Flow in a Waterjet Pump

Abstract

:1. Introduction

2. Governing Equations

3. Application of V&V Approach in Waterjet Pump

4. Waterjet Pump Geometry, Numerical Setup and Mesh Information

5. Results and Discussions

5.1. Hydrodynamic Performance for the Pump

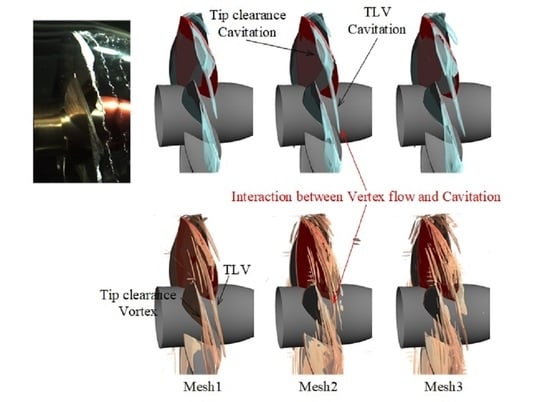

5.2. Unsteady Cavitation of the Experimental and Numerical Results

5.3. V&V Results of LES for the Tip Clearance Cavitating Flow in the Pump

5.4. Effect of Cavitation on the Vortex Distribution in the Pump

5.5. Effects of Cavitating Flow on Entropy Production Characteristics

6. Conclusions

- (1)

- The hydrodynamic performance and cavitation patterns in the pump can be precisely simulated by LES. Both the cavitation shape and location can be predicted accurately, which is in good agreement with the test. Therefore, the numerical calculation method and the adopted grid and model can be proved to be suitable for simulating the transient cavitating flow in the pump;

- (2)

- The LES error reflects the flow field around the rotor affected by transient cavitation and tip clearance flow to some extent. The LES errors calculated from the average velocity at the monitoring points inside the cavity are clearly larger than the error in the non-cavitation region. The relatively larger cavity volume variations and more violent collapse of the cavity around the head of the blade tip due to more unsteady tip clearance flow increase the difficultly of numerical calculation. The interaction between cavitation and the tip clearance flow makes the prediction of multiphase flow around a rotor blade tip much harder than that of a pure tip clearance flow;

- (3)

- The effects of the cavitation on the vorticity field are analyzed by the relative vorticity transport equation. In the cavitation area, the vorticity is mainly concentrated in the TLV cavity core and at the liquid-vapor interface. The vortex stretching term is larger around the blade tip and the dilatation term is centered near the TLV cavitation area. The baroclinic torque term is visible around the cavity interface. The Coriolis force term and viscosity term spread in the blade tip region and trailing edge wake, respectively. It reveals that the cavitation and tip clearance flow make a significant contribution to the vorticity generation and transport;

- (4)

- The flow loss characteristics are reflected by the entropy production around the rotor. It shows that the peak value appears in the tip clearance cavitation region and trailing wake region. The entropy production is dominated by the tip clearance flow and blade trailing edge wake flow, and the appearance of cavitation increases the amplitude of entropy, which indicates that cavitation will further aggravate flow instability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Booth, T.C.; Dodge, P.R.; Hepworth, H.K. Rotor-Tip Leakage: Part I—Basic Methodology. J. Eng. Gas Turbines Power 1982, 104, 154–161. [Google Scholar] [CrossRef]

- Langston, L.S. Secondary Flows in Axial Turbines—A Review. Ann. N. Y. Acad. Sci. 2010, 934, 11–26. [Google Scholar] [CrossRef]

- Arndt, R.E.A. Cavitation in vortical flows. Annu. Rev. Fluid Mech. 2002, 34, 143–175. [Google Scholar] [CrossRef]

- Bai, X.-R.; Cheng, H.-Y.; Ji, B.; Long, X.-P. Large eddy simulation of tip leakage cavitating flow focusing on cavitation-vortex interaction with Cartesian cut-cell mesh method. J. Hydrodyn. 2018, 30, 1–4. [Google Scholar] [CrossRef]

- Cheng, H.; Long, X.-P.; Ji, B.; Liu, Q.; Bai, X.-R. 3-D Lagrangian-based investigations of the time-dependent cloud cavitating flows around a Clark-Y hydrofoil with special emphasis on shedding process analysis. J. Hydrodyn. 2018, 30, 122–130. [Google Scholar] [CrossRef]

- Aeschlimann, V.; Beaulieu, S.; Houde, S.; Ciocan, G.D.; Deschênes, C. Inter-blade flow analysis of a propeller turbine runner using stereoscopic PIV. Eur. J. Mech.—B/Fluids 2013, 42, 121–128. [Google Scholar] [CrossRef]

- Lemay, S.; Aeschlimann, V.; Fraser, R.; Ciocan, G.D.; Deschênes, C. Velocity field investigation inside a bulb turbine runner using endoscopic PIV measurements. Exp. Fluids 2015, 56, 120. [Google Scholar] [CrossRef]

- Dreyer, M.; Decaix, J.; Münch-Alligné, C.; Farhat, M. Mind the gap: A new insight into the tip leakage vortex using stereo-PIV. Exp. Fluids 2014, 55, 1–13. [Google Scholar] [CrossRef]

- Zhang, D.; Shi, L.; Shi, W.; Zhao, R.; Wang, H.; van Esch, B.B. Numerical analysis of unsteady tip leakage vortex cavitation cloud and unstable suc-tion-side-perpendicular cavitating vortices in an axial flow pump. Int. J. Multiph. Flow 2015, 77, 244–259. [Google Scholar] [CrossRef]

- Guo, Q.; Huang, X.; Qiu, B. Numerical investigation of the blade tip leakage vortex cavitation in a waterjet pump. Ocean. En-Gineering 2019, 187, 106170. [Google Scholar] [CrossRef]

- Huai, W.-X.; Zhang, J.; Katul, G.G.; Cheng, Y.-G.; Tang, X.; Wang, W.-J. The structure of turbulent flow through submerged flexi-ble vegetation. J. Hydrodyn. 2019, 31, 274–292. [Google Scholar] [CrossRef]

- Zhang, D.; Shi, W.; Zhang, H.; Yao, J.; Guan, X. Application of different turbulence models for predicting performance of axial flow pump. Trans. CSAE 2012, 28, 66–71. [Google Scholar]

- You, D.; Wang, M.; Moin, P.; Mittal, R. Effects of tip-gap size on the tip-leakage flow in a turbomachinery cascade. Phys. Fluids 2006, 18, 105102. [Google Scholar] [CrossRef] [Green Version]

- Shen, J.F.; Li, Y.J.; Tang, X.L.; Liu, Z.Q. Study on characteristics of tip clearance flow in axial-flow pump based on les method. In Proceedings of the National Conference on Hydraulic Machinery and Its Systems, Hangzhou, China, 18 October 2013. [Google Scholar]

- Li, Y.; Shen, J.; Liu, Z.; Tang, X.L.; Zhang, Z.M. Large eddy simulation of unsteady flow in tip region of axial-flow pump. Trans. Chin. Soc. Agric. Mach. 2013, 44, 113–118. [Google Scholar]

- Yaojun, L.I.; Jinfeng, S.; Haijun, Y. Investigation of the effects of tip-gap size on the tip-leakage flow in an axial-flow pump using LES. J. Hydraul. Eng. 2014, 45, 235–242. [Google Scholar]

- Celik, I.B.; Cehreli, Z.N. Yavuz, I. Index of resolution quality for large eddy simulations. J. Fluids Eng. 2005, 127, 949–958. [Google Scholar] [CrossRef]

- Celik, I.; Klein, M.; Janicka, J. Assessment measures for engineering LES applications. J. Fluids Eng. 2009, 131, 031102. [Google Scholar] [CrossRef]

- Freitag, M.; Klein, M. An improved method to assess the quality of large eddy simulations in the context of implicit filtering. J. Turbul. 2006, 7, N40. [Google Scholar] [CrossRef]

- Oberkampf, W.; Roy, C. Verification and Validation in Scientific Computing; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar]

- Klein, M. An Attempt to Assess the Quality of Large Eddy Simulations in the Context of Implicit Filtering. Flow Turbul. Combust. 2005, 75, 131–147. [Google Scholar] [CrossRef]

- Xing, T. A general framework for verification and validation of large eddy simulations. J. Hydrodyn. 2015, 27, 163–175. [Google Scholar] [CrossRef]

- Dutta, R.; Xing, T. Quantitative solution verification of large eddy simulation of channel flow. In Proceedings of the 2nd Thermal and Fluid Engineering Conference, Las Vegas, NV, USA, 2–5 April 2017. [Google Scholar]

- Dutta, R.; Xing, T. Five-equation and robust three-equation methods for solution verification of large eddy simulation. J. Hydrodyn. 2018, 30, 23–33. [Google Scholar] [CrossRef]

- Long, Y.; Long, X.; Ji, B.; Xing, T. Verification and validation of Large Eddy Simulation of attached cavitating flow around a Clark-Y hydrofoil. Int. J. Multiph. Flow 2019, 115, 93–107. [Google Scholar] [CrossRef]

- Long, X.-P.; Long, Y.; Wang, W.-T.; Cheng, H.-Y.; Ji, B. Some notes on numerical simulation and error analyses of the attached turbulent cavitating flow by LES. J. Hydrodyn. 2018, 30, 369–372. [Google Scholar] [CrossRef]

- Long, Y.; Deng, L.F.; Zhang, J.Q.; Ji, B.; Long, X.P. A new method of LES verification and validation for attached turbulent cavitating flow. J. Hydrodyn. 2021, 33, 170–174. [Google Scholar] [CrossRef]

- Smagorinsky, J. General circulation experiments with the primitive equations. Mon. Weather Rev. 1963, 91, 99–164. [Google Scholar] [CrossRef]

- Nicoud, F.; Ducros, F. Subgrid-Scale Stress Modelling Based on the Square of the Velocity Gradient Tensor. Flow, Turbul. Combust. 1999, 62, 183–200. [Google Scholar] [CrossRef]

- Singhal, A.K.; Athavale, M.M.; Li, H.; Jiang, Y. Mathematical Basis and Validation of the Full Cavitation Model. J. Fluids Eng. Trans. ASME 2002, 124, 617–624. [Google Scholar] [CrossRef]

- Zwart, P.J.; Gerber, A.G.; Belamri, T. Two-Phase Flow Model for Predicting Cavitation Dynamics. In Proceedings of the ICMF 2004 International Conference on Multiphase Flow, Yokohama, Japan, 30 May–4 June 2004; pp. 152–164. [Google Scholar]

- Ji, B.; Luo, X.; Peng, X.; Wu, Y.; Xu, H. Numerical analysis of cavitation evolution and excited pressure fluctuation around a propeller in non-uniform wake. Int. J. Multiph. Flow 2012, 43, 13–21. [Google Scholar] [CrossRef]

- Roache, P.J. Verification and Validation in Computational Science and Engineering; Hermosa: Albuquerque, NM, USA, 1998. [Google Scholar]

- Long, Y.; Long, X.P.; Ji, B.; Huai, W.X.; Qian, Z.D. Verification and validation of Urans simulations of the turbulent cavitating flow around the hydrofoil. J. Hydrodyn. 2017, 29, 610–620. [Google Scholar] [CrossRef]

- Long, Y.; Han, C.; Ji, B.; Long, X.; Wang, Y. Verification and validation of large eddy simulations of turbulent cavitating flow around two marine propellers with emphasis on the skew angle effects. Appl. Ocean Res. 2020, 101, 102167. [Google Scholar] [CrossRef]

- Tian, C.L.; Chen, T.R.; Zou, T. Numerical study of unsteady cavitating flows with RANS and DES models. Mod. Phys. Lett. B 2019, 33, 17. [Google Scholar] [CrossRef]

- Yu, C.; Wang, Y.; Huang, C.; Wu, X.; Du, T. Large Eddy Simulation of Unsteady Cavitating Flow Around a Highly Skewed Propeller in Nonuniform Wake. J. Fluids Eng. 2016, 139, 041302. [Google Scholar] [CrossRef]

- Ji, B.; Luo, X.; Wang, X.; Peng, X.; Wu, Y.; Xu, H. Unsteady Numerical Simulation of Cavitating Turbulent Flow Around a Highly Skewed Model Marine Propeller. J. Fluids Eng. 2011, 133, 011102. [Google Scholar] [CrossRef]

- Wu, Q.; Huang, B.; Wang, G.; Cao, S.; Zhu, M. Numerical modelling of unsteady cavitation and induced noise around a marine propeller. Ocean Eng. 2018, 160, 143–155. [Google Scholar] [CrossRef]

- Long, Y.; Long, X.; Ji, B.; Huang, H. Numerical simulations of cavitating turbulent flow around a marine propeller behind the hull with analyses of the vorticity distribution and particle tracks. Ocean Eng. 2019, 189, 106310. [Google Scholar] [CrossRef]

- Barth, T.; Jespersen, D. The design and application of upwind schemes on unstructured meshes. In Proceedings of the 27th Aerospace Sciences Meeting, Reno, NV, USA, 9–12 January 1989. [Google Scholar]

- Han, C.-Z.; Xu, S.; Cheng, H.-Y.; Ji, B.; Zhang, Z.-Y. LES method of the tip clearance vortex cavitation in a propelling pump with special emphasis on the cavitation-vortex interaction. J. Hydrodyn. 2020, 32, 1212–1216. [Google Scholar] [CrossRef]

- Wang, J.; Cheng, H.; Xu, S.; Ji, B.; Long, X. Performance of cavitation flow and its induced noise of different jet pump cavitation reactors. Ultrason. Sonochem. 2019, 106, 215–225. [Google Scholar] [CrossRef]

- Decaix, J.; Dreyer, M.; Balarac, G.; Farhat, M.; Münch, C. RANS computations of a confined cavitating tip-leakage vortex. Eur. J. Mech. B/Fluids 2018, 67, 198–210. [Google Scholar] [CrossRef] [Green Version]

- Li, D.; Yang, Q.; Yang, W.; Chang, H.; Wang, H. Bionic leading-edge protuberances and hydrofoil cavitation. Phys. Fluids 2021, 33, 93317. [Google Scholar] [CrossRef]

- Liu, Y.; Tan, L.; Hao, Y.; Xu, Y. Energy Performance and Flow Patterns of a Mixed-Flow Pump with Different Tip Clearance Sizes. Energies 2017, 10, 191. [Google Scholar] [CrossRef]

- Kock, F.; Herwig, H. Entropy production calculation for turbulent shear flows and their implementation in cfd codes. Int. J. Heat Fluid Flow 2005, 26, 672–680. [Google Scholar] [CrossRef]

- Kock, F.; Herwig, H. Local entropy production in turbulent shear flows: A high-Reynolds number model with wall functions. Int. J. Heat Mass Transf. 2004, 47, 2205–2215. [Google Scholar] [CrossRef]

- Li, D.; Gong, R.; Wang, H.; Xiang, G.; Wei, X.; Qin, D. Entropy production analysis for hump characteristics of a pump turbine model. Chin. J. Mech. Eng. 2016, 29, 803–812. [Google Scholar] [CrossRef]

- Li, D.; Wang, H.; Qin, Y.; Han, L.; Wei, X.; Qin, D. Entropy production analysis of hysteresis characteristic of a pump-turbine model. Energy Convers. Manag. 2017, 149, 175–191. [Google Scholar] [CrossRef]

| Mesh | Number of Elements | Time Step/s |

|---|---|---|

| 1 | 6,497,196 | 1.111111 × 10−4 |

| 2 | 11,138,262 | 9.259259 × 10−5 |

| 3 | 20,429,869 | 7.716049 × 10−5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, C.; Long, Y.; Xu, M.; Ji, B. Verification and Validation of Large Eddy Simulation for Tip Clearance Vortex Cavitating Flow in a Waterjet Pump. Energies 2021, 14, 7635. https://doi.org/10.3390/en14227635

Han C, Long Y, Xu M, Ji B. Verification and Validation of Large Eddy Simulation for Tip Clearance Vortex Cavitating Flow in a Waterjet Pump. Energies. 2021; 14(22):7635. https://doi.org/10.3390/en14227635

Chicago/Turabian StyleHan, Chengzao, Yun Long, Mohan Xu, and Bin Ji. 2021. "Verification and Validation of Large Eddy Simulation for Tip Clearance Vortex Cavitating Flow in a Waterjet Pump" Energies 14, no. 22: 7635. https://doi.org/10.3390/en14227635

APA StyleHan, C., Long, Y., Xu, M., & Ji, B. (2021). Verification and Validation of Large Eddy Simulation for Tip Clearance Vortex Cavitating Flow in a Waterjet Pump. Energies, 14(22), 7635. https://doi.org/10.3390/en14227635