Application of MICMAC, Fuzzy AHP, and Fuzzy TOPSIS for Evaluation of the Maintenance Factors Affecting Sustainable Manufacturing

Abstract

:1. Introduction

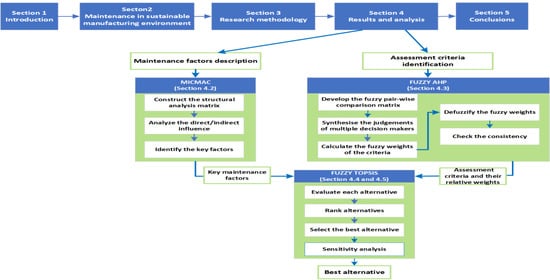

2. Maintenance in Sustainable Manufacturing Environment

3. Research Methodology

3.1. MICMAC Analysis

- 0 if there is no influence between i and j.

- 1 if there is a weak influence between i and j.

- 2 if there is a strong influence between i and j.

- 3 if there is a very strong influence between i and j.

- P if there is a potential influence between i and j.

3.2. Fuzzy AHP

3.3. Fuzzy TOPSIS

4. Results and Analysis

| Algorithm 1. Identification and evaluation of maintenance factors. |

| Step 1: Identification of maintenance factors influencing sustainable manufacturing (Ai). 1: Step 1 was performed in earlier studies described in [14]. Step 2: Analysis of the interaction between the identified factors. 2: Expert evaluation of the mutual influences between each pair of factors (weak, strong, very strong, potential). 3: Use MICMAC software (http://en.laprospective.fr/methods-of-prospective.html, accessd on 1 March 2021) to determine the mutual influence of the factors on each other. Detail: 3.1: Determine the direct influence coefficients DIi (Equation (1)) and DPi (Equation (2)). 3.2: Determine the indirect influence coefficients using matrix multiplication (M4). 3.3: Prepare the direct influence map. 3.4: Prepare the indirect influence map. 3.5: Prepare the potential indirect influence map. 3.6: Select the relevant factors Fi (cluster III and IV from the potential indirect influence map) for further analysis. Step 3: Identification and weighting of factor evaluation criteria using F-AHP. 4: Identify the Ci evaluation criteria by experts. 5: Define the pairwise comparison matrix of the criteria (in a linguistic scale). 6: Check the consistency of the pairwise experts’ judgments. Detail: 6.1: Defuzzify each triangular fuzzy number in the pairwise comparison matrix. 6.2: Calculate the consistency index of the comparison matrix (Equation (3)). 6.3: Calculate the consistency ratio of the comparison matrix (Equation (4)). 7: Calculate the value of the fuzzy synthetic extent values (Equation (5)). 8: Compute the degree of possibility (Equation (6)). 9: Calculate the degree of possibility (Equation (7)). 10: Define the priority vector (weights of criteria—wi) (Equation (8)) Step 4: Ranking of the most important maintenance factors with F-TOPSIS. 11: Determine the linguistic scale of the value ratings. 12: Assess the factors Fi against criteria Ci by decision-makers using a linguistic scale. 13: Replace the linguistic grades in decision-makers’ assessment with fuzzy grades according to the adopted scale (Step 4, Point 11). 14: Average experts’ assessments and create a fuzzy decision matrix (Equations (9) and (10)). 15: Normalize the fuzzy decision matrix (Equations (11)–(13)—only benefit criteria were used). 16: Calculate the weighted normalized decision matrix using criteria weights (Equation (14)). 17: Compute the fuzzy positive ideal solution (Equation (15)) and fuzzy negative ideal solutions (Equation (16)). 18: Calculate the distances of each factor from the fuzzy positive ideal solution (Equation (17)) and fuzzy negative ideal solution (Equation (18)). 19: Calculate the closeness coefficient CCi of each factor and rank the alternatives (Equation (19)). Step 5: Evaluation of the sensitivity of the ranking to the fluctuations of the experts’ assessments. 20: Perform F-TOPSIS analysis for hypothetical cases in which the lowest expert rating against each criterion was raised (Fi+) for the selected factor or the highest rating for each criterion was lowered (Fi−). 21: Compare the resulting rankings and analysis of their variability. |

4.1. Description of Maintenance Factors Affecting Sustainable Manufacturing

4.2. Clustering and Identification of Key Maintenance Factors Affecting Sustainable Manufacturing (MICMAC)

- The first team (D1) represented production and consisted of a production manager and a foreman;

- The second team (D2) represented the maintenance department and consisted of a maintenance manager and a maintenance technician;

- The third team represented SHE and consisted of two people: an occupational health and safety specialist and an environmental management specialist.

4.3. Assessment Criteria Identification and Weighting (F-AHP)

4.4. Ranking of the Most Important Maintenance Factors (F-TOPSIS)

- F1—(A5) Cooperation with P&Q departments;

- F2—(A6) Cooperation with the SHE department;

- F3—(A8) Implementation of preventive and prognostic service strategies;

- F4—(A9) The usage of M&O data collection and processing systems;

- F5—(A10) Modernization of machines and devices;

4.5. Sensitivity Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Division for Sustainable Development Goals. Sustainable Development Knowledge Platform. United Nations. Available online: https://sustainabledevelopment.un.org/ (accessed on 20 November 2020).

- Moldavska, A.; Welo, T. The concept of sustainable manufacturing and its definitions: A content-analysis based literature review. J. Clean. Prod. 2017, 166, 744–755. [Google Scholar] [CrossRef]

- Sartal, A.; Bellas, R.; Mejías, A.M.; García-Collado, A. The sustainable manufacturing concept, evolution and opportunities within Industry 4.0: A literature review. Adv. Mech. Eng. 2020. [Google Scholar] [CrossRef]

- Kannegiesser, M.; Günther, H.O. Sustainable development of global supply chains—Part 1: Sustainability optimization framework. Flex. Serv. Manuf. J. 2014, 26, 24–47. [Google Scholar] [CrossRef]

- Molamohamadi, Z.; Ismail, N. Developing a new scheme for sustainable manufacturing. Int. J. Mat. Mech. Manuf. 2013, 1, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Veleva, V.; Ellenbecker, M. Indicators of sustainable production: Framework and methodology. J. Clean. Prod. 2001, 9, 519–549. [Google Scholar] [CrossRef]

- Iung, B.; Levrat, E. Advanced maintenance services for promoting sustainability. Procedia CIRP 2014, 22, 15–22. [Google Scholar] [CrossRef]

- Sénéchal, O. Performance indicators nomenclatures for decision making in sustainable conditions based maintenance. IFAC PapersOnLine 2018, 51, 1137–1142. [Google Scholar] [CrossRef]

- Franciosi, C.; Di Pasquale, V.; Iannone, R.; Miranda, S. Multi-stakeholder perspectives on indicators for sustainable maintenance performance in production contexts: An exploratory study. J. Qual. Maint. Eng. 2020. [Google Scholar] [CrossRef]

- Holgado, M.; Macchi, M.; Evans, S. Exploring the impacts and contributions of maintenance function for sustainable manufacturing. Int. J. Prod. Res. 2020, 58, 7292–7310. [Google Scholar] [CrossRef]

- Amrina, E.; Yulianto, A.; Kamil, I. Fuzzy multi criteria approach for sustainable maintenance evaluation in rubber industry. Procedia Manuf. 2019, 33, 538–545. [Google Scholar] [CrossRef]

- Franciosi, C.; Voisin, A.; Miranda, S.; Riemma, S.; Iung, B. Measuring maintenance impacts on sustainability of manufacturing industries: From a systematic literature review to a framework proposal. J. Clean. Prod. 2020, 260, 121065. [Google Scholar] [CrossRef]

- Jasiulewicz-Kaczmarek, M.; Żywica, P.; Gola, A. Fuzzy set theory driven maintenance sustainability performance assessment model: A multiple criteria approach. J. Intel. Manuf. 2021. [Google Scholar] [CrossRef]

- Jasiulewicz-Kaczmarek, M. Identification of maintenance factors influencing the development of sustainable production processes—A pilot study. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; p. 062014. [Google Scholar]

- Singh, R.K.; Gupta, A. Framework for sustainable maintenance system: ISM–fuzzy MICMAC and TOPSIS approach. Ann. Oper. Res. 2020, 290, 643–676. [Google Scholar] [CrossRef]

- Balali, A.; Valipour, A.; Edwards, R.; Moehler, R. Ranking effective risks on human resources threats in natural gas supply projects using ANP-COPRAS method: Case study of Shiraz. Reliab. Eng. Syst. Saf. 2021, 208, 107442. [Google Scholar] [CrossRef]

- Ighravwe, D.E.; Oke, S.A. Applying Fuzzy Multi-Criteria Decision-Making Framework in Evaluating Maintenance Systems with an Emphasis on Human Tasks and Errors. Mahasarakham Int. J. Eng. Technol. 2021, 7, 67–77. [Google Scholar]

- EN 13306:2017. Maintenance—Maintenance Terminology; CEN–CENELEC Management Centre: Bruxelles, Belgium, 2017. [Google Scholar]

- Jasiulewicz-kaczmarek, M.; Antosz, K.; Żywica, P.; Mazurkiewicz, D.; Sun, B.; Ren, Y. Framework of machine criticality assessment with criteria interactions. Eksploat. Niezawodn. 2021, 23, 207–220. [Google Scholar] [CrossRef]

- Yan, J. Machinery Prognostics and Prognosis Oriented Maintenance Management; John Wiley & Sons: Singapore, 2015; p. 4. [Google Scholar]

- Takata, S. Maintenance-centered circular Manufacturing. Procedia CIRP 2013, 11, 23–31. [Google Scholar] [CrossRef] [Green Version]

- Takata, S.; Kimura, F.; Houten, F.J.A.M.; Westkämper, E.; Shpitalni, M.; Ceglarek, D.; Jay Lee, J. Maintenance: Changing role in life cycle management. Ann. CIRP 2004, 53, 643–656. [Google Scholar] [CrossRef]

- Ayu, K.; Yunusa-Kaltungo, A. A Holistic Framework for Supporting Maintenance and Asset Management Life Cycle Decisions for Power Systems. Energies 2020, 13, 1937. [Google Scholar] [CrossRef] [Green Version]

- Kowalski, A.; Blichtarski, M. The Method of Determining the Optimal Life Cycle of the Mining Machine. IOP Conf. Ser. Mater. Sci. Eng. 2019, 679, 012015. [Google Scholar] [CrossRef]

- Hami, N.; Ibrahim, Y.M.; Yamin, F.M.; Shafie, S.M.; Abdulameer, S.S. The Moderating Role of Sustainable Maintenance on the Relationship between Sustainable Manufacturing Practices and Social Sustainability: A Conceptual Framework. Int. J. Eng. Adv. Tech. 2019, 8, 222–228. [Google Scholar] [CrossRef]

- Liyanage, J.P.; Badurdeen, F.; Ratnayake, R.C.M. Industrial Asset Maintenance and Sustainability Performance: Economical, Environmental, and Societal Implications. In Handbook of Maintenance Management and Engineering; Springer: London, UK, 2009; pp. 665–693. [Google Scholar] [CrossRef]

- Hu, Q.; Bai, Y.; Zhao, J.; Cao, W. Modeling spare parts demands forecast under two-dimensional preventive maintenance policy. Math. Probl. Eng. 2015, 4, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Lewis, A.; Elmualim, A. Linking energy and maintenance management for sustainability through three American case studies. Facilities 2011, 29, 243–254. [Google Scholar] [CrossRef]

- Yabrudy-Mercado, D.E.; López-Sarria, B.S.; Fajardo-Cuadro, J.G.; Cardona-Agudelo, C.A. Indicators for maintenance planning based on energy efficiency in heat exchanger networks. Sci. Tech. Año XXV 2020, 25, 367–371. [Google Scholar] [CrossRef]

- Xia, T.; Xi, L.; Du, S.; Xiao, L.; Pan, E. Energy-Oriented Maintenance Decision-Making for Sustainable Manufacturing Based on Energy Saving Window. J. Manuf. Sci. Eng. 2018, 140, 051001. [Google Scholar] [CrossRef]

- Ndhaief, N.; Nidhal, R.; Hajji, A.; Bistorin, O. Environmental Issue in an Integrated Production and Maintenance Control of Unreliable Manufacturing/Remanufacturing Systems. Int. J. Prod. Res. 2020, 58, 4182–4200. [Google Scholar] [CrossRef]

- Duran, O.; Afonso, P.S.L.P. An activity based costing decision model for life cycle economic assessment in spare parts logistic management. Int. J. Prod. Econ. 2020, 222, 107499. [Google Scholar] [CrossRef]

- Turner, C.; Okorie, O.; Emmanouilidis, C.; Oyekan, J. A Digital Maintenance Practice Framework for Circular Production of Automotive. IFAC PapersOnLine 2020, 53, 19–24. [Google Scholar] [CrossRef]

- Noroozi, A.; Khakzad, N.; Khan, F.; MacKinnon, S.; Abbassi, R. The role of human error in risk analysis: Application to pre-and post-maintenance procedures of process facilities. Reliab. Eng. Syst. Saf. 2013, 119, 251–258. [Google Scholar] [CrossRef]

- Fraser, K.; Hvolby, H.H.; Tseng, T.L. Maintenance management models: A study of the published literature to identify empirical evidence. Int. J. Qual. Reliab. Manag. 2015, 32, 635–664. [Google Scholar] [CrossRef]

- Duperrin, J.C.; Godet, M. Methode de Hierarchization des Elements d’un Systeme (Method for Hierarchizing the Elements of a System); Report CEA-R-4541; Paris, France, 1973; pp. 41–45. Available online: https://hal-lara.archives-ouvertes.fr/hal-02185432/document (accessed on 1 March 2021).

- Loska, A. Exploitation assessment of selected technical objects using taxonomic methods. Eksploat. Niezawod. 2013, 15, 1–8. [Google Scholar]

- Jiang, X.; Lu, K.; Xia, B.; Liu, Y.; Cui, C. Using Integrated FISM-MICMAC Approach. Sustainability 2019, 11, 5206. [Google Scholar] [CrossRef] [Green Version]

- Saaty, T.L. Decision Making for Leaders: The Analytical Hierarchy Process for Decisions in a Complex World; Lifetime Learning Publications: Belmont, CA, USA, 1982. [Google Scholar]

- Kusumawardani, R.P.; Agintiara, M. Application of fuzzy AHP-TOPSIS method for decision making in human resource manager selection process. Procedia Comput. Sci. 2015, 72, 638–646. [Google Scholar] [CrossRef] [Green Version]

- Yucenur, G.N. A producer selection problem: A case study from Turkish food industry. Beykent Univ. J. Sci. Eng. 2017, 10, 185–212. [Google Scholar] [CrossRef]

- Shaygan, A.; Testik, Ö.M. A fuzzy AHP-based methodology for project prioritization and selection. Soft Comput. 2017, 23, 1309–1319. [Google Scholar] [CrossRef]

- Hwang, C.L.; Yoon, K. Multiple Attribute Decision Making: Methods and Applications: A State-of-the-Art Survey; Springer: Berlin, Germany, 1981; p. 13. [Google Scholar]

- Palczewski, K.; Sałabun, W. The fuzzy TOPSIS applications in the last decade. Procedia Comput. Sci. 2019, 159, 2294–2303. [Google Scholar] [CrossRef]

- Gumus, A.T. Evaluation of hazardous waste transportation firms by using a two step fuzzy AHP and TOPSIS methodology. Expert Syst. Appl. 2009, 36, 4067–4074. [Google Scholar] [CrossRef]

- Chang, D.Y. Applications of the extent analysis method on fuzzy AHP. Eur. J. Oper. Res. 1996, 95, 649–655. [Google Scholar] [CrossRef]

- Chang, D.Y. Extent analysis and synthetic decision. Optim. Tech. Appl. 1992, 1, 352–355. [Google Scholar]

- Zadeh, L.A. Fuzzy logic and approximate reasoning. Synthese 1975, 30, 407–428. [Google Scholar] [CrossRef]

- Giachetti, R.E.; Young, R.E. A parametric representation of fuzzy numbers and their arithmetic operators. Fuzzy Sets Syst. 1997, 91, 185–202. [Google Scholar] [CrossRef]

- Torfi, F.; Farahani, R.Z.; Rezapour, S. Fuzzy AHP to determine the relative weights of evaluation criteria and Fuzzy TOPSIS to rank the alternatives. Appl. Soft Comput. 2010, 10, 520–528. [Google Scholar] [CrossRef]

- Liu, Y.; Eckert, C.M.; Earl, C. A review of fuzzy AHP methods for decision-making with subjective judgements. Expert Syst. Appl. 2020, 161, 113738. [Google Scholar] [CrossRef]

- Godet, M. From Anticipation to Action: A Handbook of Strategic Prospective; UNESCO Publishing: Paris, France, 1994. [Google Scholar]

- Chen, C.T. Extensions of the TOPSIS for group decision-making under fuzzy environment. Fuzzy Sets Syst. 2000, 114, 1–9. [Google Scholar] [CrossRef]

- Piltan, F.; Kim, J.M. Fault Diagnosis of Bearings Using an Intelligence-Based Autoregressive Learning Lyapunov Algorithm. Int. J. Comput. Intell. Syst. 2021, in press. [Google Scholar] [CrossRef]

- Teixeira, C.; Lopes, I.; Figueiredo, M. Classification methodology for spare parts management combining maintenance and logistics perspectives. J. Manag. Anal. 2018, 5, 116–135. [Google Scholar] [CrossRef]

- Antosz, K.; Ratnayake, R.M.C. Spare parts’ criticality assessment and prioritization for enhancing manufacturing systems’ availability and reliability. J. Manuf. Syst. 2019, 50, 212–225. [Google Scholar] [CrossRef]

- Wakiru, J.; Pintelon, L.; Muchiri, P.N.; Chemweno, P.K. A review on lubricant condition monitoring information analysis for maintenance decision support. Mech. Syst. Signal. Pract. 2019, 118, 108–132. [Google Scholar] [CrossRef]

- Choi, B.; Suh, J.H. Forecasting Spare Parts Demand of Military Aircraft: Comparisons of Data Mining Techniques and Managerial Features from the Case of South Korea. Sustainability 2020, 12, 6045. [Google Scholar] [CrossRef]

- Zhu, S.; Jaarsveld, W.V.; Dekker, R. Spare parts inventory control based on maintenance planning. Reliab. Eng. Syst. Saf. 2020, 193, 106600. [Google Scholar] [CrossRef]

- Lejon, E.; Jeppsson, P. Integrating use phase information and virtual product representation to support Functional Products. Procedia CIRP 2015, 38, 204–209. [Google Scholar] [CrossRef] [Green Version]

- Sun, Y.; Qi, Z. How modularity influences product innovation. Manag. Decis. 2020, 58, 2743–2761. [Google Scholar] [CrossRef]

- Wu, Q.; Liao, K.; Deng, X.; Marsillac, E. Achieving automotive suppliers· mass customization through modularity. J. Manuf. Technol. Manag. 2019, 31, 306–329. [Google Scholar] [CrossRef]

- Zhang, M.; Guo, H.; Huo, B.; Zhao, X.; Huang, J. Linking supply chain quality integration with mass customization and product modularity. Int. J. Prod. Econ. 2019, 207, 227–235. [Google Scholar] [CrossRef]

- Blaise, J.C.; Levrat, E.; Iung, B. Process approach-based methodology for safe maintenance operation: From concepts to SPRIMI software prototype. Saf. Sci. 2014, 70, 99–113. [Google Scholar] [CrossRef]

- Estarrona, U.M.; Seneviratne, D.; Villarejo, R.; Galar, D. The New Asset Management: Implications of Servitization in Circular Economy. J. Ind. Eng. Manag. Sci. 2019, 6, 109–120. [Google Scholar] [CrossRef] [Green Version]

- Ren, W.; Wu, K.; Gu, Q.; Hu, Y. Intelligent decision making for service providers selection in maintenance service network: An adaptive fuzzy-neuro approach. Knowl. Based Syst. 2020, 190, 105263. [Google Scholar] [CrossRef]

- Lee, J.; Ardakani, H.D.; Yang, S.; Bagheri, B. Industrial big data analytics and cyber-physical systems for future maintenance & service innovation. Procedia CIRP 2015, 38, 3–7. [Google Scholar]

- Fathi, M.; Holland, A.; Abramovici, M.; Neubach, M. Advanced Condition Monitoring Services in Product Lifecycle Management. In Proceedings of the 2007 IEEE International Conference on Information Reuse and Integration, Las Vegas, NV, USA, 13–15 August 2007; pp. 245–250. [Google Scholar]

- Macchi, M.; Fumagalli, L.; Pinto, R.; Cavalieri, S. A decision making framework for managing maintenance spare parts in case of lumpy demand: An action research in the avionic sector. In Service Parts Management Demand Forecasting and Inventory Control; Altay, N., Litteral, L.A., Eds.; Springer: London, UK, 2011; pp. 171–202. [Google Scholar]

- Roy, R.; Stark, R.; Tracht, K.; Takata, S.; Mori, M. Continuous maintenance and the future—Foundations and technological challenges. CIRP Ann. Manuf. Technol. 2016, 65, 667–688. [Google Scholar] [CrossRef] [Green Version]

- Kozłowski, E.; Kowalska, B.; Kowalski, D.; Mazurkiewicz, D. Survival Function in the Analysis of the Factors Influencing the Reliability of Water Wells Operation. Water Resour. Manag. 2019, 33, 4909–4921. [Google Scholar] [CrossRef]

- Paprocka, I. The Model of Maintenance Planning and Production Scheduling for Maximising Robustness. Int. J. Prod. Res. 2019, 57, 4480–4501. [Google Scholar] [CrossRef]

- Erfanian, M.; Pirayesh, M. Integration Aggregate Production Planning and Maintenance Using Mixed Integer Linear Programming. In Proceedings of the 2016 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Bali, Indonesia, 4–7 December 2016; pp. 927–930. [Google Scholar] [CrossRef]

- Shankar, M.; Kumar, P.; Kannan, D.U. Analyzing the Drivers of Advanced Sustainable Manufacturing System Using AHP Approach. Sustainability 2016, 8, 824. [Google Scholar] [CrossRef] [Green Version]

- Pandey, D.; Kulkarni, M.S.; Vrat, P. Joint consideration of production scheduling, maintenance and quality policies: A review and conceptual framework. Int. J. Adv. Oper. Manag. 2010, 2, 1–24. [Google Scholar] [CrossRef]

- Lindström, J.; Larsson, H.; Jonsson, M.; Lejon, E. Towards intelligent and sustainable production: Combining and integrating online predictive maintenance and continuous quality control. Procedia CIRP 2017, 63, 443–448. [Google Scholar] [CrossRef]

- Tambe, P.P.; Kulkarni, M.S. A novel approach for production scheduling of a high pressure die casting machine subjected to selective maintenance and a sampling procedure for quality control. Int. J. Syst. Assur. Eng. Manag. 2014, 5, 407–426. [Google Scholar] [CrossRef]

- Duffuaa, S.; Kolus, A.; Al-Turki, U.; El-Khalifa, A. An integrated model of production scheduling, maintenance and quality for a single machine. Comp. Ind. Eng. 2020, 142, 106239. [Google Scholar] [CrossRef]

- Hill, D.C.; Seabrook, K.A. Safety & sustainability: Understanding the business value. Prof. Saf. 2013, 58, 81–92. [Google Scholar]

- Costella, M.F.; Dalcanton, F.; Cardinal, S.M.; Vilbert, S.S.; Pelegrini, G.A. Maintenance, occupational health and safety: A systematic review of the literature. Gestão Produção 2020, 27, e3922. [Google Scholar] [CrossRef]

- Mwanza, B.G.; Mbohwa, C. Safety in Maintenance: An Improvement Framework. Proc. Manuf. 2017, 8, 657–664. [Google Scholar] [CrossRef]

- Antosz, K. Maintenance—Identification and analysis of the competency gap. Eksploat. Niezawodn. 2018, 20, 484–494. [Google Scholar] [CrossRef]

- Iheukwumere-Esotuand, L.O.; Kaltungo, A.Y. Assessment of Barriers to Knowledge and Experience Transfer in Major Maintenance Activities. Energies 2020, 13, 1721. [Google Scholar] [CrossRef] [Green Version]

- Kans, M.; Campos, J.; Håkansson, L. A remote laboratory for Maintenance 4.0 training and education. IFAC PapersOnLine 2020, 53, 101–106. [Google Scholar] [CrossRef]

- Bokrantz, J.; Skoogh, A.; Berlin, C.; Stahre, J. Maintenance in digitalised manufacturing: Delphi-based scenarios for 2030. Int. J. Prod. Econ. 2017, 191, 154–169. [Google Scholar] [CrossRef]

- Franciosi, C.; Voisin, A.; Miranda, S.; Iung, B. Integration of I4.0 technologies with maintenance processes: What are the effects on sustainable manufacturing? IFAC PapersOnLine 2020, 53, 1–6. [Google Scholar] [CrossRef]

- Nezami, F.G.; Yildirim, M.B. A sustainability approach for selecting maintenance strategy. Int. J. Sust. Eng. 2013, 6, 332–343. [Google Scholar] [CrossRef]

- Yan, J.; Hua, D. Energy Consumption Modelling for Machine Tools After Preventive Maintenance. In Proceedings of the IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Macao, China, 7–10 December 2010; pp. 2201–2205. [Google Scholar]

- Chen, J.; Zhang, R.; Wu, D. Equipment Maintenance Business Model Innovation for Sustainable Competitive Advantage in the Digitalization Context: Connotation, Types, and Measuring. Sustainability 2018, 10, 3970. [Google Scholar] [CrossRef] [Green Version]

- Bocewicz, G.; Banaszak, Z.; Rudnik, K.; Witczak, M.; Smutnicki, C.; Wikarek, J. Milk-run routing and scheduling subject to fuzzy pickup and delivery time constraints: An ordered fuzzy numbers approach. In Proceedings of the IEEE International Conference on Fuzzy Systems, Glasgow, UK, 19–24 July 2020; p. 9177733. [Google Scholar] [CrossRef]

- Thibbotuwawa, A.; Bocewicz, G.; Radzki, G.; Nielsen, P.; Banaszak, Z. UAV Mission Planning Resistant to Weather Uncertainty. Sensors 2020, 20, 515. [Google Scholar] [CrossRef] [Green Version]

- Kotowska, J.; Markowski, M.; Burduk, A. Optimization of the supply of components for mass production with the use of the ant colony algorithm. In International Conference on Intelligent Systems in Production Engineering and Maintenance; Springer: Cham, Switzerland, 2017; pp. 347–357. [Google Scholar]

- Karim, R.; Candell, O.; Söderholm, P. Development of ICT-based maintenance support services. J. Qual. Maint. Eng. 2009, 15, 127–150. [Google Scholar] [CrossRef]

- Sun, B.; Zeng, S.; Kang, R.; Pecht, M. Benefits and Challenges of System Prognostics. IEEE Trans. Reliab. 2012, 61, 323–335. [Google Scholar] [CrossRef]

- Huanga, J.; Changa, Q.; Arinezc, J.; Xiao, G. A Maintenance and Energy Saving Joint Control Scheme for Sustainable Manufacturing Systems. Procedia CIRP 2019, 80, 263–268. [Google Scholar] [CrossRef]

- Yan, S.; MA, B.; Wang, X.; Chen, J.; Zheng, C. Maintenance policy for oil-lubricated systems with oil analysis data. Eksploat. Niezawod. 2020, 22, 455–464. [Google Scholar] [CrossRef]

- Jacobs, J.; Webber-Youngman, R.C.W. A technology map to facilitate the process of mine modernization throughout the mining cycle. J. S. Afr. I Min. Metall. 2017, 117, 636–648. [Google Scholar] [CrossRef]

- Stock, T.; Seliger, G. Opportunities of Sustainable Manufacturing in Industry 4.0. Procedia CIRP 2016, 40, 536–541. [Google Scholar] [CrossRef] [Green Version]

- Durán, O.; Macchi, M.; Roda, I. On the relationship of spare parts inventory policies with Total Cost of Ownership of industrial assets. IFAC-PapersOnLine 2016, 49, 19–24. [Google Scholar] [CrossRef] [Green Version]

- Alqahtani, A.Y.; Gupta, S.M. Warranty and preventive maintenance analysis for sustainable reverse supply chains. J. Manuf. Sci. E 2017, 2, 69–94. [Google Scholar] [CrossRef]

- Franciosi, C.; Lambiase, A.; Miranda, S. Sustainable maintenance: A periodic preventive maintenance model with sustainable spare parts management. IFAC-PapersOnLine 2017, 50, 13692–13697. [Google Scholar] [CrossRef]

- Kumar, A.; Shankar, R.; Thakur, L.S. A big data driven sustainable manufacturing framework for condition-based maintenance prediction. J. Comput. Sci-Neth. 2018, 27, 428–439. [Google Scholar] [CrossRef]

- Godichaud, M.; Tchangani, A.; Pérès, F.; Iung, B. Sustainable management of end-of-life systems. Prod. Plan. Con. 2012, 23, 216–236. [Google Scholar] [CrossRef]

- Roda, I.; Macchri, M. Studying the funding principles for integrating Asset Management in Operations: An empirical research in production companies. IFAC-PapersOnLine 2016, 49, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Deloux, E.; Castanier, B.; Bérenguer, C. Predictive maintenance policy for a gradually deteriorating system subject to stress. Reliab. Eng. Syst. Saf. 2009, 94, 418–431. [Google Scholar] [CrossRef] [Green Version]

- Duffuaa, S.O.; Ben-Daya, M.; Al-Sultan, K.S.; Andijani, A.A. A generic conceptual simulation model for maintenance systems. J. Qual. Maint. Eng. 2001, 73, 207–219. [Google Scholar] [CrossRef]

- Turki, S.; Hajej, Z.; Rezg, N. Impact of Delivery Time on Optimal Production/Delivery/Maintenance Planning. In Proceedings of the IEEE International Conference on Automation Science and Engineering (CASE), Seoul, Korea, 20–24 August 2012; pp. 335–340. [Google Scholar]

- Wang, W.Y. Optimum production and inspection modeling with minimal repair and rework considerations. Appl. Math. Model. 2013, 37, 1618–1626. [Google Scholar] [CrossRef]

- Zhang, Y.; Ren, S.; Liu, Y.; Si, S. A big data analytics architecture for cleaner manufacturing and maintenance processes of complex products. J. Clean. Prod. 2016, 142, 626–641. [Google Scholar] [CrossRef] [Green Version]

- Narayan, V. Business Performance and Maintenance: Ho ware Safety, Quality, Reliability, Productivity and Maintenance Related? J. Qual. Maint. Eng. 2012, 18, 183–195. [Google Scholar] [CrossRef]

- Bouslah, B.; Gharbi, A.; Pellerin, R. Joint economic design of production, continuous sampling inspection and preventive maintenance of a deteriorating production system. Int. J. Prod. Econ. 2016, 173, 184–198. [Google Scholar] [CrossRef]

- Glawar, R.; Karnera, M.; Nemeth, T.; Matyas, K.; Sihn, W. An approach for the integration of anticipative maintenance strategies within a production planning and control model. Procedia CIRP 2018, 67, 46–51. [Google Scholar] [CrossRef]

- Bouslah, B.; Gharbi, A.; Pellerin, R. Joint production, quality and maintenance control of a two-machine line subject to operation-dependent and quality-dependent failures. Int. J. Prod. Econ. 2018, 195, 210–226. [Google Scholar] [CrossRef]

- Ajukumar, V.N.; Gandhi, O.P. Evaluation of green maintenance initiatives in design and development of mechanical systems using an integrated approach. J. Clean. Prod. 2013, 51, 34–46. [Google Scholar] [CrossRef]

- Knowles, M. The role of maintenance in energy saving in commercial refrigeration. J. Qual. Maint. Eng. 2012, 18, 282–294. [Google Scholar] [CrossRef]

- Savino, M.; Macchi, M.; Mazza, A. Investigating the impact of social sustainability within maintenance operations: An action research in heavy industry. J. Qual. Maint. Eng. 2015, 21, 310–331. [Google Scholar] [CrossRef]

- Teymourian, K.; Seneviratne, A.M.N.B.; Galar, D. Ergonomics Contribution in Maintainability. Manag. Syst. Prod. Eng. 2017, 25, 217–223. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.; Lu, M.; Yuan, Y. Operation and maintenance integration to improve safety. Comp. Chem. Eng. 2000, 24, 401–407. [Google Scholar] [CrossRef]

- Okoh, P.; Haugen, S. Maintenance-related major accidents: Classification of causes and case study. J. Loss. Prevent. Proc. 2013, 26, 1060–1070. [Google Scholar] [CrossRef]

- Franciosi, C.; Di Pasquale, V.; Iannone, R.; Miranda, S. A taxonomy of performance shaping factors for human reliability analysis in industrial maintenance. J. Ind. Eng. Manag. 2019, 12, 115–132. [Google Scholar] [CrossRef] [Green Version]

- Savolainen, P.; Magnusson, J.; Gopalakrishnan, M.; Turanoglu Bekar, E.; Skoogh, A. Organizational Constraints in data-driven Maintenance: A case study in the automotive industry. IFAC PapersOnLine 2020, 53, 95–100. [Google Scholar] [CrossRef]

- Hu, Y.; Liu, S.; Zhang, H. Remanufacturing Decision Based on RUL Assessment. Procedia CIRP 2015, 29, 764–768. [Google Scholar] [CrossRef]

- Lee, J.; Ni, J.; Djurdjanovic, D.; Qiu, H.; Liao, H. Intelligent prognostics tools and e-maintenance. Comp. Ind. 2006, 57, 476–489. [Google Scholar] [CrossRef]

- Dombrowski, U.; Schulze, S.; Weckenborg, S. Life Cycle Costing as a Tool for effective Spare Parts Management. In Proceedings of the 16th CIRP International Conference on Life Cycle Engineering, Cairo, Egypt, 4–6 May 2009; pp. 478–483. [Google Scholar]

- Do, P.; Hoang, A.; Iung, B.; Vu, H.-C. Energy efficiency for condition-based maintenance decision-making: Application to a manufacturing platform. Proc. Inst Mech. Eng. Part O J. Risk Reliab. 2018, 232, 379–388. [Google Scholar] [CrossRef]

- Campos, J. Development in the application of ICT in condition monitoring and maintenance. Comp. Ind. 2009, 60, 1–20. [Google Scholar] [CrossRef]

- Daily, J.; Peterson, J. Predictive Maintenance: How Big Data Analysis Can Improve Maintenance. In Supply Chain Integration Challenges in Commercial Aerospace; Richter, K., Walther, J., Eds.; Springer: Cham, Switzerland, 2017. [Google Scholar]

- Guillén, A.J.; Crespo, A.; Gómez, J.F.; Sanz, M.D. A framework for effective management of condition based maintenance programs in the context of industrial development of E-Maintenance strategies. Comp. Ind. 2016, 82, 170–185. [Google Scholar] [CrossRef]

- Sari, E.; Shaharou, A.; Maaram, A.; Yazid, A.M. Sustainable maintenance performance measures: A pilot survey in Malaysian automotive companies. Procedia CIRP 2015, 26, 443–448. [Google Scholar] [CrossRef] [Green Version]

- Amrina, E.; Yulianto, A. Interpretive Structural Model of Key Performance Indicators for Sustainable Maintenance Evaluation in Rubber Industry. IOP Conf. Mater. Sci. Eng. 2018, 319, 012055. [Google Scholar] [CrossRef]

- Ashek-Al-Aziz, M.; Mahmud, S.; Islam, M.; Mahmud, J.A.; Hasib, K.M. A Comparative Study of AHP and Fuzzy AHP Method for Inconsistent Data. Int. J. Sci. Basic Appl. Res. 2020, 54, 16–37. [Google Scholar]

- Machado, C.G.; Winroth, M.P.; de Silva, E.H.D.R. Sustainable manufacturing in Industry 4.0: An emerging research agenda. Int. J. Prod. Res. 2020, 58, 1462–1484. [Google Scholar] [CrossRef]

- Felsberger, A.; Reiner, G. Sustainable Industry 4.0 in Production and Operations Management: A Systematic Literature Review. Sustainability 2020, 12, 7982. [Google Scholar] [CrossRef]

| Linguistic Expression | Abbreviation | Triangular Fuzzy Number |

|---|---|---|

| Very poor | VP | (0, 0, 1) |

| Poor | P | (0, 1, 3) |

| Medium poor | MP | (1, 3, 5) |

| Fair | F | (3, 5, 7) |

| Medium good | MG | (5, 7, 9) |

| Good | G | (7, 9, 10) |

| Very good | VG | (9, 10, 10) |

| No. | Factor | References |

|---|---|---|

| A1 | Spare parts and consumables management | [10,27,55,56,58,59,86,99,100,101] |

| A2 | Cooperation with manufacturers/suppliers of machinery | [9,10,60,65,66,86,102,103] |

| A3 | Cooperation with service providers | [9,10,64,67,68] |

| A4 | Cooperation with R&D department | [10,69,104] |

| A5 | Cooperation with P&Q departments | [9,10,69,72,75,76,77,86,104,105,106,107,108,109,110,111,112,113] |

| A6 | Cooperation with SHE department | [9,10,64,80,81,86,102,110,114,115,116,117,118,119] |

| A7 | Competence of maintenance workers | [9,10,70,82,84,85,86,110,120,121] |

| A8 | Implementation of preventive and prognostic service strategies | [10,71,85,86,100,102,122,123,124,125] |

| A9 | The usage of M&O data collection and processing systems | [57,85,86,97,126,127,128] |

| A10 | Modernization of machines and devices | [10,20,97,98,102] |

| A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | A9 | A10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| A1 | 0 | 0 | 0 | 0 | 2 | 0 | 0 | 0 | 0 | 0 |

| A2 | 1 | 0 | 1 | 0 | 1 | 1 | 2 | 1 | 1 | 1 |

| A3 | 2 | 0 | 0 | 0 | 3 | 0 | 1 | 1 | 0 | 1 |

| A4 | 1 | 1 | 1 | 0 | 2 | 2 | 1 | 0 | 0 | 2 |

| A5 | 0 | 3 | 2 | P | 0 | 0 | 2 | 0 | 3 | 3 |

| A6 | 3 | 2 | 3 | 0 | 3 | 0 | 2 | 1 | 0 | 2 |

| A7 | 0 | 0 | 0 | 0 | 2 | 0 | 0 | 3 | 0 | 2 |

| A8 | 3 | 3 | 3 | 0 | 3 | 0 | 2 | 0 | 3 | 2 |

| A9 | 3 | 2 | 3 | 0 | 3 | 2 | 1 | 3 | 0 | 1 |

| A10 | 3 | P | 1 | 0 | 1 | 0 | P | 2 | 1 | 0 |

| No. | DIi | DPi |

|---|---|---|

| A1 | 2 | 16 |

| A2 | 9 | 11 |

| A3 | 8 | 14 |

| A4 | 10 | 0 |

| A5 | 13 | 20 |

| A6 | 16 | 5 |

| A7 | 7 | 11 |

| A8 | 19 | 11 |

| A9 | 18 | 8 |

| A10 | 8 | 14 |

| 110 | 110 | |

| The highest values | ||

| The lowest values | ||

| A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | A9 | A10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| A1 | 4058 | 2934 | 3550 | 0 | 5056 | 1050 | 2980 | 3504 | 2932 | 3742 |

| A2 | 15,422 | 11,900 | 13,854 | 0 | 19,138 | 3154 | 11,276 | 11,630 | 11,517 | 14,131 |

| A3 | 12,299 | 9287 | 10,947 | 0 | 15,350 | 2772 | 9043 | 9837 | 9116 | 11,369 |

| A4 | 15,328 | 11,534 | 13,616 | 0 | 19,004 | 3330 | 11,121 | 11,912 | 11,189 | 13,906 |

| A5 | 21,859 | 16,822 | 19,623 | 0 | 26,930 | 4399 | 15,785 | 16,377 | 16,178 | 19,826 |

| A6 | 21,890 | 16,808 | 19,626 | 0 | 27,373 | 4628 | 16,057 | 16,874 | 16,287 | 20,181 |

| A7 | 14,916 | 10,873 | 13,052 | 0 | 18,451 | 3496 | 10,744 | 12,171 | 10,705 | 13,465 |

| A8 | 29,062 | 22,364 | 26,090 | 0 | 36,064 | 6033 | 21,177 | 22,122 | 21,620 | 26,599 |

| A9 | 29,112 | 21,919 | 25,850 | 0 | 36,278 | 6367 | 21,166 | 22,704 | 21,298 | 26,480 |

| A10 | 12,792 | 9766 | 11,420 | 0 | 15,939 | 2693 | 9319 | 9789 | 9494 | 11,678 |

| No. | DIi | DPi |

|---|---|---|

| A1 | 29,806 | 176,738 |

| A2 | 112,022 | 134,207 |

| A3 | 90,020 | 157,628 |

| A4 | 110,940 | 0 |

| A5 | 157,799 | 219,583 |

| A6 | 159,724 | 37,922 |

| A7 | 107,873 | 128,668 |

| A8 | 211,131 | 136,920 |

| A9 | 211,174 | 130,336 |

| A10 | 92,890 | 161,377 |

| The highest values | ||

| The lowest values |

| A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | A9 | A10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| A1 | 5720 | 5754 | 5044 | 1998 | 7360 | 1734 | 5872 | 4914 | 4102 | 5644 |

| A2 | 19,673 | 19,880 | 17,715 | 6606 | 25243 | 5137 | 19,931 | 15,710 | 14,295 | 19,429 |

| A3 | 16,844 | 16,985 | 15,024 | 5793 | 21,710 | 4689 | 17,197 | 13,944 | 12,194 | 16,664 |

| A4 | 20,902 | 20,825 | 18,614 | 6885 | 26,876 | 5784 | 21,120 | 17,078 | 14,873 | 20,476 |

| A5 | 33,511 | 33,712 | 30,183 | 11,040 | 42,980 | 8977 | 33,800 | 26,871 | 24,110 | 33,008 |

| A6 | 29,234 | 29,456 | 26,232 | 9900 | 37,738 | 7793 | 29,686 | 23,768 | 21,177 | 28,938 |

| A7 | 20,058 | 19,846 | 17,660 | 6639 | 25,783 | 5911 | 20,344 | 16,854 | 14,056 | 19,555 |

| A8 | 37,375 | 37,679 | 33,611 | 12,519 | 48,112 | 9984 | 37,866 | 30,177 | 27,050 | 36,967 |

| A9 | 36,936 | 36,994 | 32,978 | 12,345 | 47,519 | 10,018 | 37,429 | 30,159 | 26,452 | 36,311 |

| A10 | 25,893 | 26,344 | 23,435 | 8856 | 33,315 | 6665 | 26,305 | 20,727 | 18,971 | 25,745 |

| No. | DIi | DPi |

|---|---|---|

| A1 | 48,142 | 246,146 |

| A2 | 163,619 | 247,475 |

| A3 | 141,044 | 220,496 |

| A4 | 173,433 | 82,581 |

| A5 | 278,192 | 316,636 |

| A6 | 243,922 | 66,692 |

| A7 | 166,706 | 249,550 |

| A8 | 311,340 | 200,202 |

| A9 | 307,141 | 177,280 |

| A10 | 216,256 | 242,737 |

| The highest values | ||

| The lowest values |

| No | Criteria |

|---|---|

| C1 | Manufacturing cost |

| C2 | Energy consumption |

| C3 | Waste reduction |

| C4 | Operational safety |

| Linguistic Expression | Abbreviation | Triangular Fuzzy Number |

|---|---|---|

| Extremely more importance | EMI | (7/2,4,9/2) |

| Very strong importance | VSI | (5/2,3,7/2) |

| Strong importance | SI | (3/2,2,5/2) |

| Moderate importance | MI | (2/3,1,3/2) |

| Equal importance | EI | (1, 1, 1) |

| Criteria | C1 | C2 | C3 | C4 |

|---|---|---|---|---|

| C1 | (1,1,1) | (2/3,1,3/2) | (3/2,2,5/2) | (1,1,1) |

| C2 | (3/2,1,2/3) | (1,1,1) | (2/3,1,3/2) | (3/2,2,5/2) |

| C3 | (2/5,1/2,2/3) | (3/2,1,2/3) | (1,1,1) | (2/3,1,3/2) |

| C4 | (1,1,1) | (2/5,1/2,2/3) | (3/2,1,2/3) | (1,1,1) |

| Fuzzy Synthetic Extent | W′ | W | Rank | ||||

|---|---|---|---|---|---|---|---|

| S1 | 0.1953 | 0.2941 | 0.4348 | C1 | 1.000 | 0.3159 | 1 |

| S2 | 0.1797 | 0.2941 | 0.4710 | C2 | 1.000 | 0.3159 | 1 |

| S3 | 0.1281 | 0.2059 | 0.3382 | C3 | 0.6182 | 0.1953 | 2 |

| S4 | 0.1438 | 0.2059 | 0.3019 | C4 | 0.5472 | 0.1729 | 3 |

| Linguistic Terms | TFN |

|---|---|

| Very low important (VLI) | (0, 0, 1) |

| Low important (LI) | (0, 1, 3) |

| Medium low (ML) | (1, 3, 5) |

| Medium Important (MI) | (3, 5, 7) |

| Medium high (MH) | (5, 7, 9) |

| High important (HI) | (7, 9, 10) |

| Very important (VI) | (9, 10, 10) |

| Linguistic Ratings | Fuzzy Ratings | ||||||

|---|---|---|---|---|---|---|---|

| F/C | D1 | D2 | D3 | F/C | D1 | D2 | D3 |

| F1.C1 | MI | MH | MH | F1.C1 | (3, 5, 7) | (5, 7, 9) | (5, 7, 9) |

| F1.C2 | MI | MI | MI | F1.C2 | (3, 5, 7) | (3, 5, 7) | (3, 5, 7) |

| F1.C3 | HI | MI | HI | F1.C3 | (7, 9, 10) | (3, 5, 7) | (7, 9, 10) |

| F1.C4 | HI | HI | MI | F1.C4 | (7, 9, 10) | (7, 9, 10) | (3, 5, 7) |

| F2.C1 | L | ML | ML | F2.C1 | (0, 1, 3) | (1, 3, 5) | (1, 3, 5) |

| F2.C2 | MH | ML | ML | F2.C2 | (5, 7, 9) | (1, 3, 5) | (1, 3, 5) |

| F2.C3 | MH | MH | MI | F2.C3 | (5, 7, 9) | (5, 7, 9) | (3, 5, 7) |

| F2.C4 | VI | HI | VI | F2.C4 | (9, 10, 10) | (7, 9, 10) | (9, 10, 10) |

| F3.C1 | MH | HI | VI | F3.C1 | (5, 7, 9) | (7, 9, 10) | (9, 10, 10) |

| F3.C2 | MI | HI | HI | F3.C2 | (3, 5, 7) | (7, 9, 10) | (7, 9, 10) |

| F3.C3 | MH | VI | VI | F3.C3 | (5, 7, 9) | (9, 10, 10) | (9, 10, 10) |

| F3.C4 | HI | HI | VI | F3.C4 | (7, 9, 10) | (7, 9, 10) | (9, 10, 10) |

| F4.C1 | HI | VI | HI | F4.C1 | (7, 9, 10) | (9, 10, 10) | (7, 9, 10) |

| F4.C2 | MH | HI | MH | F4.C2 | (5, 7, 9) | (7, 9, 10) | (5, 7, 9) |

| F4.C3 | HI | HI | HI | F4.C3 | (7, 9, 10) | (7, 9, 10) | (7, 9, 10) |

| F4.C4 | HI | HI | HI | F4.C4 | (7, 9, 10) | (7, 9, 10) | (7, 9, 10) |

| F5.C1 | MH | MH | HI | F5.C1 | (5, 7, 9) | (5, 7, 9) | (7, 9, 10) |

| F5.C2 | HI | HI | HI | F5.C2 | (7, 9, 10) | (7, 9, 10) | (7, 9, 10) |

| F5.C3 | MH | HI | HI | F5.C3 | (5, 7, 9) | (7, 9, 10) | (7, 9, 10) |

| F5.C4 | MH | HI | HI | F5.C4 | (5, 7, 9) | (7, 9, 10) | (7, 9, 10) |

| Factor | C1 | C2 | C3 | C4 |

|---|---|---|---|---|

| F1 | (4.33, 6.33, 8.33) | (3, 5, 7) | (5.67, 7.67, 9) | (5.67, 7.67, 9) |

| F2 | (0.67, 2.33, 4.33) | (2.33, 4.33, 6.33) | (4.33, 6.33, 8.33) | (8.33, 9.67, 10) |

| F3 | (7, 8.67, 9.67) | (5.67, 7.67, 9) | (7.67, 9, 9.67) | (7.67, 9.33, 10) |

| F4 | (7.67, 9.33, 10) | (5.67, 7.67, 9.33) | (7, 9, 10) | (7, 9, 10) |

| F5 | (5.67, 7.67, 9.33) | (7, 9, 10) | (6.33, 8.33, 9.67) | (6.33, 8.33, 9.67) |

| weight | (0.2, 0.29, 0.43) | (0.18, 0.29, 0.47) | (0.13, 0.21, 0.34) | (0.14, 0.21, 0.3) |

| Factor | C1 | C2 | C3 | C4 |

|---|---|---|---|---|

| F1 | (0.43, 0.63, 0.83) | (0.3, 0.5, 0.7) | (0.5,7 0.77, 0.9) | (0.57, 0.77, 0.9) |

| F2 | (0.07, 0.23, 0.43) | (0.23, 0.43, 0.63) | (0.43, 0.63, 0.83) | (0.83, 0.97, 1) |

| F3 | (0.7, 0.87, 0.97) | (0.57, 0.77, 0.9) | (0.77, 0.9, 0.97) | (0.77, 0.93, 1) |

| F4 | (0.77, 0.93, 1) | (0.57, 0.77, 0.93) | (0.7, 0.9, 1) | (0.7, 0.9, 1) |

| F5 | (0.57, 0.77, 0.93) | (0.7, 0.9, 1) | (0.63, 0.83, 0.97) | (0.63, 0.83, 0.97) |

| Factor | C1 | C2 | C3 | C4 |

|---|---|---|---|---|

| F1 | (0.08, 0.19, 0.36) | (0.05, 0.15, 0.33) | (0.07, 0.16, 0.3) | (0.08, 0.16, 0.27) |

| F2 | (0.01, 0.07, 0.19) | (0.04, 0.13, 0.3) | (0.06, 0.13, 0.28) | (0.12, 0.2, 0.3) |

| F3 | (0.14, 0.25, 0.42) | (0.1, 0.23, 0.42) | (0.1, 0.19, 0.33) | (0.11, 0.19, 0.3) |

| F4 | (0.15, 0.27, 0.43) | (0.1, 0.23, 0.44) | (0.09, 0.19, 0.34) | (0.1, 0.19, 0.3) |

| F5 | (0.11, 0.23, 0.41) | (0.13, 0.26, 0.47) | (0.08, 0.17, 0.33) | (0.09, 0.17, 0.29) |

| F1 | F2 | F3 | F4 | F5 | |

|---|---|---|---|---|---|

| 3.28887129 | 3.40961956 | 3.10431321 | 3.09089235 | 3.1217108 | |

| 0.84075017 | 0.7069268 | 1.01839507 | 1.04164368 | 1.01647544 | |

| CCi | 0.20359013 | 0.17172813 | 0.24702089 | 0.25205919 | 0.24563308 |

| Ranking | 4 | 5 | 2 | 1 | 3 |

| Rank. | Original Rank | F1− | F1+ | F2− | F2+ | F3− | F3+ | F4− | F4+ | F5− | F5+ |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | A4 | A4 | A4 | A4 | A4 | A4 | A3 | A3 | A4 | A4 | A5 |

| 2 | A3 | A3 | A3 | A3 | A3 | A5 | A4 | A5 | A3 | A3 | A4 |

| 3 | A5 | A5 | A5 | A5 | A5 | A3 | A5 | A4 | A5 | A5 | A3 |

| 4 | A1 | A1 | A1 | A1 | A1 | A1 | A1 | A1 | A1 | A1 | A1 |

| 5 | A2 | A2 | A2 | A2 | A2 | A2 | A2 | A2 | A2 | A2 | A2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jasiulewicz-Kaczmarek, M.; Antosz, K.; Wyczółkowski, R.; Mazurkiewicz, D.; Sun, B.; Qian, C.; Ren, Y. Application of MICMAC, Fuzzy AHP, and Fuzzy TOPSIS for Evaluation of the Maintenance Factors Affecting Sustainable Manufacturing. Energies 2021, 14, 1436. https://doi.org/10.3390/en14051436

Jasiulewicz-Kaczmarek M, Antosz K, Wyczółkowski R, Mazurkiewicz D, Sun B, Qian C, Ren Y. Application of MICMAC, Fuzzy AHP, and Fuzzy TOPSIS for Evaluation of the Maintenance Factors Affecting Sustainable Manufacturing. Energies. 2021; 14(5):1436. https://doi.org/10.3390/en14051436

Chicago/Turabian StyleJasiulewicz-Kaczmarek, Małgorzata, Katarzyna Antosz, Ryszard Wyczółkowski, Dariusz Mazurkiewicz, Bo Sun, Cheng Qian, and Yi Ren. 2021. "Application of MICMAC, Fuzzy AHP, and Fuzzy TOPSIS for Evaluation of the Maintenance Factors Affecting Sustainable Manufacturing" Energies 14, no. 5: 1436. https://doi.org/10.3390/en14051436

APA StyleJasiulewicz-Kaczmarek, M., Antosz, K., Wyczółkowski, R., Mazurkiewicz, D., Sun, B., Qian, C., & Ren, Y. (2021). Application of MICMAC, Fuzzy AHP, and Fuzzy TOPSIS for Evaluation of the Maintenance Factors Affecting Sustainable Manufacturing. Energies, 14(5), 1436. https://doi.org/10.3390/en14051436