Management of Energy Enterprises in Zero-Emission Conditions: Bamboo as an Innovative Biomass for the Production of Green Energy by Power Plants

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. The Zero-Emission Program in the Strategy of Energy Companies

3.2. Energetic Properties of Biomass

3.3. Biomass Power Plant

3.4. Bamboo as Biomass

3.5. The Possibility of Growing Bamboo in Poland

4. Discussion

5. Conclusions

- (1)

- One of the most important environmental challenges that energy companies and energy-intensive industries are currently facing is the transition of the energy sector towards a safe, competitive, and low-emission energy system;

- (2)

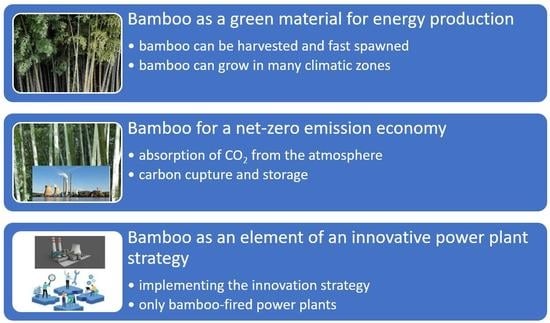

- Energy companies will increasingly take into account the use of innovative green materials that are renewable energy sources in their development strategies;

- (3)

- Biomass used for energy production should come from energy crops, such as bamboo cultivation, or from regions where forest resources that absorb CO2 are stable;

- (4)

- Enterprises will move towards eco-innovation. Research has shown the wide application of biomass, including bamboo biomass, by energy companies;

- (5)

- In many cases, businesses require minor changes to the existing infrastructure and technologies to use biomass;

- (6)

- Bamboo has sufficient mechanical and chemical-physical properties to be a material used by energy companies for direct combustion or used after specialized treatment (e.g., pyrolysis, torrefaction). An example is a power plant in Japan that is fully fired with bamboo biomass;

- (7)

- During the process of bamboo burning, a layer of clinker is formed, so additives need to be used for biomass as well as to regulate the combustion temperature and oxygen concentration.

Supplementary Materials

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- UN Climate Change Conference UK 2021. Available online: www.ukcop26.org (accessed on 6 January 2022).

- IRENA. World Energy Transitions Outlook: 1.5 °C Pathway; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2021. [Google Scholar]

- Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2021/Jun/IRENA_World_Energy_Transitions_Outlook_2021.pdf (accessed on 6 January 2022).

- Available online: https://www.unido.org/unido-cop26 (accessed on 6 January 2022).

- Kelly, F.J. COP26—Time for action. Air Qual. Atmos. Health 2022, 14, 1891. [Google Scholar] [CrossRef]

- COP26 Didn’t Solve Everything—But Researchers Must Stay Engaged. Available online: https://www.nature.com/articles/d41586-021-03433-2 (accessed on 6 January 2022).

- Available online: http://bambooproject.eu/ (accessed on 6 January 2022).

- Dwivedi, Y.K.; Hughes, L.; Kar, A.K.; Baabdullah, A.M.; Grover, P.; Abbas, R.; Andreini, D.; Abumoghli, I.; Barlette, Y.; Bunker, D.; et al. Climate change and COP26: Are digital technologies and information management part of the problem or the solution? An editorial reflection and call to action. Int. J. Inf. Manag. 2022, 63, 102456. [Google Scholar] [CrossRef]

- Bouckaert, S.; Pales, A.F.; Mcglade, C.; Remme, U.; Wanner, B.; Varro, L.; D’Ambrosio, D.; Spencer, T. Net Zero by 2050: A Roadmap for the Global Energy Sector; International Energy Agency: Paris, France, 2021. [Google Scholar]

- Available online: https://www.iea.org/reports/net-zero-by-2050 (accessed on 6 January 2022).

- Available online: https://www.energymanagermagazine.co.uk/decarbonising-the-economy-no-regrets-pathways-to-hydrogen/ (accessed on 6 January 2022).

- Baran, M.; Kuźniarska, A.; Makieła, Z.J.; Sławik, A.; Stuss, M.M. Does ESG Reporting Relate to Corporate Financial Performance in the Context of the Energy Sector Transformation? Evidence from Poland. Energies 2022, 15, 477. [Google Scholar] [CrossRef]

- Pronińska, K.; Księżopolski, K. Baltic Offshore Wind Energy Development—Poland’s Public Policy Tools Analysis and the Geostrategic Implications. Energies 2021, 14, 4883. [Google Scholar] [CrossRef]

- Energy Policy of Poland until 2040; Ministry of Climate and Environment: Warsaw, Poland, 2021.

- Available online: https://www.mckinsey.com/pl/~/media/mckinsey/locations/europe%20and%20middle%20east/polska/raporty/carbon%20neutral%20poland%202050/carbon%20neutral%20poland_mckinsey%20report.pdf (accessed on 6 January 2022).

- Malec, M. The prospects for decarbonization in the context of reported resources and energy policy goals: The case of Poland. Energy Policy 2022, 161, 112763. [Google Scholar] [CrossRef]

- Forum Energii, Energetyka Węglowa na Zakręcie. 2021. Available online: https://www.forum-energii.eu/pl/analizy/transformacja-2021 (accessed on 6 January 2022).

- Brauers, H.; Oei, P.Y. The political economy of coal in Poland: Drivers and barriers for a shift away from fossil fuels. Energy Policy 2020, 144, 111621. [Google Scholar] [CrossRef]

- Borowski, P.F. Digitization, digital twins, blockchain, and industry 4.0 as elements of management process in enterprises in the energy sector. Energies 2021, 14, 1885. [Google Scholar] [CrossRef]

- Yoesgiantoro, D.; Panunggul, D.A.; Corneles, D.E.; Yudha, N.F. The Effectiveness of Development Bamboo Biomass Power Plant (Case Study: Siberut Island, The District of Mentawai Islands). In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2016; Volume 265, p. 012001. [Google Scholar]

- Visser, L.; Hoefnagels, R.; Junginger, M. Wood pellet supply chain costs—A review and cost optimization analysis. Renew. Sustain. Energy Rev. 2020, 118, 109506. [Google Scholar] [CrossRef]

- Suluh, S.; Sampelawang, P.; Sirande, N. An Analysis of the Use of Local Bamboo as an Alternative Energy Source. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 619, p. 012006. [Google Scholar]

- Liu, Z.; Mi, B.; Jiang, Z.; Fei, B.; Cai, Z. Improved bulk density of bamboo pellets as biomass for energy production. Renew. Energy 2016, 86, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Sritong, C.; Kunavongkrit, A.; Piumsombun, C. Bamboo: An innovative alternative raw material for biomass power plants. Int. J. Innov. Manag. Technol. 2012, 3, 759. [Google Scholar]

- Burchart-Korol, D.; Gazda-Grzywacz, M.; Zarebska, K. Research and Prospects for the Development of Alternative Fuels in the Transport Sector in Poland: A Review. Energies 2020, 13, 2988. [Google Scholar] [CrossRef]

- Chin, K.; Ibrahim, S.; Hakeem, K.; H’ng, P.; Lee, S.; Mohd Lila, M. Bioenergy production from bamboo: Potential source from Malaysia’s perspective. BioRes 2017, 12, 6844–6867. [Google Scholar] [CrossRef] [Green Version]

- Muh, E.; Tabet, F.; Amara, S. Biomass Conversion to Fuels and Value-Added Chemicals: A Comprehensive Review of the Thermochemical Processes. Curr. Altern. Energy 2021, 4, 3–25. [Google Scholar] [CrossRef]

- Available online: https://www.buettner-energy-dryer.com/en/drying-energy-application/biomass-dryer/?gclid=EAIaIQobChMIuMiiqrmJ9AIVkkiRBR0CzwaBEAMYAyAAEgKql_D_BwE (accessed on 6 January 2022).

- Gebreegziabher, T.; Oyedun, A.O.; Luk, H.T.; Lam, T.Y.G.; Zhang, Y.; Hui, C.W. Design and optimization of biomass power plant. Chem. Eng. Res. Des. 2014, 92, 1412–1427. [Google Scholar] [CrossRef]

- Ogawa, S.; Ogawa, K.; Hirogaki, T.; Aoyama, E. Eco-Efficiency evaluation of binder-free green composites made from bamboo fibers extracted with a machining centre. Adv. Mater. Process. Technol. 2016, 2, 418–426. [Google Scholar]

- Borowski, P.F.; Patuk, I.; Bandala, E.R. Innovative Industrial Use of Bamboo as Key “Green” Material. Sustainability 2022, 14, 1955. [Google Scholar] [CrossRef]

- Available online: https://www.kobize.pl/uploads/materialy/materialy_do_pobrania/monitorowanie_raportowanie_weryfikacja_emisji_w_eu_ets/WO_i_WE_do_monitorowania-ETS-2021.pdf (accessed on 6 January 2022).

- Available online: https://www.forestresearch.gov.uk/tools-and-resources/fthr/biomass-energy-resources/reference-biomass/facts-figures/carbon-emissions-of-different-fuels/ (accessed on 6 January 2022).

- Truong, A.H.; Le, T.M.A. Overview of Bamboo Biomass for Energy Production; Hal.: Hanoi, Vietnam, 2014. [Google Scholar]

- Available online: https://www.nedo.go.jp/content/100895415.pdf (accessed on 6 January 2022).

- Available online: https://eit.europa.eu/news-events/news/eit-innoenergy-supports-bamboo-energy-make-difference-energy-market (accessed on 6 January 2022).

- Available online: https://www.electrifi.eu/project/beam/ (accessed on 6 January 2022).

- Available online: https://burness.com/blog/bamboo-charcoal-a-sustainable-energy-source-for-africa (accessed on 6 January 2022).

- Silva, M.F.; Menis-Henrique, M.E.; Felisberto, M.H.; Goldbeck, R.; Clerici, M.T. Bamboo as an eco-friendly material for food and biotechnology industries. Curr. Opin. Food Sci. 2020, 33, 124–130. [Google Scholar] [CrossRef]

- Shu, B.; Xiao, Z.; Hong, L.; Zhang, S.; Li, C.; Fu, N.; Lu, X. Review on the application of bamboo-based materials in construction engineering. J. Renew. Mater. 2020, 8, 1215–1242. [Google Scholar]

- Xu, X.; Xu, P.; Zhu, J.; Li, H.; Xiong, Z. Bamboo construction materials: Carbon storage and potential to reduce associated CO2 emissions. Sci. Total Environ. 2022, 814, 152697. [Google Scholar] [CrossRef]

- Rocky, B.P.; Thompson, A.J. Production and modification of natural bamboo fibers from four bamboo species, and their prospects in textile manufacturing. Fibers Polym. 2020, 21, 2740–2752. [Google Scholar] [CrossRef]

- Scurlock, J.M.; Dayton, D.C.; Hames, B. Bamboo: An overlooked biomass resource? Biomass Bioenergy 2000, 19, 229–244. [Google Scholar] [CrossRef] [Green Version]

- Bossle, M.B.; de Barcellos, M.D.; Vieira, L.M.; Sauvée, L. The drivers for adoption of eco-innovation. J. Clean. Prod. 2016, 113, 861–872. [Google Scholar] [CrossRef]

- Borowski, P.F. Innovation strategy on the example of companies using bamboo. J. Innov. Entrep. 2021, 10, 3. [Google Scholar] [CrossRef] [PubMed]

- Available online: http://greengoldbamboo.com/news-room/bamboo-for-biomass-a-potential-source-of-green-bio-fuel/5444 (accessed on 6 January 2022).

- Darabant, A.; Haruthaithanasan, M.; Atkla, W.; Phudphong, T.; Thanavat, E.; Haruthaithanasan, K. Bamboo biomass yield and feedstock characteristics of energy plantations in Thailand. Energy Procedia 2014, 59, 134–141. [Google Scholar] [CrossRef] [Green Version]

- Siraj, M.A. Bamboo Power. Available online: https://www.thehindu.com/features/homes-and-gardens/green-living/bamboo-power/article5900988.ece (accessed on 6 January 2022).

- Available online: https://h2tools.org/hyarc/calculator-tools/lower-and-higher-heating-values-fuels (accessed on 6 January 2022).

- Kumar, R.; Chandrashekar, N. Fuel properties and combustion characteristics of some promising bamboo species in India. J. For. Res. 2014, 25, 471–476. [Google Scholar] [CrossRef]

- Wafiq, A.; Hamed, A.; Elmaddah, E.; El-Sady, D.; Elawwad, A.; Abuelazayem, S. Guidelines on Sustainable Bamboo Energy Production and Investment in Africa, INBAR. 2022. Available online: https://www.inbar.int/resources/inbar_publications/guidelines-on-sustainable-bamboo-energy-production-and-investment/ (accessed on 1 February 2022).

- Qian, X.; Lee, S.; Soto, A.M.; Chen, G. Regression model to predict the higher heating value of poultry waste from proximate analysis. Resources 2018, 7, 39. [Google Scholar] [CrossRef] [Green Version]

- Engler, B.; Schoenherr, S.; Zhong, Z.; Becker, G. Suitability of bamboo as an energy resource: Analysis of bamboo combustion values dependent on the culm’s age. Int. J. For. Eng. 2012, 23, 114–121. [Google Scholar] [CrossRef] [Green Version]

- Sharma, R.; Wahono, J.; Baral, H. Bamboo as an alternative bioenergy crop and powerful ally for land restoration in Indonesia. Sustainability 2018, 10, 4367. [Google Scholar] [CrossRef] [Green Version]

- Available online: https://asia.nikkei.com/Spotlight/Environment/Bamboo-power-Japanese-plant-fires-up-for-trial-runs (accessed on 6 January 2022).

- Fuchihata, M.; Omatsu, D. Observation of ash and clinker formation behavior of bamboo chips. Proc. Symp. Environ. Eng. 2018, 28, 211. [Google Scholar] [CrossRef]

- Yang, J.; Feng, Z.; Ni, L.; Gao, Q.; He, Y.; Hou, Y.; Liu, Z. Thermal Characteristics of Ash from Bamboo and Masson Pine Blends: Influence of Mixing Ratio and Heating Rate. ACS Omega 2021, 6, 7008–7014. [Google Scholar] [CrossRef]

- Ali, U.; Font-Palma, C.; Akram, M.; Agbonghae, E.O.; Ingham, D.B.; Pourkashanian, M. Comparative potential of natural gas, coal and biomass fired power plant with post-combustion CO2 capture and compression. Int. J. Greenh. Gas Control 2017, 63, 184–193. [Google Scholar] [CrossRef]

- Available online: www.fargesia.pl (accessed on 6 January 2022).

- Chung, M.J.; Wang, S.Y. Physical and mechanical properties of composites made from bamboo and woody wastes in Taiwan. J. Wood Sci. 2019, 65, 57. [Google Scholar] [CrossRef]

- Borowski, P.F. Bamboo as an innovative material for many branches of world industry. Ann. Wars. Univ. Life Sci. SGGW For. Wood Technol. 2019, 107, 13–18. [Google Scholar] [CrossRef]

- Zuo, Y.; Maness, P.C.; Logan, B.E. Electricity production from steam-exploded corn stover biomass. Energy Fuels 2006, 20, 1716–1721. [Google Scholar] [CrossRef]

- Qian, X.; Lee, S.; Chandrasekaran, R.; Yang, Y.; Caballes, M.; Alamu, O.; Chen, G. Electricity evaluation and emission characteristics of poultry litter co-combustion process. Appl. Sci. 2019, 9, 4116. [Google Scholar] [CrossRef] [Green Version]

- Abedin, M.R.; Das, H.S. Electricity from rice husk: A potential way to electrify rural Bangladesh. Int. J. Renew. Energy Res. 2014, 4, 604–609. [Google Scholar]

- Rusch, F.; de Abreu Neto, R.; de Moraes Lúcio, D. Energy properties of bamboo biomass and mate co-products. SN Appl. Sci. 2021, 3, 602. [Google Scholar] [CrossRef]

- Chao, C.Y.H.; Kwong, P.C.W.; Wang, J.H.; Cheung, C.W.; Kendall, G. Co-Firing coal with rice husk and bamboo and the impact on particulate matters and associated polycyclic aromatic hydrocarbon emissions. Bioresour. Technol. 2008, 99, 83–93. [Google Scholar] [CrossRef]

- Chen, D.; Liu, D.; Zhang, H.; Chen, Y.; Li, Q. Bamboo pyrolysis using TG–FTIR and a lab-scale reactor: Analysis of pyrolysis behavior, product properties, and carbon and energy yields. Fuel 2015, 148, 79–86. [Google Scholar] [CrossRef]

- Dong, Q.; Xiong, Y. Kinetics study on conventional and microwave pyrolysis of moso bamboo. Bioresour. Technol. 2014, 171, 127–131. [Google Scholar] [CrossRef]

- Hu, J.; Yan, Y.; Evrendilek, F.; Buyukada, M.; Liu, J. Combustion behaviors of three bamboo residues: Gas emission, kinetic, reaction mechanism and optimization patterns. J. Clean. Prod. 2019, 235, 549–561. [Google Scholar] [CrossRef]

- Potential of Bamboo for Renewable. Available online: https://www.inbar.int/wp-content/uploads/2021/10/October-2021_Potential-of-Bamboo-for-Renewable-Energy.pdf (accessed on 6 January 2022).

- Van Dam, J.E.; Elbersen, H.W.; Montaño, C.M.D. Bamboo production for industrial utilization. Perenn. Grasses Bioenergy Bioprod. 2018, 175–216. [Google Scholar] [CrossRef]

- Zhu, Y.; Hu, J.; Yang, W.; Zhang, W.; Zeng, K.; Yang, H.; Du, S.; Chen, H. Ash fusion characteristics and transformation behaviors during bamboo combustion in comparison with straw and poplar. Energy Fuels 2018, 32, 5244–5251. [Google Scholar] [CrossRef]

- Nuamah, A.; Malmgren, A.; Riley, G.; Lester, E. Biomass Co-Firing. Compr. Renew. Energy 2012, 5, 55–73. [Google Scholar] [CrossRef]

- Truth or Trend: Is Bamboo Sustainable? Available online: https://www.ecoandbeyond.co/articles/is-bamboo-sustainable/ (accessed on 6 January 2022).

- Rusch, F.; de Moraes Lúcio, D.; de Campos, R.F. Potential of bamboo for energy purposes. Res. Soc. Dev. 2020, 9, e40973537. [Google Scholar] [CrossRef]

| Main Issues to Consider | Name of Source | Group of Publications |

|---|---|---|

| The use of furnace and post-mining waste for the production of new products. Decommissioning ineffective coal blocks. Investing in renewable energy sources. Development of nuclear energy. | Enea Annual Report (www.enea.pl) * Current Reports Tauron (www.tauron.pl) * Exxonmobil Annual Report (www.corporate.exxonmobil.com) * | Annual reports of the energy company |

| Bamboo as a material for energy production, a material for co-combustion, or as an independent input for combustion in a power plant fired only with bamboo or as a material for creating charcoal. | World Bamboo and Rattan (ISSN 1672-0431) Journal of Bamboo Research (ISSN1000-6567) The Journal of Bamboo and Rattan (ISSN 1569-1594) INBAR (www.inbar.int) * | Bamboo journals |

| Shutting down coal power plants, moving away from coal as energy. More areas on Earth should be planted with new forests to produce green biomass and hydrogen as fuel needs to be developed. | Energies (ISSN 1996-1073) Energy Policy (ISSN: 0301-4215) Energy Future (ISSN 2278-7186) Energy Journal (ISSN 0195-6574) Energy Manager Magazine (https://www.energymanagermagazine.co.uk/) * Sustainability (ISSN 2071-1050) Management (eISSN 2299-193X) | Energy journals |

| Achieving the goal of climate neutrality (all countries should attain climate neutrality in the electricity production sector). | IEA (International Energy Agency) IRENA (International Renewable Energy Agency) | Energy agencies |

| Thermochemical Conversion | ||

|---|---|---|

| direct combustion (steam turbine, electricity) | gasification (gas turbine) | pyrolysis (gas, charcol, torrefaction) |

| Name of the Project | Organization | Country |

|---|---|---|

| NEDO projects in the spotlight | Kumamoto/Bamboo Energy Co., Ltd. [35] | Japan |

| EIT InnoEnergy supports Bamboo Energy | Institute for Energy Research of Catalonia (IREC) [36] | Spain |

| Bamboo Energy Fund–Bamboo Energy Access Multiplier (BEAM) | EDFIMC–ElectriFI [37] | Belgium (HQ) realization places: Sub-Saharian Africa and Asia |

| BAMBOO E.U.-funded project | Bamboo project is funding from the European Union’s Horizon 2020 research and innovation program under grant agreement N°820771 [7] | European Union |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borowski, P.F. Management of Energy Enterprises in Zero-Emission Conditions: Bamboo as an Innovative Biomass for the Production of Green Energy by Power Plants. Energies 2022, 15, 1928. https://doi.org/10.3390/en15051928

Borowski PF. Management of Energy Enterprises in Zero-Emission Conditions: Bamboo as an Innovative Biomass for the Production of Green Energy by Power Plants. Energies. 2022; 15(5):1928. https://doi.org/10.3390/en15051928

Chicago/Turabian StyleBorowski, Piotr F. 2022. "Management of Energy Enterprises in Zero-Emission Conditions: Bamboo as an Innovative Biomass for the Production of Green Energy by Power Plants" Energies 15, no. 5: 1928. https://doi.org/10.3390/en15051928

APA StyleBorowski, P. F. (2022). Management of Energy Enterprises in Zero-Emission Conditions: Bamboo as an Innovative Biomass for the Production of Green Energy by Power Plants. Energies, 15(5), 1928. https://doi.org/10.3390/en15051928