Perspectives on the Advancement of Industry 4.0 Technologies Applied to Water Pumping Systems: Trends in Building Pumps

Abstract

:1. Introduction

2. Methodology

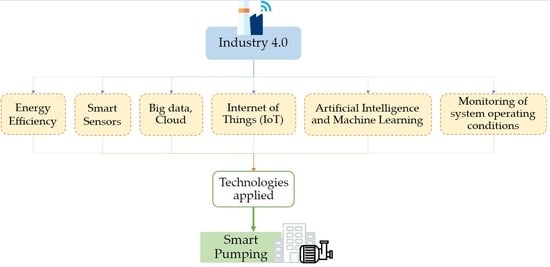

2.1. Identification of the Main Technologies of I4.0

2.2. Mapping of Application Possibilities of I4.0 Technologies in Building Pumping Systems

3. Industry 4.0: Applications in Systems and Intelligent Building Pumping

3.1. Mapping and Identification of I4.0 Technologies Applicable in Building Pumping Systems

3.1.1. Smart Sensors

Sensors for Hydraulic Measurements and Water Quality

Sensors for Measuring Mechanical Quantities

Sensors for Measuring Electrical Quantities

3.1.2. Big Data & Data Mining

3.1.3. Cloud & Edge Computing

3.1.4. Machine Learning and Artificial Intelligence

3.1.5. Internet of Things (IoT)

3.1.6. Human Machine Interface (HMI)

3.1.7. Systems Integration & Network Operation

3.1.8. Cyber Security

3.2. Implementation of I4.0 Technologies in Building Pumping Systems

- Pump speed control maintaining a pressure requested by the system.

- Applying VSDs reduces motor wear due to reduced speed, vibration, and torque.

- Soft start of the motor and gradual accelerations to reduce large electrical transients where high-starting currents can cause voltage drops in the electrical network.

- Soft start of the motor and gradual accelerations, reducing the mechanical stress of the shaft, as well as the thermal stresses in the windings and mechanical stresses in the couplings and belts.

- Reduction of sudden changes in water speed (transients), which may result in water hammer, cavitation, and vibration of the pump motor assembly [42].

- A small reduction in speed or flow can significantly reduce energy usage.

- Reduction in the maintenance fee of the motor-pump set.

- A total of 20 to 40% energy consumption, a typical 38% water leakage reduction, 53% reduced breakdowns, and extended motor pump life.

3.2.1. Operation at the Point of the Best Performance

3.2.2. Demand Side Management (DSM) Using VSD

3.3. Research Limitations

- The research was limited to evaluating the possibilities of application of I4.0 technologies in a building water pumping system, but these technologies could be applied in other types of drives such as: compression, elevation, ventilation, etc.

- The research did not delve into the discussion of communication protocols between the various systems.

- We recommend continuing the research with the construction of an IoT architecture for application in a pumping system using I4.0 technologies, enabling the experimental validation of the proposal.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yannopoulos, S.I.; Lyberatos, G.; Theodossiou, N.; Li, W.; Valipour, M.; Tamburrino, A.; Angelakis, A.N. Evolution of Water Lifting Devices (Pumps) over the Centuries Worldwide. Water 2015, 7, 5031–5060. [Google Scholar] [CrossRef] [Green Version]

- Rio Carrillo, A.M.; Frei, C. Water: A key resource in energy production. Energy Policy 2009, 37, 4303–4312. [Google Scholar] [CrossRef]

- World Urbanization Prospects The 2018 Revision; UN Department of Economic and Social Affairs: New York, NY, USA, 2019.

- Abergel, T.; Delmastro, C. Tracking Buildings 2021; International Energy Agency: Paris, France, 2021. [Google Scholar]

- Plappally, A.K.; Lienhard, V.J.H. Energy requirements for water production, treatment, end use, reclamation, and disposal. Renew. Sustain. Energy Rev. 2012, 16, 4818–4848. [Google Scholar] [CrossRef]

- Müller, T.M.; Leise, P.; Lorenz, I.S.; Altherr, L.C.; Pelz, P.F. Optimization and validation of pumping system design and operation for water supply in high-rise buildings. Optim. Eng. 2020, 22, 643–686. [Google Scholar] [CrossRef]

- Altherr, L.C.; Leise, P.; Pfetsch, M.E.; Schmitt, A. Resilient layout, design and operation of energy-efficient water distribution networks for high-rise buildings using MINLP. Optim. Eng. 2019, 20, 605–645. [Google Scholar] [CrossRef]

- De Souza, D.F.; Salotti, F.A.M.; Sauer, I.L.; Tatizawa, H.; de Almeida, A.T.; Kanashiro, A.G. An assessment of the impact of brazilian energy efficiency policies for electric motors. Energy Nexus 2021, 5, 100033. [Google Scholar] [CrossRef]

- Arun Shankar, V.K.; Umashankar, S.; Paramasivam, S.; Hanigovszki, N. A comprehensive review on energy efficiency enhancement initiatives in centrifugal pumping system. Appl. Energy 2016, 181, 495–513. [Google Scholar] [CrossRef]

- Bortoni, E.C.; Bernardes, J.V.; da Silva, P.V.V.; Faria, V.A.D.; Vieira, P.A.V. Evaluation of manufacturers strategies to obtain high-efficient induction motors. Sustain. Energy Technol. Assess. 2019, 31, 221–227. [Google Scholar] [CrossRef]

- De Almeida, A.; Fong, J.; Brunner, C.U.; Werle, R.; Van Werkhoven, M. New technology trends and policy needs in energy efficient motor systems—A major opportunity for energy and carbon savings. Renew. Sustain. Energy Rev. 2019, 115, 109384. [Google Scholar] [CrossRef]

- Carravetta, A.; Giugni, M.; Malavasi, S. Application of innovative technologies for active control and energy efficiency in water supply systems. Water 2020, 12, 3278. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Sustainable Industry 4.0 framework: A systematic literature review identifying the current trends and future perspectives. Process Saf. Environ. Prot. 2018, 117, 408–425. [Google Scholar] [CrossRef]

- Shaikh, P.H.; Nor, N.B.M.; Nallagownden, P.; Elamvazuthi, I.; Ibrahim, T. A review on optimized control systems for building energy and comfort management of smart sustainable buildings. Renew. Sustain. Energy Rev. 2014, 34, 409–429. [Google Scholar] [CrossRef]

- Ding, Z.; Liu, R.; Li, Z.; Fan, C. A thematic network-based methodology for the research trend identification in building energy management. Energies 2020, 13, 4621. [Google Scholar] [CrossRef]

- Lytras, M.D.; Visvizi, A. Who uses smart city services and what to make of it: Toward interdisciplinary smart cities research. Sustainability 2018, 10, 1998. [Google Scholar] [CrossRef] [Green Version]

- Di Nardo, A.; Boccelli, D.L.; Herrera, M.; Creaco, E.; Cominola, A.; Sitzenfrei, R.; Taormina, R. Smart urban water networks: Solutions, trends and challenges. Water 2021, 13, 501. [Google Scholar] [CrossRef]

- De Souza, D.F.; da Guarda, E.L.; Sauer, I.L.; Tatizawa, H. Energy Efficiency Indicators for Water Pumping Systems in Multifamily Buildings. Energies 2021, 14, 7152. [Google Scholar] [CrossRef]

- Lee, C.; Lim, C. From technological development to social advance: A review of Industry 4.0 through machine learning. Technol. Forecast. Soc. Chang. 2021, 167, 120653. [Google Scholar] [CrossRef]

- Klingenberg, C.O.; Borges, M.A.V.; Antunes, J.A.V. Industry 4.0 as a data-driven paradigm: A systematic literature review on technologies. J. Manuf. Technol. Manag. 2021, 32, 570–592. [Google Scholar] [CrossRef]

- Rupp, M.; Schneckenburger, M.; Merkel, M.; Börret, R.; Harrison, D.K. Industry 4.0: A technological-oriented definition based on bibliometric analysis and literature review. J. Open Innov. Technol. Mark. Complex. 2021, 7, 68. [Google Scholar] [CrossRef]

- Calabrese, A.; Levialdi Ghiron, N.; Tiburzi, L. ‘Evolutions’ and ‘revolutions’ in manufacturers’ implementation of industry 4.0: A literature review, a multiple case study, and a conceptual framework. Prod. Plan. Control. 2021, 32, 213–227. [Google Scholar] [CrossRef]

- Bittencourt, V.L.; Alves, A.C.; Leão, C.P. Industry 4.0 triggered by Lean Thinking: Insights from a systematic literature review. Int. J. Prod. Res. 2021, 59, 1496–1510. [Google Scholar] [CrossRef]

- Silvestri, L.; Forcina, A.; Introna, V.; Santolamazza, A.; Cesarotti, V. Maintenance transformation through Industry 4.0 technologies: A systematic literature review. Comput. Ind. 2020, 123, 103335. [Google Scholar] [CrossRef]

- De la Peña Zarzuelo, I.; Freire Soeane, M.J.; López Bermúdez, B. Industry 4.0 in the port and maritime industry: A literature review. J. Ind. Inf. Integr. 2020, 20, 100173. [Google Scholar] [CrossRef]

- Echchakoui, S.; Barka, N. Industry 4.0 and its impact in plastics industry: A literature review. J. Ind. Inf. Integr. 2020, 20, 100172. [Google Scholar] [CrossRef]

- Núñez-Merino, M.; Maqueira-Marín, J.M.; Moyano-Fuentes, J.; Martínez-Jurado, P.J. Information and digital technologies of Industry 4.0 and Lean supply chain management: A systematic literature review. Int. J. Prod. Res. 2020, 58, 5034–5061. [Google Scholar] [CrossRef]

- Sartal, A.; Bellas, R.; Mejías, A.M.; García-Collado, A. The sustainable manufacturing concept, evolution and opportunities within Industry 4.0: A literature review. Adv. Mech. Eng. 2020, 12, 1687814020925232. [Google Scholar] [CrossRef]

- Vianna, F.R.P.M.; Graeml, A.R.; Peinado, J. The role of crowdsourcing in industry 4.0: A systematic literature review. Int. J. Comput. Integr. Manuf. 2020, 33, 411–427. [Google Scholar] [CrossRef]

- Osterrieder, P.; Budde, L.; Friedli, T. The smart factory as a key construct of industry 4.0: A systematic literature review. Int. J. Prod. Econ. 2020, 221, 107476. [Google Scholar] [CrossRef]

- Mariani, M.; Borghi, M. Industry 4.0: A bibliometric review of its managerial intellectual structure and potential evolution in the service industries. Technol. Forecast. Soc. Chang. 2019, 149, 119752. [Google Scholar] [CrossRef]

- Piccarozzi, M.; Aquilani, B.; Gatti, C. Industry 4.0 in management studies: A systematic literature review. Sustainability 2018, 10, 3821. [Google Scholar] [CrossRef] [Green Version]

- Saucedo-Martínez, J.A.; Pérez-Lara, M.; Marmolejo-Saucedo, J.A.; Salais-Fierro, T.E.; Vasant, P. Industry 4.0 framework for management and operations: A review. J. Ambient Intell. Humaniz. Comput. 2018, 9, 789–801. [Google Scholar] [CrossRef]

- Mutchek, M.; Williams, E. Moving Towards Sustainable and Resilient Smart Water Grids. Challenges 2014, 5, 123–137. [Google Scholar] [CrossRef] [Green Version]

- Jan, F.; Min-Allah, N.; Düştegör, D. IoT Based Smart Water Quality Monitoring: Recent Techniques, Trends and Challenges for Domestic Applications. Water 2021, 13, 1729. [Google Scholar] [CrossRef]

- Antonino-Daviu, J. Electrical Monitoring under Transient Conditions: A New Paradigm in Electric Motors Predictive Maintenance. Appl. Sci. 2020, 10, 6137. [Google Scholar] [CrossRef]

- Mousmoulis, G.; Karlsen-Davies, N.; Aggidis, G.; Anagnostopoulos, I.; Papantonis, D. Experimental analysis of cavitation in a centrifugal pump using acoustic emission, vibration measurements and flow visualization. Eur. J. Mech. B/Fluids 2019, 75, 300–311. [Google Scholar] [CrossRef] [Green Version]

- Myhre, B.; Petersen, S.; Ugarelli, R. Using Wireless Vibration Monitoring to Enable Condition-based Maintenance of Rotating Machinery in the Water and Wastewater Industries. Procedia Eng. 2014, 89, 1397–1403. [Google Scholar] [CrossRef] [Green Version]

- Mounce, S.R.; Pedraza, C.; Jackson, T.; Linford, P.; Boxall, J.B. Cloud based machine learning approaches for leakage assessment and management in smart water networks. Procedia Eng. 2015, 119, 43–52. [Google Scholar] [CrossRef] [Green Version]

- Hu, Q.; Ohata, E.F.; Silva, F.H.S.; Ramalho, G.L.B.; Han, T.; Rebouças Filho, P.P. A new online approach for classification of pumps vibration patterns based on intelligent IoT system. Measurement 2020, 151, 107138. [Google Scholar] [CrossRef]

- Filipe, J.; Bessa, R.J.; Reis, M.; Alves, R.; Póvoa, P. Data-driven predictive energy optimization in a wastewater pumping station. Appl. Energy 2019, 252, 113423. [Google Scholar] [CrossRef] [Green Version]

- Dutta, N.; Palanisamy, K.; Subramaniam, U.; Padmanaban, S.; Holm-Nielsen, J.B.; Blaabjerg, F.; Almakhles, D.J. Identification of water hammering for centrifugal pump drive systems. Appl. Sci. 2020, 10, 2683. [Google Scholar] [CrossRef] [Green Version]

- Bhardwaj, A.S.; Saraf, R.; Nair, G.G.; Vallabhaneni, S. Real-time monitoring and predictive failure identification for electrical submersible pumps. In Proceedings of the Society of Petroleum Engineers—Abu Dhabi International Petroleum Exhibition and Conference 2019, ADIP 2019, Abu Dhabi, UAE, 11–14 November 2019. [Google Scholar]

- Achieng, K.O. Evaluating pump performance using laboratory observations and machine learning. ISH J. Hydraul. Eng. 2019, 27, 174–181. [Google Scholar] [CrossRef]

- Subramaniam, U.; Dutta, N.; Padmanaban, S.; Almakhles, D.; Kyslan, K.; Fedak, V. Identification of sludge in water pumping system using support vector machine. In Proceedings of the International Conference on Electical Drives and Power Electronics, Nový Smokovec, Slovakia, 24–26 September 2019; pp. 403–408. [Google Scholar]

- Feng, H.; Wang, Y.; Qiao, L.; Ganwei, B.; Zhu, J. Internet of Thing System to Extract Hierarchical Healthy and Efficiency Information for Pump Station Optimization. In Proceedings of the 2018 2nd International Conference on Big Data and Internet of Things, Beijing, China, 24–26 October 2018. [Google Scholar] [CrossRef]

- Stancel, E.; Stoian, I.; Kovacs, I.; Gyurka, B.Z.; Balogh, S. Urban water supply distributed control system. In Proceedings of the 2008 IEEE International Conference on Automation, Quality and Testing, Robotics, Cluj-Napoca, Romania, 22–25 May 2008; pp. 316–320. [Google Scholar] [CrossRef]

- Bayindir, R.; Cetinceviz, Y. A water pumping control system with a programmable logic controller (PLC) and industrial wireless modules for industrial plants—An experimental setup. ISA Trans. 2011, 50, 321–328. [Google Scholar] [CrossRef] [PubMed]

- Tuptuk, N.; Hazell, P.; Watson, J.; Hailes, S. A Systematic Review of the State of Cyber-Security in Water Systems. Water 2021, 13, 81. [Google Scholar] [CrossRef]

- Makropoulos, C.K.; Natsis, K.; Liu, S.; Mittas, K.; Butler, D. Decision support for sustainable option selection in integrated urban water management. Environ. Model. Softw. 2008, 23, 1448–1460. [Google Scholar] [CrossRef]

- Yuan, M. An Analysis on Optimization of Living and Fire Water Supply Systems of Small High-Rise Residential Blocks. IOP Conf. Ser. Earth Environ. Sci. 2017, 94, 012118. [Google Scholar] [CrossRef]

- Ochella, S.; Shafiee, M.; Sansom, C. Adopting machine learning and condition monitoring P-F curves in determining and prioritizing high-value assets for life extension. Expert Syst. Appl. 2021, 176, 114897. [Google Scholar] [CrossRef]

- Garcia, M.; Panagiotou, P.A.; Antonino-Daviu, J.A.; Gyftakis, K.N. Efficiency Assessment of Induction Motors Operating Under Different Faulty Conditions. IEEE Trans. Ind. Electron. 2019, 66, 8072–8081. [Google Scholar] [CrossRef]

- Fong, J.; Ferreira, F.J.T.E.; Silva, A.M.; de Almeida, A.T. IEC61800-9 system standards as a tool to boost the efficiency of electric motor driven systems worldwide. Inventions 2020, 5, 20. [Google Scholar] [CrossRef]

- Huse, S.N.; Kale, R.D.; Dhote, V.P. Development of Smart Water Supply System for University Water Supply Through Automation and Real-Time Operations. J. Inst. Eng. Ser. B 2020, 101, 497–510. [Google Scholar] [CrossRef]

- Hanigovszki, N. Developments and Trends in the Adjustable Speed Drives Industry. Proceedings of 2019 International Aegean Conference on Electrical Machines and Power Electronics (ACEMP) & 2019 International Conference on Optimization of Electrical and Electronic Equipment (OPTIM) , Istanbul, Turkey, 27–29 August 2019; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2019; pp. 51–56. [Google Scholar]

- Hammo, S.; Viholainen, J. Testing the accuracy of pump flow calculation without metering. World Pumps 2005, 2005, 36–39. [Google Scholar] [CrossRef]

- Emami Javanmard, M.; Ghaderi, S.F.; Sangari, M.S. Integrating energy and water optimization in buildings using multi-objective mixed-integer linear programming. Sustain. Cities Soc. 2020, 62, 102409. [Google Scholar] [CrossRef]

- Müller, T.M.; Altherr, L.C.; Leise, P.; Pelz, P.F. Optimization of Pumping Systems for Buildings: Experimental Validation of Different Degrees of Model Detail on a Modular Test Rig. In Operations Research Proceedings; Springer International Publishing: Cham, Switzerland, 2020; pp. 481–488. [Google Scholar] [CrossRef]

- Coello, C.A.C. An updated survey of GA-based multiobjective optimization techniques. ACM Comput. Surv. 2000, 32, 109–143. [Google Scholar] [CrossRef]

| # | Title | Journal | Year | Reference |

|---|---|---|---|---|

| 1 | From technological development to social advance: A review of Industry 4.0 through machine learning | Technological Forecasting and Social Change | 2021 | Lee and Lim [19] |

| 2 | Industry 4.0 as a data-driven paradigm: a systematic literature review on technologies | Journal of Manufacturing Technology Management | 2021 | Klingenberg et al. [20] |

| 3 | Industry 4.0: A technological-oriented definition based on bibliometric analysis and literature review | Journal of Open Innovation: Technology, Market, and Complexity | 2021 | Rupp et al. [21] |

| 4 | Evolutions and revolutions in manufacturers’ implementation of industry 4.0: a literature review, a multiple case study, and a conceptual framework | Production Planning & Control | 2021 | Calabrese et al. [22] |

| 5 | Industry 4.0 triggered by Lean Thinking: insights from a systematic literature review | International Journal of Production Research | 2020 | Bittencourt et al. [23] |

| 6 | Maintenance transformation through Industry 4.0 technologies: A systematic literature review | Computers in Industry | 2020 | Silvestri et al. [24] |

| 7 | Industry 4.0 in the port and maritime industry: A literature review | Journal of Industrial Information Integration | 2020 | De la Peña Zarzuelo et al. [25] |

| 8 | Industry 4.0 and its impact in plastics industry: A literature review | Journal of Industrial Information Integration | 2020 | Echchakoui and Barka [26] |

| 9 | Information and digital technologies of Industry 4.0 and Lean supply chain management: a systematic literature review | International Journal of Production Research | 2020 | Núñez-Merino et al. [27] |

| 10 | The sustainable manufacturing concept, evolution and opportunities within Industry 4.0: A literature review | Advances in Mechanical Engineering | 2020 | Sartal et al. [28] |

| 11 | The role of crowdsourcing in industry 4.0: a systematic literature review | International Journal of Computer Integrated Manufacturing | 2020 | Vianna et al. [29] |

| 12 | The smart factory as a key construct of industry 4.0: A systematic literature review | International Journal of Production Economics | 2020 | Osterrieder et al. [30] |

| 13 | Industry 4.0: A bibliometric review of its managerial intellectual structure and potential evolution in the service industries | Technological Forecasting and Social Change | 2019 | Mariani and Borghi [31] |

| 14 | Industry 4.0 in management studies: A systematic literature review | Sustainability | 2018 | Piccarozzi et al. [32] |

| 15 | Sustainable Industry 4.0 framework: A systematic literature review identifying the current trends and future perspectives | Process Safety and Environmental Protection | 2018 | Kamble et al. [13] |

| 16 | Industry 4.0 framework for management and operations: a review | Journal of Ambient Intelligence e Humanized Computing | 2018 | Saucedo-Martínez et al. [33] |

| Item | Technologies Linked to I4.0 | Application in Building Water Pumping Systems | References Analyzed |

|---|---|---|---|

| 1 | Smart Sensors | ● | [17,34,35,36,37,38] |

| 2 | Big Data & Data Mining | ● | [17,39] |

| 3 | Cloud & Edge Computing | ● | [39,40] |

| 4 | Machine Learning & Artificial Intelligence (AI) | ● | [39,40,41,42,43,44,45] |

| 5 | Internet of Things (IoT) | ● | [35,40] |

| 6 | Human Machine Interface (HMI) | ◐ | [46] |

| 7 | Systems Integration & Network Operation | ◐ | [47,48] |

| 8 | Cyber Security | ◐ | [49] |

| 9 | Autonomous Robotics | ◯ | - |

| 10 | Automatic identification and digital product memory | ◯ | - |

| 11 | 3D printing | ◯ | - |

| 12 | Augmented Reality or Virtual Reality | ◯ | - |

| 13 | Simulations | ◐ | [6,50] |

| 14 | Additive and Intelligent Manufacturing | ◯ | - |

| 15 | Machine-to-Machine (M2M) Communication | ◯ | - |

| 16 | Knowledge-Based Systems (KBS) & Semantic Web | ◐ | [51] |

| 17 | Automated guided vehicles (AGV) | ◯ | - |

| 18 | Cyberphysical Systems | ◯ | - |

| Item | Method | Paper | Journal | Year | Reference |

|---|---|---|---|---|---|

| 1 | Multi-objective optimization | An Updated Survey of GA-Based Multiobjective Optimization Techniques | ACM Computing Surveys | 2020 | Coello [60] |

| 2 | Genetic Algorithm | Decision support for sustainable option selection in integrated urban water management | Environmental Modelling & Software | 2008 | Klingenberg et al. [20] |

| 3 | Mixed-integer nonlinear programming | Optimization and validation of pumping system design and operation for water supply in high-rise buildings | Optimization and Engineering | 2021 | Müller et al. [6] |

| 4 | Multi-criteria analysis | An Analysis on Optimization of Living and Fire Water Supply Systems of Small High-Rise Residential Blocks | Earth and Environmental Science | 2017 | Yuan [51] |

| 5 | Multi-objective mixed integer linear programming | Integrating energy and water optimization in buildings using multi-objective mixed-integer linear programming | Sustainable Cities and Society | 2020 | Emami Javanmard et al. [58] |

| 6 | Mixed-integer nonlinear programming | Optimization of Pumping Systems for Buildings: Experimental Validationof Different Degrees of Model Detail on a Modular Test Rig | Operations Research Proceedings 2019 | 2019 | Müller et al. [59] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Souza, D.F.; da Guarda, E.L.A.; da Silva, W.T.P.; Sauer, I.L.; Tatizawa, H. Perspectives on the Advancement of Industry 4.0 Technologies Applied to Water Pumping Systems: Trends in Building Pumps. Energies 2022, 15, 3319. https://doi.org/10.3390/en15093319

de Souza DF, da Guarda ELA, da Silva WTP, Sauer IL, Tatizawa H. Perspectives on the Advancement of Industry 4.0 Technologies Applied to Water Pumping Systems: Trends in Building Pumps. Energies. 2022; 15(9):3319. https://doi.org/10.3390/en15093319

Chicago/Turabian Stylede Souza, Danilo Ferreira, Emeli Lalesca Aparecida da Guarda, Welitom Ttatom Pereira da Silva, Ildo Luis Sauer, and Hédio Tatizawa. 2022. "Perspectives on the Advancement of Industry 4.0 Technologies Applied to Water Pumping Systems: Trends in Building Pumps" Energies 15, no. 9: 3319. https://doi.org/10.3390/en15093319

APA Stylede Souza, D. F., da Guarda, E. L. A., da Silva, W. T. P., Sauer, I. L., & Tatizawa, H. (2022). Perspectives on the Advancement of Industry 4.0 Technologies Applied to Water Pumping Systems: Trends in Building Pumps. Energies, 15(9), 3319. https://doi.org/10.3390/en15093319