3.1. Weather Data

Figure 3 shows global solar radiation intensity (

G) and wind speed (

Vw) during the three days of the experiment.

It indicates that for all the three days,

G remained fairly stable with similar profile however with a slight difference in the peak as well as average hourly radiation intensity summarized in

Table 3.

For all the three days, the speed (

Vw) remained very low with a peak and average values of 0.9 m/s and 0.2 m/s. The airflow around the PV surface caused by windy conditions induces natural convection heat losses empirically predicted by Tiwari [

44]. The approach is based on combined convective and radiative heat loss coefficient (

h) applicable to air velocities ≤3 m/s given by Equation (1):

The

h calculated through Equation (1) ranges between 7.6–9 W/m

2·K at peak and 6–6.34 W/m

2·K on average for the front surface for the three days. The

h value calculated for the back surface remained lower than that of the front surface, ranging from 6.3–6.7 W/m

2·K at peak and −0.58–6 W/m

2·K on average. It can be noticed that on average the

h value did not differ substantially between the front and back PV surface. However the peak

h value at the PV back surface remained substantially lower than at the front surface. The substantially lower peak

h value at the back surface yielded lesser heat loss and resulted in a substantial temperature rise at the back compared to the surface of the reference PV, noticeable in

Figure 4 and

Figure 5.

The lower

h values indicate that natural convection cannot effectively cool the PV at this site, thereby resulting in higher PV temperatures that eventually affects the PV electrical conversion efficiency. However, lower

h values can be potentially beneficial once the concept of thermal energy storage and recovery is introduced in the PV, as it would minimize heat losses. The solar radiation absorbed by the PV (

Qpv) depends on the surface area (

A) and cleanliness of the PV surface represented by dusting coefficient 0.77 (

dc) and the absorptance (α) of the PV panel as given by Equation (2):

The

Qpv values are summarized in

Table 3, which indicates that PV receives reasonably different amount of radiation each day, with a highest deviation amongst the three days of 9.2%.

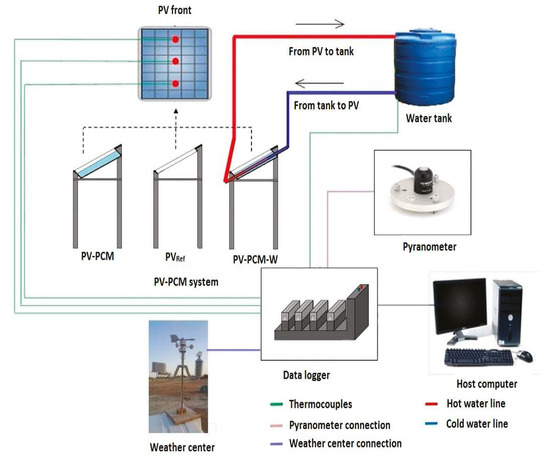

3.2. Temperature Drop

The measured front surface temperatures of the reference PV (

Tα), PV-PCM (

Tβ) and PV-PCM with water circulation (

Tγ) along with ambient temperature (

Tamb) are presented in

Figure 4.

Figure 4 shows that at start of the experiment,

Tamb was 16 °C, which increased with a stable gradient reaching peak of 32 °C at 13:00 for day 1. It can be observed that

Tamb remained at all times below the PCM melting initiation temperature (

Tm) of 37 °C indicating that

Tamb alone would not trigger PCM melting. At the start of the experiment,

Tαf,

Tβf and

Tγf were almost the same (11 °C) being substantially lower than

Tm, indicating that PCM contained at the PV back was in solid state at the start of the experiment which was also confirmed by visual inspection. As radiation hits the PV at 7:00 am, the temperature started to increase for the three PV modules however each with a different gradient. As expected,

Tαf exhibited a higher gradient of rise followed by

Tβf and

Tγf with a time lag caused by a higher thermal inertia achieved by the inclusion of the PCM (in PV-PCM and PV-PCM-W) compared to the PV alone. The

Tαf reached its peak at 53 °C at 1:25 PM while

Tβf and

Tγf remained below 44 °C at the same time yielding a drop of 9 °C at peak. The average

Tαf reached 38.5 °C, followed by 33.5 °C and 33.4 °C in the cases of

Tβf and

Tγf, respectively, rendering an average temperature drop of 5 °C compared to the PV without PCM. The water circulation at 13:00 induced a slight additional temperature drop observed in

Tγf. A similar trend in temperature rise was observed for the remaining two days with slightly different magnitudes. The different

Tαf,

Tβf and

Tγf values resulted in different amounts of heat being discarded to the environment through natural convection and radiation, quantified by Equations (3)–(5):

where

Ql and

A represent the heat loss and cross-section area of the PV panel, respectively. Applying Equations (3)–(5), on the measured data, it is found that the front surface of the reference PV discarded 380 Wh/day to ambient, which was reduced to 242 Wh/day (for PV-PCM) and 232 Wh/day for PV-PCM with water flow.

The

Tpcm along with the back surface temperatures of the reference PV (

Tαb), PV-PCM (

Tβb) and PV-PCM with water circulation (

Tγb) are presented in

Figure 5. All the temperatures,

Tαb,

Tβb,

Tγb and

Tpcm were almost the same at the start of the experiment, however they differed in transient temperature rise afterwards, reaching peak values of 57 °C, 39 °C, 38 °C and 42 °C, respectively. It can be see that inclusion of the PCM caused a delay in the temperature rise compared to the PV alone due to the increased thermal inertia of the system caused by the PCM’s latent heat absorption. The peak temperature drop was 19 °C (from 57 °C to 38 °C). Taking the average of the temperature curves, it was noted that an average temperature drop of 10 °C was achieved at the back surface of PV-PCM for day 1, attributed to the heat stored in the PCM. The reduced

Tβb,

Tγb prevented heat loss from the back surface of the PV-PCM compared to the reference PV calculated by the combined convection and radiation heat loss Equations (6)–(8) below:

Heat losses at the back of the PV surface are calculated by applying Equations (6)–(8) on the experimental data from

Figure 5. The heat losses dropped from 409 Wh/day for the reference PV (

Qlαb) to 143 Wh/day for both PV-PCM and PV-PCM-W (

Qlβb and

Qlγb, respectively). By combining the front and back surface heat losses, the total heat loss dropped from 794 Wh/day (reference PV) to 385 Wh/day in case of PV-PCM and 375 Wh/day for PV-PCM-W preventing a heat loss of 409 Wh/day and 419 Wh/day, respectively.

Heat losses prevented by the PCM alone are calculated by deducting the sensible heat stored in metallic parts in PV-PCM system calculated using

Table 4 (53 Wh/day) [

40,

42,

45]. The heat loss thereby prevented by the PCM dropped to 356 Wh/day.

It can be seen that the inclusion of a PCM reduced the PV temperature (

Figure 4 and

Figure 5) while reducing heat losses. The novelty of the latent heat storage concept lies in reducing the heat losses by maintaining a lower temperature compared to sensible heat dissipation systems. The heat retention along with lower PV temperature has two benefits. The reduced temperature can increase the PV power output as discussed in

Section 3.4, while the retained heat (solely due to heat loss prevention) can be utilized for water heating, as discussed in

Section 3.3. The PV temperature drop along with heat retention and utilization by PCM is in agreement with the reported literature findings [

46].

The retained heat was consumed in melting the PCM which can be determined by observing changes in PCM temperature (

Tpcm).

Figure 5 shows that

Tpcm reached 37 °C (start of PCM melting) at 11:00, increasing to 42 °C (end of PCM melting) at 12:40 and continued to rise to 43 °C at 13:00. This indicates that PCM had completely melted before 13:00 prior to triggering the water flow to remove the heat stored in the melted PCM to heat the water. At nighttime, the

Tpcm dropped below 37 °C (PCM solidification temperature) at 21:00 and reached the lowest value of 13 °C by the morning. It indicates that the PCM had completely solidified before the start of the next day, which was also confirmed by visual inspection. Since the PCM showed complete phase change (melting and solidification), the energy stored can be calculated by assuming complete solid-liquid phase transition given by Equations (9)–(11):

where ρ,

V,

Cp are density, volume and heat capacity, while subscripts

i and

f represent the initial and final state of the PCM. Heat absorbed by the reference PV (

Qα), PV-PCM (

Qβ) and PV-PCM-W (

Qγ) calculated by Equations (9)–(11) are 15 kWh/day, 418 Wh/day and 429 Wh/day, respectively. The heat stored (418 Wh/day and 429 Wh/day) is in close agreement to the prevented heat loss (409 Wh/day and 419 Wh/day) by PV-PCM and PV-PCM-W, respectively, which proves the accuracy of our experiments.

3.4. Improvement in PV Power Output

The decrease in temperature reported in

Section 3.2 has a positive effect on the PV voltage but a negative effect on current due to the decreased charge mobility. The measured

Voc presented in

Figure 7 shows that PV-PCM and PV-PCM-W maintained a higher

Voc compared to the reference PV. The peak

Voc was recorded as 18.6 V for reference PV (

Vocα), 20.3 volt for PV-PCM (

Vocβ) and 20.3 V for PV-PCM-W (

Vocγ). It indicates that inclusion of PCM yielded an ~9% increase in

Voc by virtue of maintaining lower temperatures.

The

Isc presented in

Figure 8 shows a relatively negligible difference amongst the three systems apart from that at the peak. The reference PV maintained a slight higher current (

Iscα) compared to PV-PCM (

Iscβ) and PV-PCM-W (

Iscγ) due to being at higher temperature.

From recorded

Voc and

Isc, the power produced by PV is calculated by applying the fill factor (

FF) correlation given by Equation (13):

where

P is the electrical power produced by the PV. The

FF is considered to be constant (0.7) deduced from PV data sheet.

Figure 9 shows that inclusion of PCM produced higher peak power (

Pβ =

Pγ = 34 W) compared to the reference PV (

Pα = 32 W) yielding an increase of ~6.5%. The average power produced by inclusion of PCM (

Pβ =

Pγ = 20 W) was of ~6% higher compared to that of the reference PV (

Pγ = 18.9 W). The total electrical energy produced increased from 272 Wh/day for reference PV to 288 Wh/day for the PV-PCM and PV-PCM-W (increase of 18 Wh/day) indicating an increase of 6% (equivalent to increase in PV efficiency by 1.3%). However since water was circulated behind the PV for heat extraction, the additional power would be needed to account for pressure drop in water circuit. The additional power consumed by the pump due to pressure drop in PV water circulation is calculated by assuming 10 m additional water head with a flow 0.027 L/s. It resulted in the additional shaft power of 4 W with total energy consumed being 12 Wh/day as the water was circulated for three hours a day. The additional power required (12 Wh/day) is still lower than improved PV power output by PV cooling (18 Wh/day) so the concept is justified.

The total electrical energy produced, heat losses and the energy storage capacity of each of the module are summarized in

Figure 10. It shows that the reference PV showed a highest heat loss (

Ql) and lowest thermal energy storage capacity (

Qs) while the PV-PCM and PV-PCM-W showed lower heat losses and higher thermal energy storage capacity. It can also be seen that the PV-PCM and PV-PCM-W produced higher electrical energy (

Qe) compared to that of the reference PV. Thus it can be concluded that the PV-PCM system can increase electrical output as well as thermal energy storage capacity of PV system due to temperature regulation and latent heat absorption in PCM.