Preliminary Development of a Free Piston Expander–Linear Generator for Small-Scale Organic Rankine Cycle (ORC) Waste Heat Recovery System

Abstract

:1. Introduction

2. Experimental Setup and Procedure

2.1. Working Principle and Function of the Free Piston Expander-Linear Generator

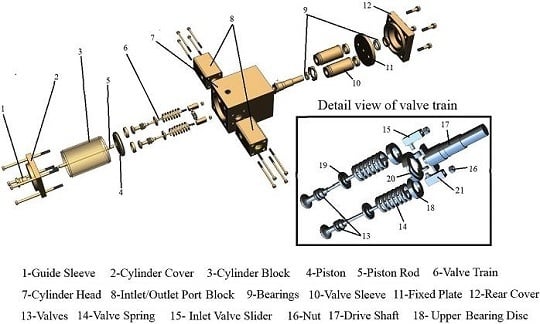

2.2. Conceptual Design of the Free Piston Expander

2.2.1. Configuration and Main Parameters

- (1)

- Intake temperature of the working fluid is 300–350 K;

- (2)

- Intake pressure of the working fluid is 0.8–1 MPa;

- (3)

- Maximal expansion ratio of the FPE is 9;

- (4)

- Intake volume flow rate of the working fluid is 10–20 m3/h;

- (5)

- Exhaust back pressure is 0.11–0.13 MPa.

2.2.2. Energy Loss Mechanisms

- (1)

- Incomplete expansion. During the expansion process, the expansion of the working fluid in the cylinder is incomplete because of the limitation in actual piston stroke and valve timing. In-cylinder pressure is higher than exhaust back pressure at the end of expansion process;

- (2)

- Heat transfer. The working process of the FPE is not adiabatic because of the temperature difference between the FPE cylinder (or working fluid) and the ambient environment. Thus, heat exchange occurs between the FPE cylinder (or working fluid) and the ambient environment;

- (3)

- Flow loss during intake and exhaust processes. The inlet and outlet valves are used to control inlet and outlet valve timing, respectively; hence, flow loss occurs in the actual intake and exhaust processes;

- (4)

- Mechanical friction. The primary mechanical friction occurs in the following contact segments: piston and cylinder wall, piston rod and guide sleeve, drive shaft and bearing/cover, cam plate and valve slider, etc. A wear-resistant material with high strength (e.g., aluminum alloy and aluminum bronze) is used in designing the FPE process to reduce wear and improve the fatigue life of relevant components;

- (5)

- Leakage. When the cylinder is full of working fluid, there exists more or less leakage in the gap between the piston and cylinder wall.

2.2.3. Lubrication and Sealing

2.2.4. Valve Train

2.3. Air Test Rig of the Free Piston Expander-Linear Generator

2.4. Experimental Procedure

3. Results and Discussion

3.1. Three-Dimensional Numerical Simulation of the Free Piston Expander

3.1.1. Grid Generation

3.1.2. Boundary Conditions and Dynamic Mesh

3.1.3. Unsteady Flow Behavior during the Intake and Exhaust Processes

3.2. Analysis of the Actual Working Process of the Free Piston Expander

3.3. Indicated Efficiency of the Free Piston Expander

3.4. Electric Power Output of Free Piston Expander-Linear Generator

4. Conclusions

- (1)

- The working principle of the FPE-LG is proven feasible through the air test rig. However, further test of the FPE-LG in a small-scale ORC system should be performed in the future;

- (2)

- The energy-conversion efficiency of the expander is obviously affected by the intake parameters. The indicated efficiency of the FPE can reach 66.2% and the maximal electric power output of the FPE-LG can reach 22.7 W when the working frequency is 3 Hz and the intake pressure is 0.2 MPa;

- (3)

- Two large-scale vortices are formed during the intake process. To improve the energy conversion efficiency of the FPE, several practical approaches should be adopted to adjust the intake flow and to reduce the energy losses caused by large-scale vortex flow.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| p | in-cylinder pressure (MPa) |

| Pin | intake pressure (MPa) |

| V | sweep volume (L) |

| θ | cam plate rotational angles after the beginning of the curved surface for lifting up inlet valve (degree) |

| electric power output (W) | |

| P0 | cylinder pressure at the equilibrium position (MPa) |

| L | oscillation amplitude (m) |

| γ | polytropic exponent |

| A | piston cross sectional area (m2) |

| m | moving mass (kg) |

| f0 | natural frequency (Hz) |

| k | the equivalent stiffness (N/m) |

Acronyms

| FPE | free piston expander |

| LG | linear generator |

| IC | internal combustion |

| TDC | top dead center |

| BDC | bottom dead center |

| WHR | waste heat recovery |

| ORC | organic Rankine cycle |

| CFD | computational fluid dynamic |

References

- Aghaali, H.; Ångström, H.E. A review of turbocompounding as a waste heat recovery system for internal combustion engines. Renew. Sustain. Energy Rev. 2015, 49, 813–824. [Google Scholar] [CrossRef]

- Yu, G.P.; Shu, G.Q.; Tian, H.; Wei, H.Q.; Liu, L.N. Simulation and thermodynamic analysis of a bottoming organic Rankine cycle (ORC) of diesel engine (DE). Energy 2013, 51, 281–290. [Google Scholar] [CrossRef]

- Saidur, R.; Rezaei, M.; Muzammil, W.K.; Hassan, M.H.; Paria, S.; Hasanuzzaman, M. Technologies to recover exhaust heat from internal combustion engines. Renew. Sustain. Energy Rev. 2012, 16, 5649–5659. [Google Scholar] [CrossRef]

- Sprouse, C.; Depcik, C. Review of organic Rankine cycles for internal combustion engine exhaust waste heat recovery. Appl. Therm. Eng. 2013, 51, 711–722. [Google Scholar] [CrossRef]

- Song, J.; Gu, C.W. Parametric analysis of a dual loop Organic Rankine Cycle (ORC) system for engine waste heat recovery. Energy Convers. Manag. 2015, 105, 995–1005. [Google Scholar] [CrossRef]

- Quoilin, S.; Aumann, R.; Grill, A.; Schuster, A.; Lemort, V.; Spliethoff, H. Dynamic modeling and optimal control strategy of waste heat recovery Organic Rankine Cycles. Appl. Energy 2011, 88, 2183–2190. [Google Scholar] [CrossRef]

- Yang, F.B.; Zhang, H.G.; Bei, C.; Song, S.S.; Wang, E.H. Parametric optimization and performance analysis of ORC (organic Rankine cycle) for diesel engine waste heat recovery with a fin-and-tube evaporator. Energy 2015, 91, 128–141. [Google Scholar] [CrossRef]

- Kang, S.H. Design and preliminary tests of ORC (organic Rankine cycle) with two-stage radial turbine. Energy 2016, 96, 142–154. [Google Scholar] [CrossRef]

- Horst, T.A.; Tegethoff, W.; Eilts, P.; Koehler, J. Prediction of dynamic Rankine Cycle waste heat recovery performance and fuel saving potential in passenger car applications considering interactions with vehicles’ energy management. Energy Convers. Manag. 2014, 78, 438–451. [Google Scholar] [CrossRef]

- Tang, H.; Wu, H.G.; Wang, X.L.; Xing, Z.W. Performance study of a twin-screw expander used in a geothermal organic Rankine cycle power generator. Energy 2015, 90, 631–642. [Google Scholar] [CrossRef]

- Wu, Y.T.; Lei, B.; Ma, C.F.; Zhao, L.; Wang, J.F.; Guo, H.; Lu, Y.W. Study on the Characteristics of Expander Power Output Used for Offsetting Pumping Work Consumption in Organic Rankine Cycles. Energies 2014, 7, 4957–4971. [Google Scholar] [CrossRef]

- Quoilin, S. Sustainable energy conversion through the use of organic Rankine cycles for waste heat recovery and solar applications. Ph.D. Thesis, University of Liège, Wallonia, Belgium, 2011. [Google Scholar]

- Antonelli, M.; Baccioli, A.; Francesconi, M.; Desideri, U.; Martorano, L. Operating maps of a rotary engine used as an expander for micro-generation with various working fluids. Appl. Energy 2014, 113, 742–750. [Google Scholar] [CrossRef]

- Ziviani, D.; Beyene, A.; Venturini, M. Advances and challenges in ORC systems modeling for low grade thermal energy recovery. Appl. Energy 2014, 121, 79–95. [Google Scholar] [CrossRef]

- Qiu, G.Q.; Liu, H.; Riffat, S. Expanders for micro-CHP systems with organic Rankine cycle. Appl. Therm. Eng. 2011, 31, 3301–3307. [Google Scholar] [CrossRef]

- Muhammad, I.; Muhammad, U.; Park, B.S.; Lee, D.H. Volumetric expanders for low grade heat and waste heat recovery applications. Renew. Sustain. Energy Rev. 2016, 57, 1090–1109. [Google Scholar]

- Bao, J.J.; Zhao, L. A review of working fluid and expander selections for organic Rankine cycle. Renew. Sustain. Energy Rev. 2013, 24, 325–342. [Google Scholar] [CrossRef]

- Quoilin, S.; Van Den Broek, M.; Declaye, S.; Dewallef, P.; Lemort, V. Technoeconomic survey of Organic Rankine Cycle (ORC) systems. Renew. Sustain. Energy Rev. 2013, 22, 168–186. [Google Scholar] [CrossRef]

- Young, M.K.; Dong, G.S.; Chang, G.K. Optimization of Design Pressure Ratio of Positive Displacement Expander for Vehicle Engine Waste Heat Recovery. Energies 2014, 7, 6105–6117. [Google Scholar]

- Declaye, S.; Quoilin, S.; Guillaume, L.; Lemort, V. Experimental study on an open-drive scroll expander integrated into an ORC (Organic Rankine Cycle) system with R245fa as working fluid. Energy 2013, 55, 173–183. [Google Scholar] [CrossRef]

- Clemente, S.; Micheli, D.; Reini, M.; Taccani, R. Energy efficiency analysis of organic Rankine cycles with scroll expanders for cogenerative applications. Appl. Energy 2012, 97, 792–801. [Google Scholar] [CrossRef]

- Lemort, V.; Quoilin, S.; Cuevas, C.; Lebrun, J. Testing and modeling a scroll expander integrated into an organic Rankine cycle. Appl. Therm. Eng. 2009, 29, 3094–3102. [Google Scholar] [CrossRef]

- Gao, W.Z.; Zhai, J.M.; Li, G.H.; Bian, Q.; Feng, L.M. Performance evaluation and experiment system for waste heat recovery of diesel engine. Energy 2013, 55, 226–235. [Google Scholar]

- Glavatskaya, Y.; Podevin, P.; Lemort, V.; Shonda, O.; Descombes, G. Reciprocating Expander for an Exhaust Heat Recovery Rankine Cycle for a Passenger Car Application. Energies 2012, 5, 1751–1765. [Google Scholar] [CrossRef]

- Chiong, M.; Rajoo, S.; Romagnoli, A. Nozzle Steam Piston Expander for Engine Exhaust Energy Recovery. SAE Tech. Pap. 2015. [Google Scholar] [CrossRef]

- Badami, M.; Mura, M. Preliminary design and controlling strategies of a small-scale wood waste Rankine Cycle (RC) with a reciprocating steam engine (SE). Energy 2009, 34, 1315–1324. [Google Scholar] [CrossRef]

- Zhang, B.; Peng, X.; He, Z.; Xing, Z.; Shu, P. Development of a double acting free piston expander for power recovery in transcritical CO2 cycle. Appl. Therm. Eng. 2007, 27, 1629–1636. [Google Scholar] [CrossRef]

- Han, Y.Q.; Kang, J.J.; Zhang, G.P.; Liu, Z.C.; Tian, J.; Chai, J.H. Performance evaluation of free piston compressor coupling organic Rankine cycle under different operating conditions. Energy Convers. Manag. 2014, 86, 340–348. [Google Scholar] [CrossRef]

- Han, Y.Q.; Kang, J.J.; Wang, X.F.; Liu, Z.C.; Tian, J.; Wang, Y.Q. Modelling and simulation analysis of an ORC-FPC waste heat recovery system for the stationary CNG-fuelled compressor. Appl. Therm. Eng. 2015, 87, 481–490. [Google Scholar] [CrossRef]

- Weiss, L.W. Study of a MEMS-Based free piston expander for energy sustainability. J. Mech. Des. 2010, 132, 1–8. [Google Scholar] [CrossRef]

- Champagne, C.; Weiss, L. Performance analysis of a miniature free piston expander for waste heat energy harvesting. Energy Convers. Manag. 2013, 76, 883–892. [Google Scholar] [CrossRef]

- Nickl, J.; Will, G.; Quack, H.; Kraus, W.E. Integration of a three-stage expander into a CO2 refrigeration system. Int. J. Refrig. 2005, 28, 1219–1224. [Google Scholar] [CrossRef]

- Li, Q.F.; Xiao, J.; Huang, Z. Simulation of a two-stroke free-piston engine for electrical power generation. Energy Fuels 2008, 22, 3443–3449. [Google Scholar] [CrossRef]

- Feng, H.H.; Song, Y.; Zuo, Z.X.; Shang, J.; Wang, Y.D.; Roskilly, A.P. Stable Operation and Electricity Generating Characteristics of a Single-Cylinder Free Piston Engine Linear Generator: Simulation and Experiments. Energies 2015, 8, 765–785. [Google Scholar] [CrossRef]

- Yuan, C.H. Research on Performance Characteristics and Design Technology of Free-piston Diesel Engine for Linear Generator. Ph.D. Thesis, Beijing Institute of Technology, Beijing, China, 2014. [Google Scholar]

- Jiang, Y.T.; Ma, Y.T.; Fu, L.; Li, M.X. Some design features of CO2 two-rolling piston expander. Energy 2013, 55, 916–924. [Google Scholar] [CrossRef]

- Baek, J.S.; Groll, E.A.; Lawless, P.B. Piston-cylinder work producing expansion device in a transcritical carbon dioxide cycle. Part I: Experimental investigation. Int. J. Refrig. 2005, 28, 141–151. [Google Scholar] [CrossRef]

- Wang, W.; Wu, Y.T.; Ma, C.F.; Liu, L.D.; Yu, J. Preliminary experimental study of single screw expander prototype. Appl. Therm. Eng. 2011, 31, 3684–3688. [Google Scholar] [CrossRef]

- Turbulence. ANSYS FLUENT Release 14.5 Theroy Guide; ANSYS Inc.: Cecil Township, PA, USA, 2012; pp. 51–54. [Google Scholar]

- Wei, M.S.; Song, P.P.; Zhao, B.; Shi, L.; Wang, Z.X.; Ma, C.C. Unsteady flow in the suction process of a scroll expander for an ORC waste heat recovery system. Appl. Therm. Eng. 2015, 78, 460–470. [Google Scholar] [CrossRef]

- Song, P.P.; Wei, M.S.; Liu, Z.; Zhao, B. Effects of suction port arrangements on a scroll expander for a small scale ORC system based on CFD approach. Appl. Energy 2015, 150, 274–285. [Google Scholar] [CrossRef]

- Xiao, J.; Li, Q.F.; Huang, Z. Motion characteristic of a free piston linear engine. Appl. Energy 2010, 87, 1288–1294. [Google Scholar] [CrossRef]

| Items | Parameters | Units |

|---|---|---|

| Cylinder diameter | 80 | mm |

| Working frequency | 1–8 | Hz |

| Maximal piston stroke length | 100 | mm |

| Intake duration | 0–90 | degree |

| Exhaust duration | 180–360 | degree |

| Piston rod diameter | 10 | mm |

| Inlet port diameter | 22 | mm |

| Outlet port diameter | 25 | mm |

| Relative clearance factor | 1/18 | - |

| Items | Type | Technical parameter |

|---|---|---|

| Pressure sensor | TCT–1201 | Power supply is 24 V, range is 0–1.5 MPa, accuracy is ±0.2% |

| Temperature sensor | WZ/P–DK | Power supply is 24 V, range is −20–100 °C, accuracy is ±0.5% |

| Draw wire position transducer | TWLB | Power supply is 24 V, range is 0–400 mm, accuracy is 0.5% |

| Flow rate measurement | Volumetric turbo flow meter | Range is 5–42 m3/h, temperature range is −50–180 °C, accuracy is ±1.5% |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Zhang, H.; Yang, F.; Song, S.; Chang, Y.; Yu, F.; Wang, J.; Yao, B. Preliminary Development of a Free Piston Expander–Linear Generator for Small-Scale Organic Rankine Cycle (ORC) Waste Heat Recovery System. Energies 2016, 9, 300. https://doi.org/10.3390/en9040300

Li G, Zhang H, Yang F, Song S, Chang Y, Yu F, Wang J, Yao B. Preliminary Development of a Free Piston Expander–Linear Generator for Small-Scale Organic Rankine Cycle (ORC) Waste Heat Recovery System. Energies. 2016; 9(4):300. https://doi.org/10.3390/en9040300

Chicago/Turabian StyleLi, Gaosheng, Hongguang Zhang, Fubin Yang, Songsong Song, Ying Chang, Fei Yu, Jingfu Wang, and Baofeng Yao. 2016. "Preliminary Development of a Free Piston Expander–Linear Generator for Small-Scale Organic Rankine Cycle (ORC) Waste Heat Recovery System" Energies 9, no. 4: 300. https://doi.org/10.3390/en9040300

APA StyleLi, G., Zhang, H., Yang, F., Song, S., Chang, Y., Yu, F., Wang, J., & Yao, B. (2016). Preliminary Development of a Free Piston Expander–Linear Generator for Small-Scale Organic Rankine Cycle (ORC) Waste Heat Recovery System. Energies, 9(4), 300. https://doi.org/10.3390/en9040300