Techno-Economic Analysis of Integrating First and Second-Generation Ethanol Production Using Filamentous Fungi: An Industrial Case Study

Abstract

:1. Introduction

2. Methods

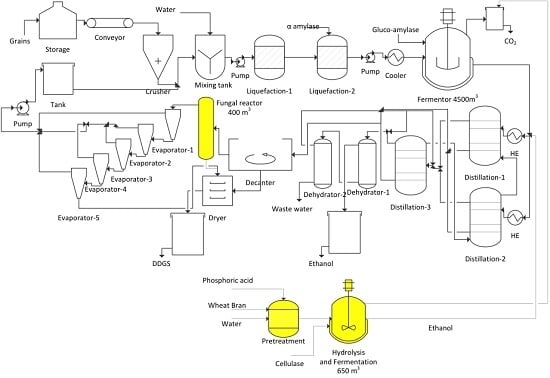

2.1. Process Description

2.1.1. Thin Stillage Modification (Scenario A)

2.1.2. Whole-Stillage Modification (Scenario B)

2.1.3. Integration of Lignocelluloses (Scenario C)

2.2. Energy and Economics

2.3. Sensitivity Analysis

3. Results and Discussion

3.1. Thin Stillage and Stillage Modification

3.1.1. Technical Analysis

3.1.2. Economic Analysis

3.2. Integration of Lignocelluloses

3.3. Sensitivity Analysis

3.4. Limitations and Future Considerations

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| CCP | Cumulative Cash Position |

| DDGS | Dried Distillers Grains with Solubles |

| FPU | Filter Paper Units |

| NPV | Net Present Value |

| PBP | Payback Period |

| SSF | Simultaneous Saccharification and Fermentation |

| TS | Total Solids |

| VVM | Volume per Volume per Minute |

References

- Ljiljana, M.; Olgica, G.; Marica, R. The bioethanol production with the thin stillage recirculation. Chem. Ind. Chem. Eng. Q./CICEQ 2009, 15, 49–52. [Google Scholar]

- Chum, H.L.; Warner, E.; Seabra, J.E.; Macedo, I.C. A comparison of commercial ethanol production systems from Brazilian sugarcane and US corn. Biofuels Bioprod. Biorefining 2014, 8, 205–223. [Google Scholar] [CrossRef]

- Tao, L.; Aden, A. The economics of current and future biofuels. In Vitro Cell. Dev. Biol. Plant 2009, 45, 199–217. [Google Scholar] [CrossRef]

- Chovau, S.; Degrauwe, D.; Van der Bruggen, B. Critical analysis of techno-economic estimates for the production cost of lignocellulosic bio-ethanol. Renew. Sustain. Energy Rev. 2013, 26, 307–321. [Google Scholar] [CrossRef]

- Soetaert, W.; Vandamme, E.J. Biofuels in Perspective, Biofuels; John Wiley & Sons, Ltd.: London, UK, 2009. [Google Scholar]

- Hamelinck, C.N.; Hooijdonk, G.V.; Faaij, A.P.C. Ethanol from lignocellulosic biomass: Techno-economic performance in short-, middle- and long-term. Biomass Bioenergy 2005, 28, 384–410. [Google Scholar] [CrossRef]

- Lennartsson, P.R.; Erlandsson, P.; Taherzadeh, M.J. Integration of the first and second generation bioethanol processes and the importance of by-products. Bioresour. Technol. 2014, 165, 3–8. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, J.A.; Lennartsson, P.R.; Edebo, L.; Taherzadeh, M.J. Zygomycetes-based biorefinery: Present status and future prospects. Bioresour. Technol. 2013, 135, 523–532. [Google Scholar] [CrossRef] [PubMed]

- Zamani, A. Superabsorbent Polymers from the Cell Wall of Zygomycetes Fungi; Chalmers University of Technology: Gothenburg, Sweden, 2010. [Google Scholar]

- Ferreira, J.A.; Lennartsson, P.R.; Taherzadeh, M.J. Production of ethanol and biomass from thin stillage using food-grade Zygomycetes and Ascomycetes filamentous fungi. Energies 2014, 7, 3872–3885. [Google Scholar] [CrossRef]

- Arora, A.; Seth, A.; Dien, B.S.; Belyea, R.L.; Singh, V.; Tumbleson, M.; Rausch, K.D. Microfiltration of thin stillage: Process simulation and economic analyses. Biomass Bioenergy 2011, 35, 113–120. [Google Scholar] [CrossRef]

- Sosa, M.; Chovau, S.; van der Bruggen, B.; Espinosa, J. Ethanol production from corn contaminated with fumonisins: A preliminary economic analysis including novel processing alternatives. Ind. Eng. Chem. Res. 2013, 52, 7504–7513. [Google Scholar] [CrossRef]

- Kim, Y.; Mosier, N.; Ladisch, M.R. Process simulation of modified dry grind ethanol plant with recycle of pretreated and enzymatically hydrolyzed distillers’ grains. Bioresour. Technol. 2008, 99, 5177–5192. [Google Scholar] [CrossRef] [PubMed]

- Perkis, D.; Tyner, W.; Dale, R. Economic analysis of a modified dry grind ethanol process with recycle of pretreated and enzymatically hydrolyzed distillers’ grains. Bioresour. Technol. 2008, 99, 5243–5249. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.; Barrows, F.T. Methods to recover value-added coproducts from dry grind processing of grains into fuel ethanol. J. Agric. Food. Chem. 2013, 61, 7325–7332. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez, L.F.; Li, C.; Khanna, M.; Spaulding, A.D.; Lin, T.; Eckhoff, S.R. An engineering and economic evaluation of quick germ–quick fiber process for dry-grind ethanol facilities: Analysis. Bioresour. Technol. 2010, 101, 5282–5289. [Google Scholar] [CrossRef] [PubMed]

- Meyer, P.A.; Tews, I.J.; Magnuson, J.K.; Karagiosis, S.A.; Jones, S.B. Techno-economic analysis of corn stover fungal fermentation to ethanol. Appl. Energy 2013, 111, 657–668. [Google Scholar] [CrossRef]

- Sokhansanj, S.; Mani, S.; Tagore, S.; Turhollow, A. Techno-economic analysis of using corn stover to supply heat and power to a corn ethanol plant–Part 1: Cost of feedstock supply logistics. Biomass Bioenergy 2010, 34, 75–81. [Google Scholar] [CrossRef]

- Mani, S.; Sokhansanj, S.; Tagore, S.; Turhollow, A. Techno-economic analysis of using corn stover to supply heat and power to a corn ethanol plant–Part 2: Cost of heat and power generation systems. Biomass Bioenergy 2010, 34, 356–364. [Google Scholar] [CrossRef]

- Wang, L.; Hanna, M.A.; Weller, C.L.; Jones, D.D. Technical and economical analyses of combined heat and power generation from distillers grains and corn stover in ethanol plants. Energ. Convers. Manag. 2009, 50, 1704–1713. [Google Scholar] [CrossRef]

- Kazi, F.K.; Fortman, J.A.; Anex, R.P.; Hsu, D.D.; Aden, A.; Dutta, A.; Kothandaraman, G. Techno-economic comparison of process technologies for biochemical ethanol production from corn stover. Fuel 2010, 89, S20–S28. [Google Scholar] [CrossRef]

- Roy, P.; Tokuyasu, K.; Orikasa, T.; Nakamura, N.; Shiina, T. A techno-economic and environmental evaluation of the life cycle of bioethanol produced from rice straw by RT-CaCCO process. Biomass Bioenergy 2012, 37, 188–195. [Google Scholar] [CrossRef]

- Tewfik, S.R.; Sorour, M.H.; Abulnour, A.M.; Talaat, H.A.; Mitry, N.R. Techno-economic investigations on the small-scale production of ethanol from egyptian rice straw. Chem. Eng. Trans. 2010, 21, 451–456. [Google Scholar]

- Wingren, A.; Galbe, M.; Zacchi, G. Techno-economic evaluation of producing ethanol from softwood: Comparison of SSF and SHF and identification of bottlenecks. Biotechnol. Progr. 2003, 19, 1109–1117. [Google Scholar] [CrossRef] [PubMed]

- Barta, Z.; Reczey, K.; Zacchi, G. Techno-economic evaluation of stillage treatment with anaerobic digestion in a softwood-to-ethanol process. Biotechnol. Biofuels 2010, 3. [Google Scholar] [CrossRef] [PubMed]

- Mesa, L.; López, N.; Cara, C.; Castro, E.; González, E.; Mussatto, S.I. Techno-economic evaluation of strategies based on two steps organosolv pretreatment and enzymatic hydrolysis of sugarcane bagasse for ethanol production. Renew. Energ. 2016, 86, 270–279. [Google Scholar] [CrossRef]

- Macrelli, S.; Mogensen, J.; Zacchi, G. Techno-economic evaluation of 2nd generation bioethanol production from sugar cane bagasse and leaves integrated with the sugar-based ethanol process. Biotechnol. Biofuels 2012, 5. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, J.A.; Lennartsson, P.R.; Taherzadeh, M.J. Production of ethanol and biomass from thin stillage by Neurospora intermedia: A pilot study for process diversification. Eng. Life Sci. 2015, 15, 751–759. [Google Scholar] [CrossRef]

- Nair, R.B.; Lundin, M.; Brandberg, T.; Lennartsson, P.R.; Taherzadeh, M.J. Dilute phosphoric acid pretreatment of wheat bran for enzymatic hydrolysis and subsequent ethanol production by edible fungi Neurospora intermedia. Ind. Crops Prod. 2015, 69, 314–323. [Google Scholar] [CrossRef]

- Rajendran, K.; Rajoli, S.; Teichert, O.; Taherzadeh, M.J. Impacts of retrofitting analysis on first generation ethanol production: Process design and techno-economics. Bioprocess Biosyst. Eng. 2015, 38, 389–397. [Google Scholar] [CrossRef] [PubMed]

- Turton, R.; Bailie, R.C.; Whiting, W.B.; Shaeiwitz, J.A. Analysis, Synthesis and Design of Chemical Processes; Pearson Education: Upper Saddle River, NJ, USA, 2008. [Google Scholar]

- Aden, A.; Foust, T. Technoeconomic analysis of the dilute sulfuric acid and enzymatic hydrolysis process for the conversion of corn stover to ethanol. Cellulose 2009, 16, 535–545. [Google Scholar] [CrossRef]

| Component | Weight (g/g Dry Basis) |

|---|---|

| Arabinan | 0.078 ± 0.013 |

| Galactan | 0.006 ± 0.009 |

| Glucan | 0.249 ± 0.005 |

| Mannan | 0.001 ± 0.003 |

| Xylan | 0.152 ± 0.01 |

| Starch | 0.193 ± 0.004 |

| Type | Assumption |

|---|---|

| Annual processing capacity | 150,400 tons grains/year |

| Cost index | 2013 1st quarter |

| Annual operating time | 8000 h |

| Depreciation method | Straight line |

| Working capital | 15% |

| Tax rate | 33% |

| Interest rate | 6% |

| Lifetime of the plant | 20 years |

| Salvage value | 5% |

| Electricity | 0.067 USD/kWh |

| Water | 0.5 USD/m3 |

| Waste water treatment | 0.1 USD/m3 |

| Steam | 0.01 USD/kg |

| Grains | 300 USD/ton |

| Wheat Bran | 70 USD/ton |

| Carbon dioxide | 0.1 USD/kg |

| Ethanol cost | 875 USD/ton |

| DDGS cost | 370 USD/ton |

| α-Amylase | 4.6 USD/kg |

| Glucoamylase | 5.3 USD/kg |

| Cellulase | 10 USD/kg |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rajendran, K.; Rajoli, S.; Taherzadeh, M.J. Techno-Economic Analysis of Integrating First and Second-Generation Ethanol Production Using Filamentous Fungi: An Industrial Case Study. Energies 2016, 9, 359. https://doi.org/10.3390/en9050359

Rajendran K, Rajoli S, Taherzadeh MJ. Techno-Economic Analysis of Integrating First and Second-Generation Ethanol Production Using Filamentous Fungi: An Industrial Case Study. Energies. 2016; 9(5):359. https://doi.org/10.3390/en9050359

Chicago/Turabian StyleRajendran, Karthik, Sreevathsava Rajoli, and Mohammad J. Taherzadeh. 2016. "Techno-Economic Analysis of Integrating First and Second-Generation Ethanol Production Using Filamentous Fungi: An Industrial Case Study" Energies 9, no. 5: 359. https://doi.org/10.3390/en9050359

APA StyleRajendran, K., Rajoli, S., & Taherzadeh, M. J. (2016). Techno-Economic Analysis of Integrating First and Second-Generation Ethanol Production Using Filamentous Fungi: An Industrial Case Study. Energies, 9(5), 359. https://doi.org/10.3390/en9050359