Idealized vs. Realistic Microstructures: An Atomistic Simulation Case Study on γ/γ′ Microstructures

Abstract

:1. Introduction

2. Methods

2.1. Sample Geometry

2.1.1. Idealized Samples

2.1.2. Realistic Samples

2.2. Simulation Details

3. Results

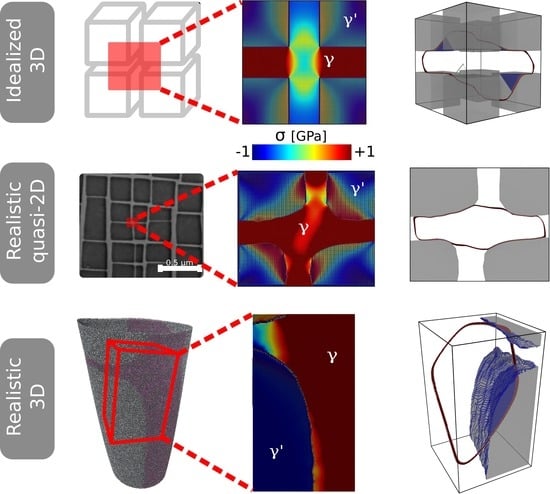

3.1. Misfit Stresses

3.2. Evolution of a Dislocation Loop

4. Discussion

5. Conclusions

- The virial expression for the atomic stress results in a stress description that is consistent with FE simulations, even for bi-atomic systems like that found in idealized γ/ microstructures. This has been demonstrated by comparing the stresses in the embedded cube atomistic sample with those of an FE sample with PBCs and anisotropic elastic constants as defined by the interatomic potential.

- The near conformance of the stress state in the atomistic sample and the corresponding FE sample lets one conclude that FE simulations or concurrent multiscale models can be used to obtain the effective stress state in γ/ microstructures and, thus, expedite significantly expensive atomistic calculations.

- Significantly different stress states are observed in the γ and phases of the different samples, which can essentially be ascribed to the sample generation procedure and the boundary conditions applied.

- Samples with PBCs lead to stresses that are quantitatively lower than samples with fully-3D fixed BCs. Qualitatively, however, the stress state, i.e., tensile stresses in channels parallel to the loading direction and compressive stresses in channels orthogonal to the loading direction, is, nevertheless, similar in the samples with PBCs or fully-fixed BCs.

- 2D/quasi-2D BCs can result in a fictitious stress state that may not be observable in full 3D setups and must be used with utmost care in atomistic simulations.

- The incorporation of experimental information into atomistic microstructures, e.g., topological features like curvature or variation in chemical composition, although necessary, may not be sufficient enough to provide improved insights into material behavior. The influence of accompanying BCs must also be accounted for.

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Reed, R.C. The Superalloys: Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2006. [Google Scholar]

- Van Sluytman, J.S.; Pollock, T.M. Optimal precipitate shapes in nickel-base γ/γ′ alloys. Acta Mater. 2012, 60, 1771–1783. [Google Scholar] [CrossRef]

- Murakumo, T.; Kobayashi, T.; Koizumi, Y.; Harada, H. Creep behaviour of Ni-base single-crystal superalloys with various γ′ volume fraction. Acta Mater. 2004, 52, 3737–3744. [Google Scholar] [CrossRef]

- Thorntona, K.; Akaiwab, N.; Voorhees, P.W. Large-scale simulations of Ostwald ripening in elastically stressed solids: I. Development of microstructure. Acta Mater. 2004, 52, 1353–1364. [Google Scholar] [CrossRef]

- Carroll, L.J.; Feng, Q.; Pollock, T.M. Interfacial dislocation networks and creep in directional coarsened Ru-containing nickel-base single-crystal superalloys. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2008, 39, 1290–1307. [Google Scholar] [CrossRef]

- Kamaraj, M. Rafting in single crystal nickel-base superalloys—An overview. Sadhana 2003, 28, 115–128. [Google Scholar] [CrossRef]

- Zhang, J.X.; Murakumo, T.; Koizumi, Y.; Kobayashi, T.; Harada, H.; Masaki, S. Interfacial dislocation networks strengthening a fourth-generation single-crystal TMS-138 superalloy. Metall. Mater. Trans. A 2002, 33, 3741–3746. [Google Scholar] [CrossRef]

- Farkas, D. Atomistic simulations of metallic microstructures. Curr. Opin. Solid State Mater. Sci. 2013, 17, 284–297. [Google Scholar] [CrossRef]

- Bitzek, E.; Kermode, J.R.; Gumbsch, P. Atomistic aspects of fracture. Int. J. Fract. 2015, 191, 13–30. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, Z.; Huang, M. Atomistic modeling of the interaction between matrix dislocation and interfacial misfit dislocation networks in Ni-based single crystal superalloy. Comput. Mater. Sci. 2013, 70, 178–186. [Google Scholar] [CrossRef]

- Zhu, T.; Wang, C. Misfit dislocation networks in the γ/γ′ phase interface of a Ni-based single-crystal superalloy: Molecular dynamics simulations. Phys. Rev. B 2005, 72, 014111. [Google Scholar] [CrossRef]

- Kohler, C.; Kizler, P.; Schmauder, S. Atomistic simulation of the pinning of edge dislocations in Ni by Ni3Al precipitates. Mater. Sci. Eng. A 2005, 400, 481–484. [Google Scholar] [CrossRef]

- Zhu, T.; Wang, C.; Gan, Y. Effect of Re in γ phase, γ′ phase and γ/γ′ interface of Ni-based single-crystal superalloys. Acta Mater. 2010, 58, 2045–2055. [Google Scholar] [CrossRef]

- Djuansjah, J.R.; Yashiro, K.; Tomita, Y. Computational study on misfit dislocation in Ni-based superalloys by quasicontinuum method. Mater. Trans. 2008, 49, 2507–2514. [Google Scholar] [CrossRef]

- Xie, H.X.; Wang, C.Y.; Yu, T. Motion of misfit dislocation in an Ni/Ni3Al interface: A molecular dynamics simulations study. Model. Simul. Mater. Sci. Eng. 2009, 17. [Google Scholar] [CrossRef]

- Ye, X.J.; Liu, C.S.; Zhong, W.; Du, Y.W. Precipitate size dependence of Ni/Ni3Al interface energy. Phys. Lett. A 2015, 379, 37–40. [Google Scholar] [CrossRef]

- Prakash, A.; Guénolé, J.; Wang, J.; Müller, J.; Spiecker, E.; Mills, M.J.; Povstugar, I.; Choi, P.; Raabe, D.; Bitzek, E. Atom probe informed simulations of dislocation-precipitate interactions reveal the importance of local interface curvature. Acta Mater. 2015, 92, 33–45. [Google Scholar] [CrossRef]

- Dream3D. Available online: http://dream3d.bluequartz.net (accessed on 28 May 2015).

- NanoSCULPT. Available online: http://www.gmp.ww.uni-erlangen.de/nanoSCULPT.php (accessed on 15 May 2016).

- Moody, M.P.; Ceguerra, A.V.; Breen, A.J.; Cui, X.Y.; Gault, B.; Stephenson, L.T.; Marceau, R.K.W.; Powles, R.C.; Ringer, S.P. Atomically resolved tomography to directly inform simulations for structure-property relationships. Nat. Commun. 2014, 5, 5501. [Google Scholar] [CrossRef] [PubMed]

- Dingreville, R.; Karnesky, R.A.; Puel, G.; Schmitt, J.-H. Review of the synergies between computational modeling and experimental characterization of materials across length scales. J. Mater. Sci. 2016, 51, 1178–1203. [Google Scholar] [CrossRef]

- Friak, M.; Tytko, D.; Holec, D.; Choi, P.P.; Eisenlohr, P.; Raabe, D.; Neugebauer, J. Synergy of atom-probe structural data and quantum-mechanical calculations in a theory-guided design of extreme-stiffness superlattices containing metastable phases. New J. Phys. 2015, 17, 093004. [Google Scholar] [CrossRef]

- Wu, W.; Guo, Y.; Wang, Y.; Mueller, R.; Gross, D. Molecular dynamics simulation of the structural evolution of misfit dislocation networks at γ/γ′ phase interfaces in Ni-based superalloys. Philos. Mag. 2011, 91, 357–372. [Google Scholar] [CrossRef]

- Yashiro, K.; Naito, M.; Tomita, Y. Molecular dynamics simulation of dislocation nucleation and motion at γ/γ′ interface in Ni-based superalloy. Int. J. Mech. Sci. 2002, 44, 1845–1860. [Google Scholar] [CrossRef]

- Haghighat, S.M.H.; Eggeler, G.; Raabe, D. Effect of climb on dislocation mechanisms and creep rates in γ′-strengthened Ni base superalloy single crystals: A discrete dislocation dynamics study. Acta Mater. 2013, 61, 3709–3723. [Google Scholar] [CrossRef]

- Vattré, A.; Devincre, B.; Roos, A. Dislocation dynamics simulations of precipitation hardening in Ni-based superalloys with high γ′ volume fraction. Intermetallics 2009, 17, 988–994. [Google Scholar] [CrossRef]

- Link, T.; Epishin, A.; Fedelich, B. Inhomogeneity of misfit stresses in nickel-base superalloys: Effect on propagation of matrix dislocation loops. Philos. Mag. 2009, 89, 1141–1159. [Google Scholar] [CrossRef]

- Meissonnier, F.T.; Busso, E.P.; O’Dowd, N.P. Finite element implementation of a generalised non-local rate-dependent crystallographic formulation for finite strains. Int. J. Plast. 2001, 17, 601–640. [Google Scholar] [CrossRef]

- Prakash, A.; Weygand, S.M.; Riedel, H. Modeling the evolution of texture and grain shape in Mg alloy AZ31 using the crystal plasticity finite element method. Comput. Mater. Sci. 2009, 45, 744–750. [Google Scholar] [CrossRef]

- Schmidt, I. Numerical homogenisation of an elasto-plastic model-material with large elastic strains: Macroscopic yield surfaces and the eulerian normality rule. Comput. Mech. 2011, 48, 579–590. [Google Scholar] [CrossRef]

- Heckl, A.; Neumeier, S.; Göken, M.; Singer, R.F. The effect of Re and Ru on γ/γ′ microstructure, γ-solid solution strengthening and creep strength in nickel-base superalloys. Mater. Sci. Eng. A 2011, 528, 3435–3444. [Google Scholar] [CrossRef]

- Prakash, A.; Hummel, M.; Schmauder, S.; Bitzek, E. NanoSCULPT: A methodology for generating realistic configurations for atomistic simulations. MethodsX 2016, 3, 219–230. [Google Scholar] [CrossRef] [PubMed]

- NanoSCULPT. Available online: https://bitbucket.org/arunpksh/nanosculpt/wiki/Home (accessed on 15 May 2016).

- Mishin, Y. Atomistic modeling of the γ and γ′-phases of the Ni-Al system. Acta Mater. 2004, 52, 1451–1467. [Google Scholar] [CrossRef]

- Bitzek, E.; Koskinen, P.; Gähler, F.; Moseler, M.; Gumbsch, P. Structural relaxation made simple. Phys. Rev. Lett. 2006, 97, 170201. [Google Scholar] [CrossRef] [PubMed]

- Bitzek, E.; Brandl, C.; Weygand, D.; Derlet, P.M.; van Swygenhofen, H. Atomistic simulation of a dislocation shear loop interacting with grain boundaries in nanocrystalline aluminium. Model. Simul. Mater. Sci. Eng. 2009, 17, 055008. [Google Scholar] [CrossRef]

- Beeler, J.R. Radiation Effects Computer Experiments; North-Holland Publishing Company: Amsterdam, The Netherlands, 1983. [Google Scholar]

- Scattergood, R.O.; Bacon, D.J. The strengthening effect of voids. Acta Metall. 1982, 30, 1665–1677. [Google Scholar] [CrossRef]

- Glatzel, U.; Feller-Kniepmeier, M. Calculations of internal stresses in the γ/γ′ microstructure of a nickel-base superalloy with high volume fraction of the γ-phase. Scr. Metall. 1989, 23, 1839–1844. [Google Scholar] [CrossRef]

- Fedelich, B. A microstructure based constitutive model for the mechanical behavior at high temperatures of nickel-base single crystal superalloys. Comput. Mater. Sci. 1999, 16, 248–258. [Google Scholar] [CrossRef]

- Allen, M.P.; Tildesley, D.J. Computer Simulation of Liquids; Clarendon Press: Oxford, UK, 1996. [Google Scholar]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO—The Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2010, 18, 015012. [Google Scholar] [CrossRef]

- Begau, C.; Hartmaier, A.; George, E.P.; Pharr, G.M. Atomistic processes of dislocation generation and plastic deformation during nanoindentation. Acta Mater. 2011, 59, 934–942. [Google Scholar] [CrossRef]

- Amodeo, J.; Begau, C.; Bitzek, E. Atomistic simulations of compression tests on Ni3Al nanocubes. Mater. Res. Lett. 2014, 2, 140–145. [Google Scholar] [CrossRef]

- Withers, P.J.; Bhadeshia, H.K.D.H. Residual stress. Part 2—Nature and origins. Mater. Sci. Technol. 2001, 17, 366–375. [Google Scholar] [CrossRef]

- Korsunsky, A.M.; Guénolé, J.; Salvati, E.; Sui, T.; Mousavi, M.; Prakash, A.; Bitzek, E. Quantifying eigenstrain distributions induced by focused ion beam damage in silicon. Mater. Lett. 2016, 185, 47–49. [Google Scholar] [CrossRef]

- Preußner, J.; Rudnik, Y.; Brehm, H.; Völkl, R.; Glatzel, U. A dislocation density based material model to simulate the anisotropic creep behavior of single-phase and two-phase single crystals. Int. J. Plast. 2009, 25, 973–994. [Google Scholar] [CrossRef]

- Admal, N.C.; Tadmor, E.B. A unified interpretation of stress in molecular systems. J. Elast. 2010, 100, 63–143. [Google Scholar] [CrossRef]

- Cheung, K.S.; Yip, S. Atomic-level stress in an inhomogeneous system. J. Appl. Phys. 1991, 70, 5688–5690. [Google Scholar] [CrossRef]

- Zimmerman, J.A.; Jones, R.E.; Klein, P.A.; Bammann, D.J.; Webb, E.B.; Hoyt, J.J. Continuum Definitions for Stress in Atomistic Simulations; Technical Report for Sandia National Lab: Albuquerque, NM, USA, 2002. [Google Scholar]

- Zimmerman, J.A.; Webb, E.B.; Hoyt, J.J.; Jones, R.E.; Klein, P.A.; Bammann, D.J. Calculation of stress in atomistic simulation. Model. Simul. Mater. Sci. Eng. 2004, 12, S319–S332. [Google Scholar] [CrossRef]

- Möller, J.J.; Prakash, A.; Bitzek, E. FE2AT: Finite element informed atomistic simulations. Model. Simul. Mater. Sci. Eng. 2013, 21, 055011. [Google Scholar] [CrossRef]

- Miller, R.E.; Tadmor, E.B. The Quasicontinuum Method: Overview, applications and current. J. Comput.-Aided Mater. Des. 2002, 9, 203–239. [Google Scholar] [CrossRef]

- Curtin, W.A.; Miller, R.E. Atomistic/continuum coupling in computational materials science. Model. Simul. Mater. Sci. Eng. 2003, 11, R33–R68. [Google Scholar] [CrossRef]

- Miller, R.E.; Tadmor, E.B. A unified framework and performance benchmark of fourteen multiscale atomistic/continuum coupling. Model. Simul. Mater. Sci. Eng. 2009, 17, 053001. [Google Scholar] [CrossRef]

- Sato, J.; Omori, T.; Oikawa, K.; Ohnuma, I. Cobalt-base high-temperature alloys. Science 2006, 312, 90–91. [Google Scholar] [CrossRef] [PubMed]

- Bauer, A.; Neumeier, S.; Pyczak, F.; Göken, M. Microstructure and creep strength of different γ/γ′-strengthened Co-base superalloy variants. Scr. Mater. 2010, 63, 1197–1200. [Google Scholar] [CrossRef]

- Srolovitz, D.; Vitek, V. Atomistic Simulation of Materials: Beyond Pair Potentials; Springer: New York, NY, USA, 1989. [Google Scholar]

- Yamakov, V.; Wolf, D.; Phillpot, S.; Mukherjee, A.; Gleiter, H. Dislocation processes in the deformation of nanocrystalline aluminium by molecular-dynamics simulation. Nat. Mater. 2002, 1, 45–49. [Google Scholar] [CrossRef] [PubMed]

- Yamakov, V.; Wolf, D.; Phillpot, S.R.; Gleiter, H. Deformation twinning in nanocrystalline Al by molecular dynamics simulation. Acta Mater. 2002, 50, 5005–5020. [Google Scholar] [CrossRef]

- Frøseth, A.G.; Derlet, P.M.; van Swygenhoven, H. Twinning in nanocrystalline fcc metals. Adv. Eng. Mater. 2005, 7, 16–20. [Google Scholar] [CrossRef]

- Prakash, A.; Nöhring, W.G.; Lebensohn, R.A.; Höppel, H.W.; Bitzek, E. A multiscale simulation framework of the accumulative roll bonding process accounting for texture evolution. Mater. Sci. Eng. A 2010, 631, 104–119. [Google Scholar] [CrossRef]

- Segurado, J.; Lebensohn, R.; Lorca, J.L.; Tomé, C.N. Multiscale modeling of plasticity based on embedding the viscoplastic self-consistent formulation in implicit finite elements. Int. J. Plast. 2012, 28, 124–140. [Google Scholar] [CrossRef]

- Roters, F.; Eisenlohr, P.; Hantcherli, L.; Tjahjanto, D.D.; Bieler, T.R.; Raabe, D. Overview of constitutive laws, kinematics, homogenization and multiscale methods in crystal plasticity finite-element modeling: Theory, experiments, applications. Acta Mater. 2010, 58, 1152–1211. [Google Scholar] [CrossRef]

| Sample Name → | S | S | S | S | S | S | |

|---|---|---|---|---|---|---|---|

| Attributes ↓ | |||||||

| Sample dimensions (nm) | 100 × 100 × 100 | 100 × 100 × 100 | 150 ×125 × 50 | 150 × 125 × 50 | 75 × 45 × 44 | 75 × 45 × 44 | |

| Sample type | Idealized | Idealized | Idealized | Realistic | Realistic | Realistic | |

| Number of atoms/elements | 512,000 | 89,703,072 | 83,598,900 | 84,196,035 | 13,515,848 | 13,515,848 | |

| Boundary condition in x | PBC | PBC | fixed | fixed | fixed | fixed | |

| Boundary condition in y | PBC | PBC | fixed | fixed | fixed | fixed | |

| Boundary condition in z | PBC | PBC | PBC | PBC | fixed | fixed | |

| Type of interfaces | Planar | Planar | Planar | Curved | Curved | Curved | |

| Sharp edges/corners | present | present | present | absent | absent | absent | |

| γ-channel size (nm) | 25 | 25 | 25 | ≈25 | ≈15 | ≈15 | |

| area fraction (along the (001) plane) | 56.25% | 56.25% | 66.67% | 62.3% | ≈25.7%–≈46.8% * | ≈25.7%–≈46.8% * | |

| volume fraction | 42.2% | 42.2% | 66.67% | 62.3% | 34.6% | 34.6% | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prakash, A.; Bitzek, E. Idealized vs. Realistic Microstructures: An Atomistic Simulation Case Study on γ/γ′ Microstructures. Materials 2017, 10, 88. https://doi.org/10.3390/ma10010088

Prakash A, Bitzek E. Idealized vs. Realistic Microstructures: An Atomistic Simulation Case Study on γ/γ′ Microstructures. Materials. 2017; 10(1):88. https://doi.org/10.3390/ma10010088

Chicago/Turabian StylePrakash, Aruna, and Erik Bitzek. 2017. "Idealized vs. Realistic Microstructures: An Atomistic Simulation Case Study on γ/γ′ Microstructures" Materials 10, no. 1: 88. https://doi.org/10.3390/ma10010088

APA StylePrakash, A., & Bitzek, E. (2017). Idealized vs. Realistic Microstructures: An Atomistic Simulation Case Study on γ/γ′ Microstructures. Materials, 10(1), 88. https://doi.org/10.3390/ma10010088